Patents

Literature

214results about "Ceramic containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

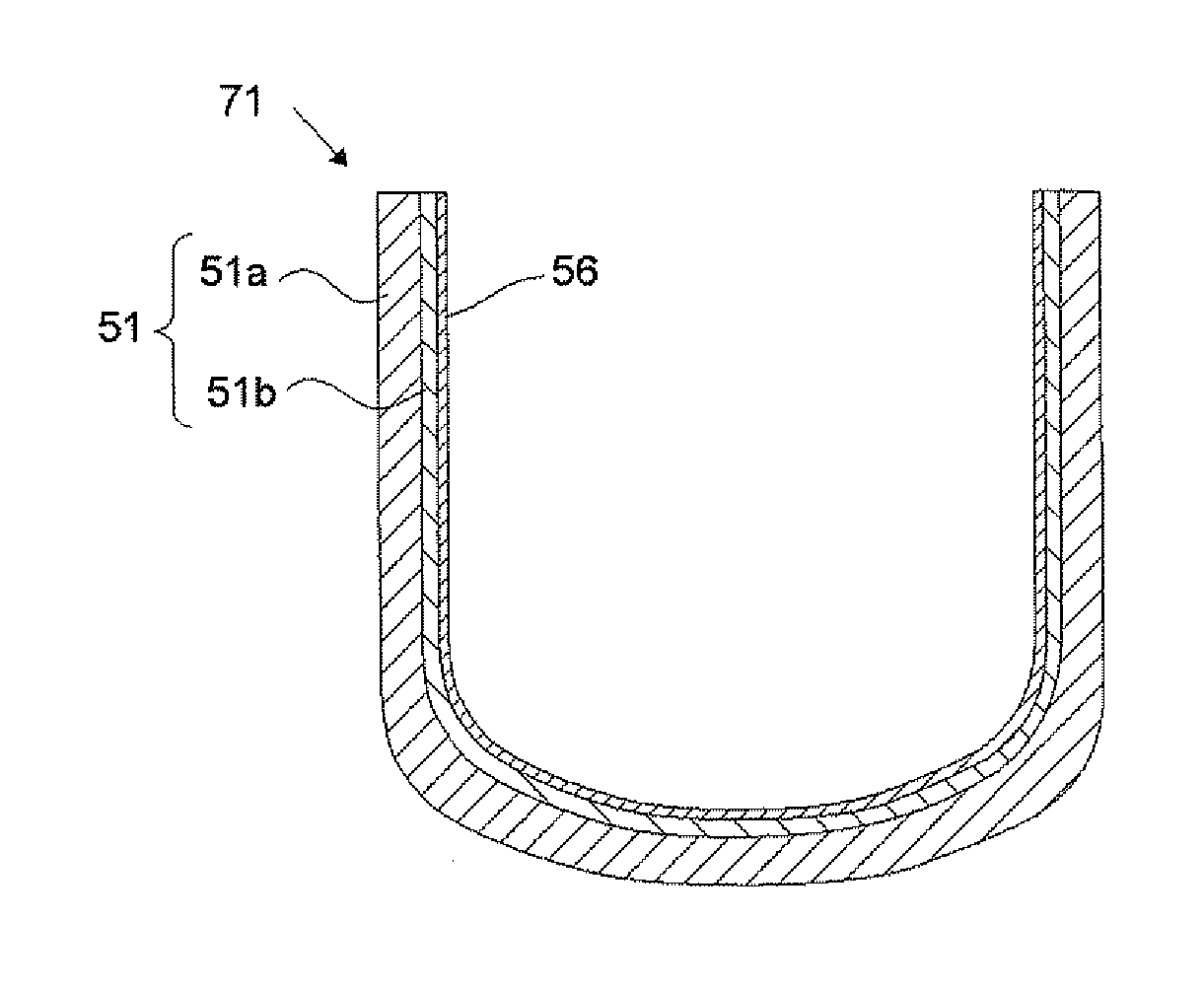

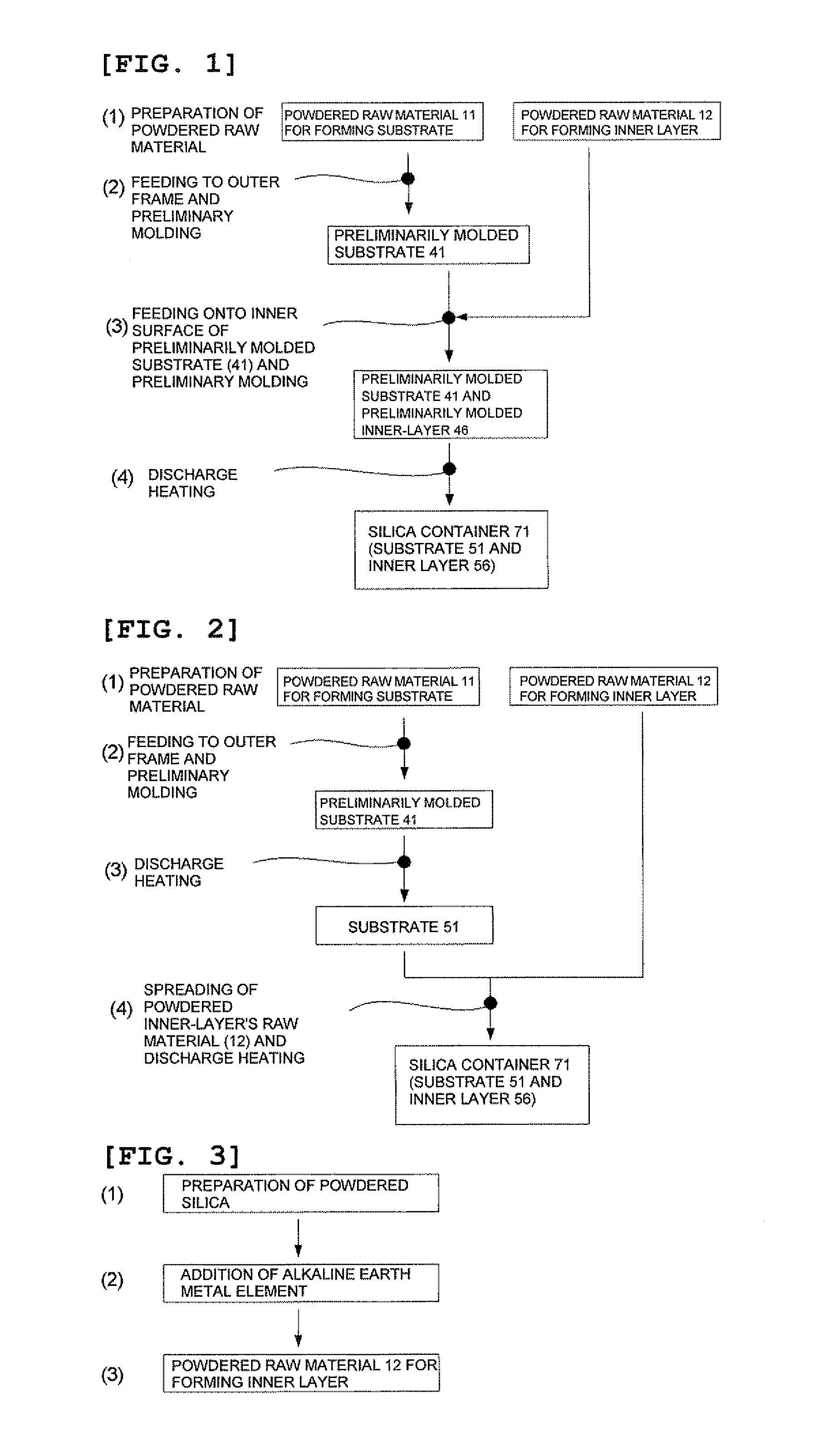

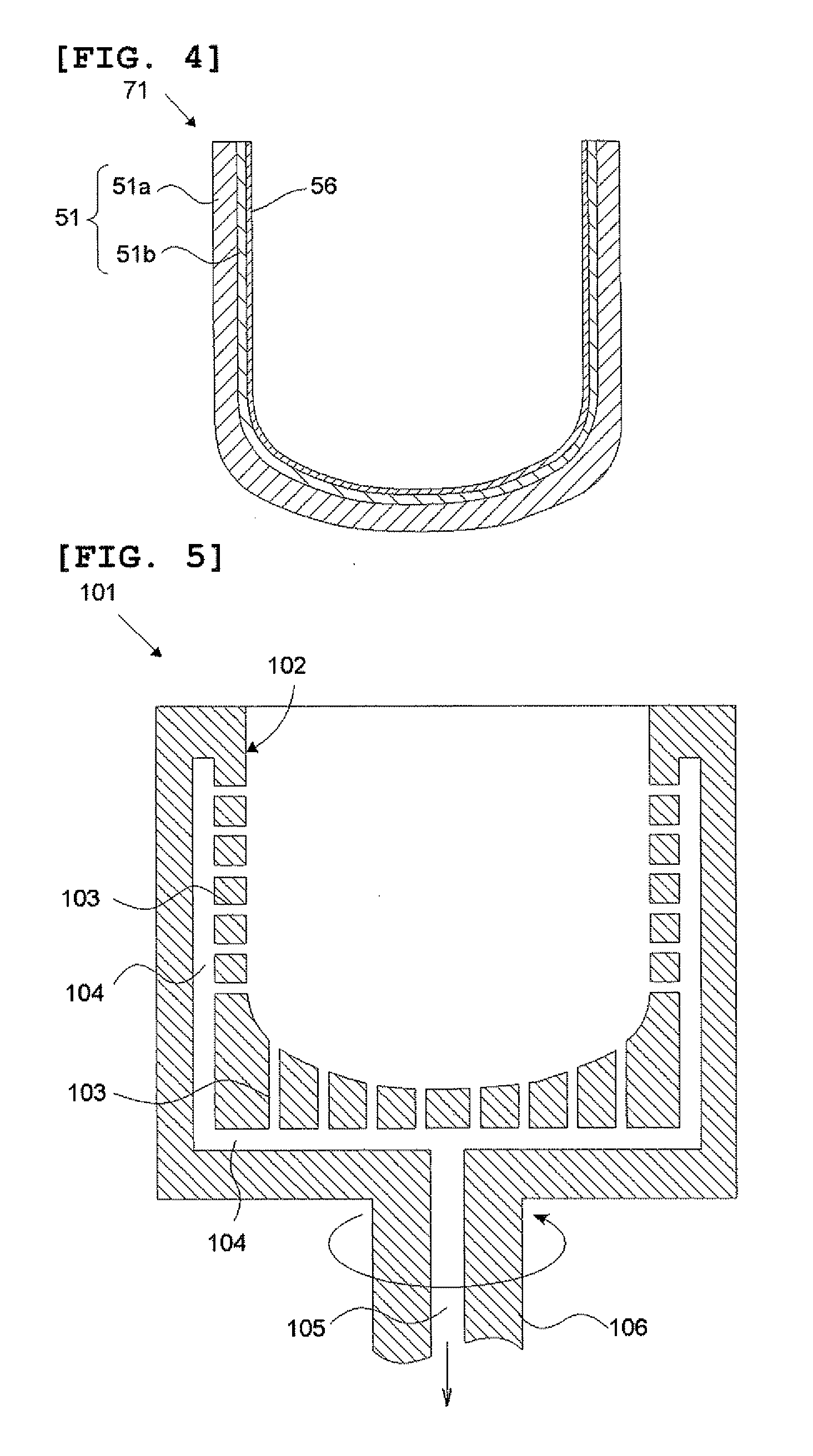

Silica container and method for producing the same

InactiveUS20110272322A1Increased durabilitySuppress generationAfter-treatment apparatusPolycrystalline material growthHydrogenFused glass

The present invention is a method for producing a silica container having a substrate containing gaseous bubbles in its outer peripheral part and an inner layer comprised of a transparent silica glass formed on an inner surface of the substrate, wherein a powdered raw material for forming a substrate containing Li, Na, and K with the total concentration of 50 or less ppm by weight and a powdered raw material for forming an inner layer containing Ca, Sr, and Ba with the total concentration of 50 to 2000 ppm by weight are prepared; a preliminarily molded substrate is formed in a frame; a preliminarily molded inner layer is formed on an inner surface of the preliminarily molded substrate; and the preliminarily molded substrate and molded inner layer are heated from inside thereof by a discharge-heat melting method under a gas atmosphere containing a hydrogen gas or a helium gas or a gas mixture thereof with the ratio of more than 10% by volume thereby making an outer peripheral part of the preliminarily molded substrate to a sintered body and an inner peripheral part of the preliminarily molded substrate and the preliminarily molded inner layer to a fused glass body. With this, a method for producing a silica container, producible with a low cost and having a high durability and dimensional precision, and a container of this sort can be provided.

Owner:SHIN ETABU QUARTZ PRODS

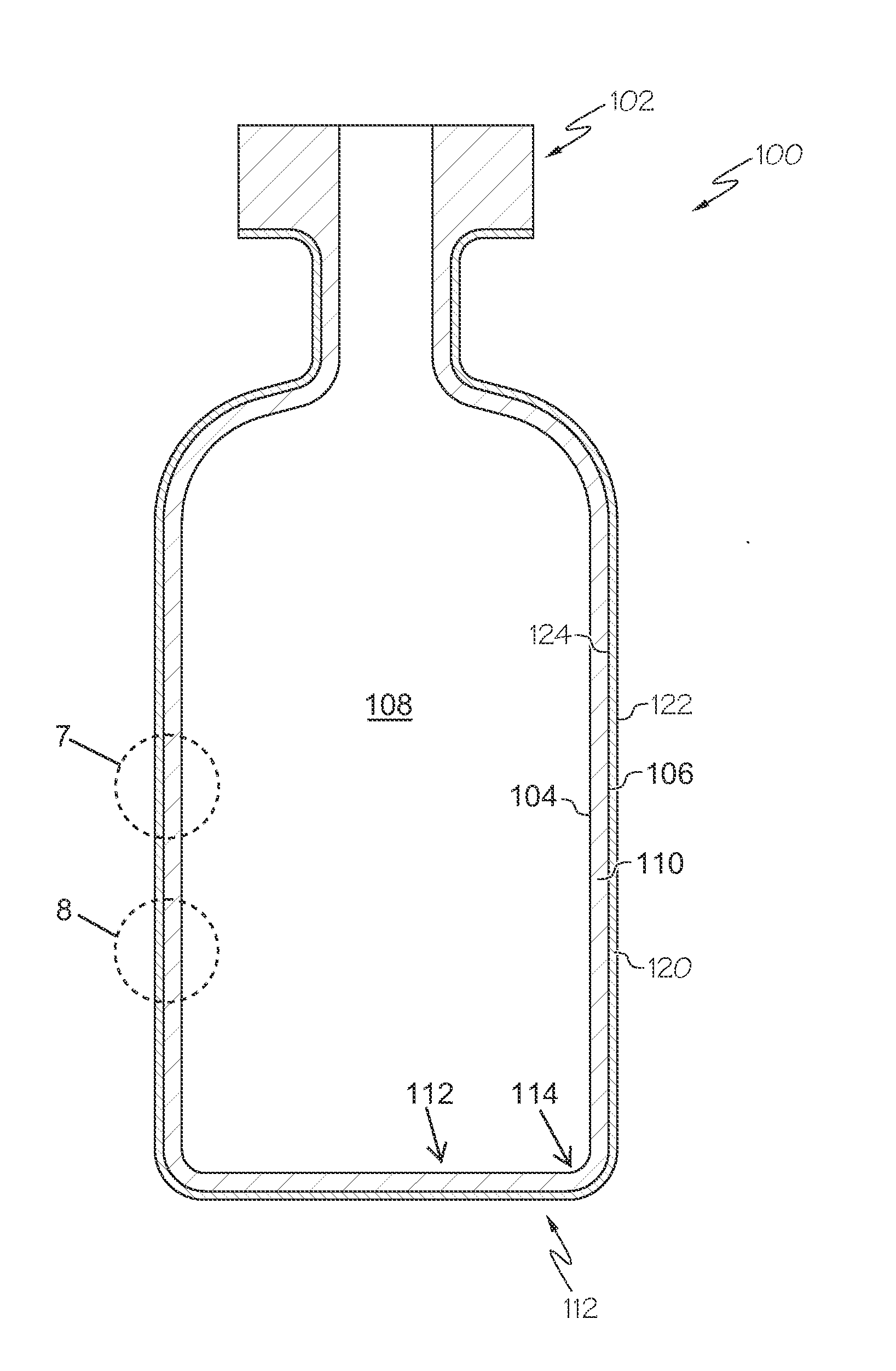

Glass packaging ensuring container integrity

ActiveUS20140120279A1Reducing and eliminating potentialCatastrophic failure is enhancedGlass blowing apparatusGlass/slag layered productsEngineeringCatastrophic failure

A strengthened glass container or vessel such as, but not limited to, vials for holding pharmaceutical products or vaccines in a hermetic and / or sterile state. The strengthened glass container undergoes a strengthening process that produces compression at the surface and tension within the container wall. The strengthening process is designed such that the tension within the wall is great enough to ensure catastrophic failure of the container, thus rendering the product unusable, should sterility be compromised by a through-wall crack. The tension is greater than a threshold central tension, above which catastrophic failure of the container is guaranteed, thus eliminating any potential for violation of pharmaceutical integrity.

Owner:CORNING INC

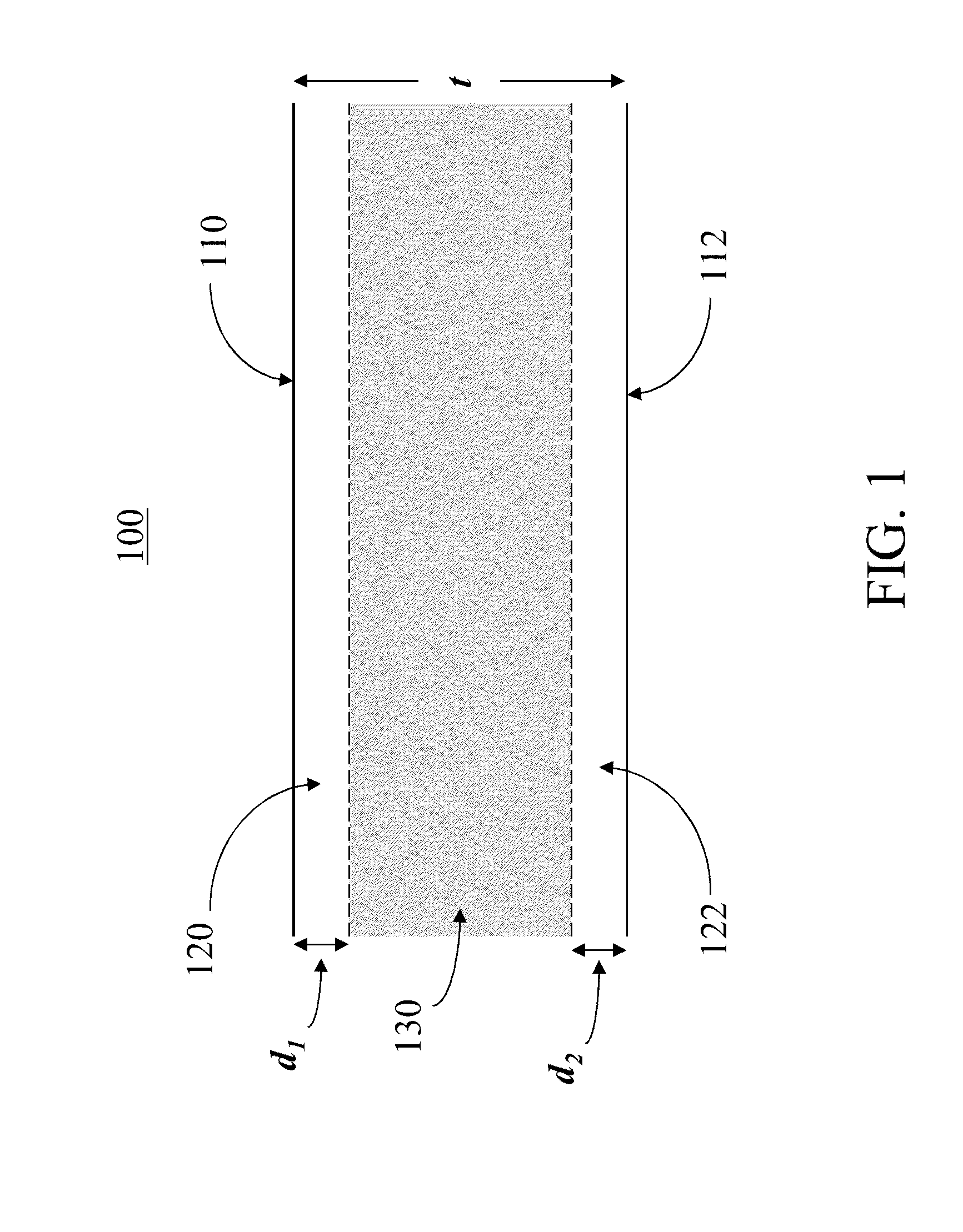

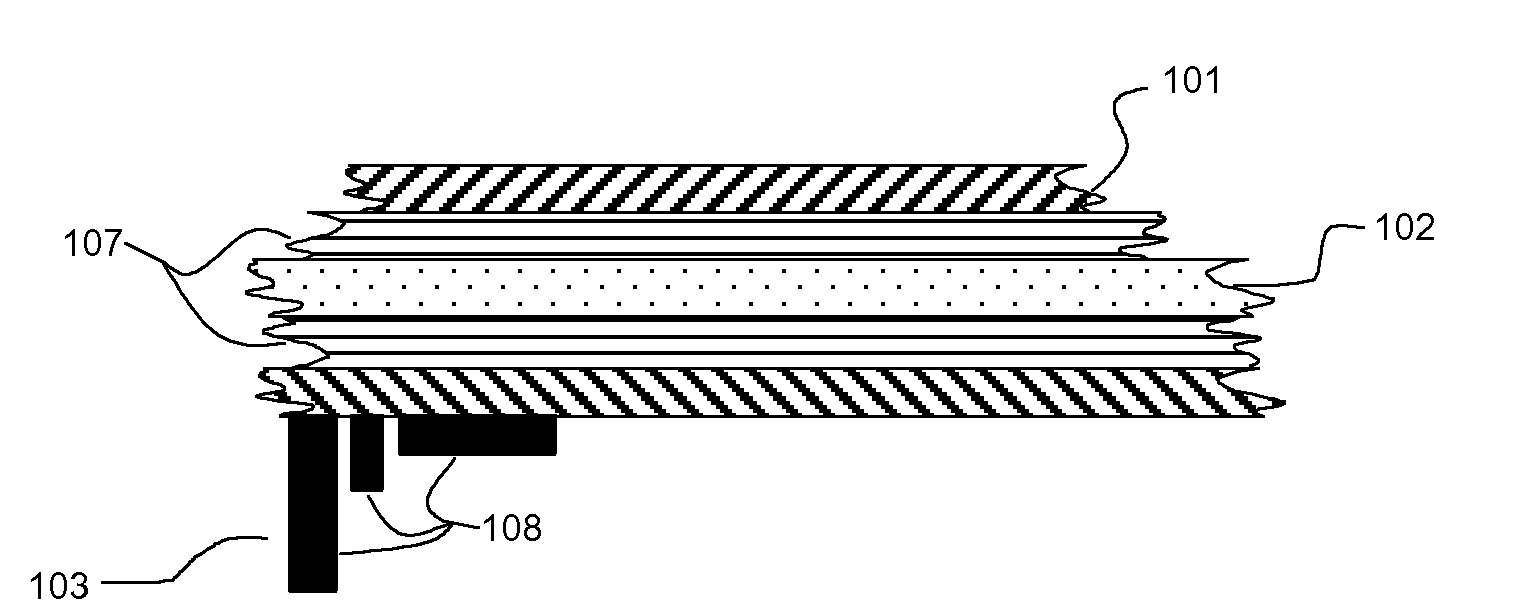

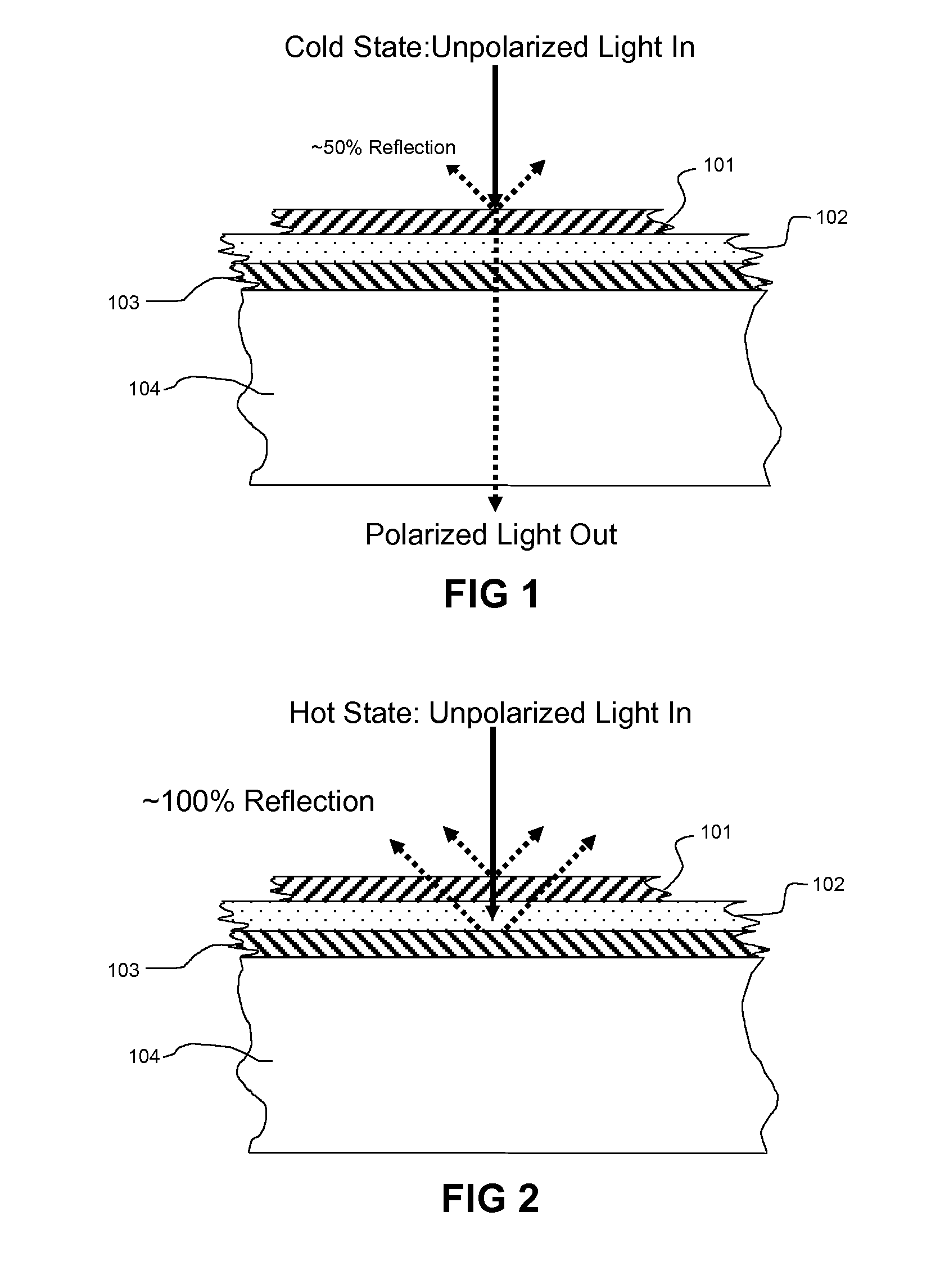

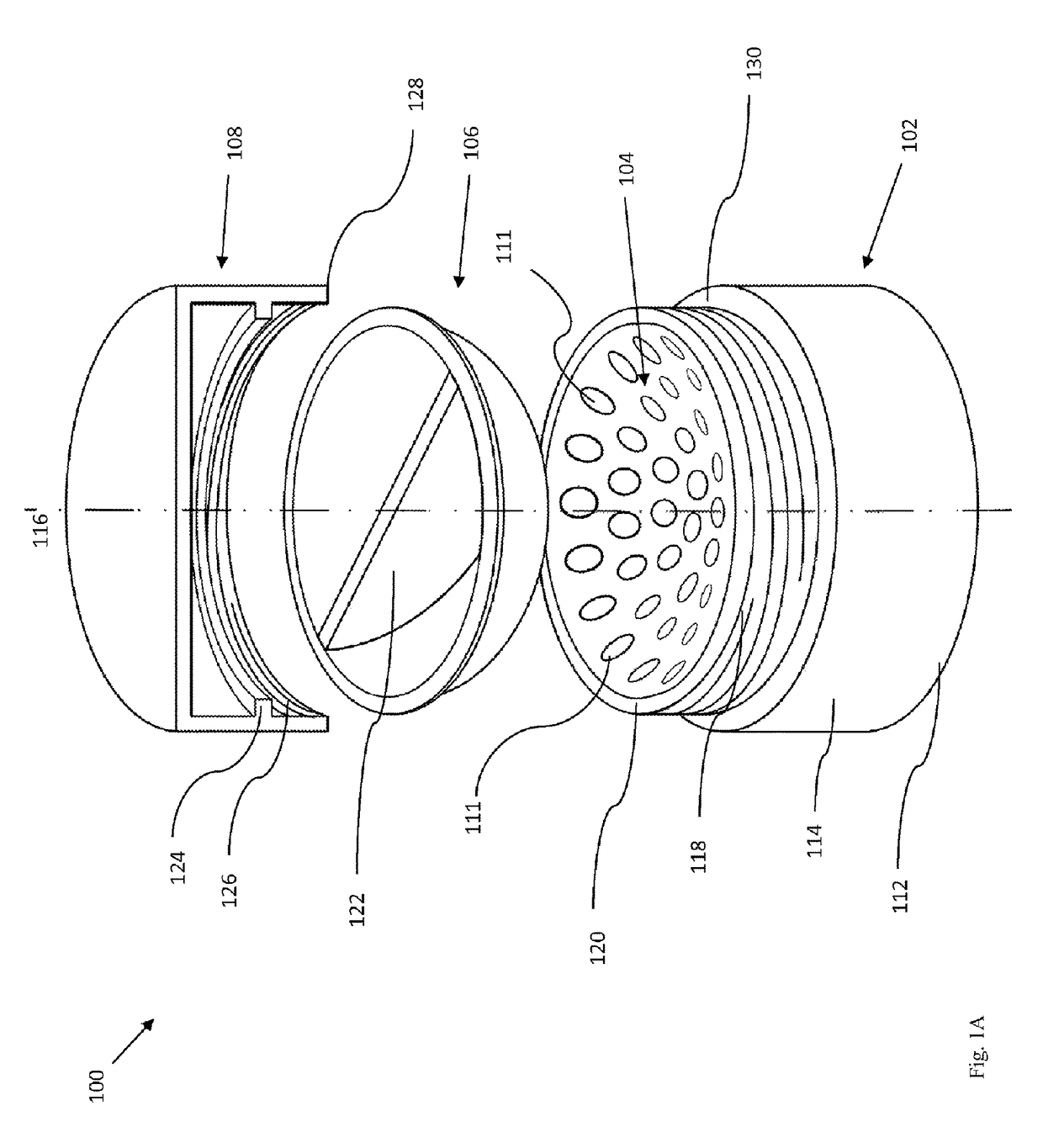

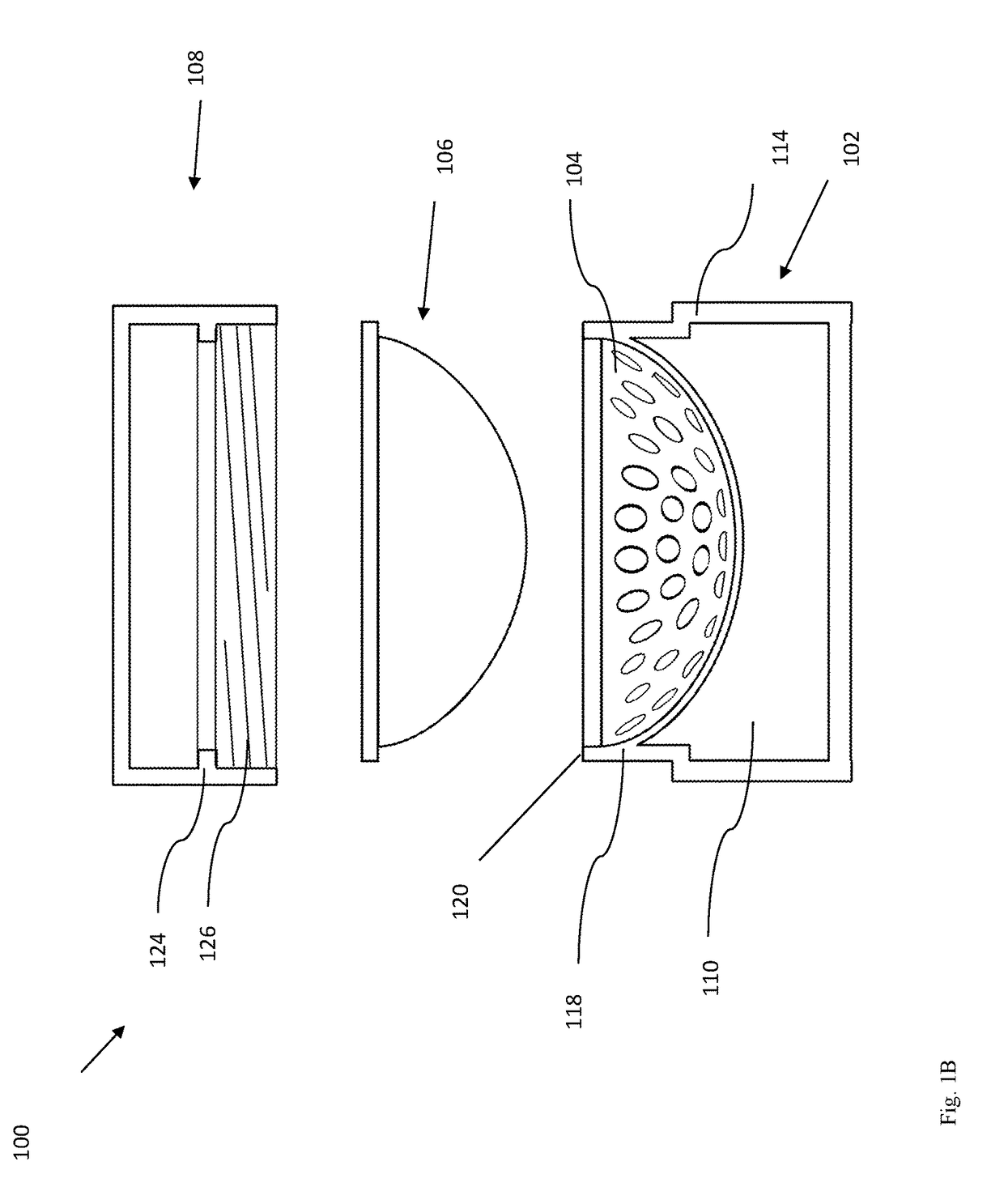

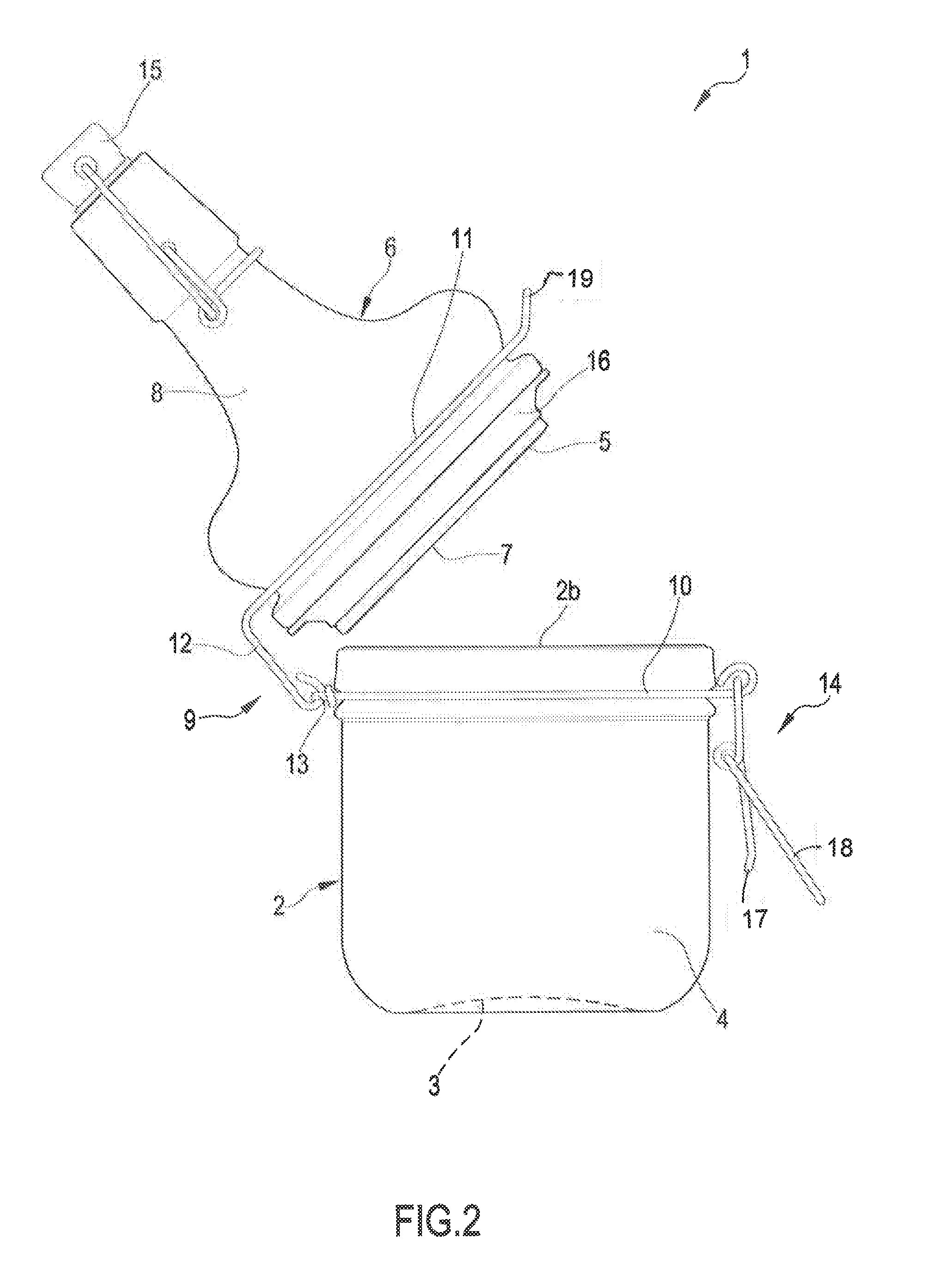

Insulating Glass Unit as Shipping Container

InactiveUS20100001008A1Minimize reflection lossAvoid formingDomestic cooling apparatusLighting and heating apparatusInsulated glazingEngineering

An insulating glass unit (IGU) is used for storing and transporting thermoreflective filters or other thin, fragile devices, chiefly because such filters are often fragile and heavy. Because the IGU may also be the functional enclosure for the thermoreflective filter when it is installed in a building, using the IGU as a shipping container minimizes the total handling of the unpackaged filter and therefore minimizes the risk of damage or breakage.

Owner:RAVENBRICK

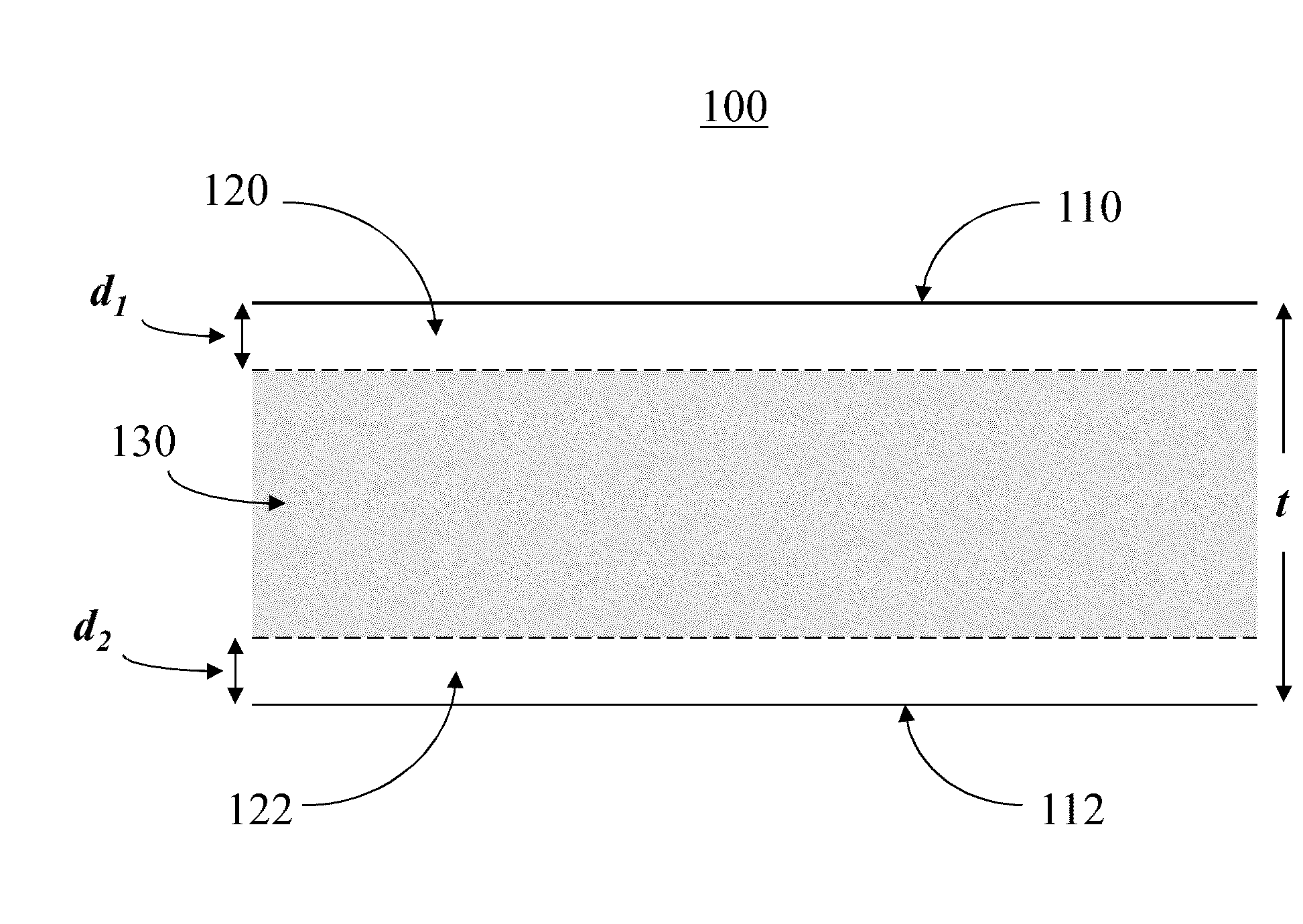

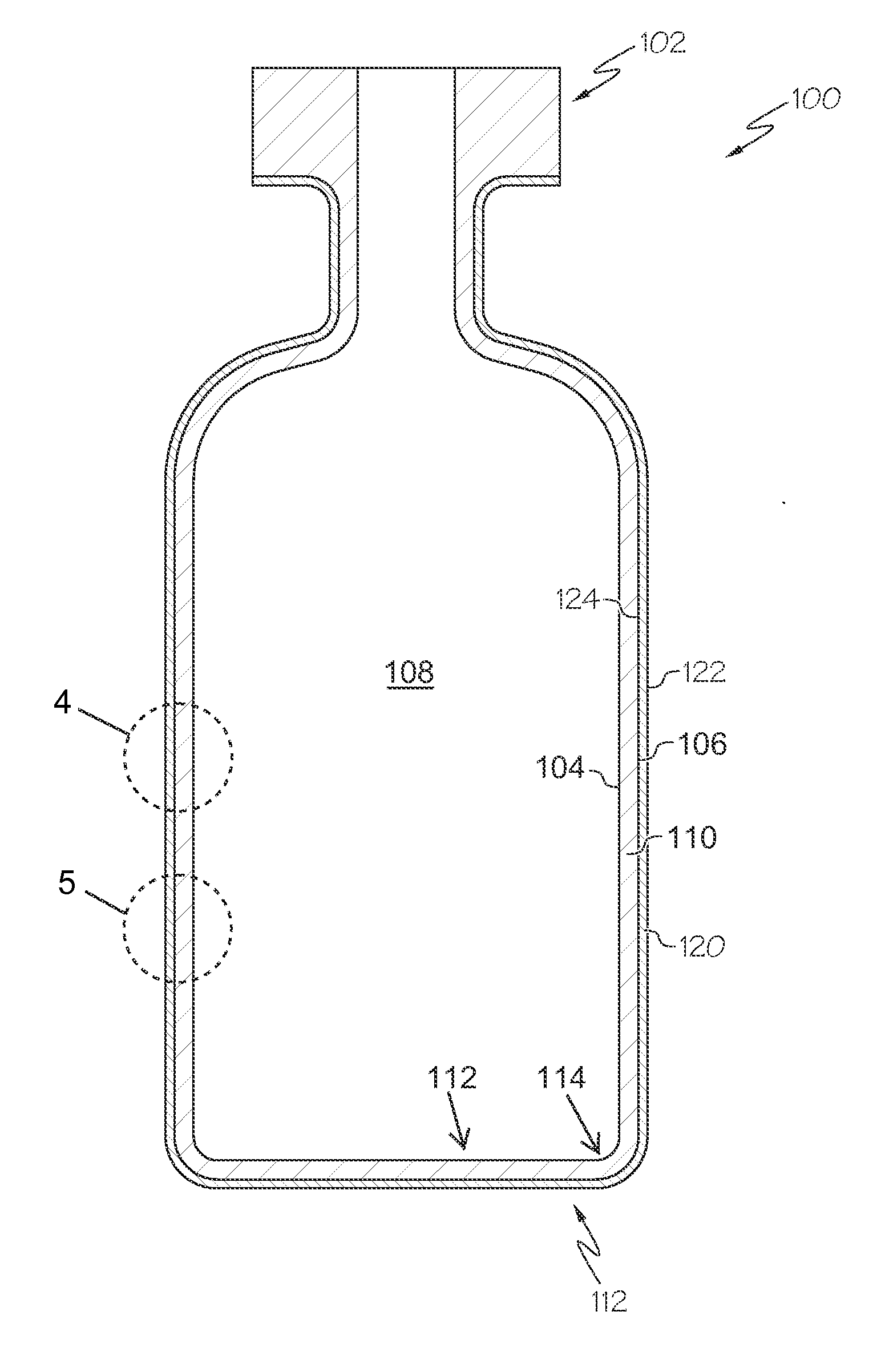

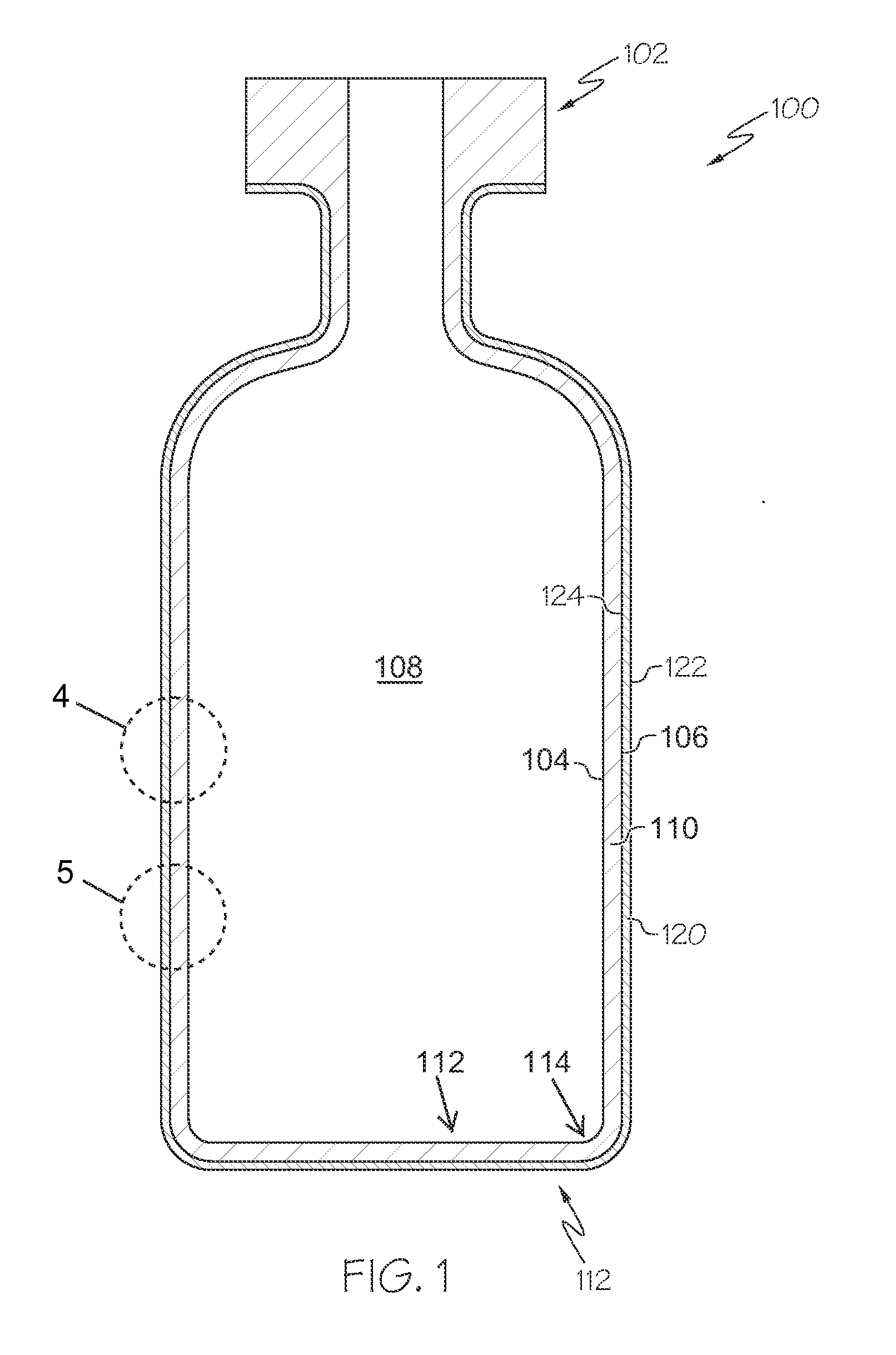

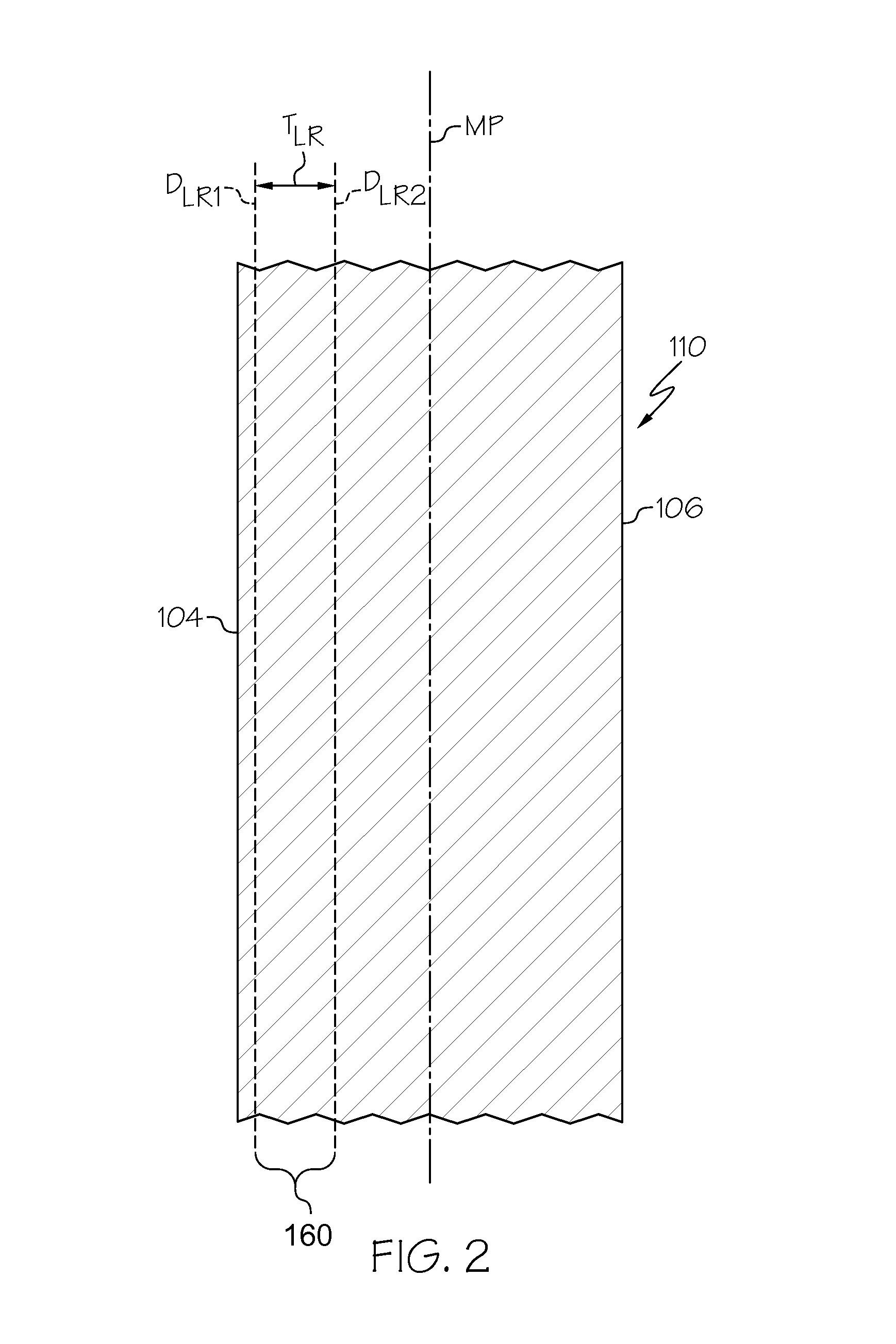

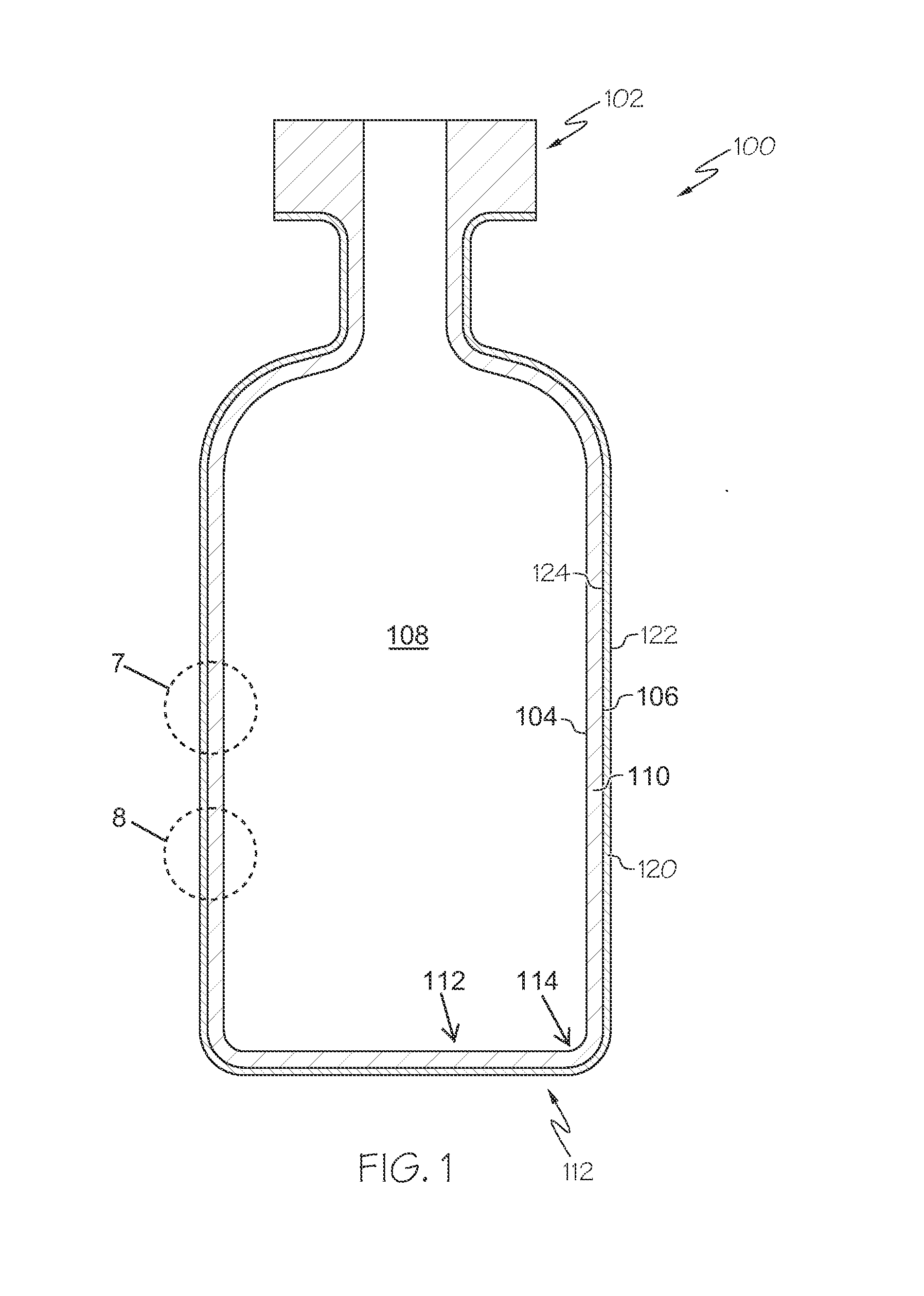

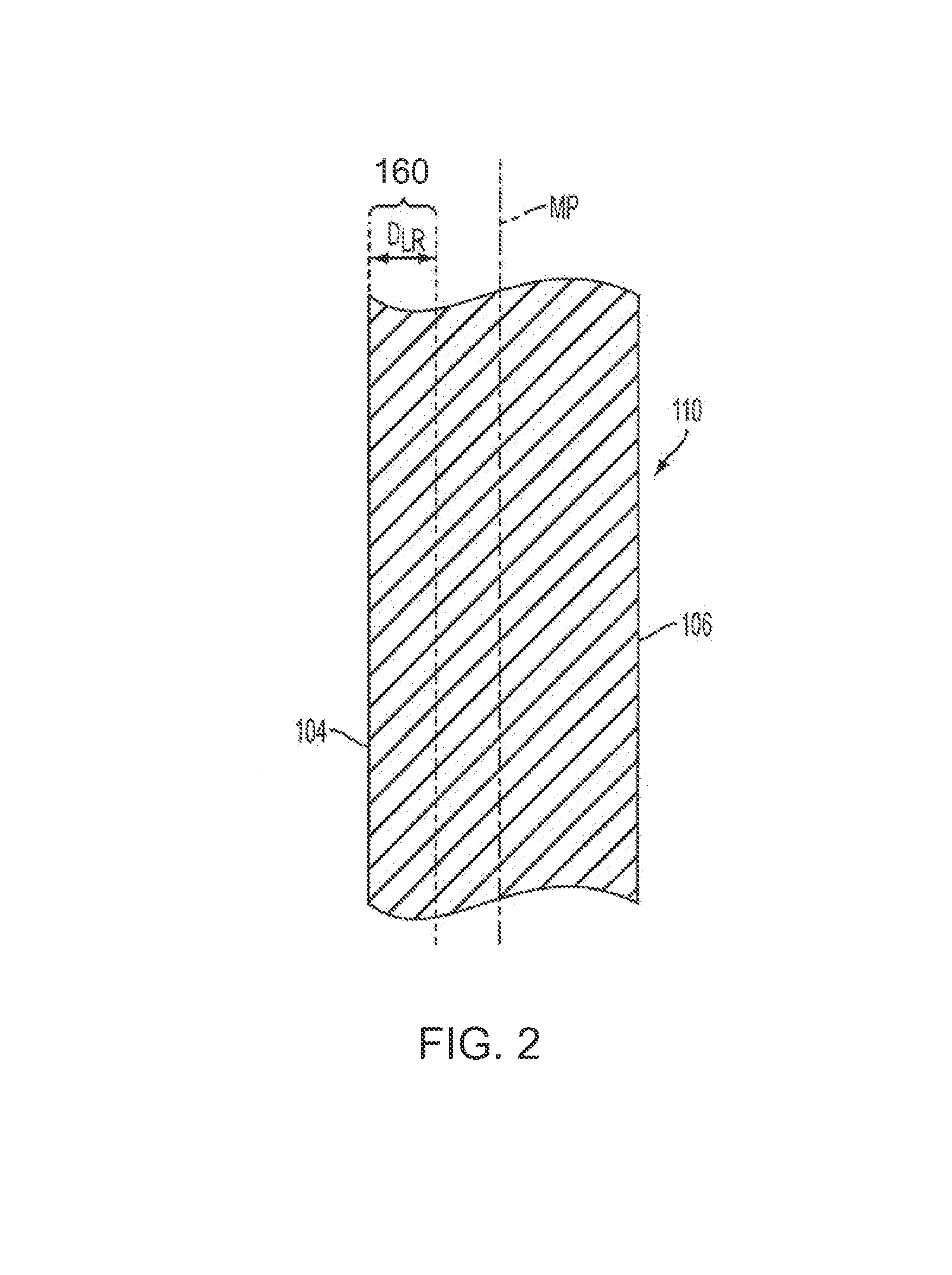

Delamination resistant glass containers with heat-tolerant coatings

Delamination resistant glass containers with heat-tolerant coatings are disclosed. In one embodiment, a glass container may include a glass body having an interior surface, an exterior surface and a wall thickness extending from the exterior surface to the interior surface. At least the interior surface of the glass body is delamination resistant. The glass container may further include a heat-tolerant coating positioned on at least a portion of the exterior surface of the glass body. The heat-tolerant coating may be thermally stable at temperatures greater than or equal to 260° C. for 30 minutes.

Owner:CORNING INC

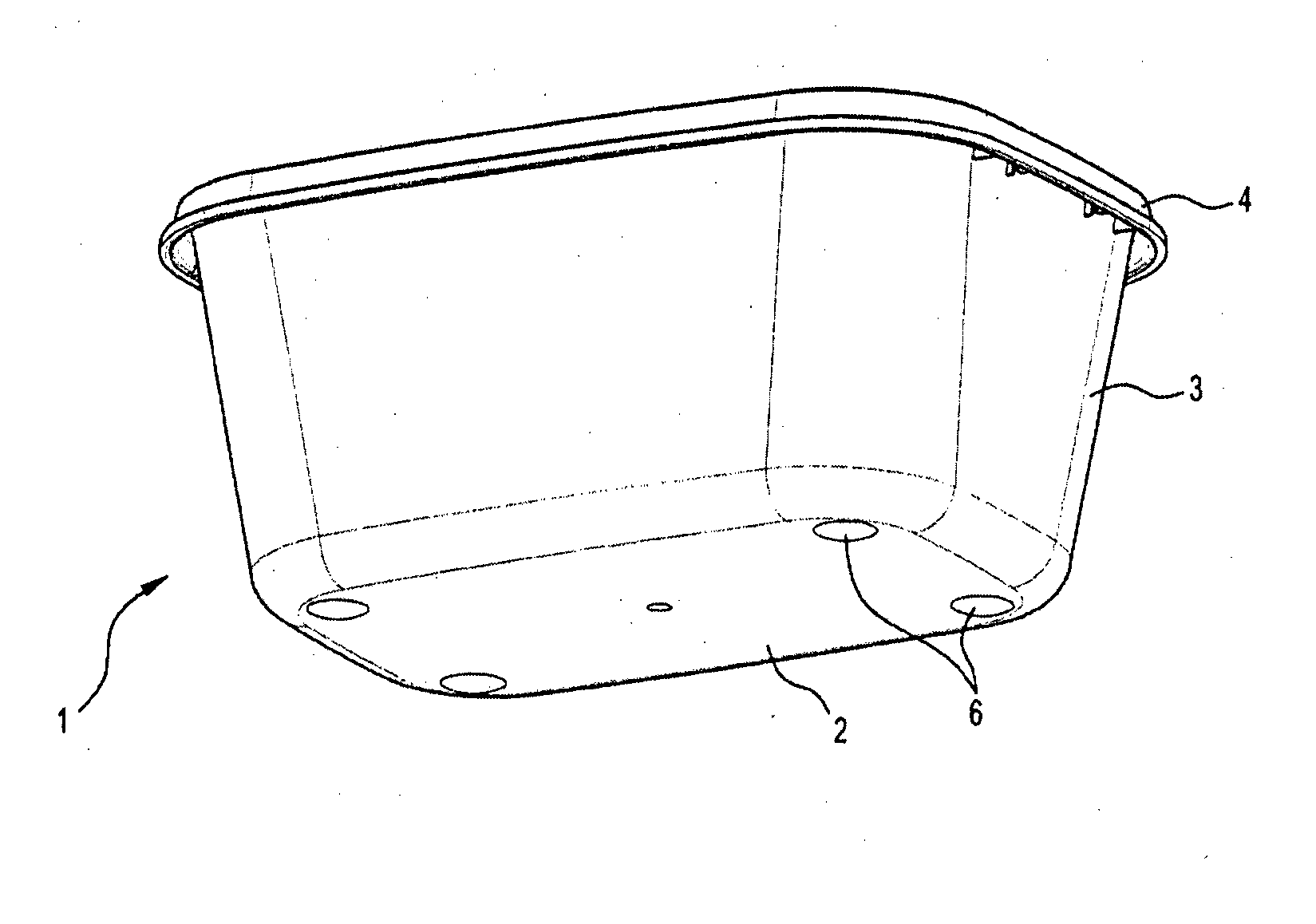

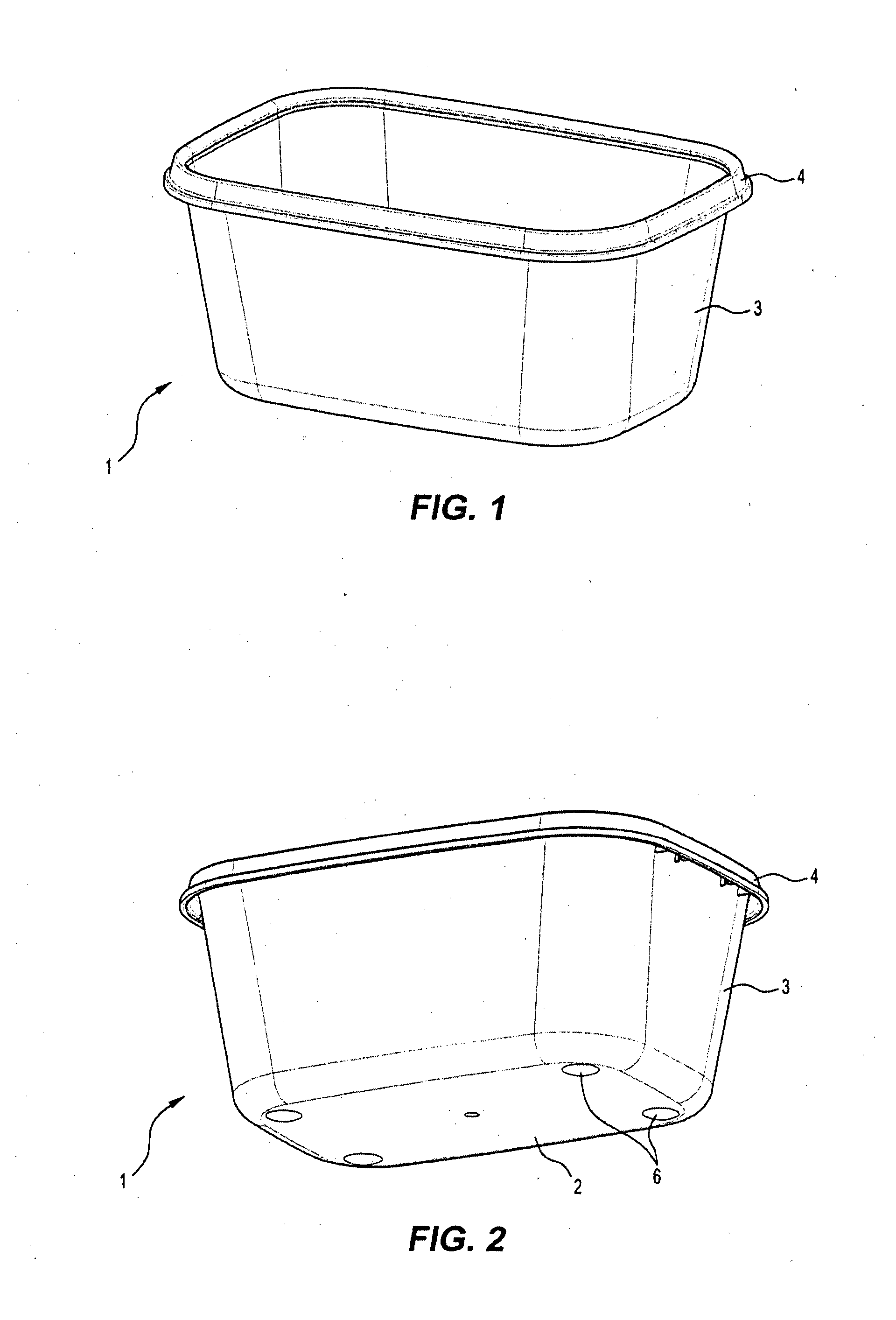

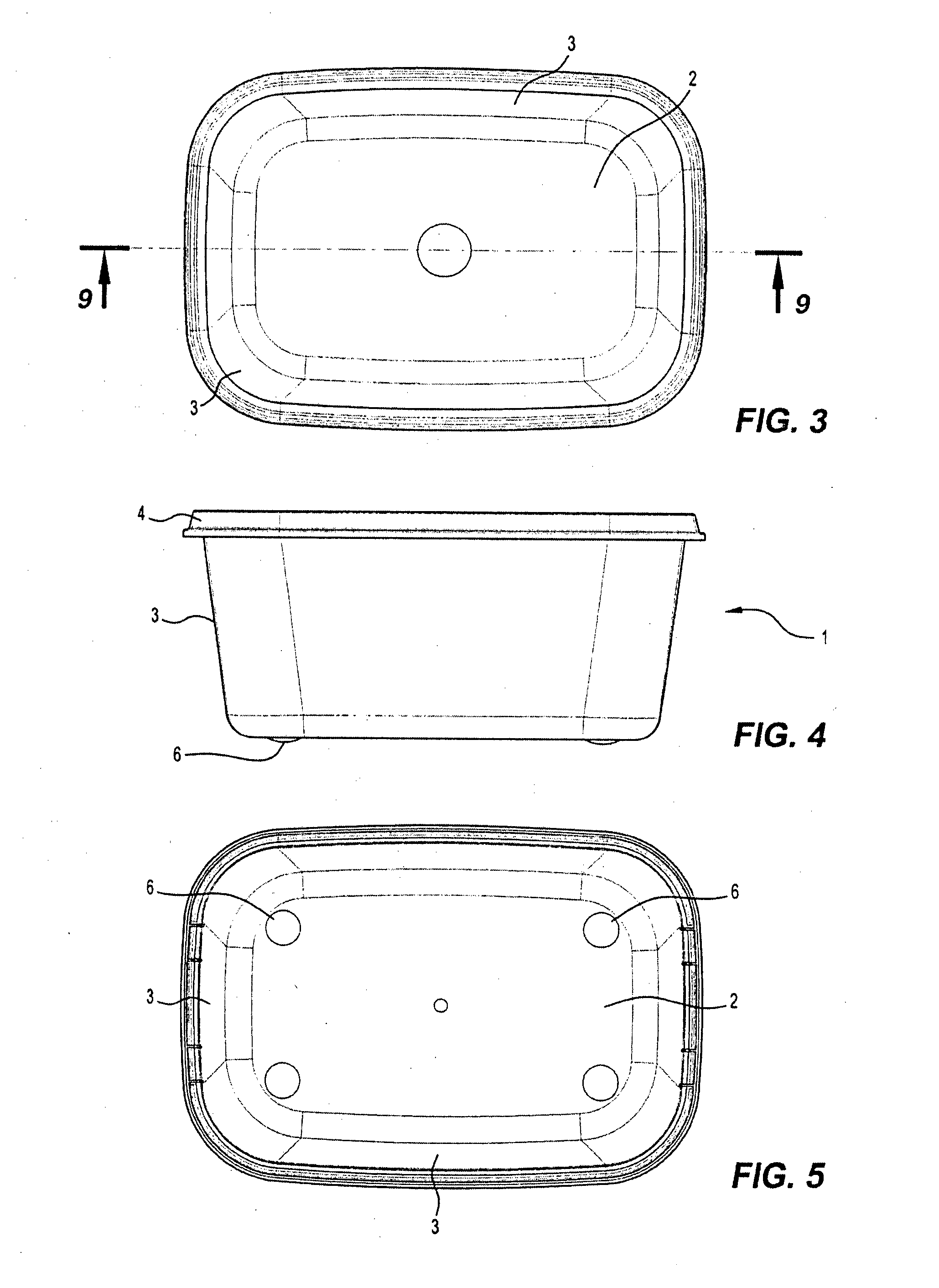

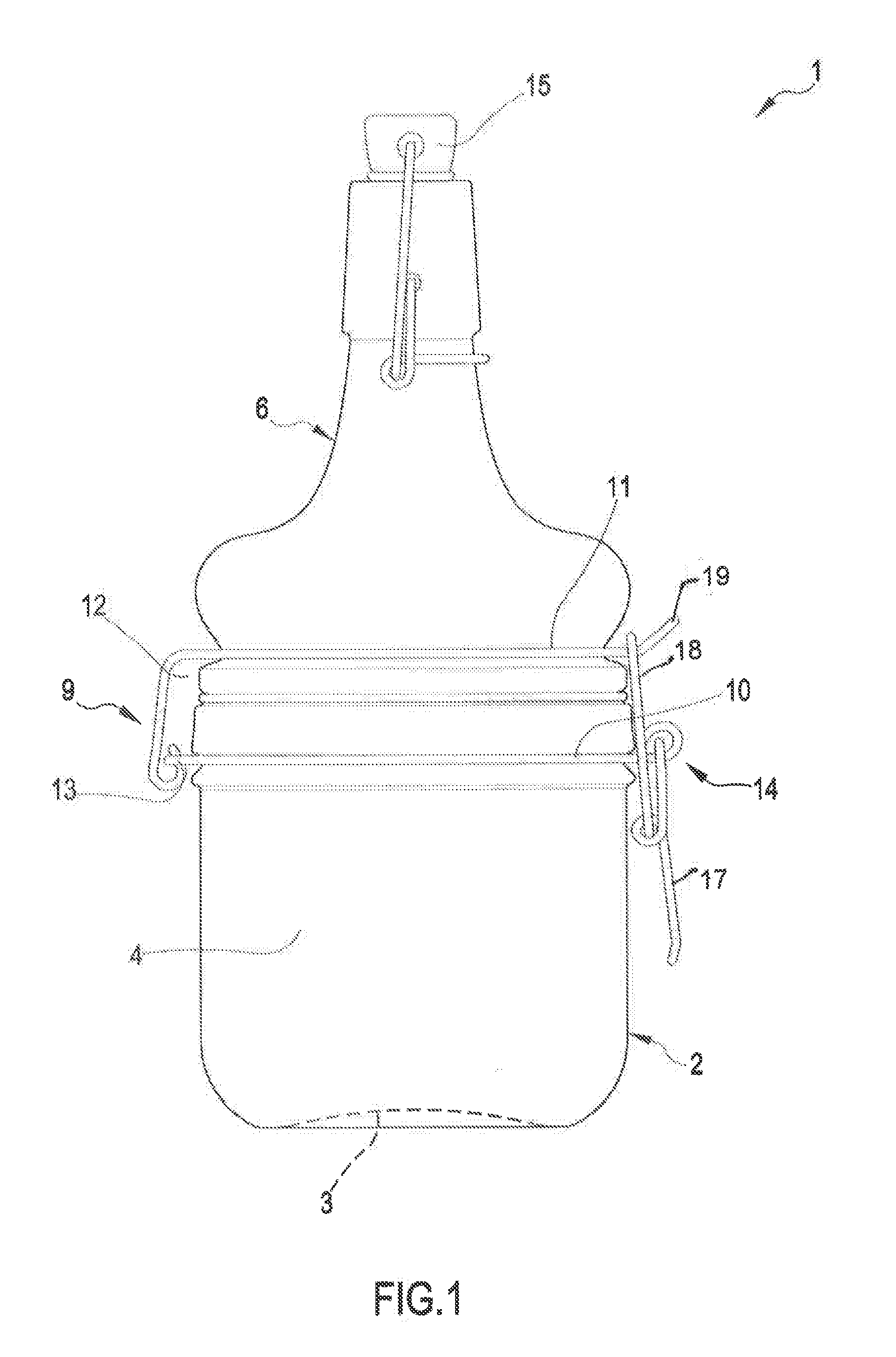

Sealable containers

ActiveUS20150232242A1Deterioration of contentImprove sealingContainer decorationsLevel indicationsEngineering

Owner:THE DECOR

Delamination resistant glass containers with heat-tolerant coatings

ActiveUS20140001076A1Thermally stablePharmaceutical containersMedical packagingMaterials scienceCoating

Delamination resistant glass containers with heat-tolerant coatings are disclosed. In one embodiment, a glass container may include a glass body having an interior surface, an exterior surface and a wall thickness extending from the exterior surface to the interior surface. At least the interior surface of the glass body is delamination resistant. The glass container may further include a heat-tolerant coating positioned on at least a portion of the exterior surface of the glass body. The heat-tolerant coating may be thermally stable at temperatures greater than or equal to 260° C. for 30 minutes.

Owner:CORNING INC

Heat insulating container and manufacture method therefor

InactiveUS20050084633A1Improve insulation effectDomestic cooling apparatusLighting and heating apparatusHigh reflectivityRadiant heat

A heat insulating container is described, including an outer glass container and an inner glass container housed therein with a gap formed in-between as a heat insulating layer. A radiant heat preventive film containing a metal oxide is disposed on at least one of the external surface of the inner container or the internal surface of the outer container, wherein the radiant heat preventive film has a reflectivity of 35% or higher with a wavelength of 15 μm. When the thickness of the radiant heat preventive film is 3000 Å, the Hall mobility “x” (cm2 / V·s) and the carrier concentration “y” (cm−3) of the same satisfy the following formulae: y≧−5×1020x+2×1021 and y≧−6×1018x+3×1020. When the thickness of the radiant heat preventive film is 5000 Å, x and y satisfy the following formulae: y≧−5×1020x+3×1021 and y≧−6×1018x+7×1020. Such radiant heat preventive films can have high reflectivity.

Owner:BABA NAOHO +2

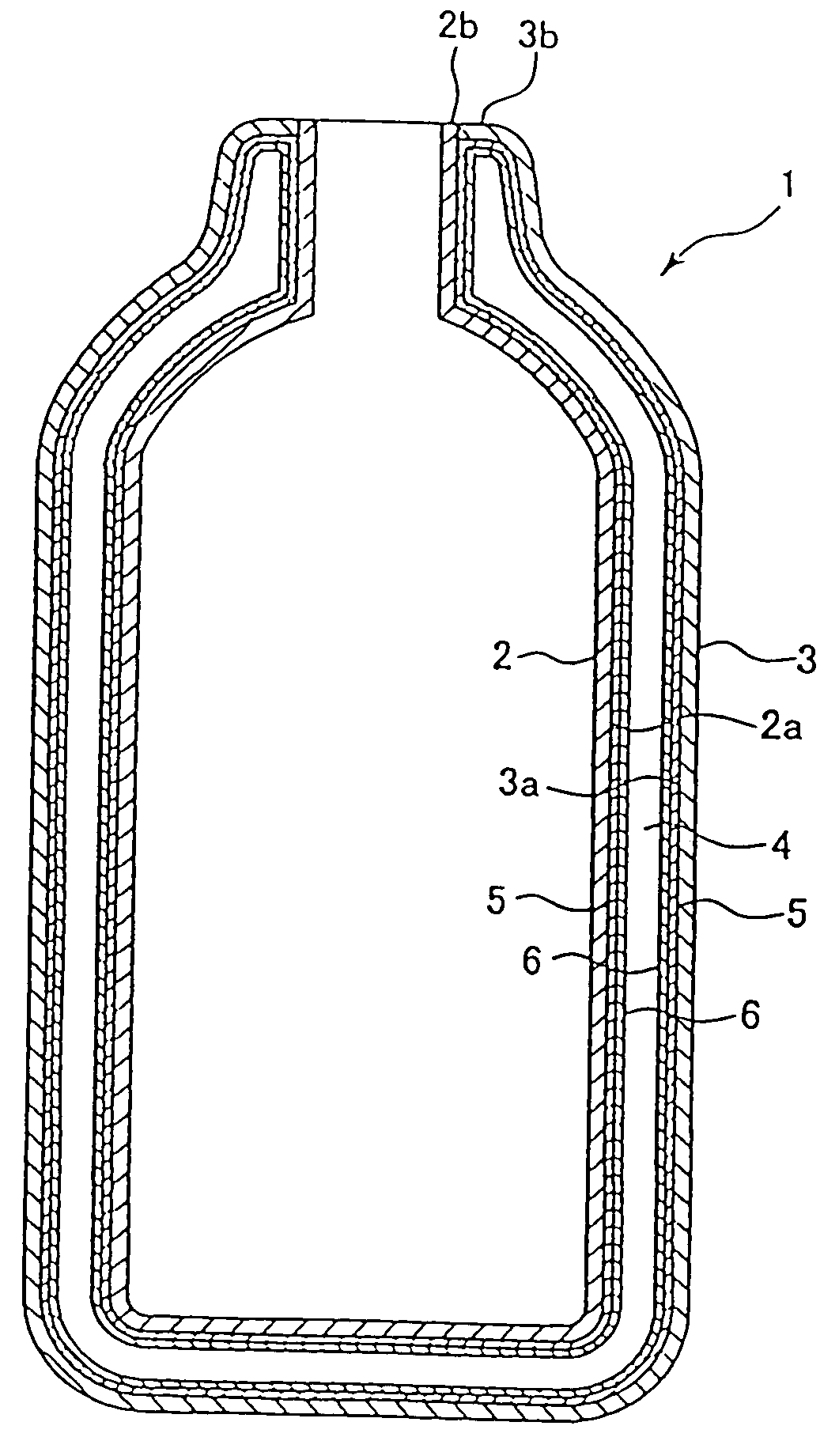

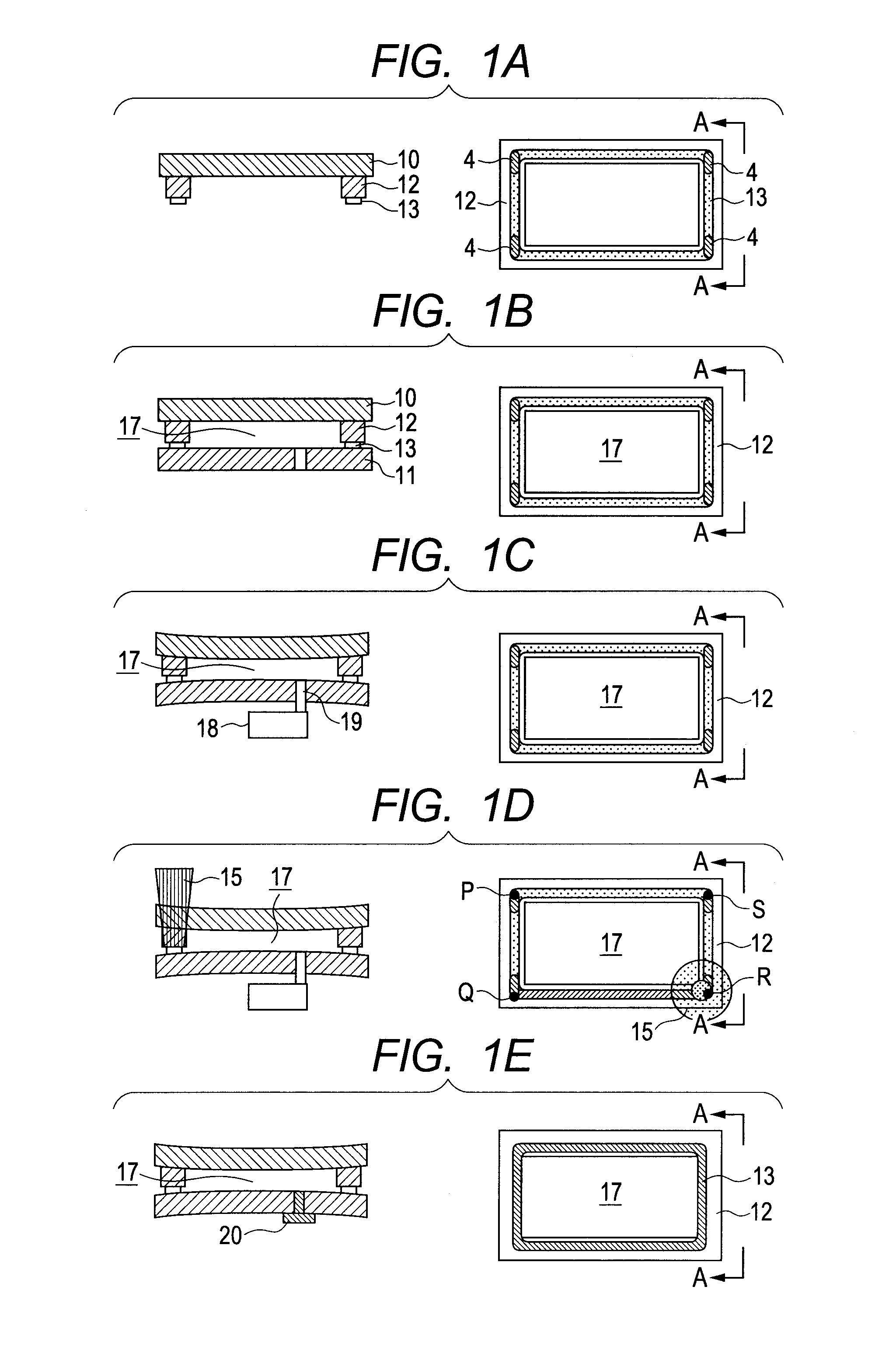

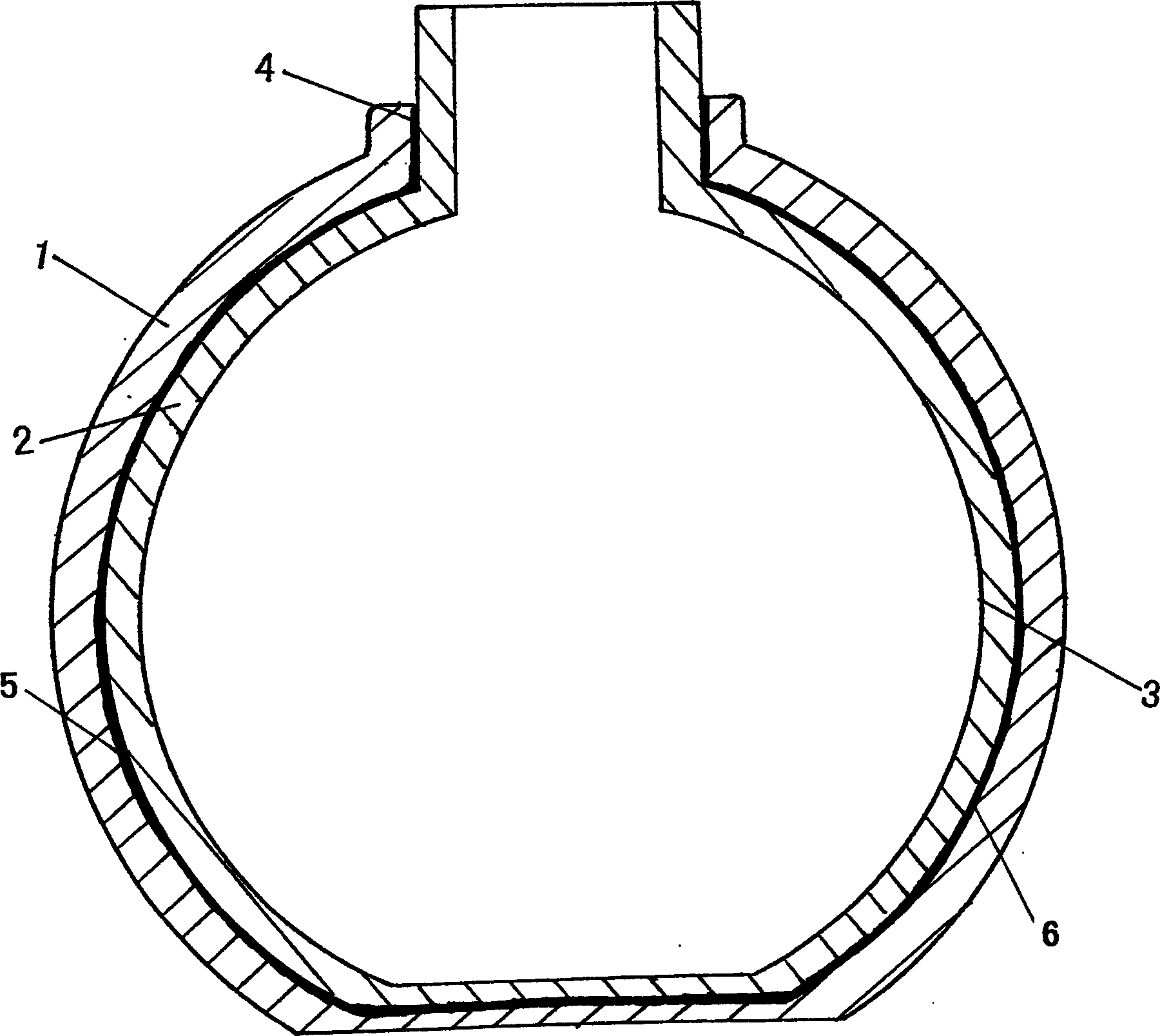

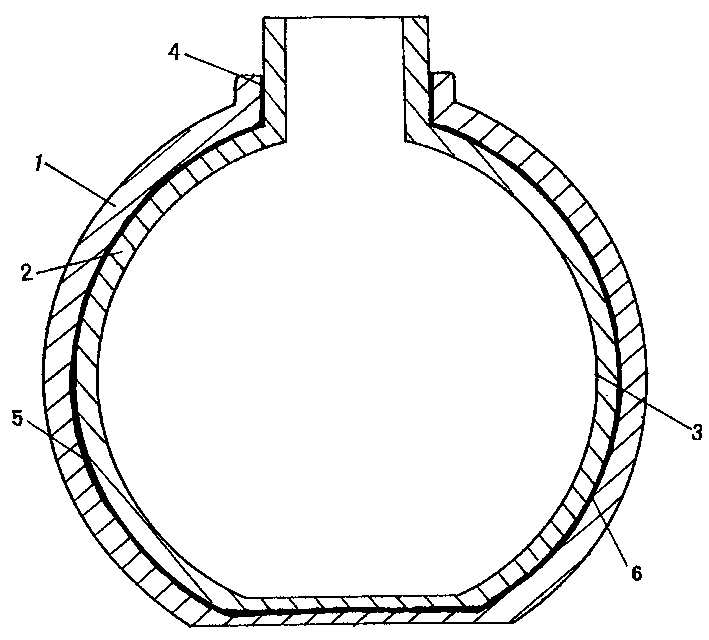

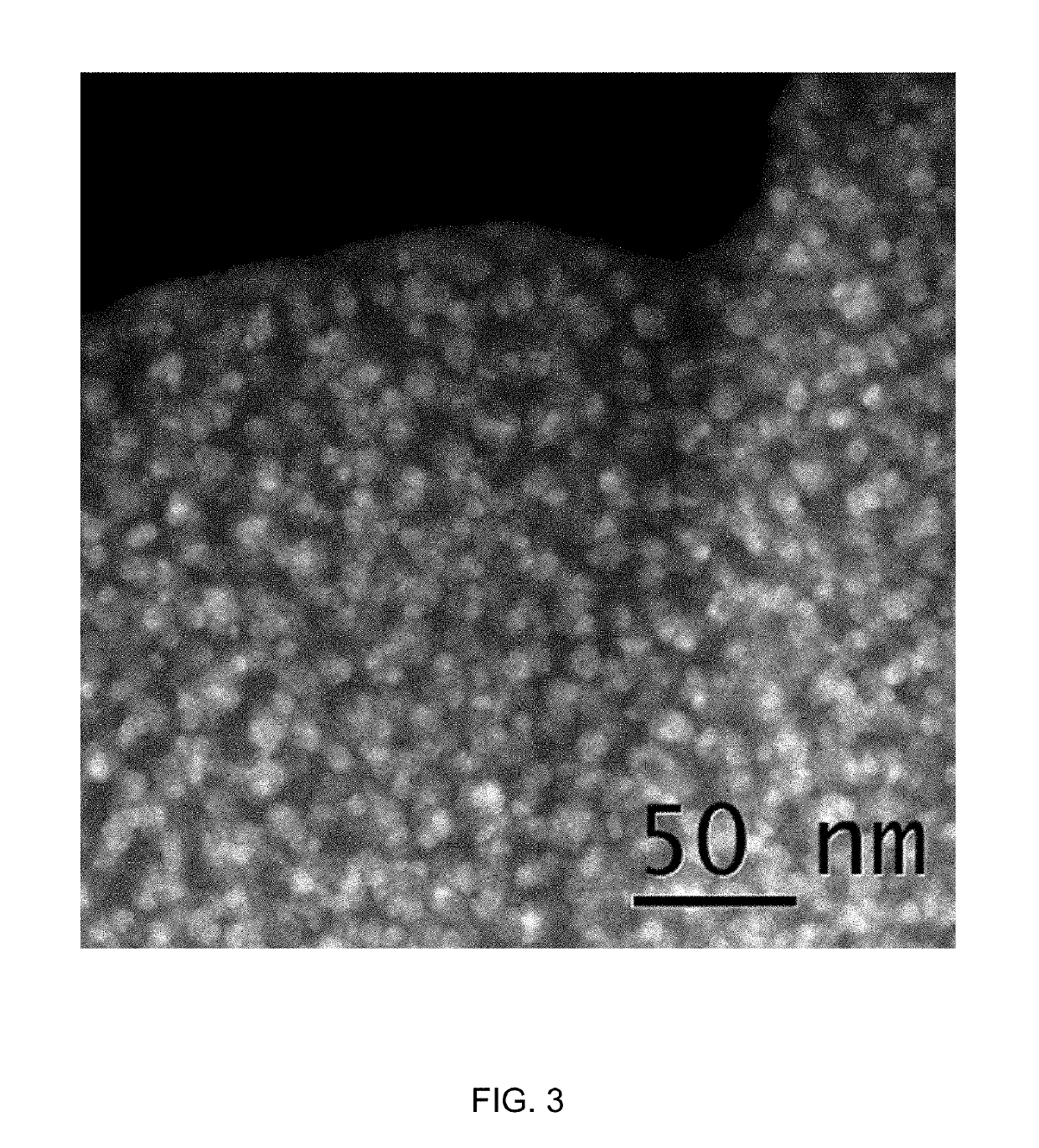

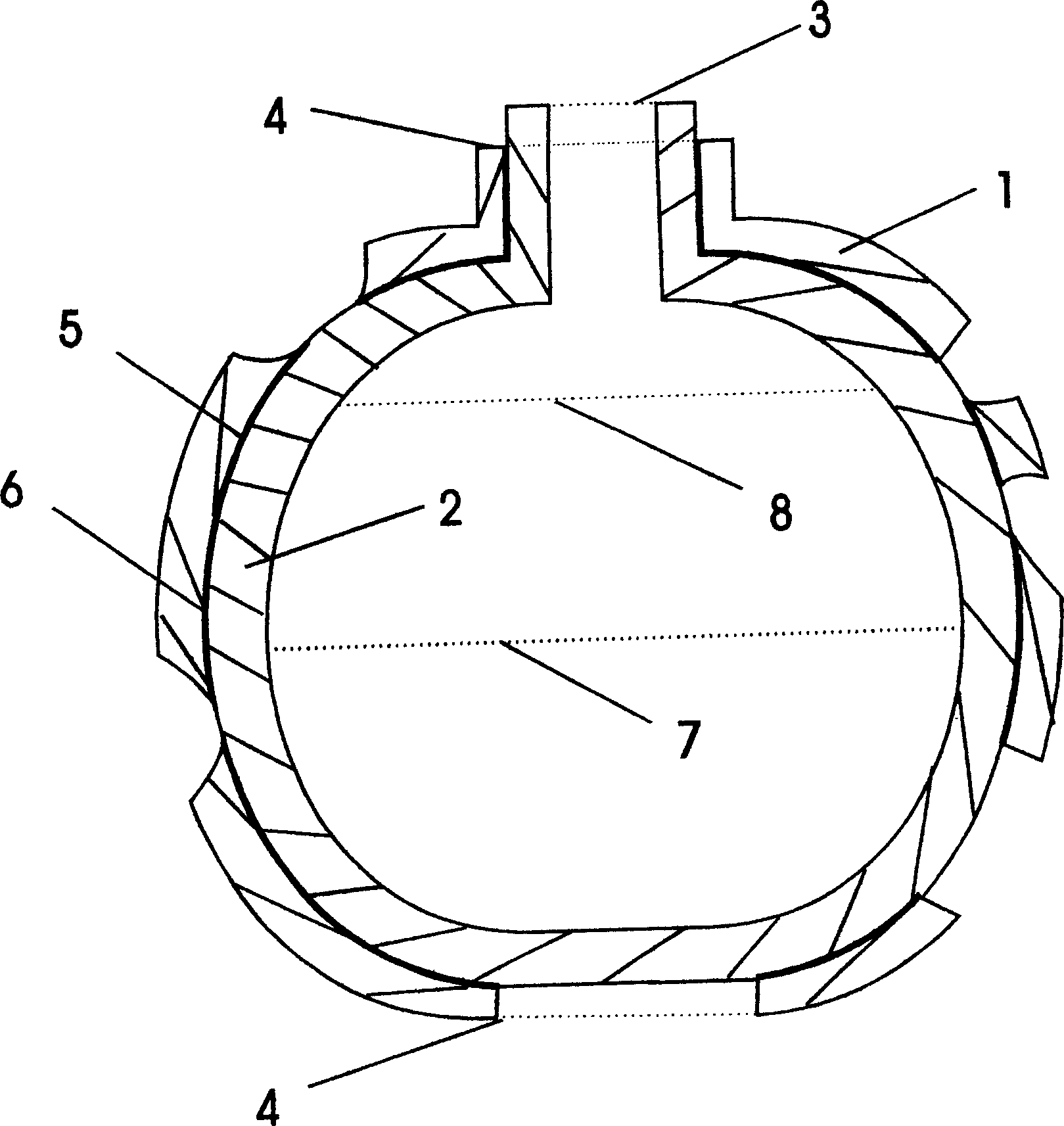

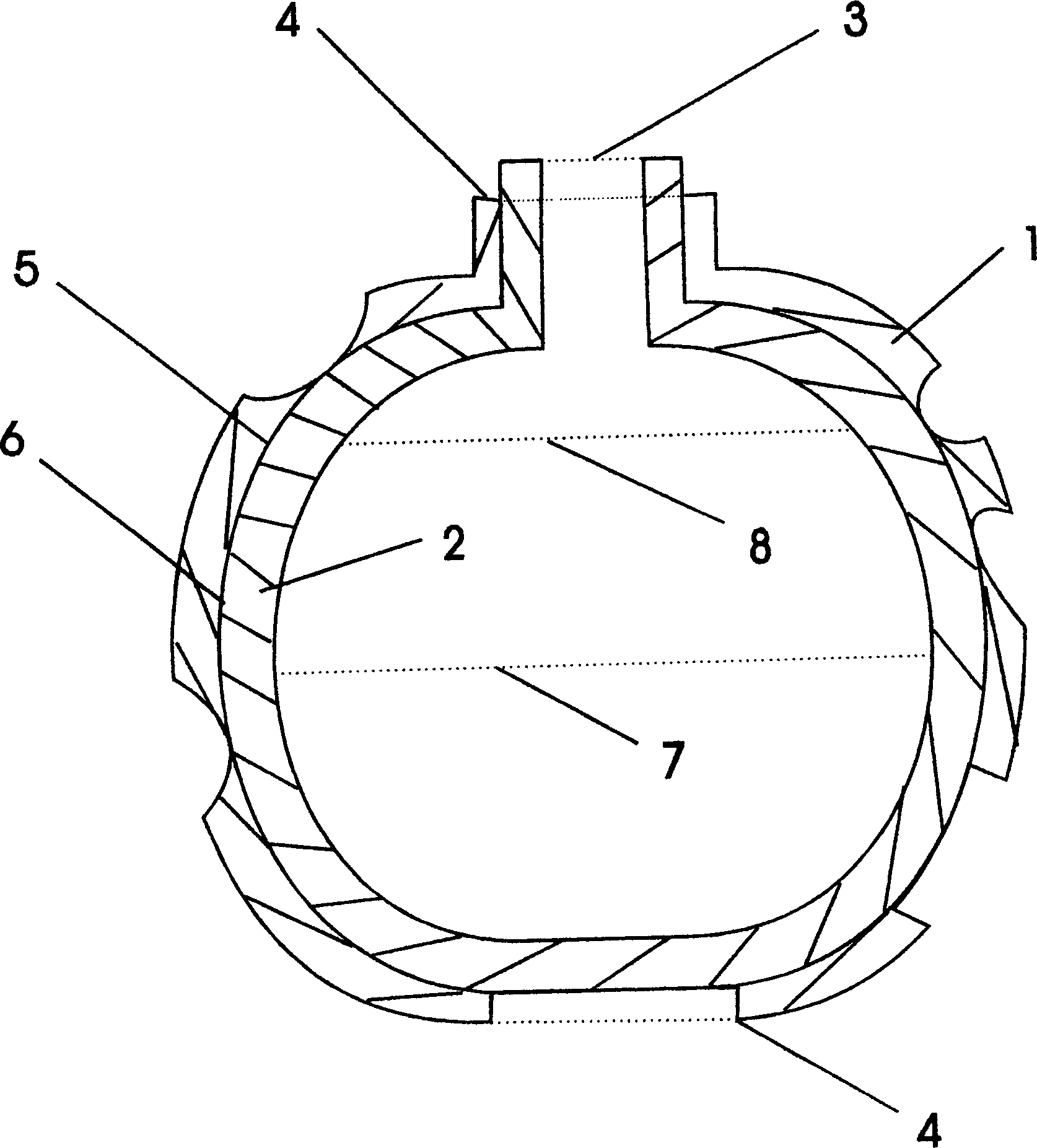

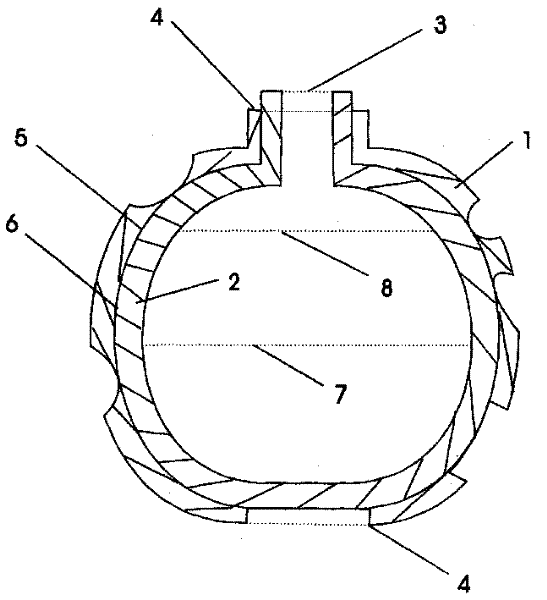

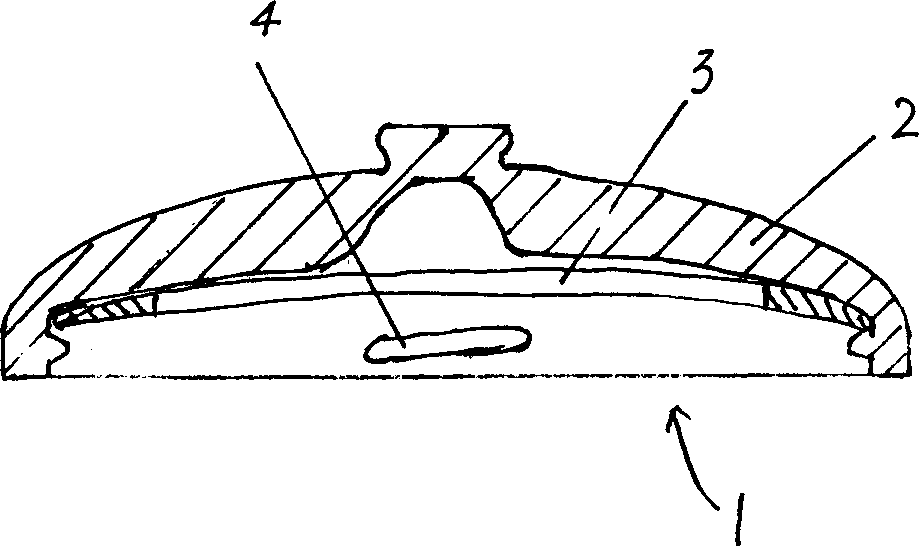

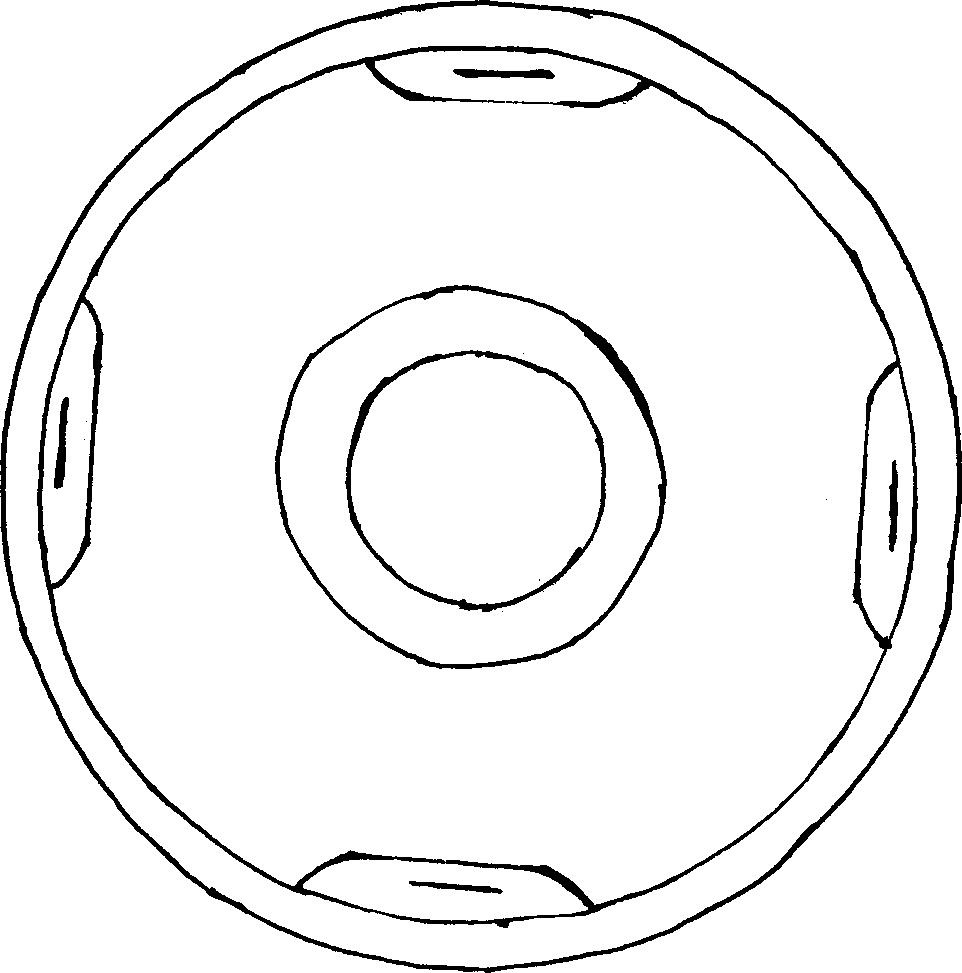

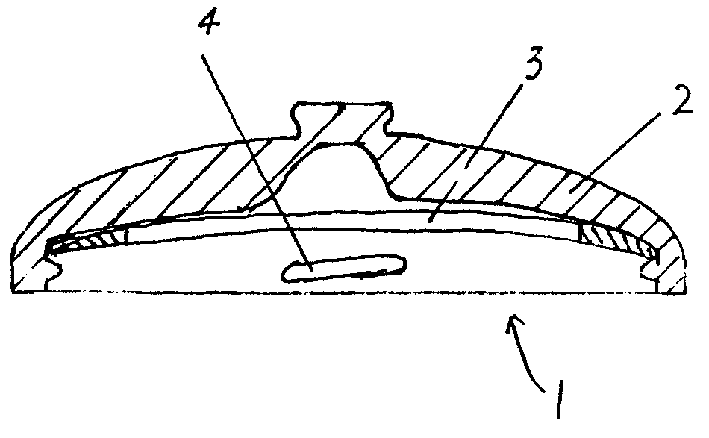

Multilayer structured quartz glass crucible and method for producing the same

InactiveUS6841210B2Reduce infrared transmittanceOscillation suppressionCrystallization separationBy zone-melting liquidsCrucibleSingle crystal

Disclosed is a multilayer structured quartz glass crucible, for pulling up silicon single crystal, whose structure has at least three layers comprising: a translucent outer layer made of naturally occurring quartz glass and having a large number of pores, a translucent intermediate layer, made of synthetic quartz glass and having a large number of pores, and a transparent inner layer substantially free from pores and made of a synthetic quartz glass. Thermal convection within the silicon melt is suppressed by use of the quartz glass crucible, thereby preventing oscillation on the surface of the silicon melt. A method for producing the quartz glas crucible is also disclosed.

Owner:HERAEUS QUARZGLAS +1

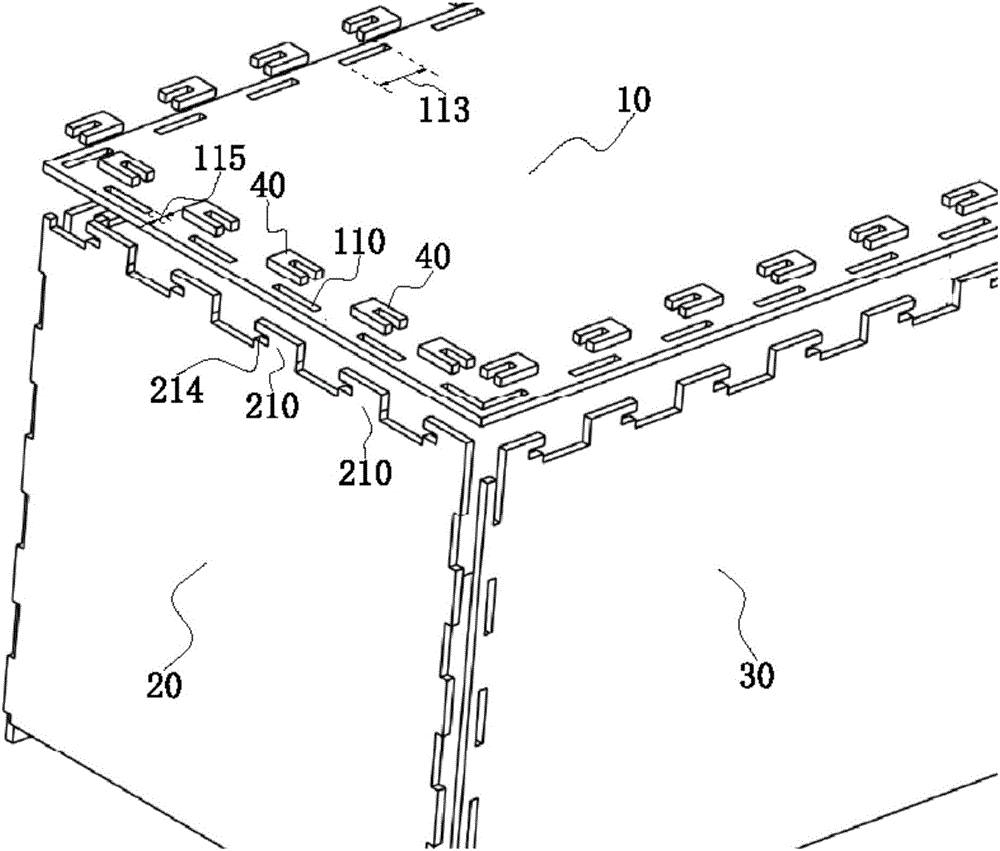

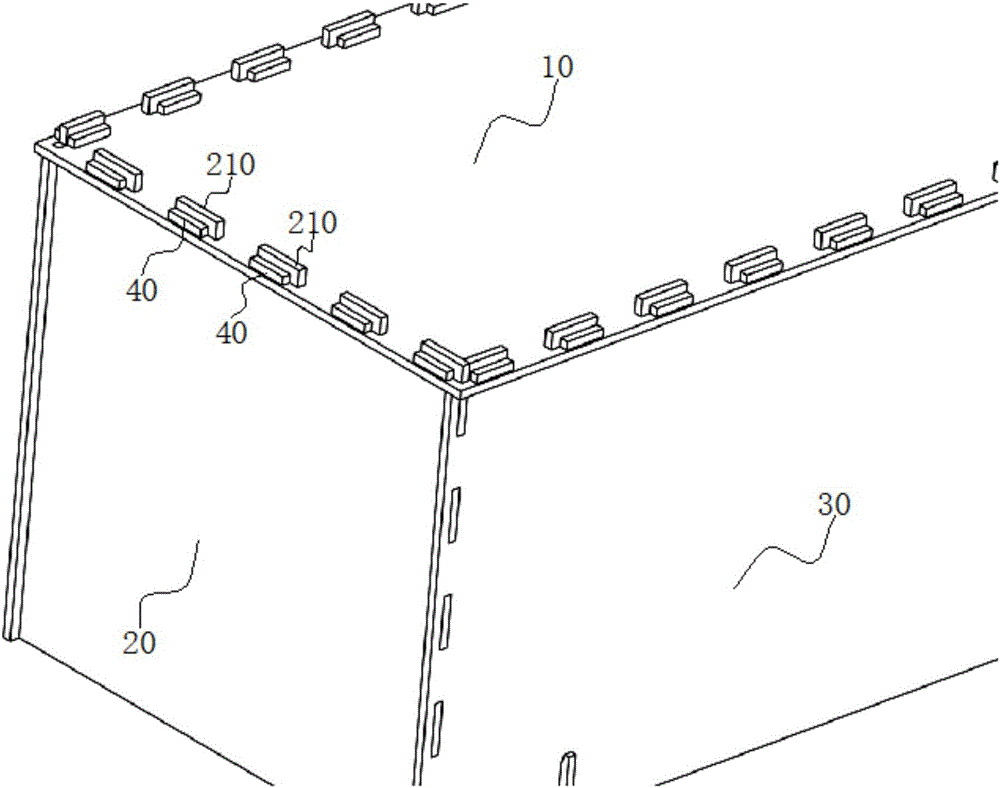

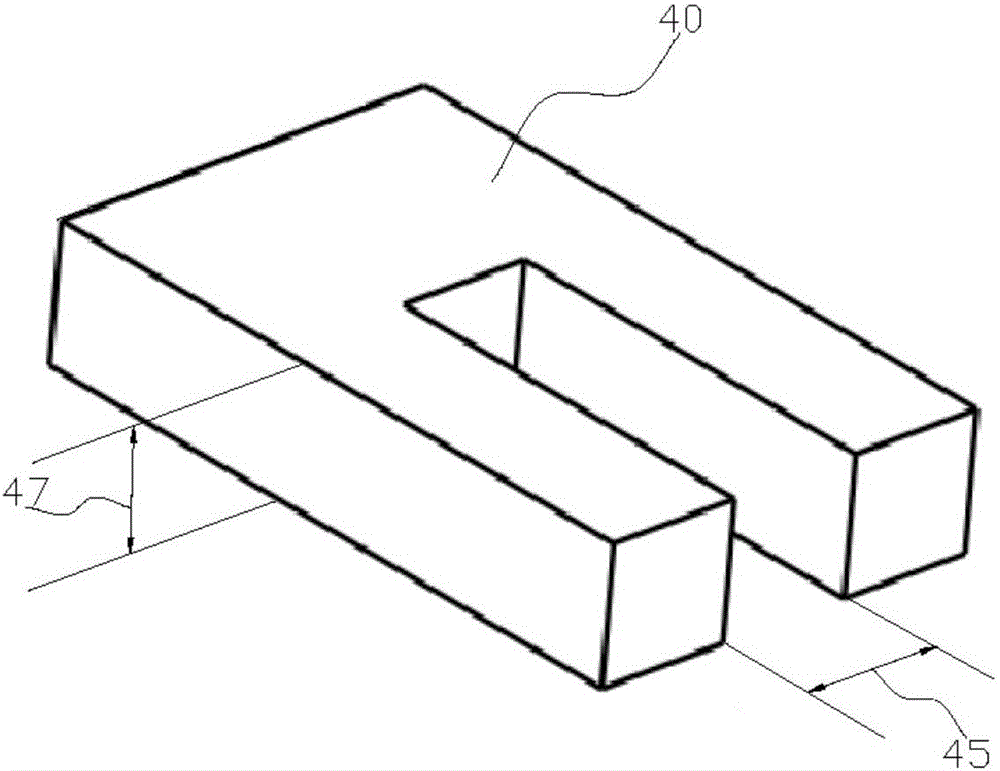

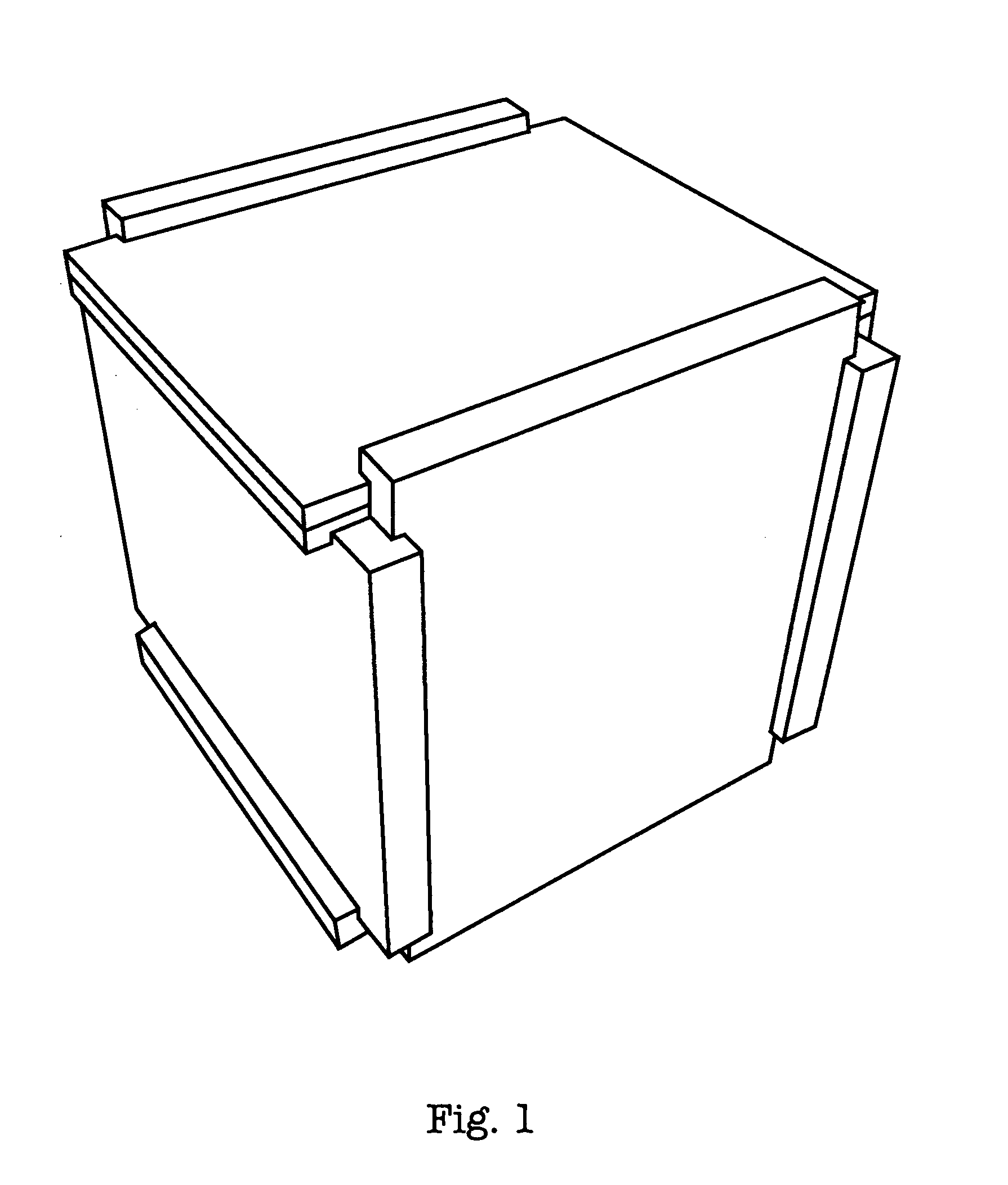

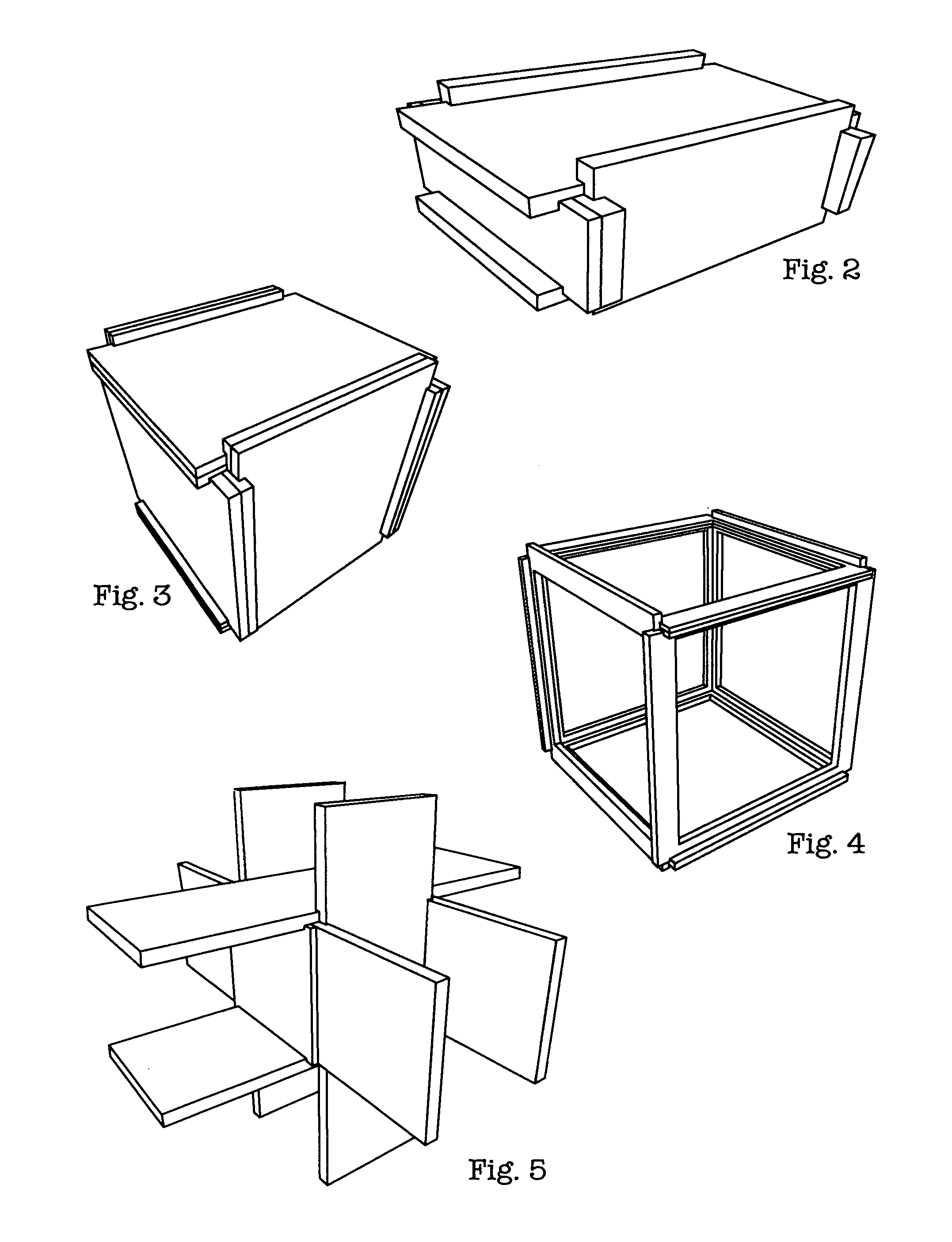

Splicing structure, splicing method and splicing box body

ActiveCN105691821ASmall footprintEasy to makeDomestic cooling apparatusLighting and heating apparatusEngineeringInjection molding machine

The inventor provides a splicing structure, a splicing method and a splicing box body. The problems that the injection molding cost of the box body is high and the box body molded by injection occupies a large space and is inconvenient to transport and store are solved. The inventor relates to the splicing structure, in particular to a splicing structure between plates. The splicing structure comprises a first side plate, a second side plate and a fastener, wherein at least one hole is formed in the position, close to at least one side edge, of the first side plate, and the hole penetrates through the two sides of the first side plate; at least one bulge is arranged in the position, close to at least one side edge, of the second side plate; the bulge is opposite to the hole, and the bulge can penetrate through the hole and can be embedded in the hole; an open slot is formed in at least one side of the bulge; and after the bulge penetrates through the hole, the fastener is embedded in the open slot so as to assemble and fix the first side plate and the second side plate.

Owner:BIOLOGICAL TECH INST OF FUJIAN ACADEMY OF AGRI SCI +1

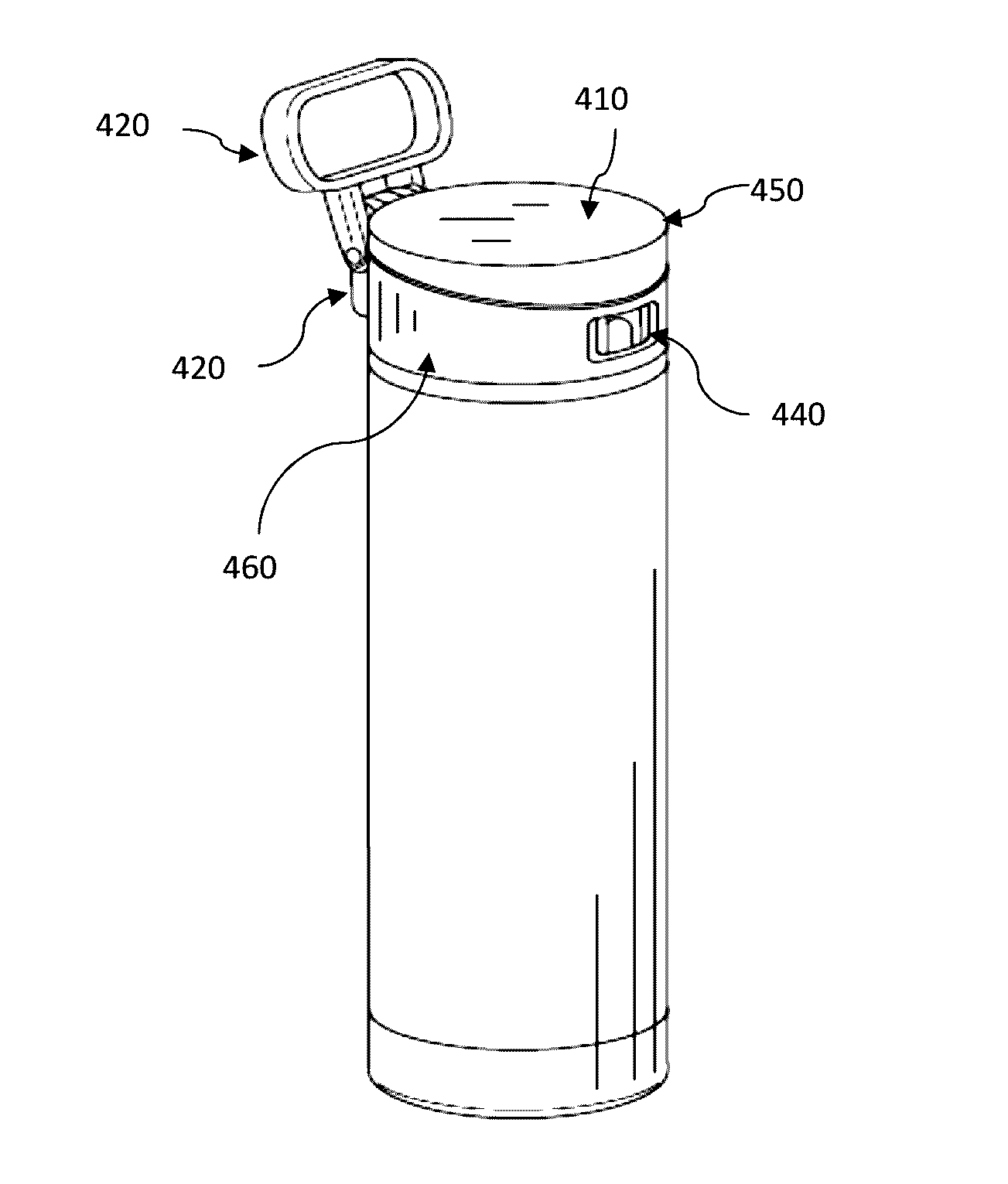

Substantively hermetically sealing container

ActiveUS20180016055A1Closure with auxillary devicesPackaging toiletriesEngineeringMechanical engineering

Owner:TOBEY TED

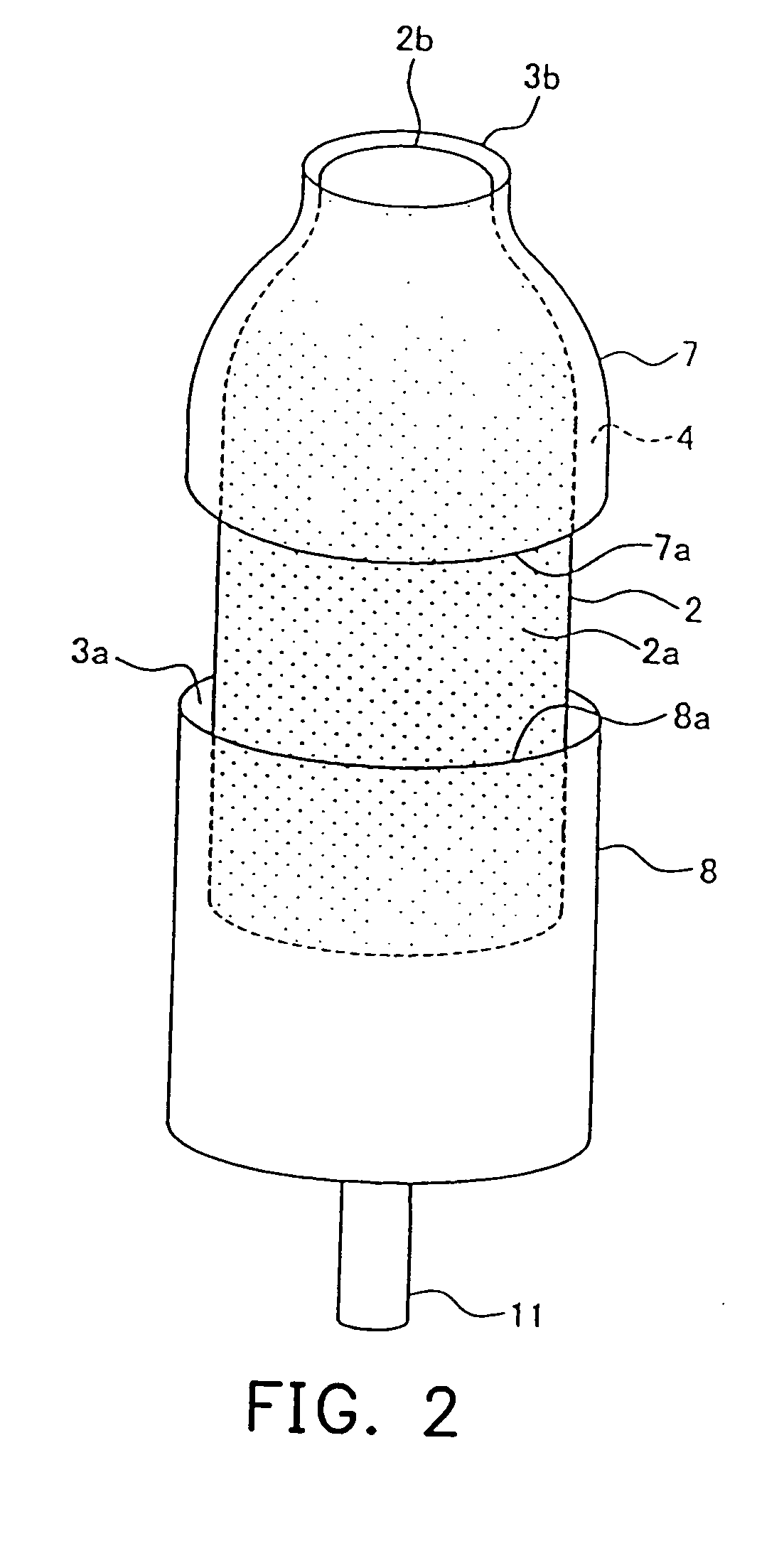

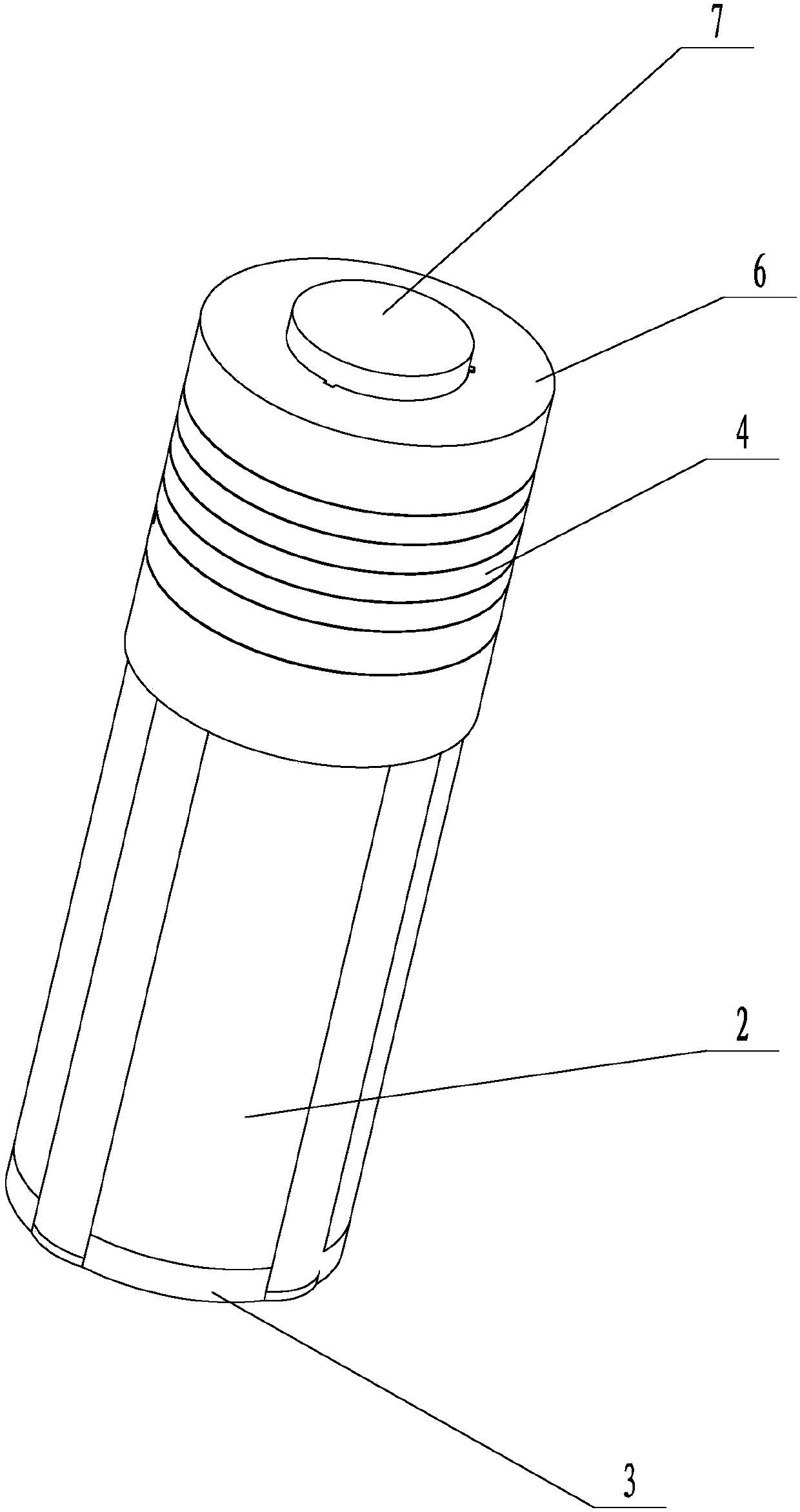

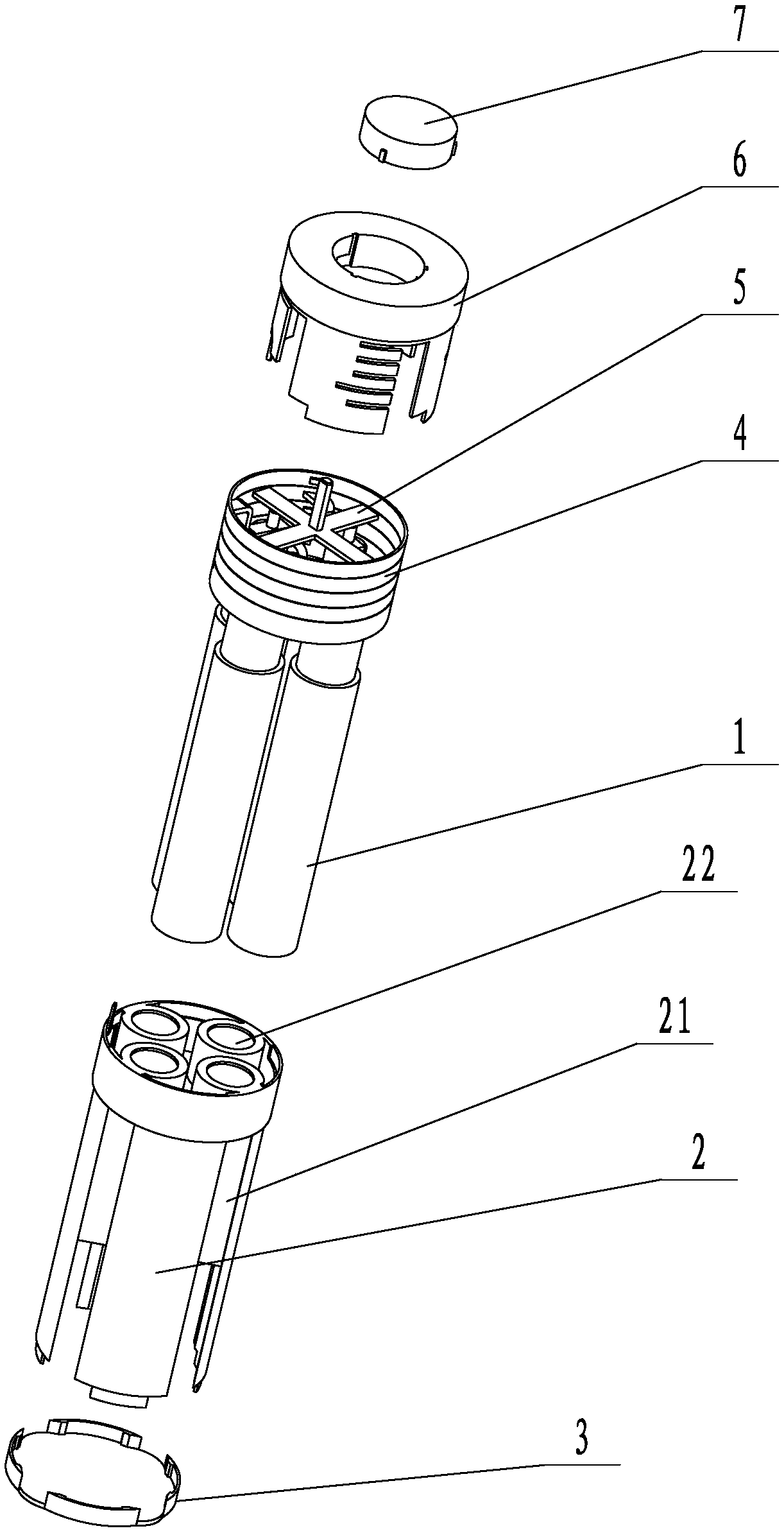

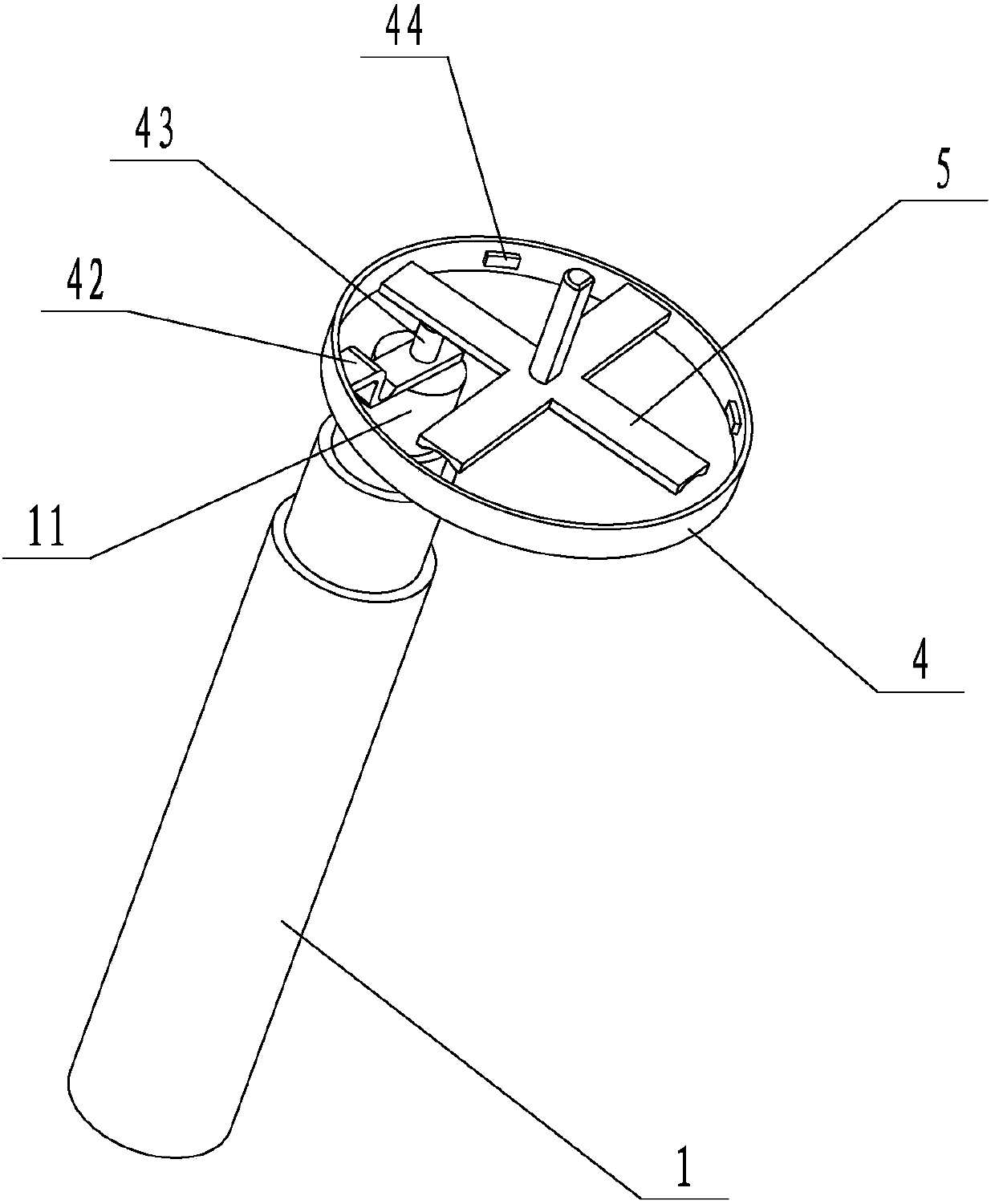

Convenient and fast type combined bottle

The invention discloses a convenient and fast type combined bottle. The convenient and fast type combined bottle comprises a spray head, an outer bottle and multiple inner bottles. The outer bottle isinternally provided with a cavity, and the multiple inner bottles are put in the cavity. The upper end of each inner bottle is provided with a press type liquid suction pump. Each press type liquid suction pump communicates with the spray head through a connecting pipe. The outer bottle is further provided with a rotary pressing device. The rotary pressing device is provided with multiple rotating parts, wherein the rotating parts are in one to one correspondence with the inner bottles. Each rotating part can be used for pressing the press type liquid suction pump of the corresponding inner bottle in a rotary manner. According to the combined bottle, the multiple inner bottles which are independent of one another are put in the outer bottle and can be filled with emulsion products of different types; by means of the rotary pressing device, discharging can be achieved through each single inner bottle or mixed discharging can be achieved through the multiple inner bottles; the number ofbottles needing to be carried when a user gets out can be reduced; in addition, matched mixed use of the different types of emulsion can be achieved through the combined bottle; the combined bottle is easier and more convenient to operate; operation efficiency is improved; and time of the user is saved.

Owner:江门市江海区长河塑胶厂有限公司

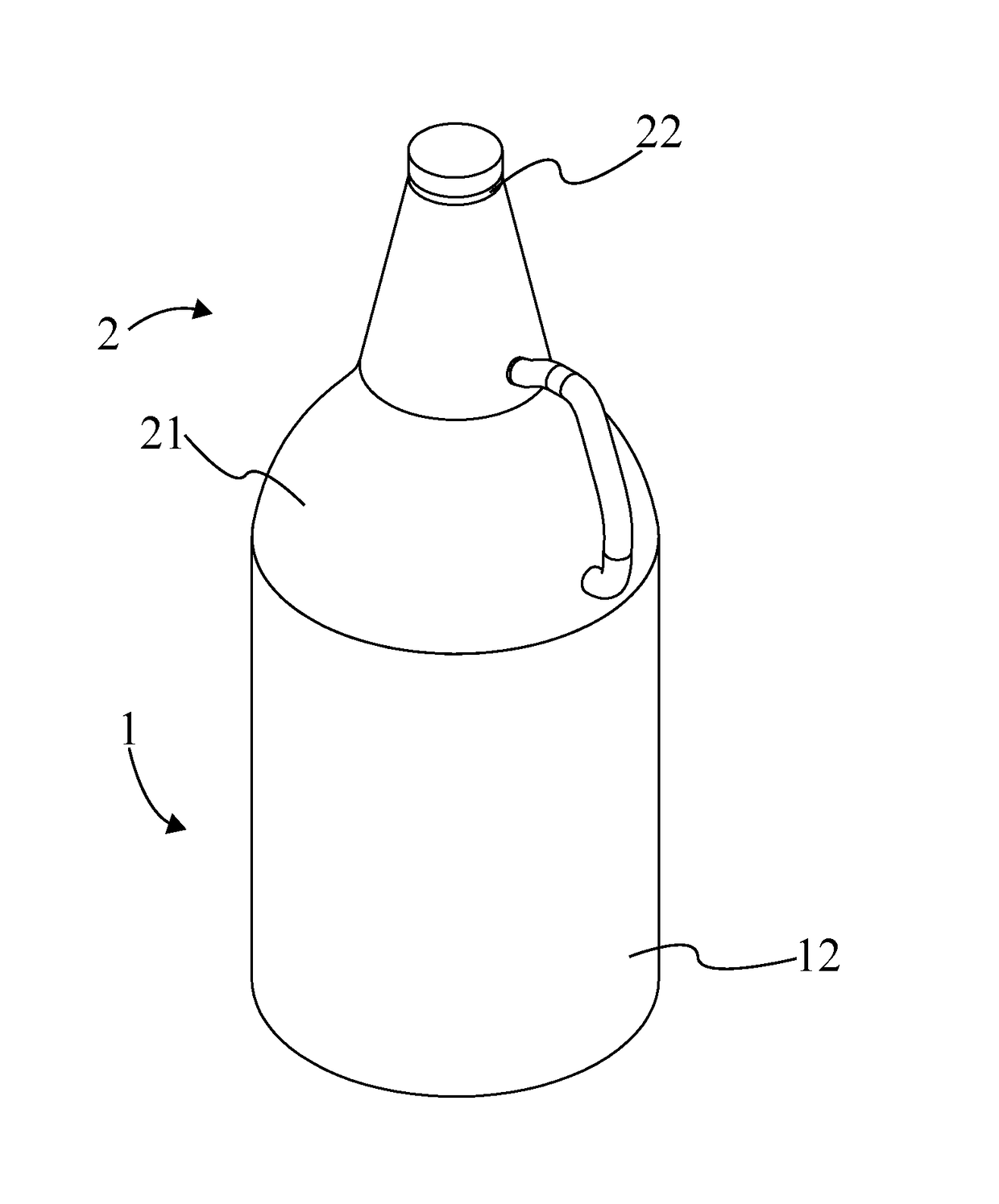

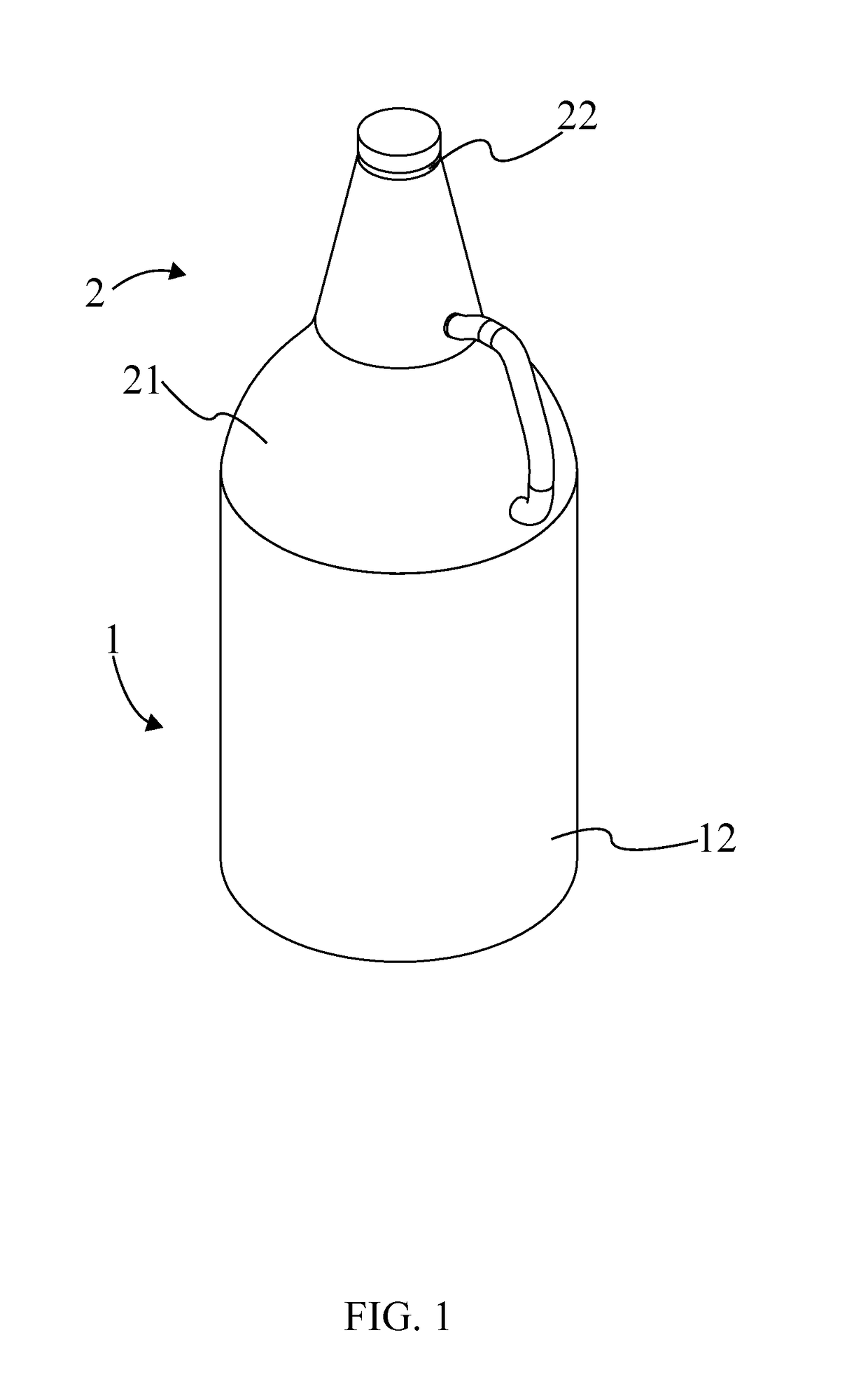

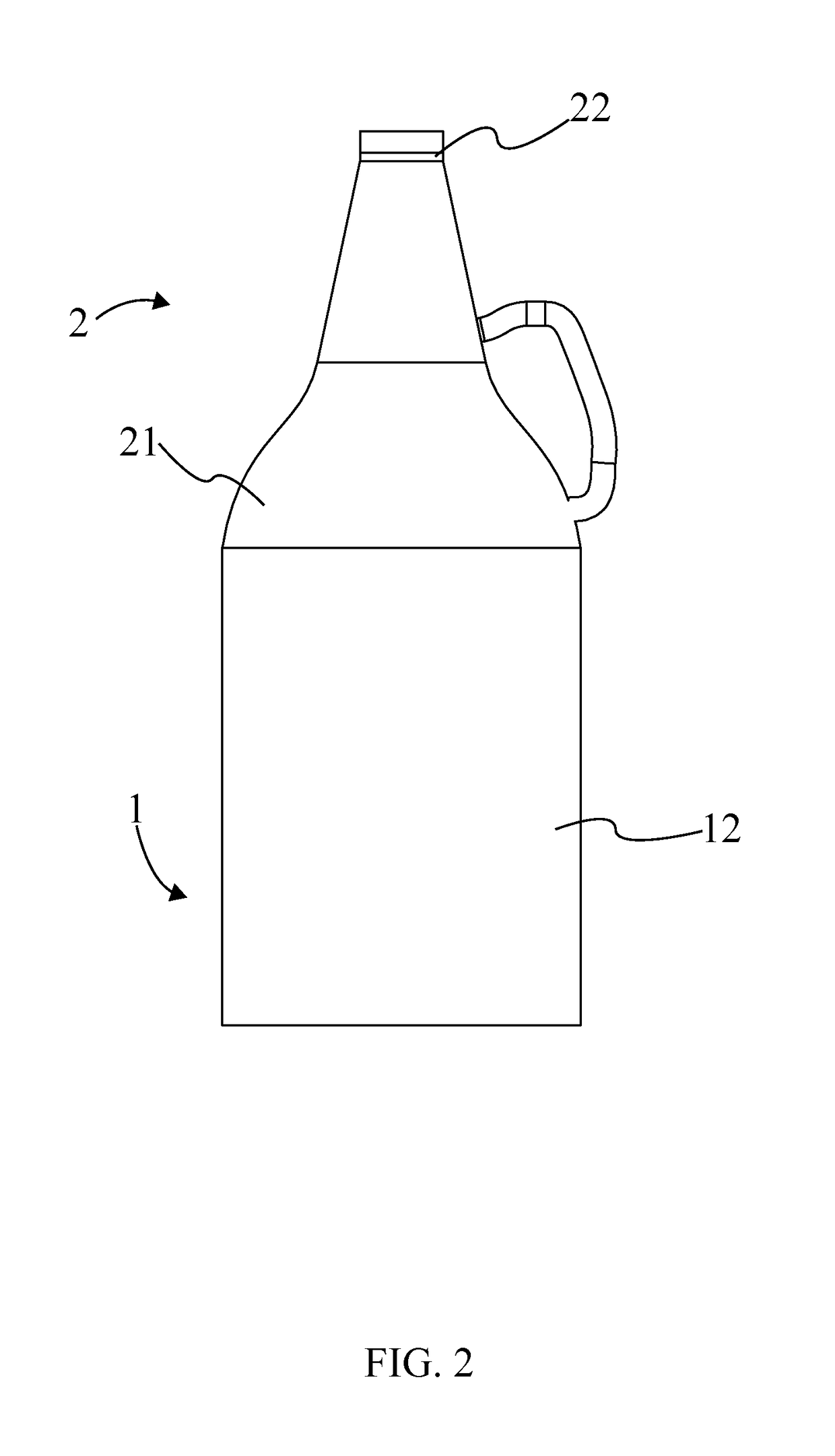

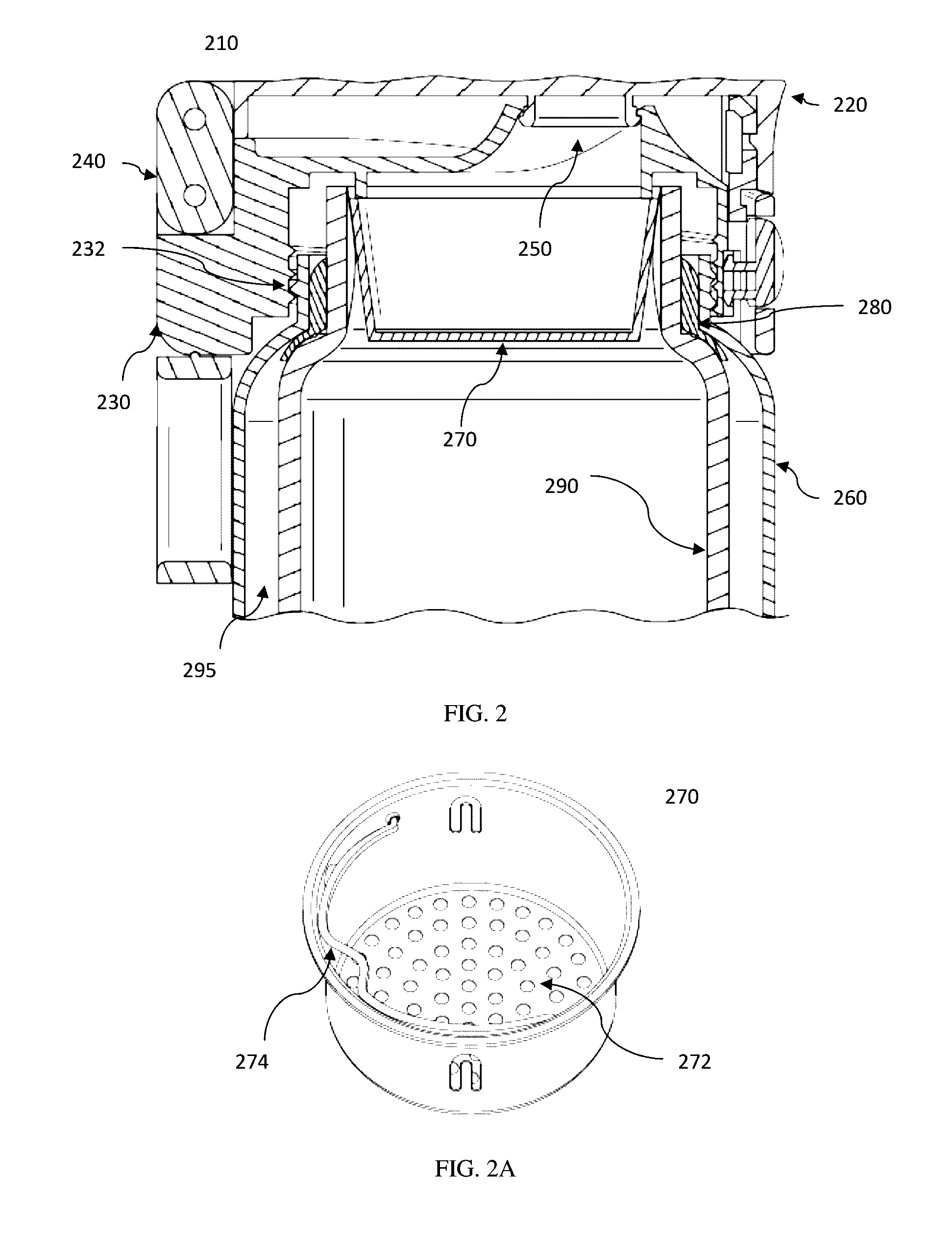

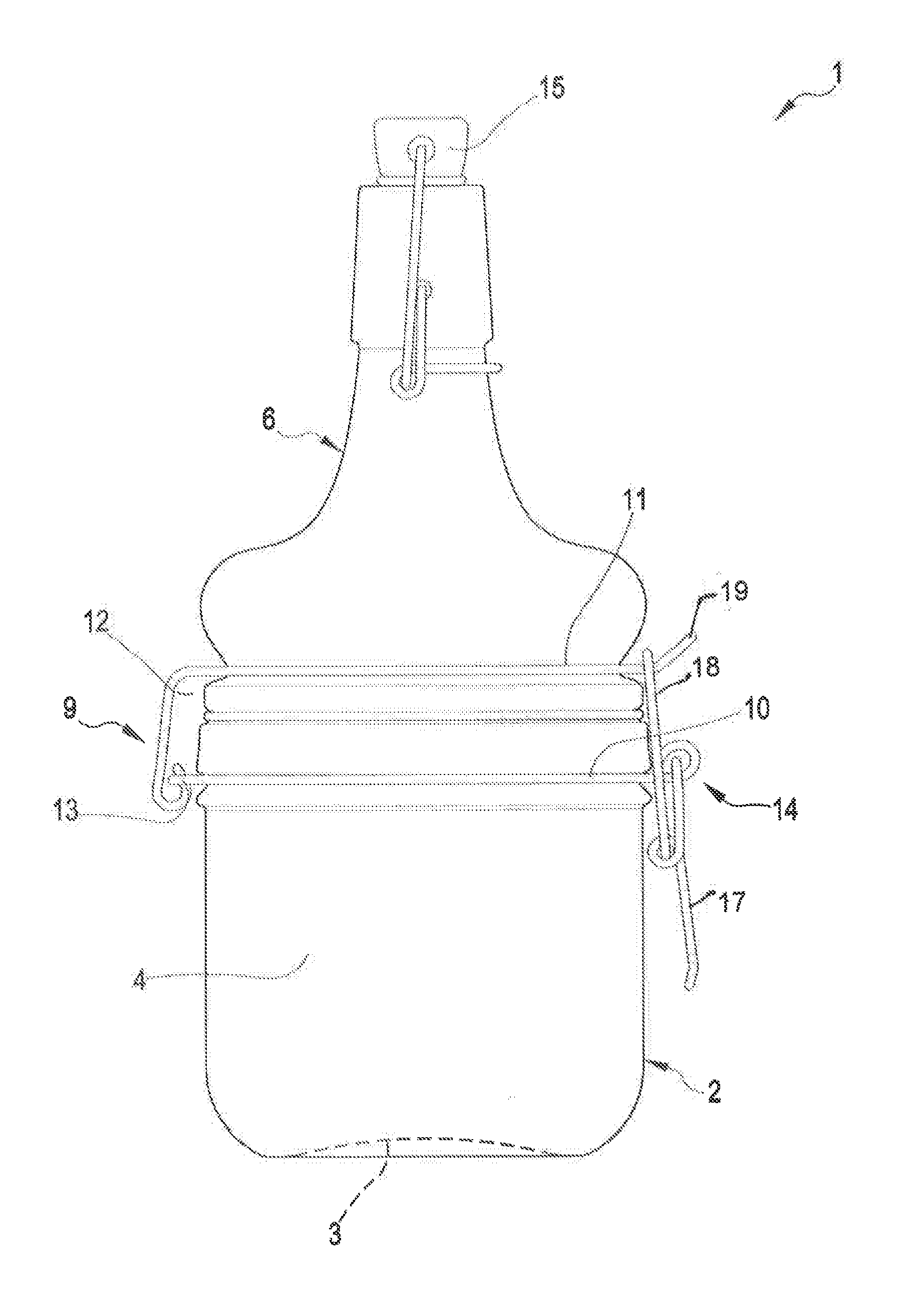

Growler

An improved growler has a lower container portion and upper container portion which can be unscrewed from each other. Once separated, the lower container portion and upper container portion are more easily and effectively cleaned, especially when compared to existing growlers. The improved growler benefits further from the addition at least one fluid transfer port. One fluid transfer port, placed on a lateral surface of the lower container portion, is a self-sealing valve (e.g. stem valve) that allows for the improved growler to be more easily filled from a keg tap or similar device. A second fluid transfer port can be positioned into a neck of the upper container portion, which allows for air to flow into the improved growler in order to facilitate smoother pouring of liquids. A fluid transfer port is also capable of converting the improved growler into a smoking apparatus by coupling with a stem bowl.

Owner:VIEDT CASH J

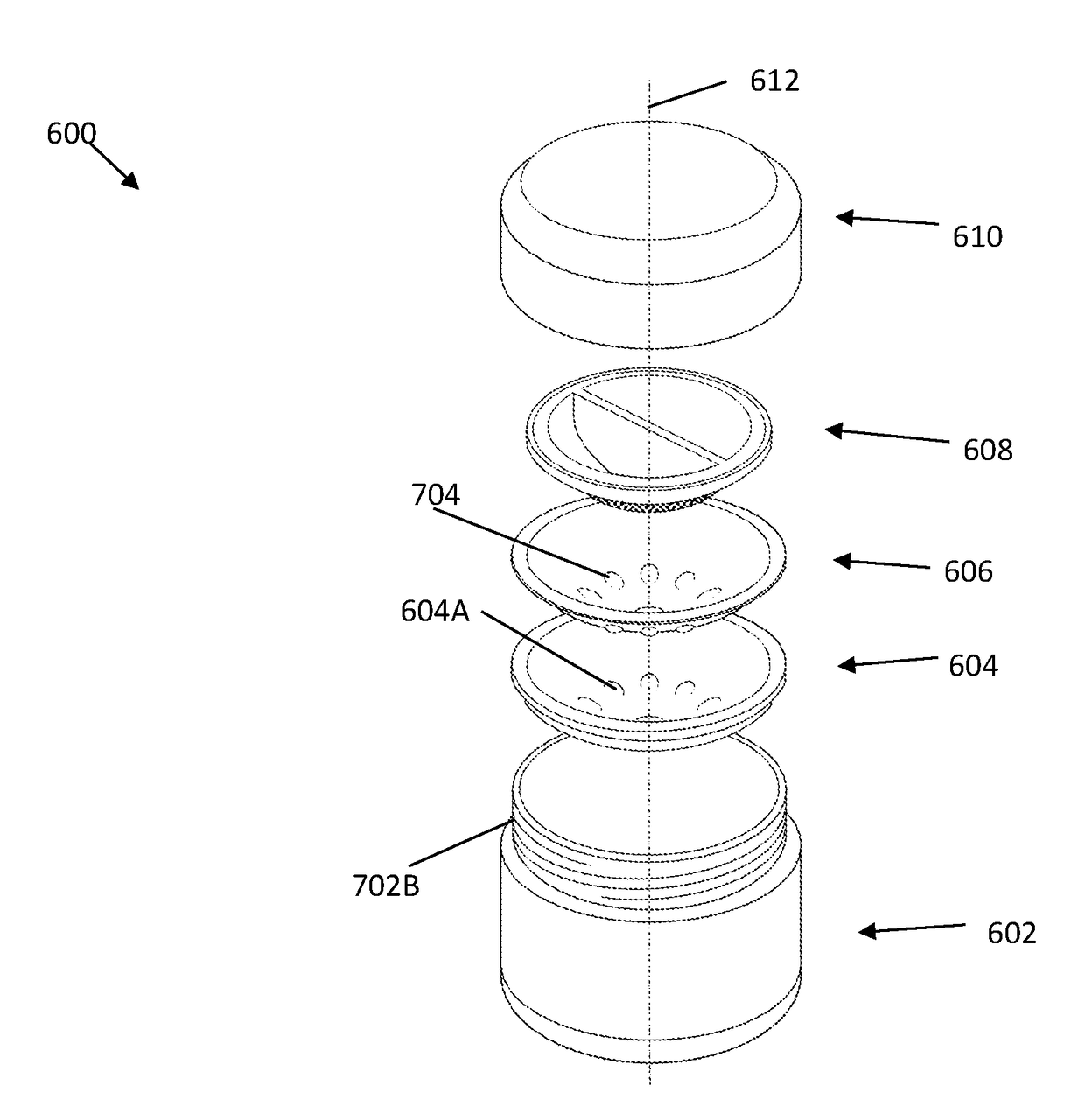

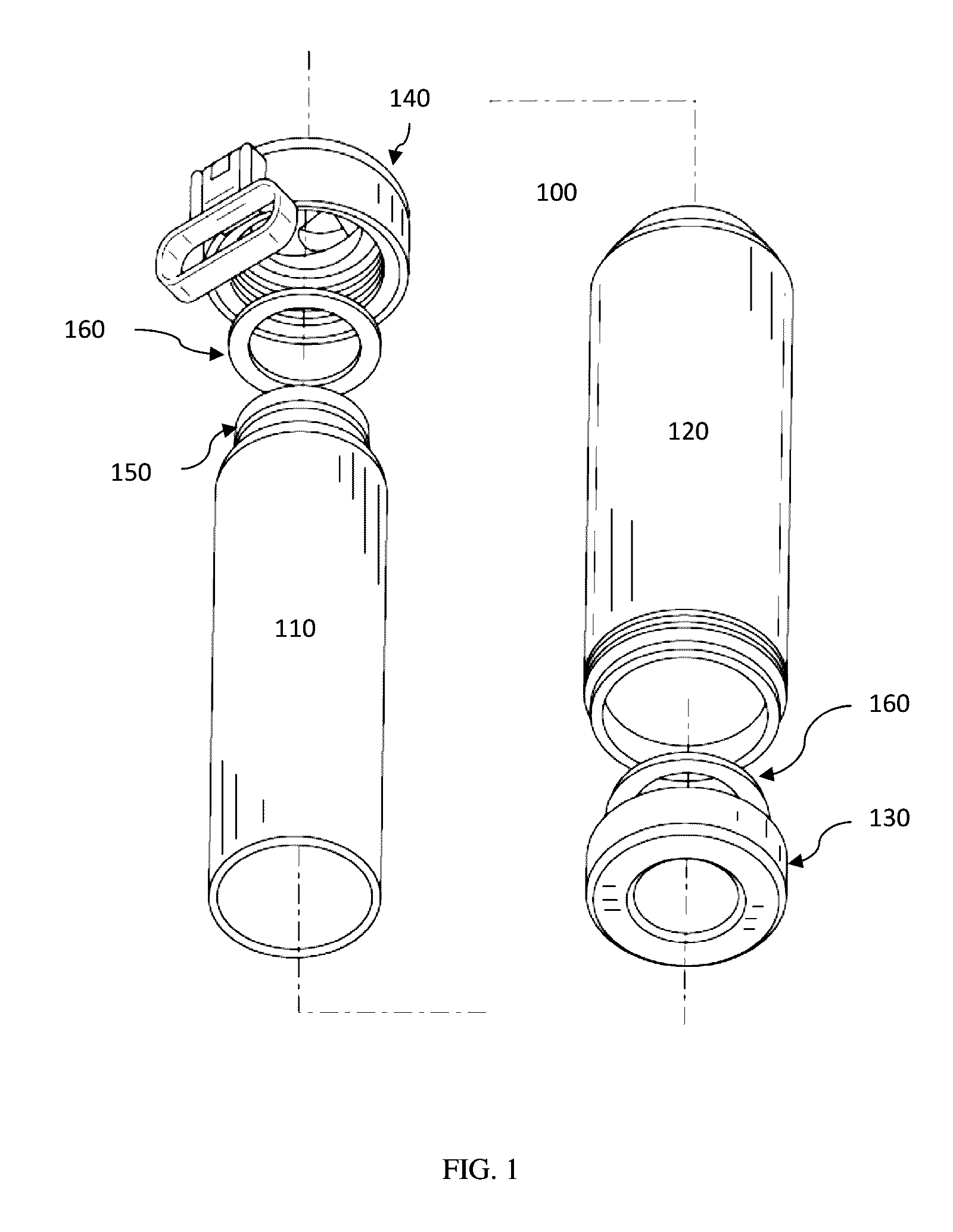

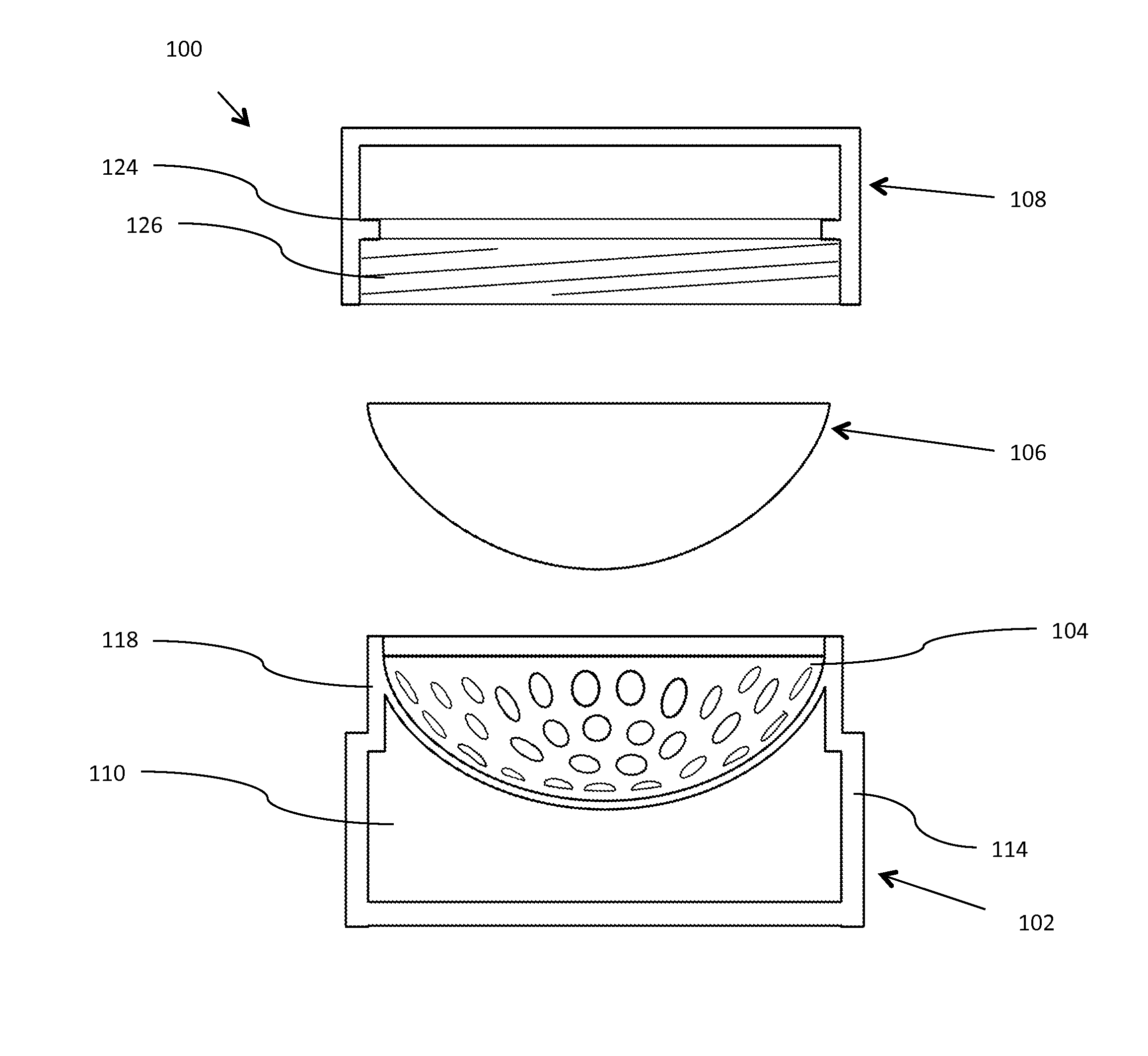

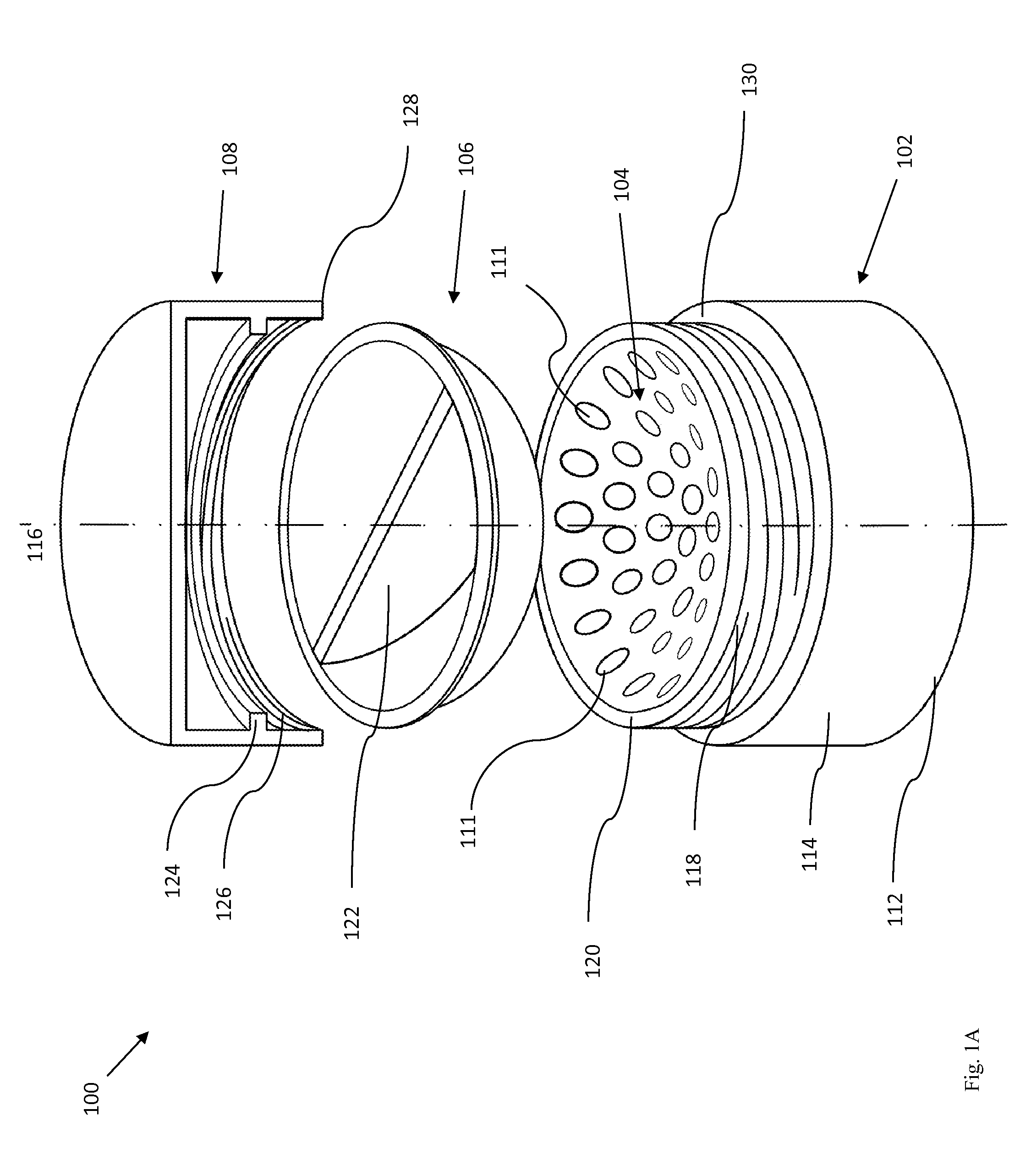

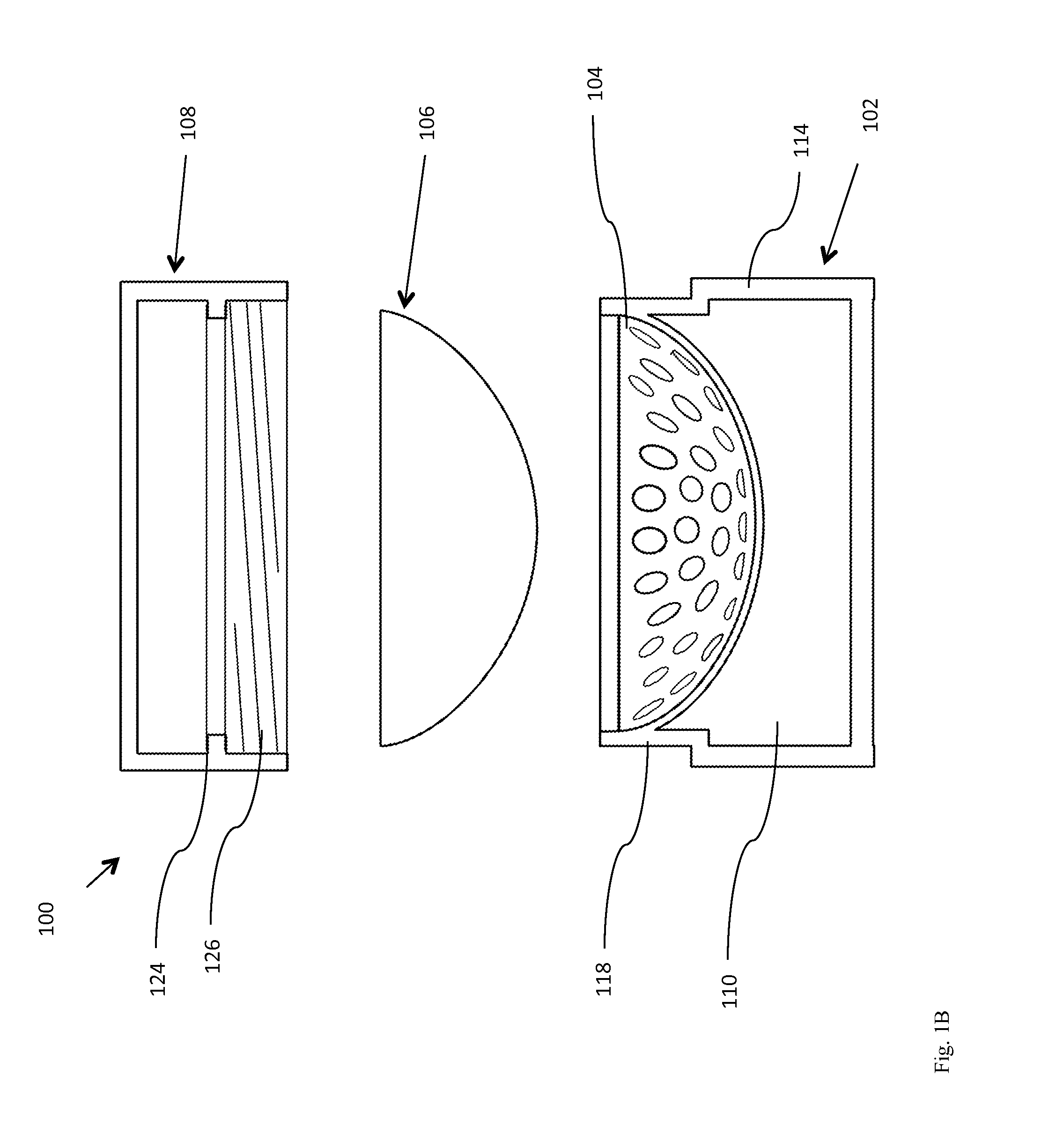

Modular Water Bottle System

ActiveUS20170057691A1Domestic cooling apparatusLighting and heating apparatusEngineeringWater bottle

The invention described herein is a modular water bottle system comprising an inner bottle, where an outer shell, further comprising an open top portion and an open bottom portion, fits around the inner bottle, where a base member is removably threaded onto the outer shell bottom portion, and where a cap assembly is removably threaded onto the outer shell top portion, where a sealing ring positioned around a neck of the inner bottle press seals against the an inner surface of the outer shell when the cap assembly is threaded onto the outer shell top portion. A design insert may be positioned between the inner bottle and the outer shell.

Owner:CLARK FRANKLIN D

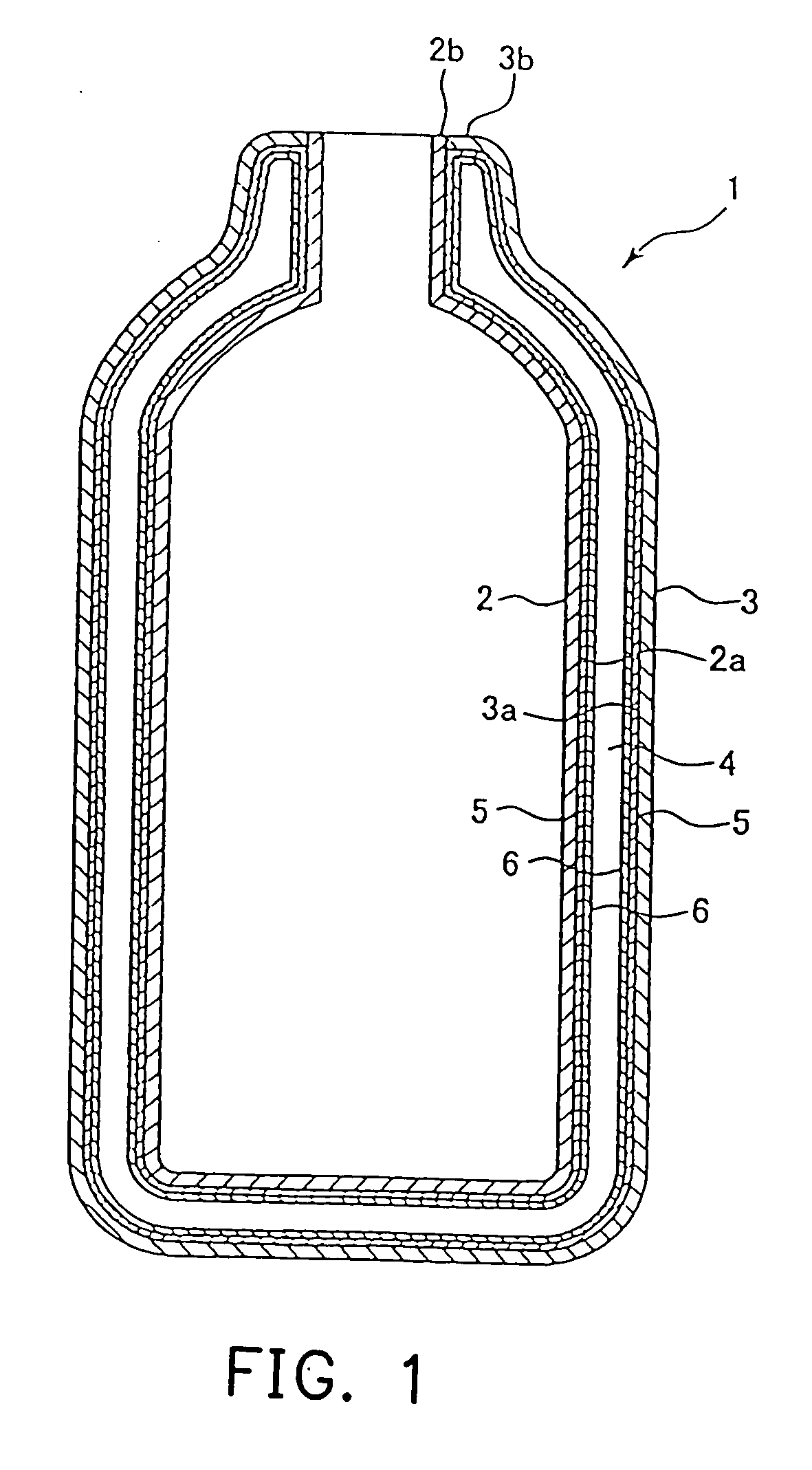

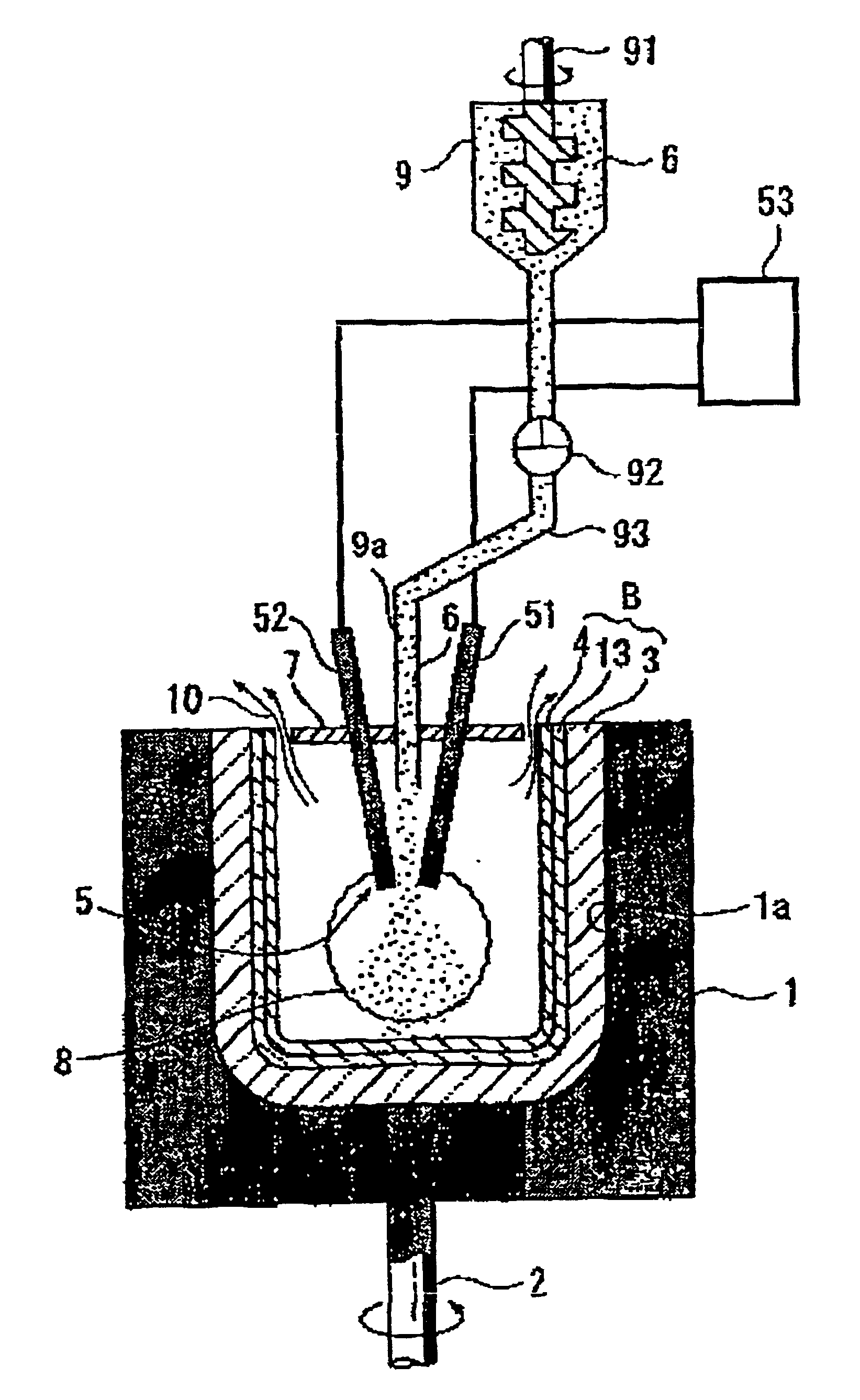

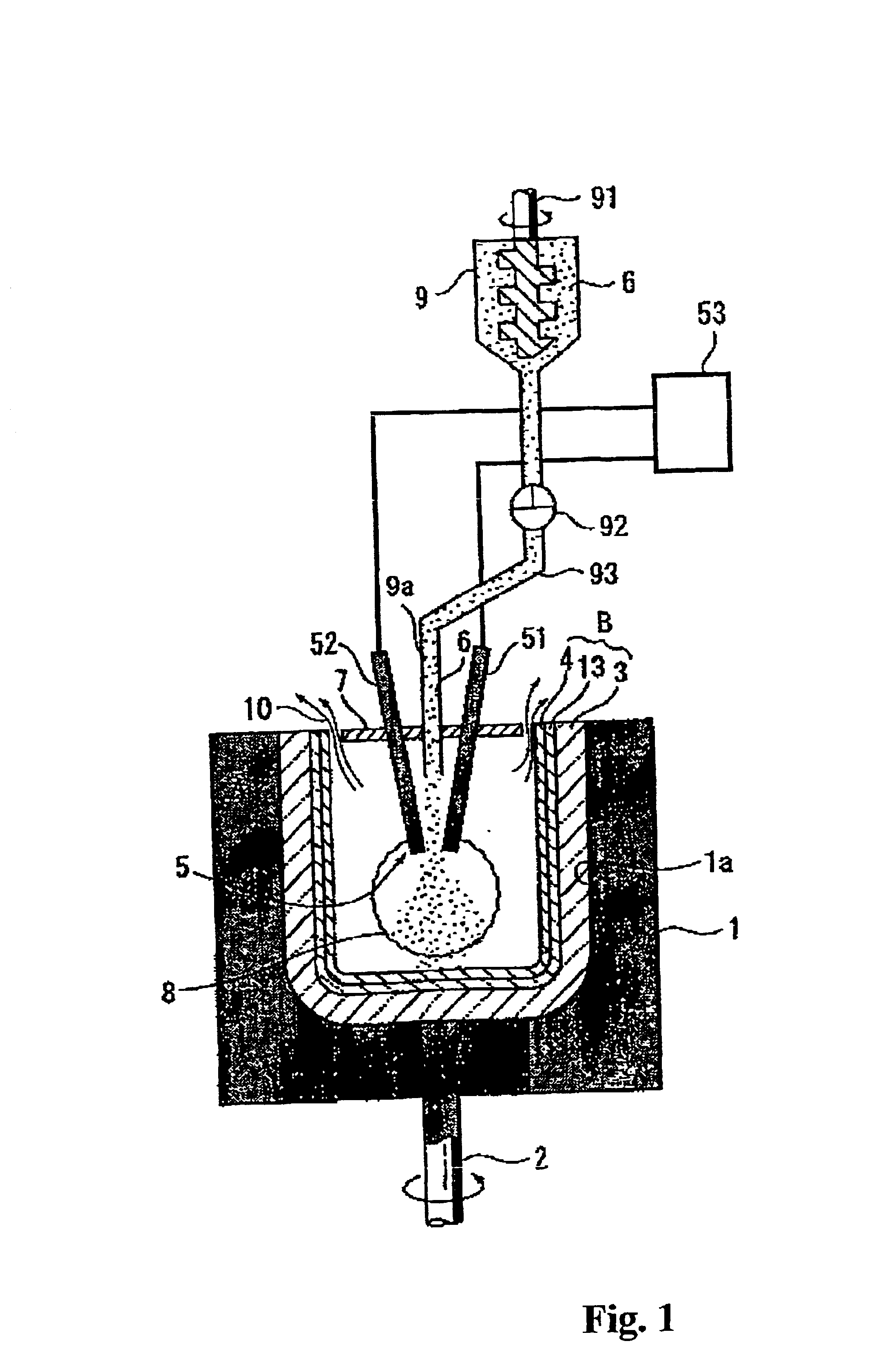

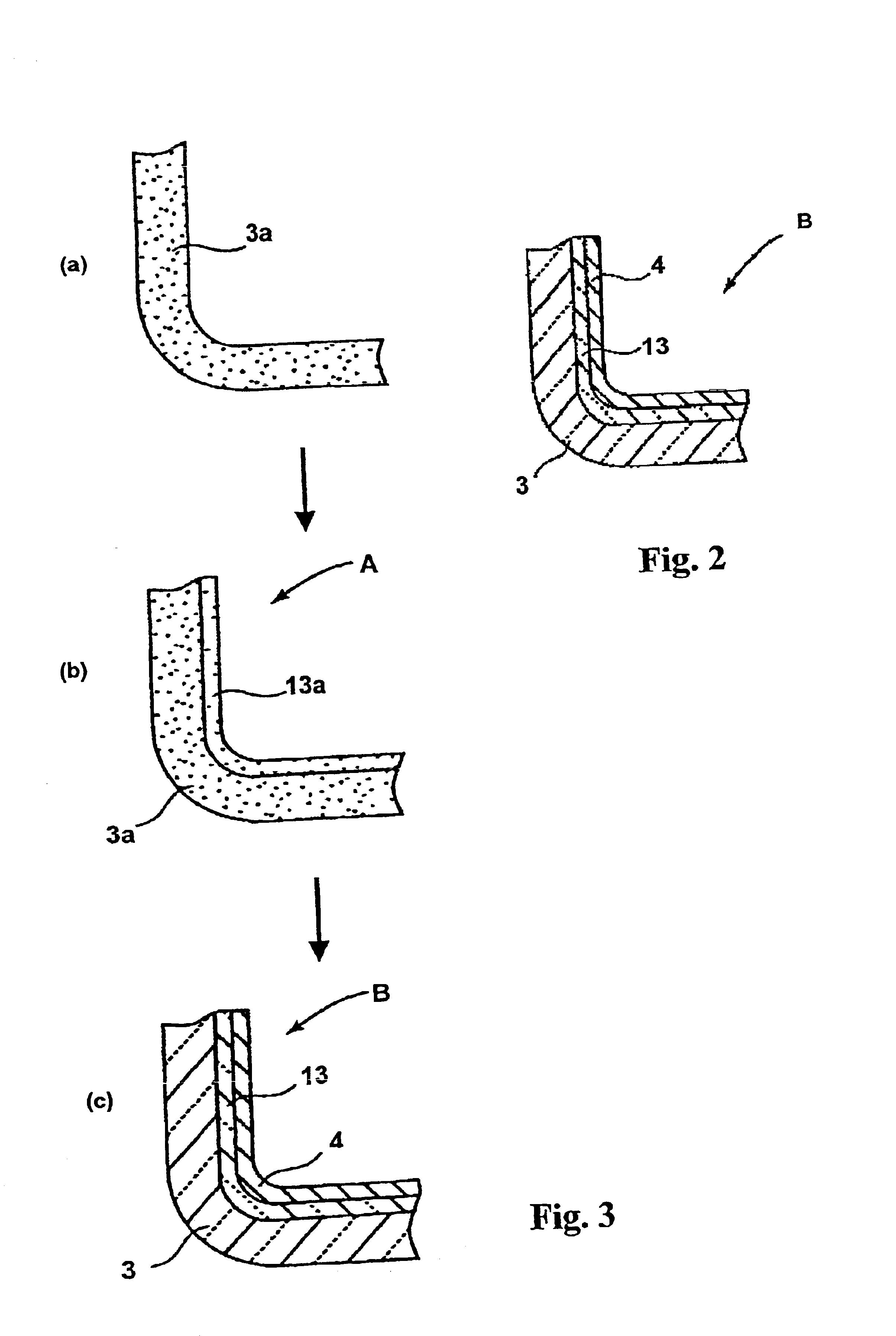

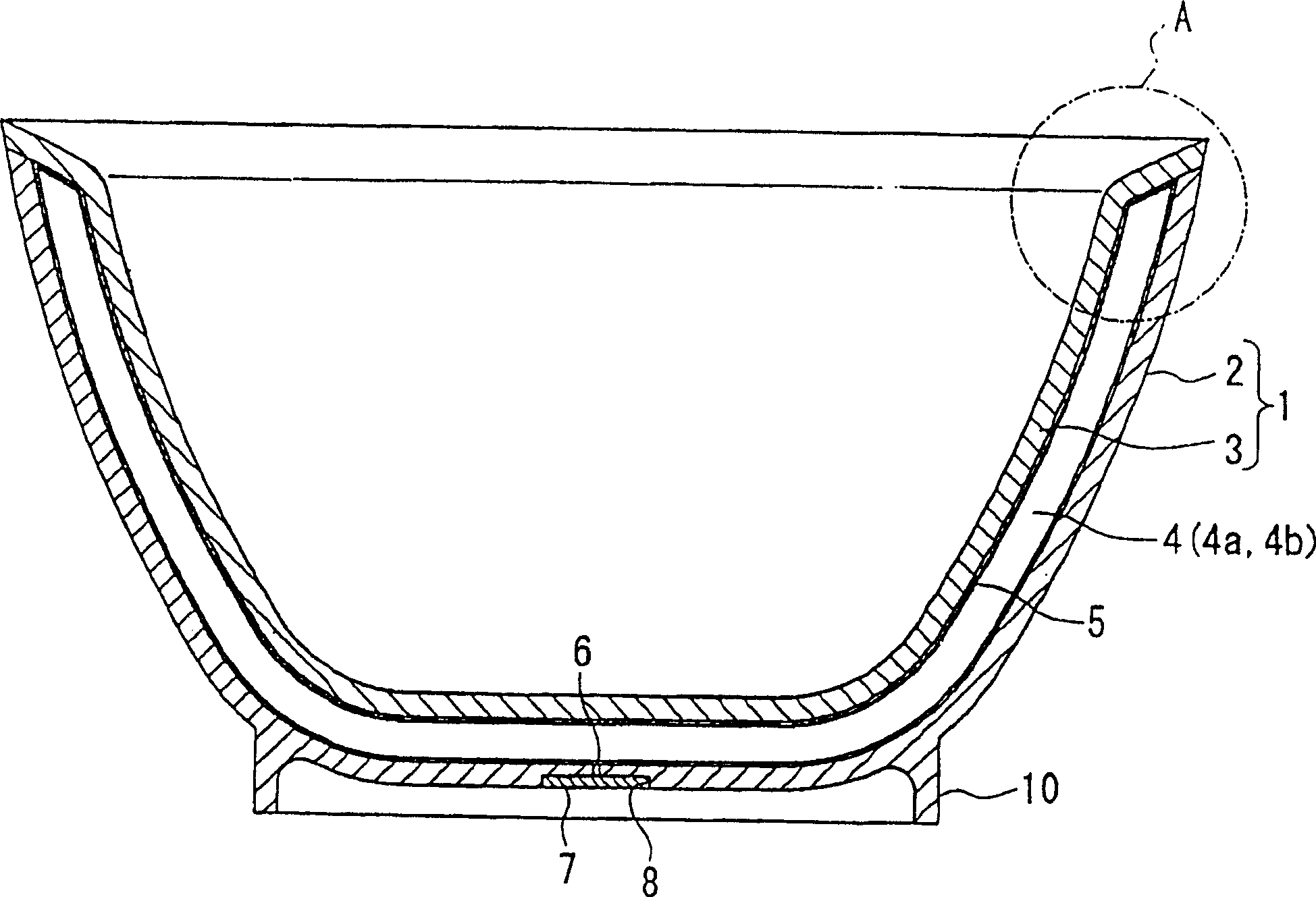

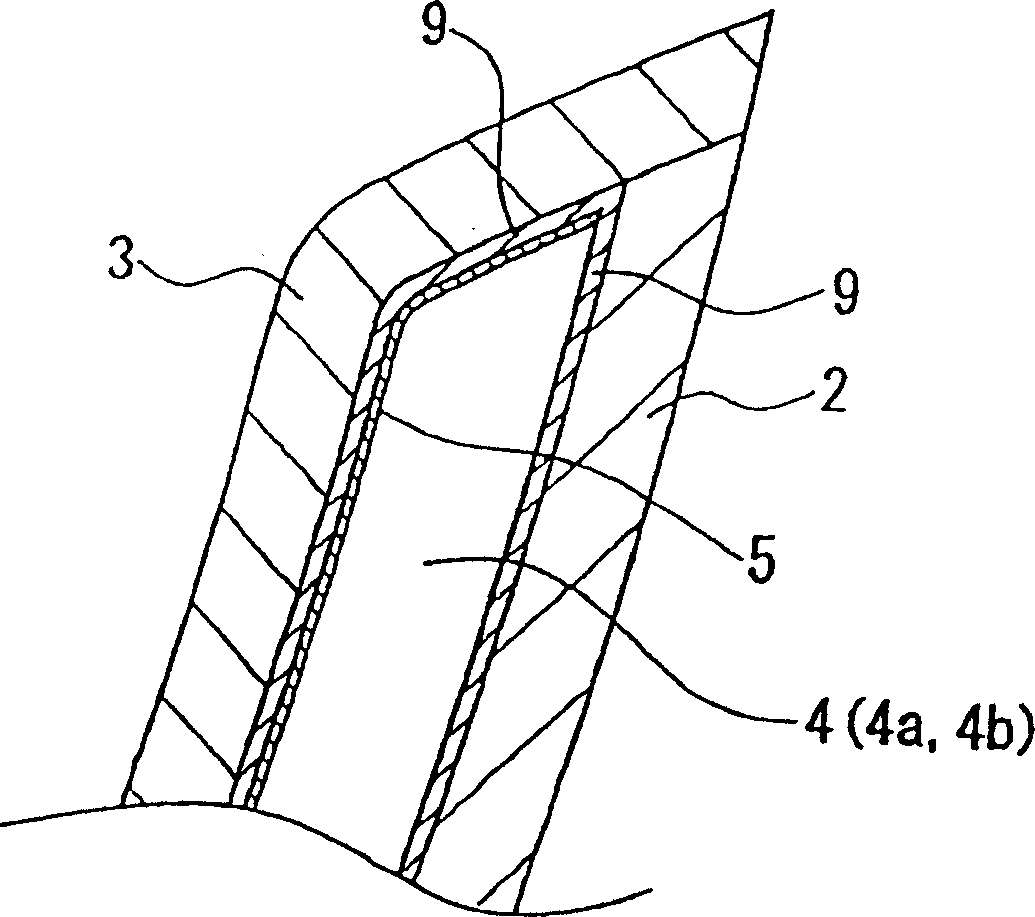

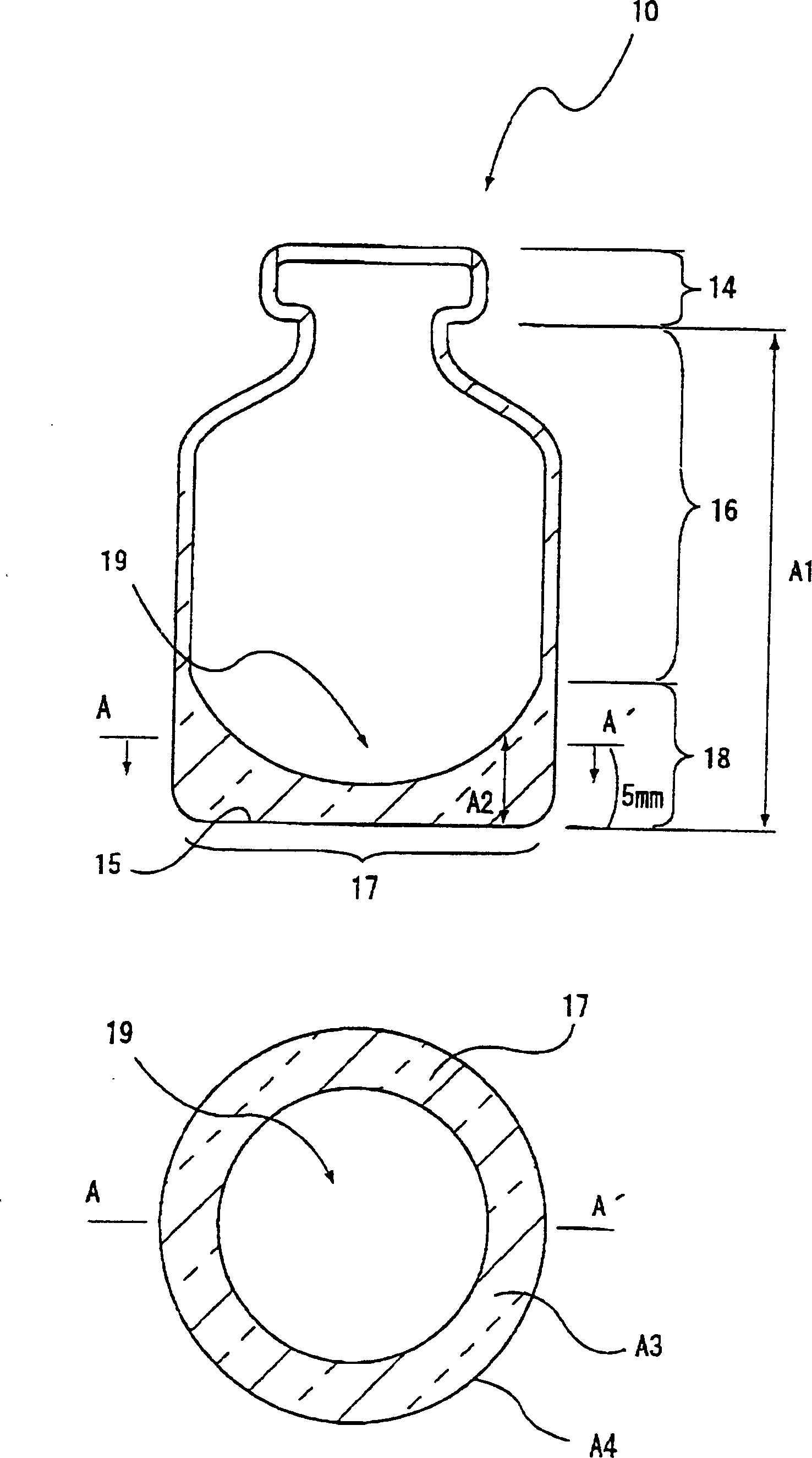

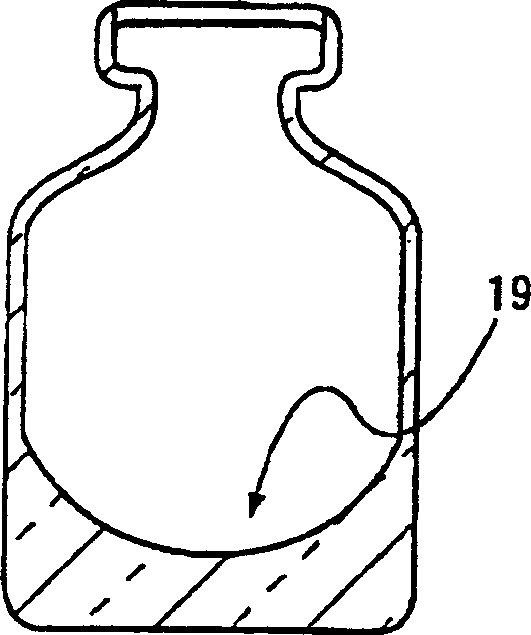

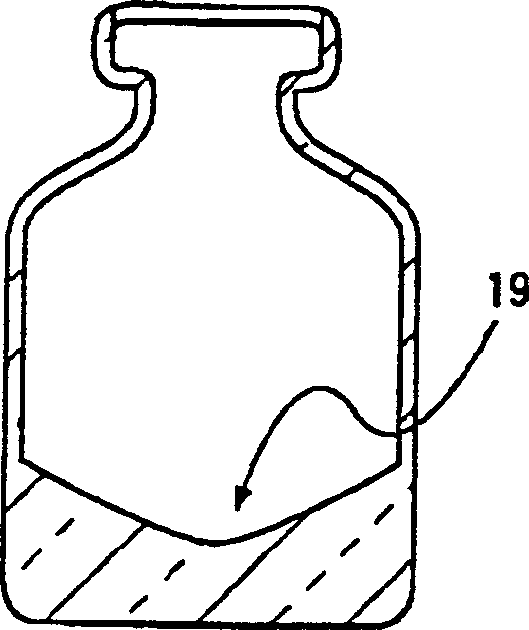

Heat insulation container and its producing method

InactiveCN1388051AImprove insulation effectDomestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention provides a heat insulation container with excellent heat insulation performance using pottery used in general households. For this heat insulation container 1 made of the pottery, an inner container 3 made of the pottery is integrated inside an outer container 2 made of the pottery through a gap part 4. A glass layer is arranged on at least one of the gap part side of the inner and outer containers or the atmosphere side of the inner and outer containers.

Owner:NIPPON SANSO CORP

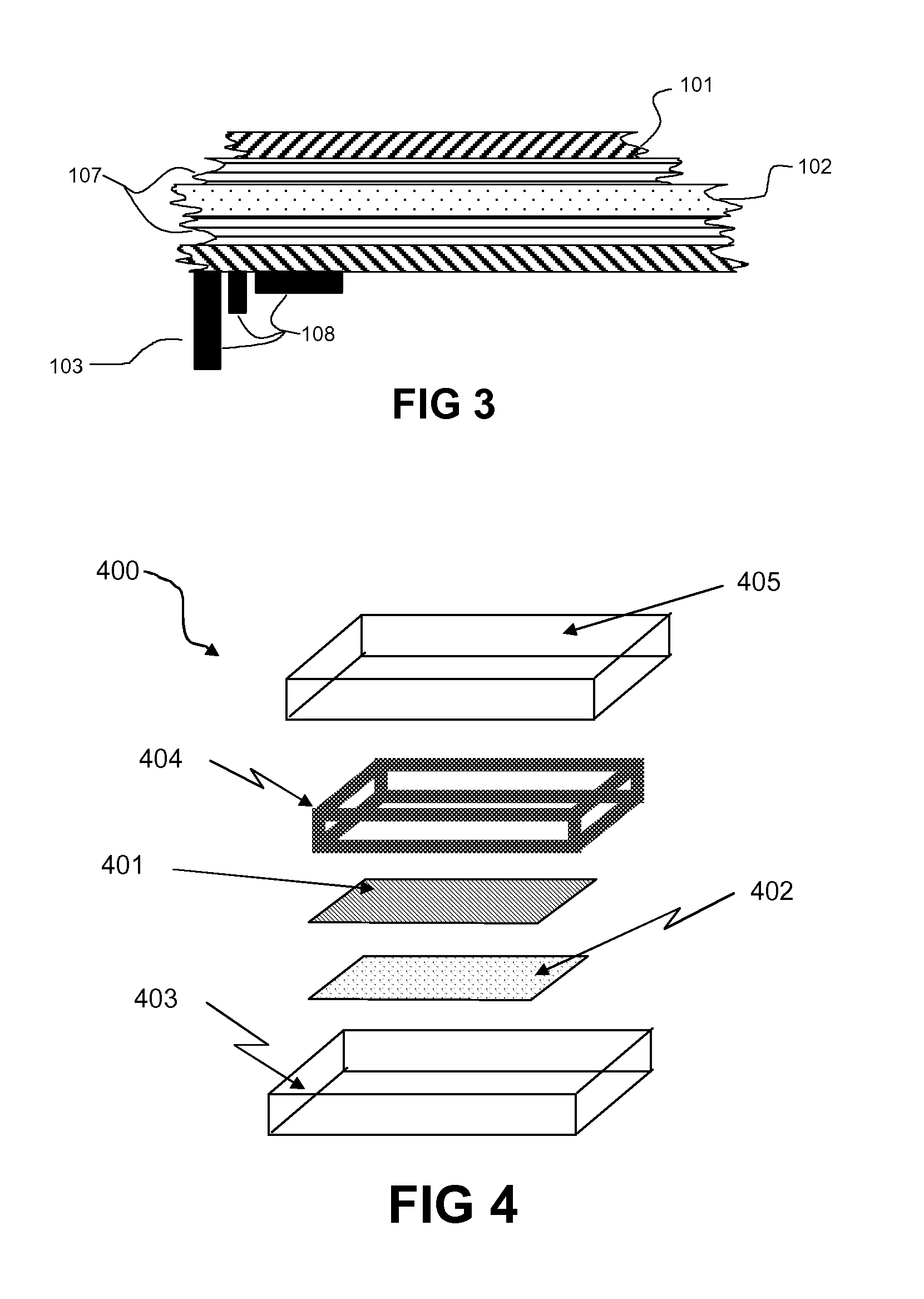

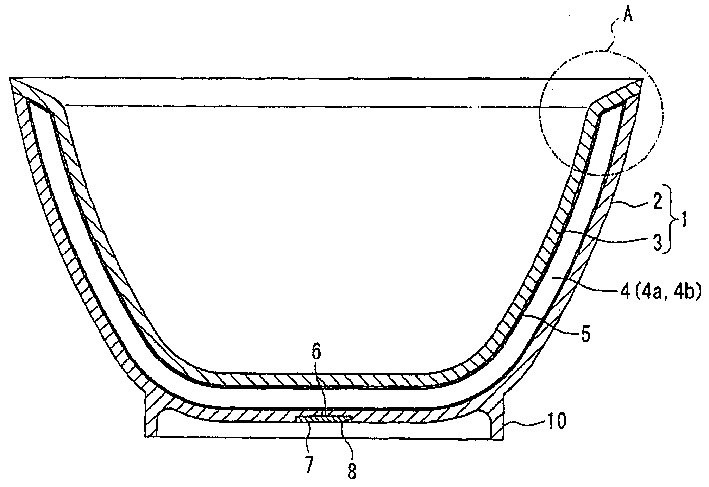

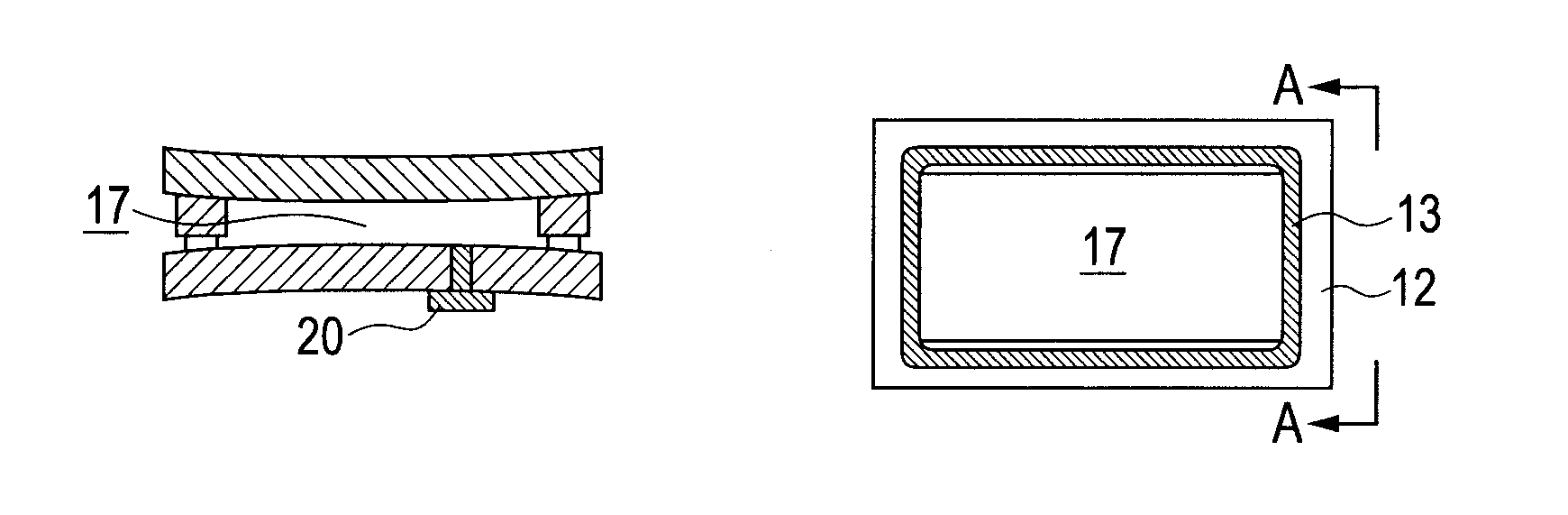

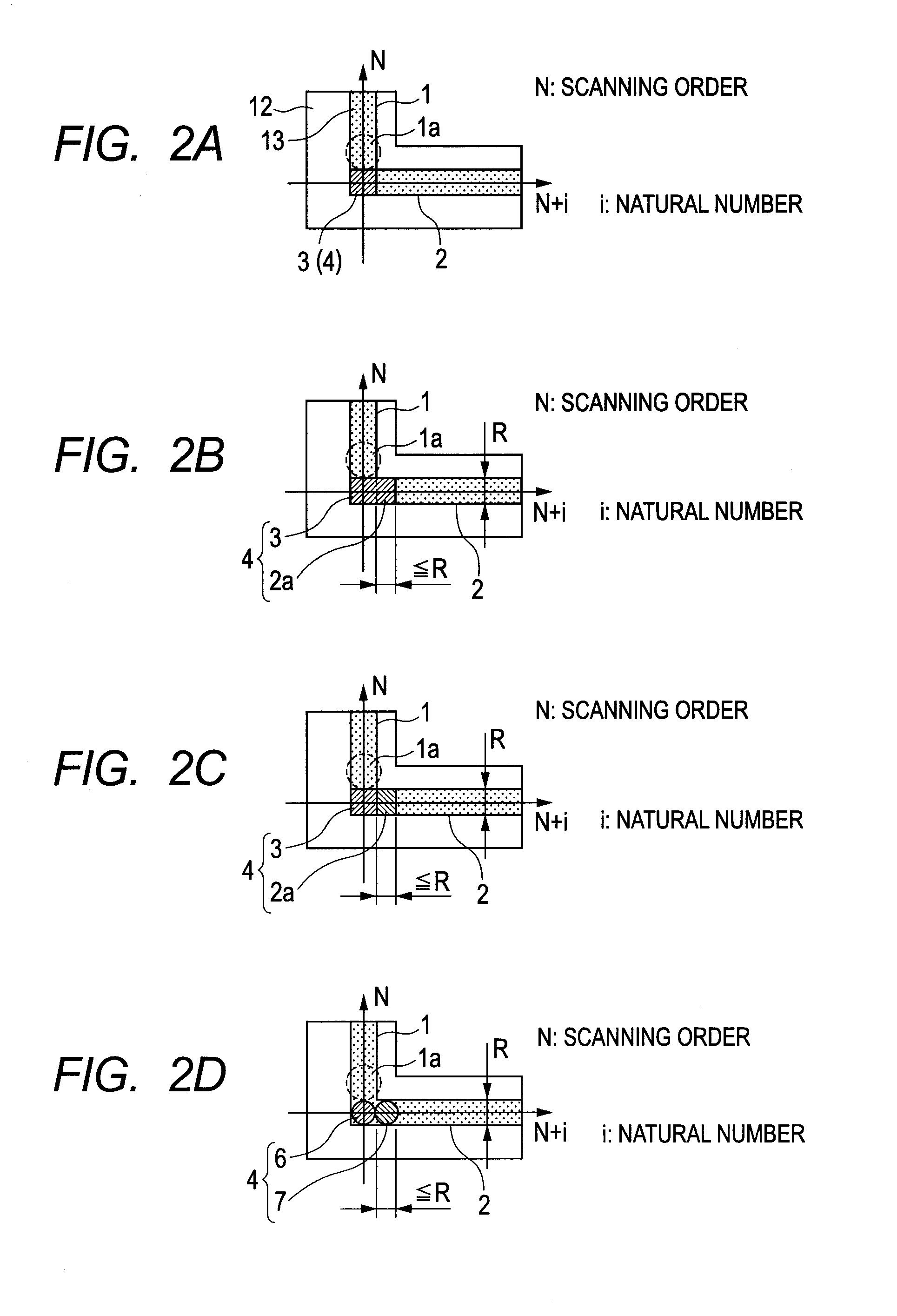

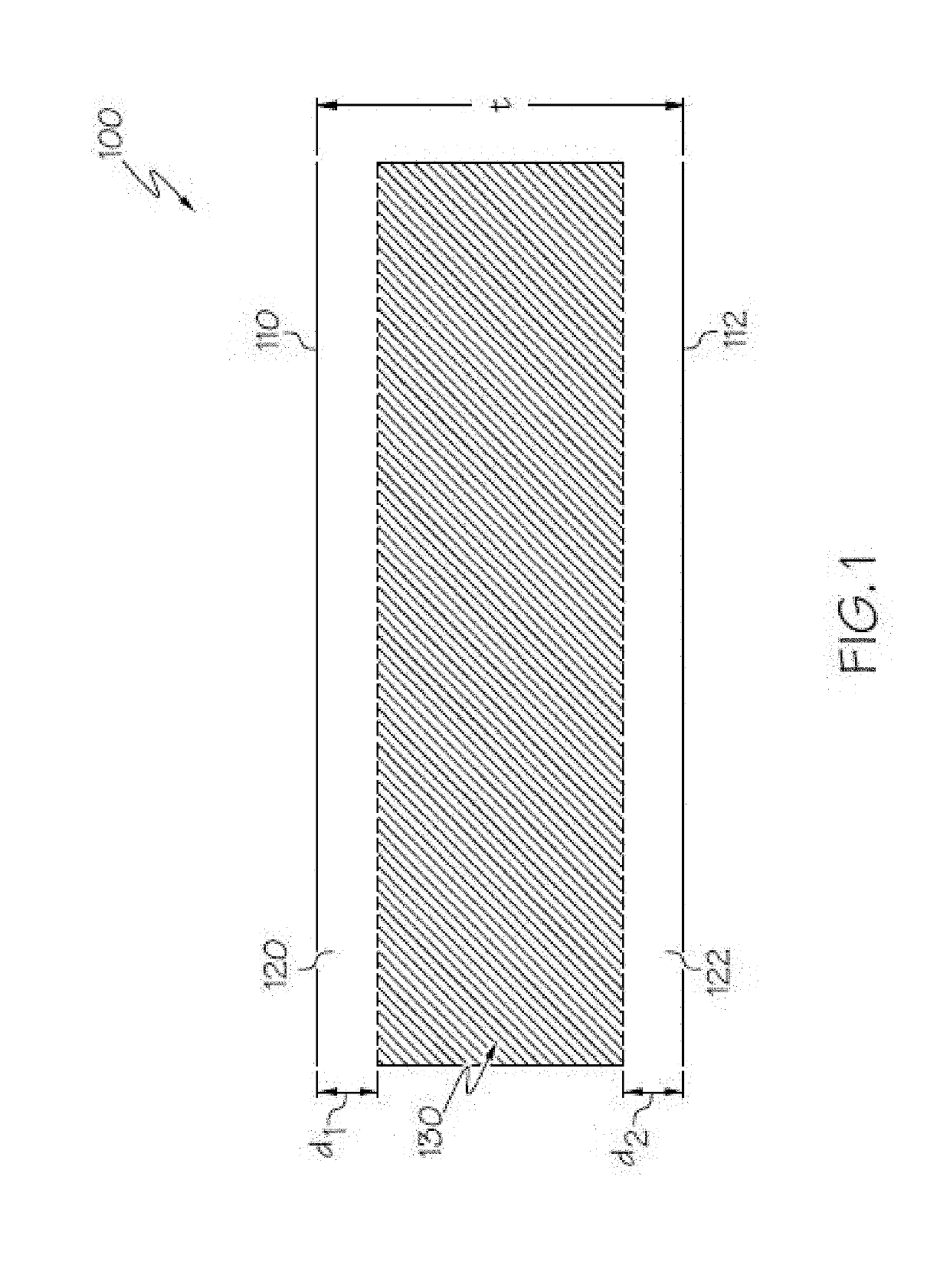

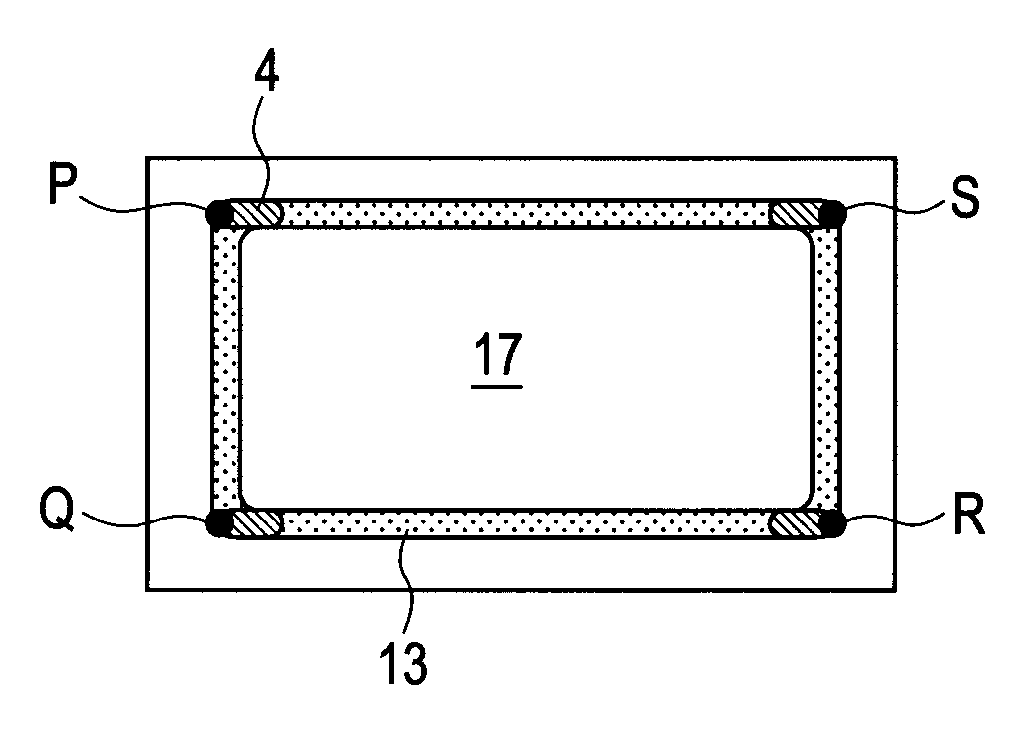

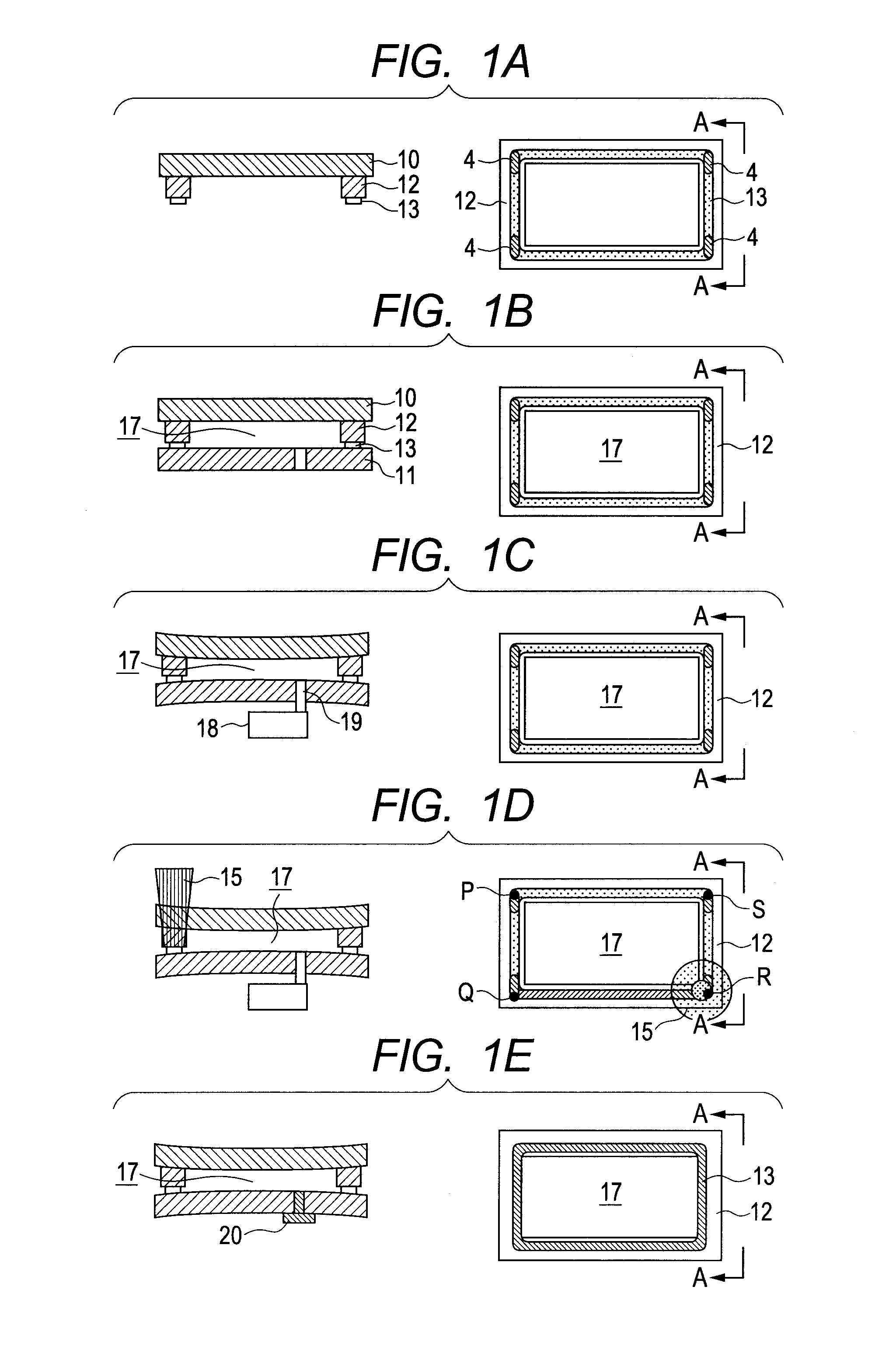

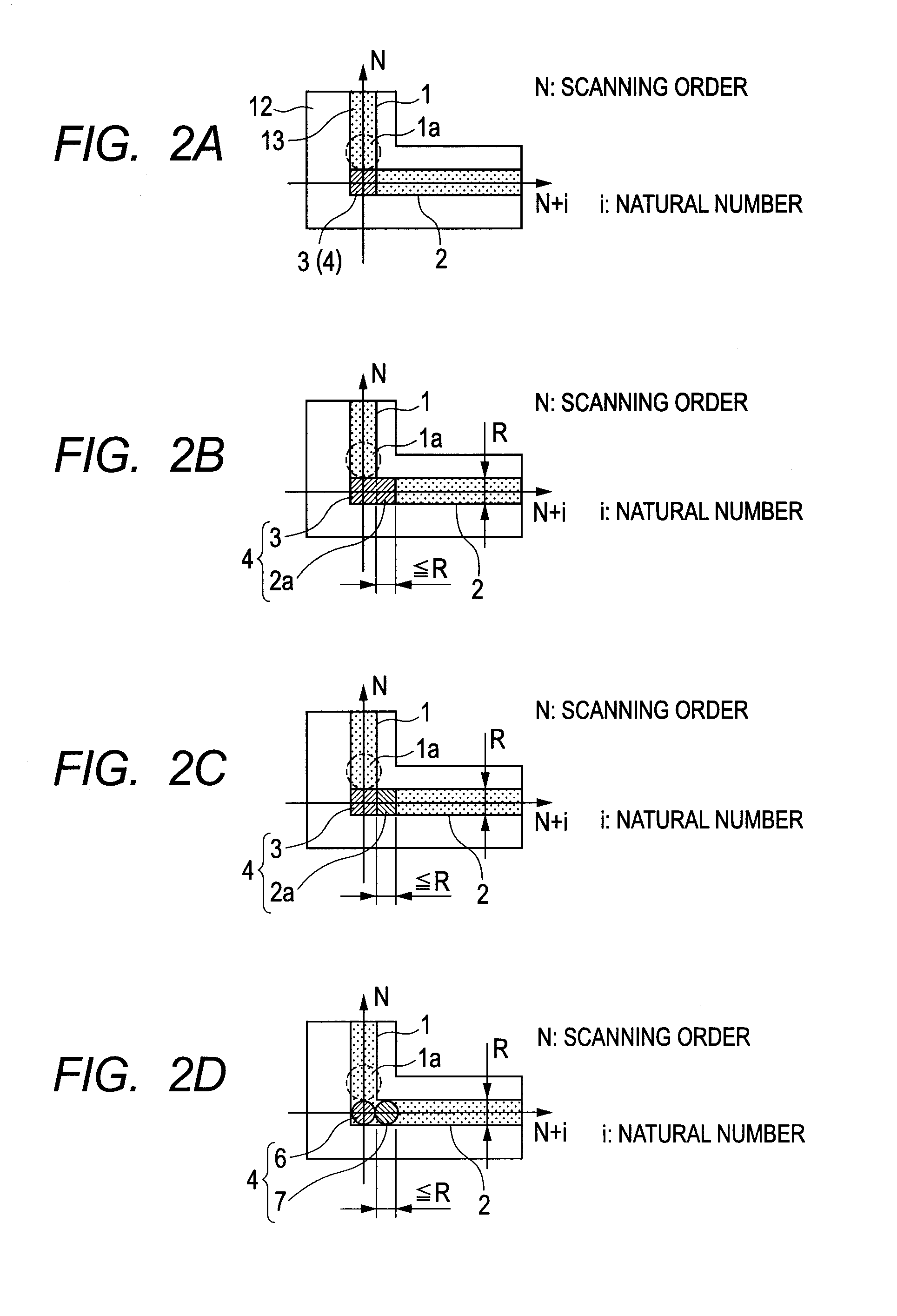

Manufacturing method of hermetic container

InactiveUS20110237150A1Reduce film thicknessSpacing distanceSolid-state devicesCeramic containersNegative temperatureCoupling

A manufacturing method of a high-reliability hermetic container includes an assembling step of arranging, between first and second glass substrates, a sealing material including first and second straight line portions stretching in different directions and a coupling portion connecting these straight line portions, with a viscosity of the sealing material having a negative temperature coefficient, and a scanning sealing step of performing scanning to the first straight line portion and the coupling portion while irradiating local heating light at least once. Scanning to the second straight line portion and the coupling portion is performed while irradiating the local heating light at least once, and the assembling step further forms at least a part of the sealing material at the coupling portion with a film thickness thinner than the sealing material in a region adjacent to the coupling portion of the first straight line portion.

Owner:CANON KK

Ceramic inner tube metal container and producing method thereof

InactiveCN1472115AEnrich the packaging marketSolve the problem of not being able to make metal containers with ceramic inner tubesLinings/internal coatingsRigid containersMetallurgyMetal

Owner:蒋荣昌

Container Assembly

A container assembly includes a first container having a first opening, and a second container having a lid wall. A closure hingedly interconnects the first and second containers for swinging movement between a stacked position in which the lid wall overlies and closes the first opening, and an unstacked position in which the lid wall is removed from the first opening. The closure maintains the containers interconnected throughout the movement between the stacked and unstacked positions.

Owner:BERLIN PACKAGING ITALY SPA

Ion exchangeable, transparent gahnite-spinel glass ceramics with high hardness and modulus

ActiveUS20190161397A1Casings with display/control unitsCasings/cabinets/drawers detailsIon exchangeSpinel

A transparent gahnite-spinel glass ceramic is provided. The glass ceramic includes a first crystal phase including (MgxZn1−x)Al2O4 where x is less than 1 and a second crystal phase including tetragonal ZrO2. The glass ceramic may be ion exchanged. Methods for producing the glass ceramic are also provided.

Owner:CORNING INC

Low-gravity glass container and producing method thereof

InactiveCN1552604AStable sprayingEasy to take outGlass blowing apparatusCeramic containersBlow moldingMechanical engineering

A glass container with lower gravitational center is made up by use of a blowing mould and a convex bulkhead. The finished glass container has thick and concave bottom.

Owner:上海高雅玻璃有限公司

Glass container with a hollow-out metal covering having a bottom and glass container with a ring-band shaped metal-covering ornament and their production methods

InactiveCN1521090AWide variety of productsCoverings/external coatingsCeramic containersBand shapeWine bottle

The present invention relates to container and is especially glass container with bottomed and hollowed decorative metal jacket or annular decorative metal jacket. The glass container has outer surface fitting closely to or embedded with the inner cavity of the metal jacket. The production process of the glass container with decorative jacket is also provided. The decorative glass container has complicated artistic design and is suitable for use as wine bottle, drinking set, tableware, tea set, tea and health article container, artistic container, etc. The present invention has wide application foreground.

Owner:蒋荣昌

Manufacturing method of hermetic container

InactiveUS8257130B2Reduce film thicknessSpacing distanceMechanical working/deformationLamination ancillary operationsNegative temperatureCoupling

A manufacturing method of a high-reliability hermetic container includes an assembling step of arranging, between first and second glass substrates, a sealing material including first and second straight line portions stretching in different directions and a coupling portion connecting these straight line portions, with a viscosity of the sealing material having a negative temperature coefficient, and a scanning sealing step of performing scanning to the first straight line portion and the coupling portion while irradiating local heating light at least once. Scanning to the second straight line portion and the coupling portion is performed while irradiating the local heating light at least once, and the assembling step further forms at least a part of the sealing material at the coupling portion with a film thickness thinner than the sealing material in a region adjacent to the coupling portion of the first straight line portion.

Owner:CANON KK

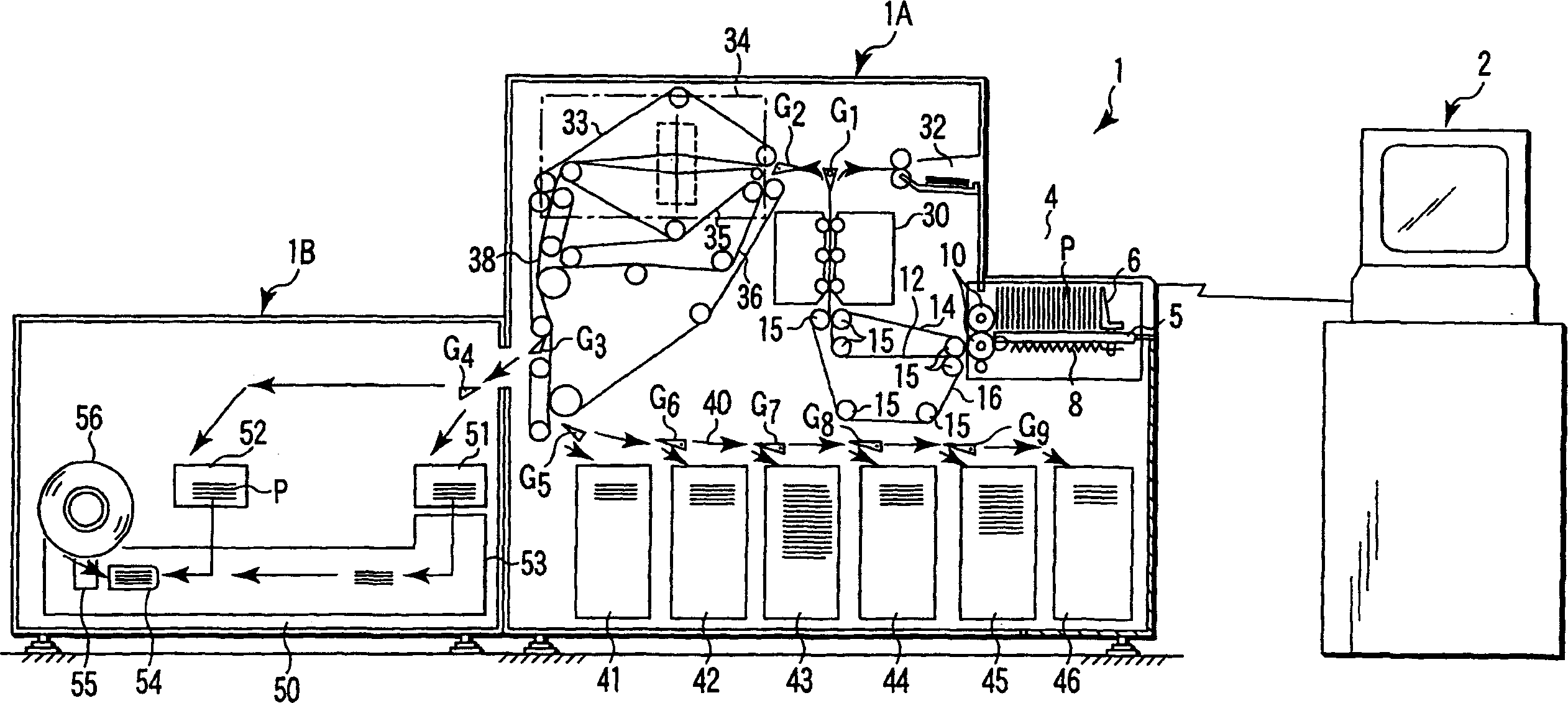

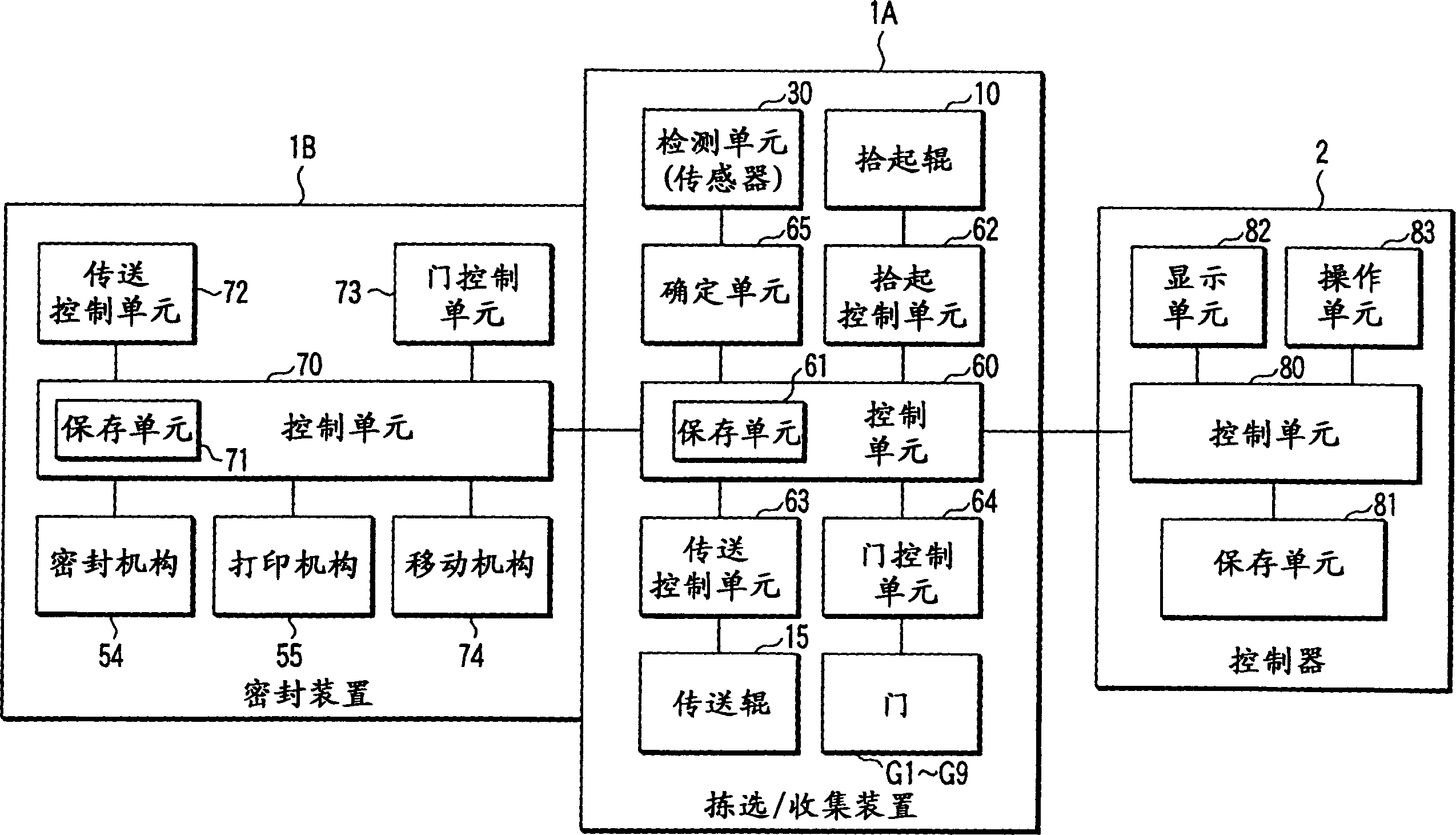

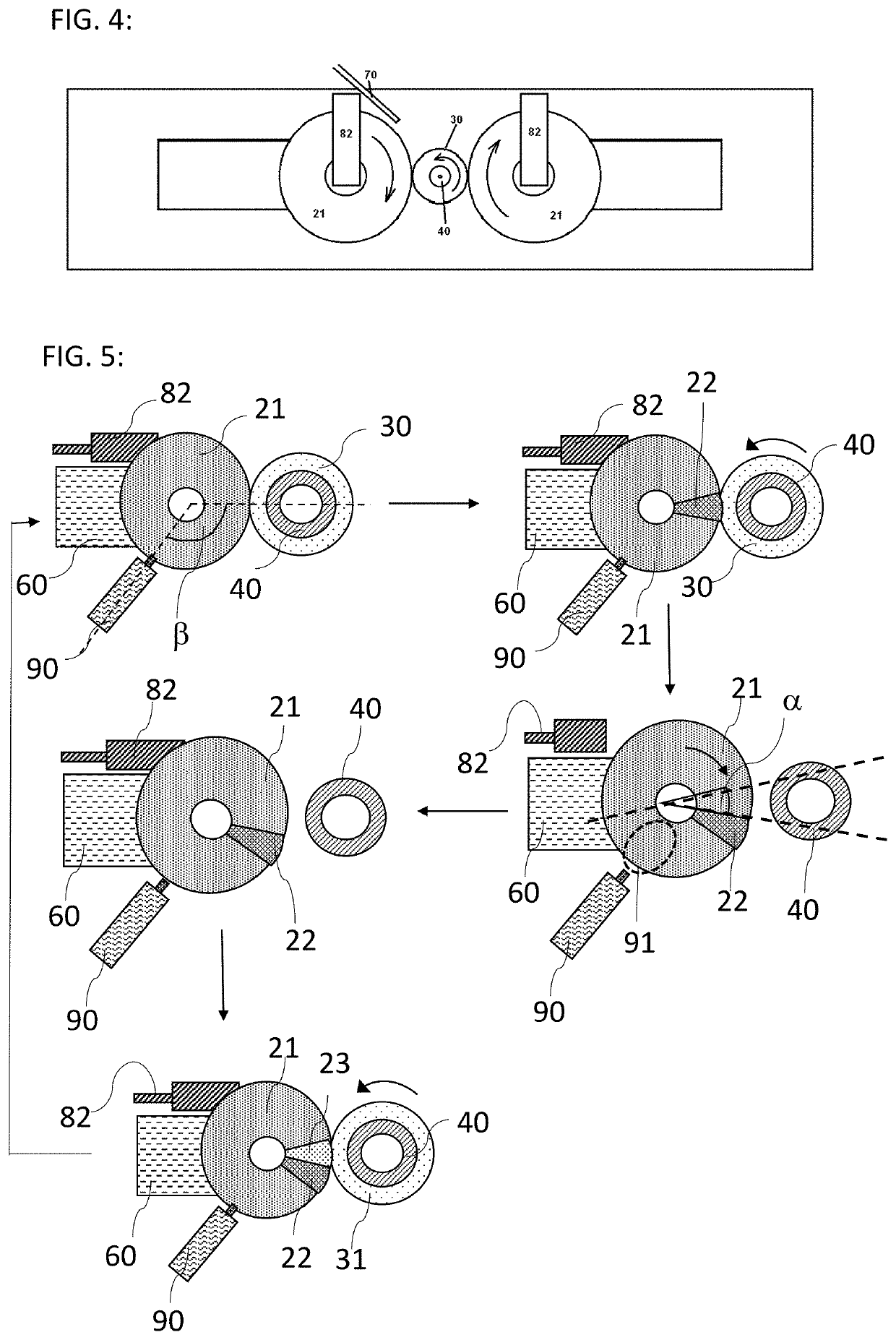

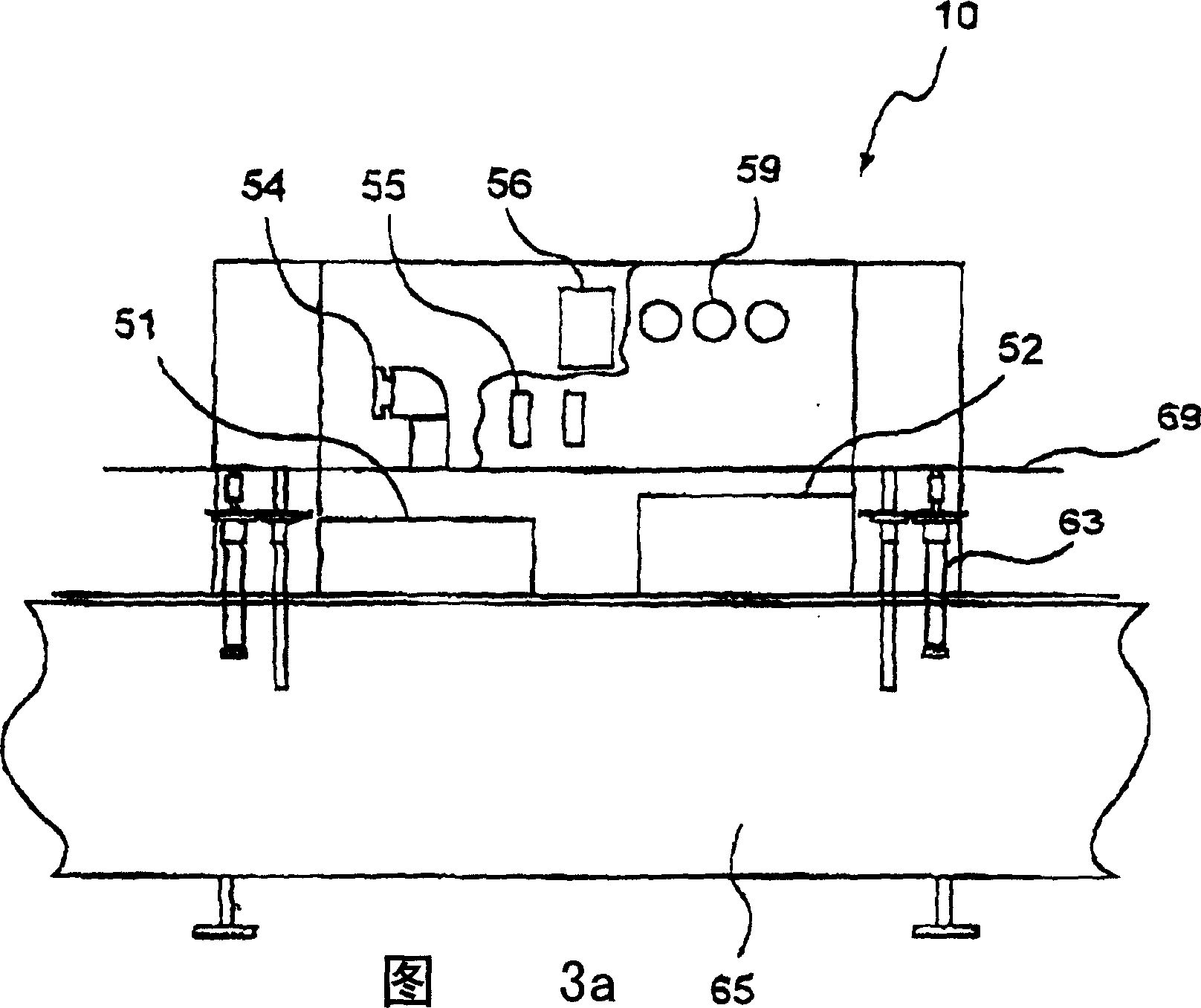

Sheet processing apparatus

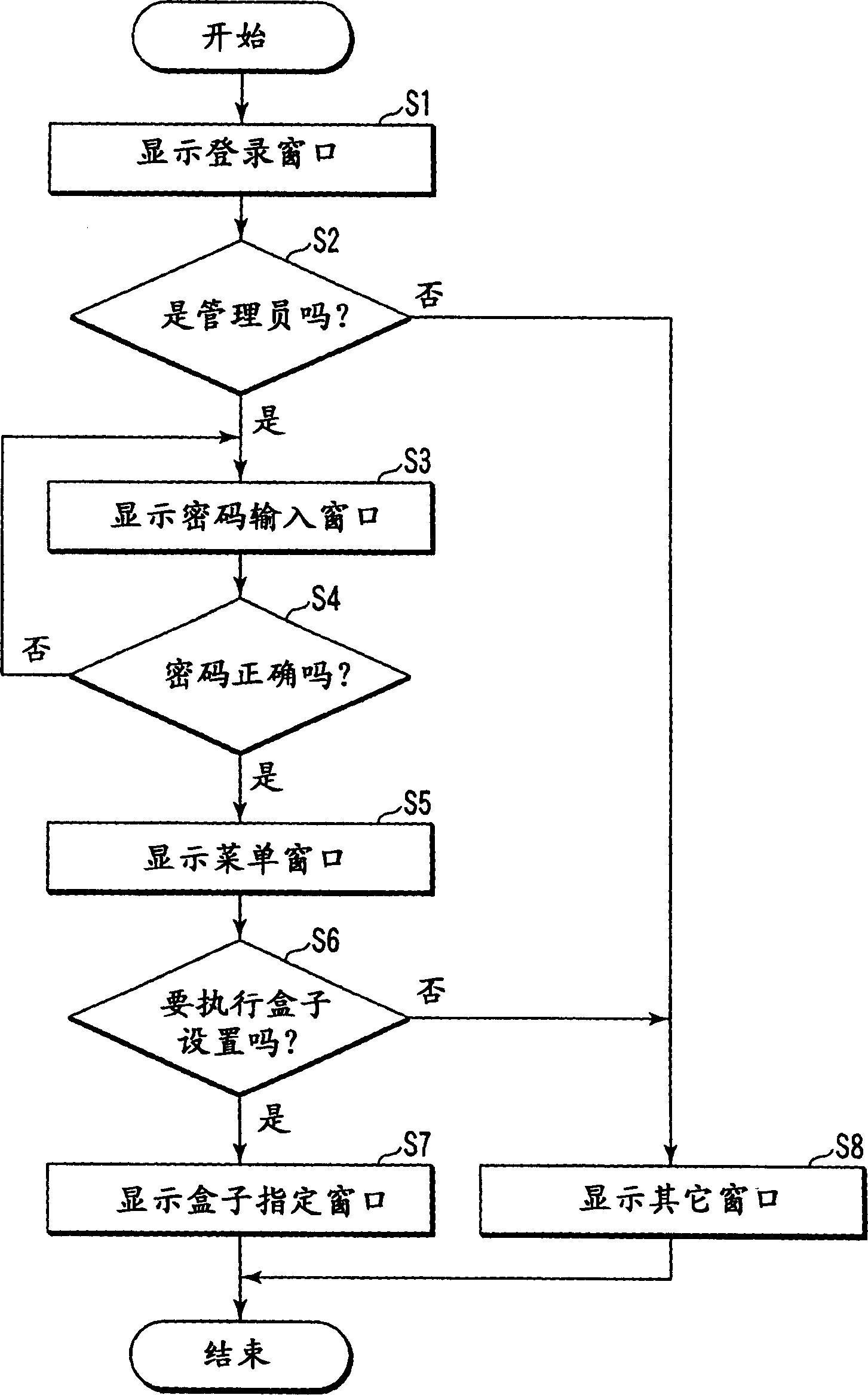

InactiveCN1807212AEasy to set upPaper-money testing devicesCoin/currency accepting devicesCheck sheetEngineering

In a sheet processing apparatus which checks sheets and sorts the sheets for a plurality of cassettes (41-46, 51, 52) on the basis of the check result and conditions for the sheets which are assigned to the respective cassettes (41-46, 51, 52), conditions for sheets such as bill types and bill states which are assigned to the respective cassettes (41-46, 51, 52) are displayed on a display unit (82). When an instruction to save these setting contents is issued while a cassette and conditions for sheets which are displayed on the display unit (82) are selected, the selected conditions for sheets are assigned to the selected cassette.

Owner:KK TOSHIBA

Method for producing lead-free low-temperature embossed decoration-fired glass wine bottles

InactiveCN103318507AConvenient sourceNo pollution in the processPackage recyclingCeramic containersCalciteWine bottle

The invention discloses a method for producing lead-free low-temperature embossed decoration-fired glass wine bottles and belongs to the field of glass manufacturing. According to the method, lead-free white broken glass, white quartz sand, sodium carbonate, albites, calcites, anhydrous sodium sulphate, cobalt powder, 2mm-thick pattern paper and removable films are used as raw materials. A water washer, a mixing machine, a boiler, a kiln, a forming machine, an annealing box, an adapter sticking box, a gas glass decoration firing furnace and a film removing box serve as equipment. The method comprises the steps of water washing of the lead-free white broken glass, raw material mixing, fusing, forming, annealing, film sticking, decoration firing and film tearing off to obtain the lead-free low-temperature embossed decoration-fired glass wine bottles. The method has the advantages of being simple in process, capable of obtaining raw materials conveniently, low in production cost, pollution-free and applicable to industrial production. The product lead-free low-temperature embossed decoration-fired glass wine bottles can be used as packaging materials for high-grade white spirits and are lead-free and recyclable after usage.

Owner:XINYI XINAODE GLASS PROD LTD

Substantively hermetically sealing container

ActiveUS20150114965A1Closure with auxillary devicesRigid containersEngineeringMechanical engineering

Owner:TOBEY TED

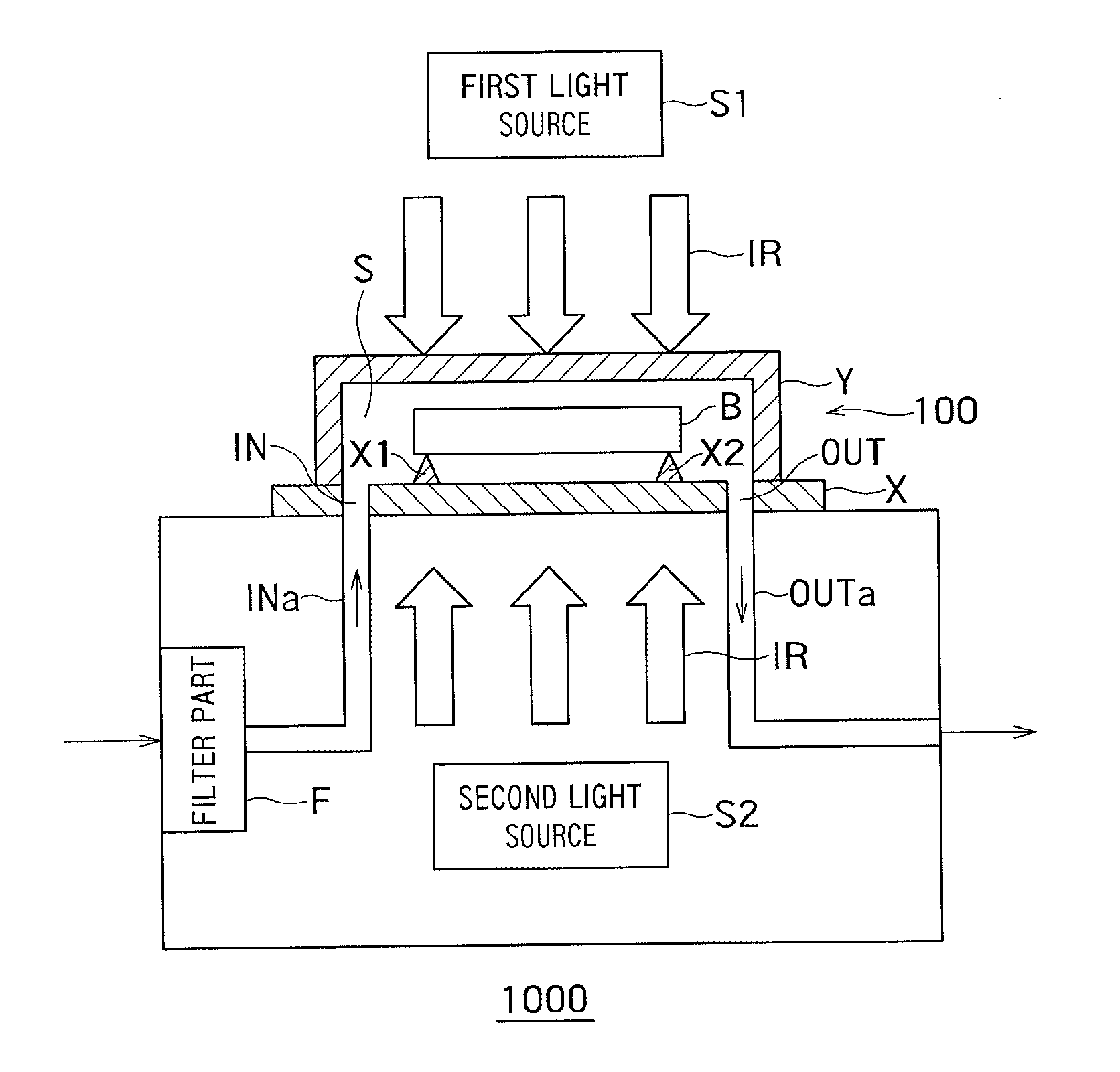

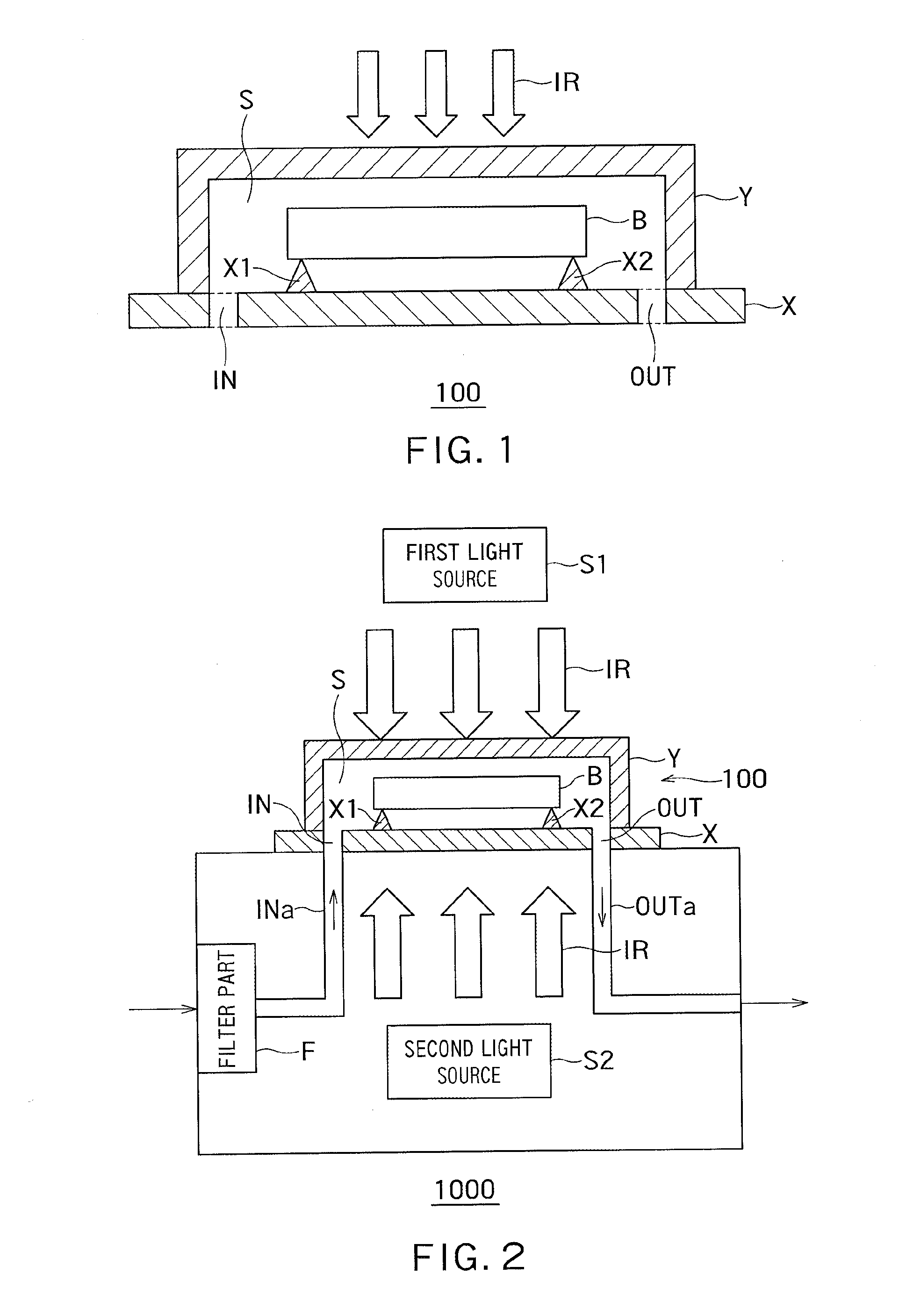

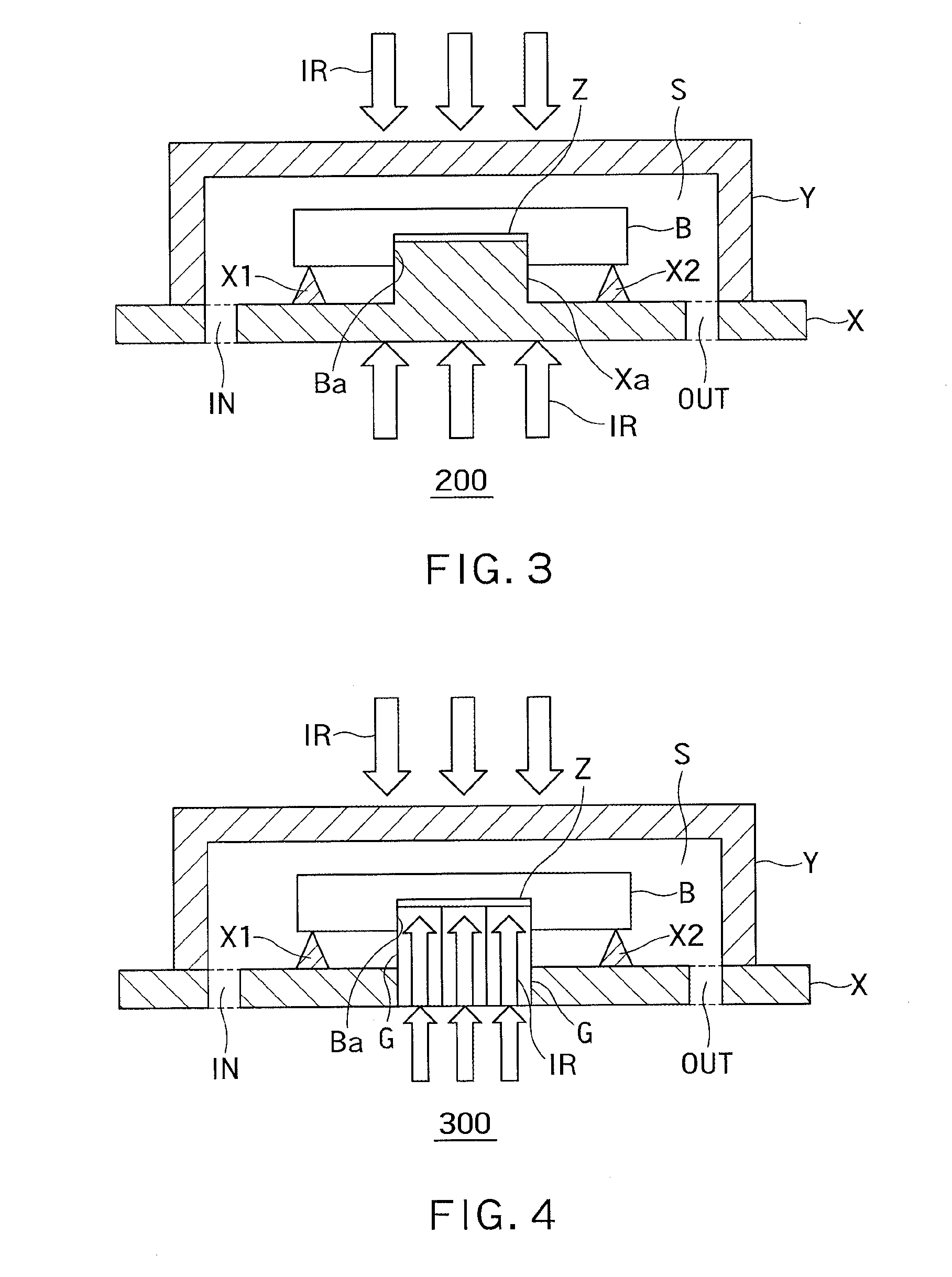

Substrate storing case, substrate cleaning apparatus and substrate storing case cleaning apparatus

The substrate storing case includes a base being made of quartz glass, and having a supporting part that is formed on an upper surface thereof and supports a substrate. The substrate storing case includes a top cover being made of quartz glass, and being in contact with the base to cover the substrate on the upper surface of the base. The substrate includes a first absorptive member that absorbs infrared rays and generates heat. The base or the top cover has an intake port that is in communication with a space enclosed by the upper surface of the base and the top cover and is capable of being opened and closed, and an outlet port that is in communication with the space and is capable of being opened and closed.

Owner:KK TOSHIBA

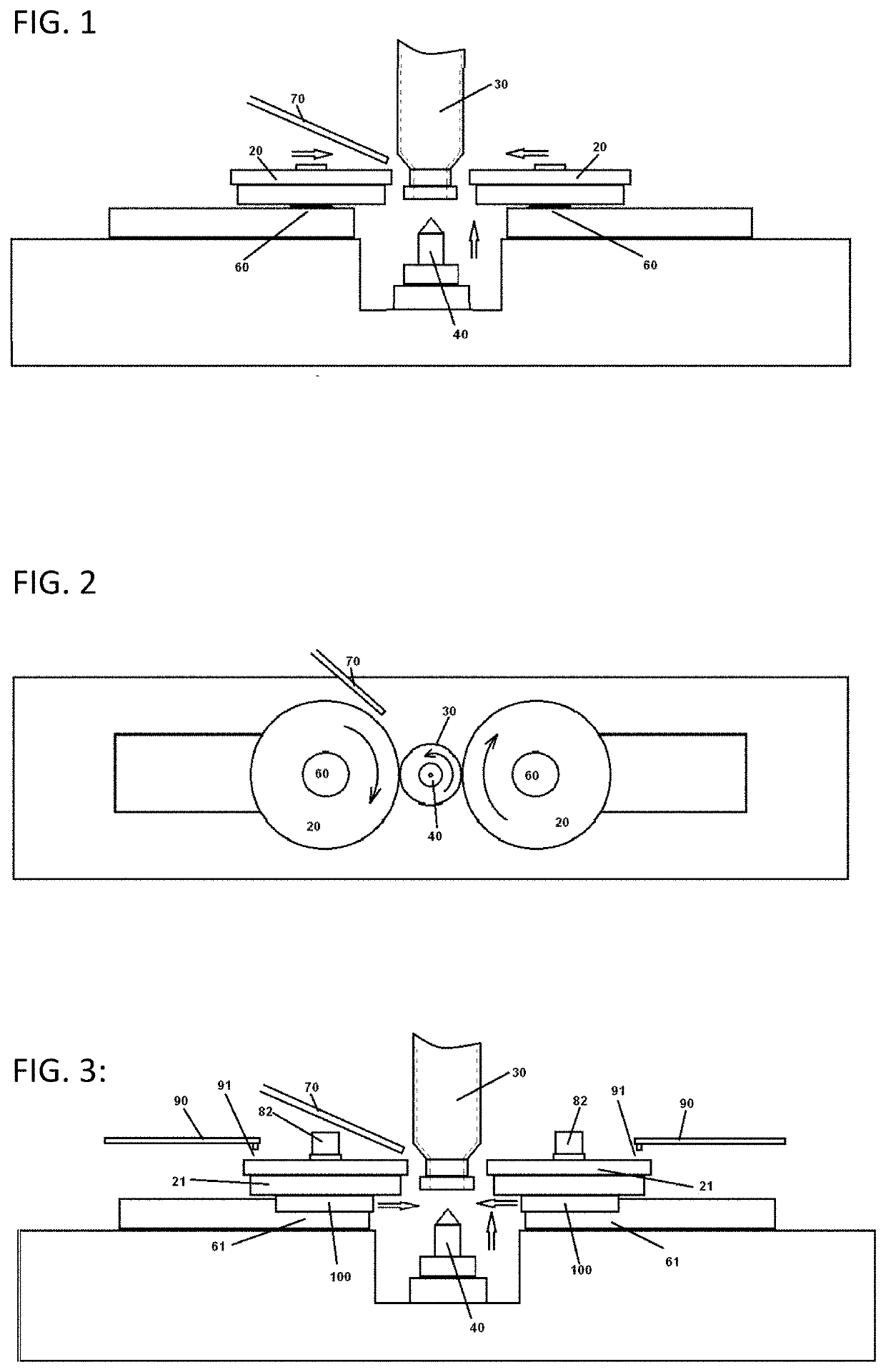

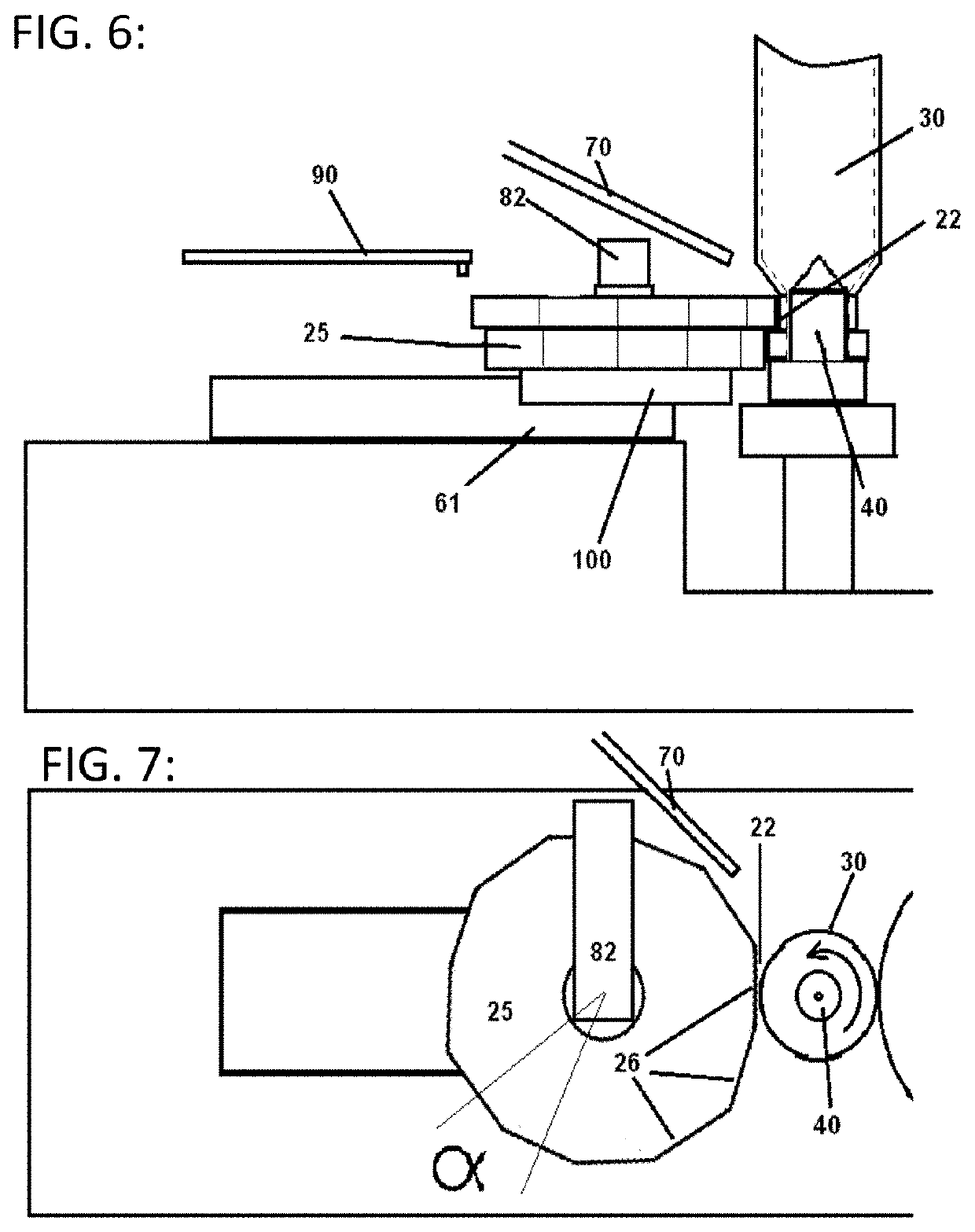

Method and apparatus for the hot forming of glass workpieces, and hot-formed glass container

ActiveUS20200123038A1Reduce formationReduce wearInfusion syringesPharmaceutical containersFree rotationThermoforming

Owner:SCHOTT PHARMA SCHWEIZ AG

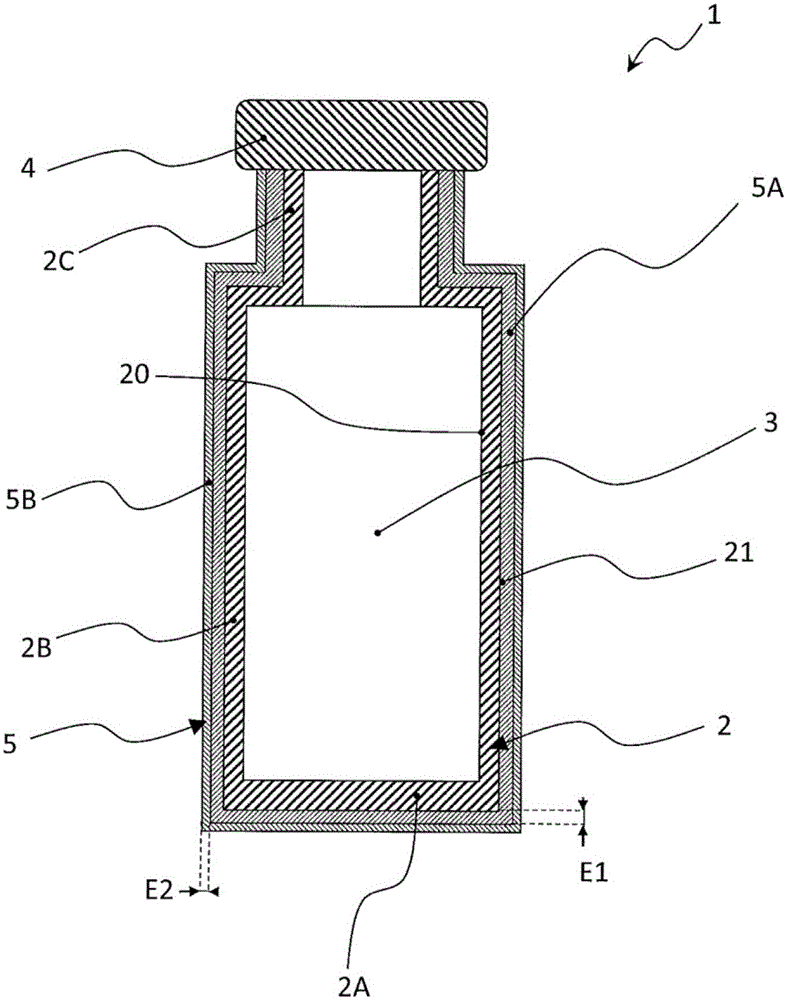

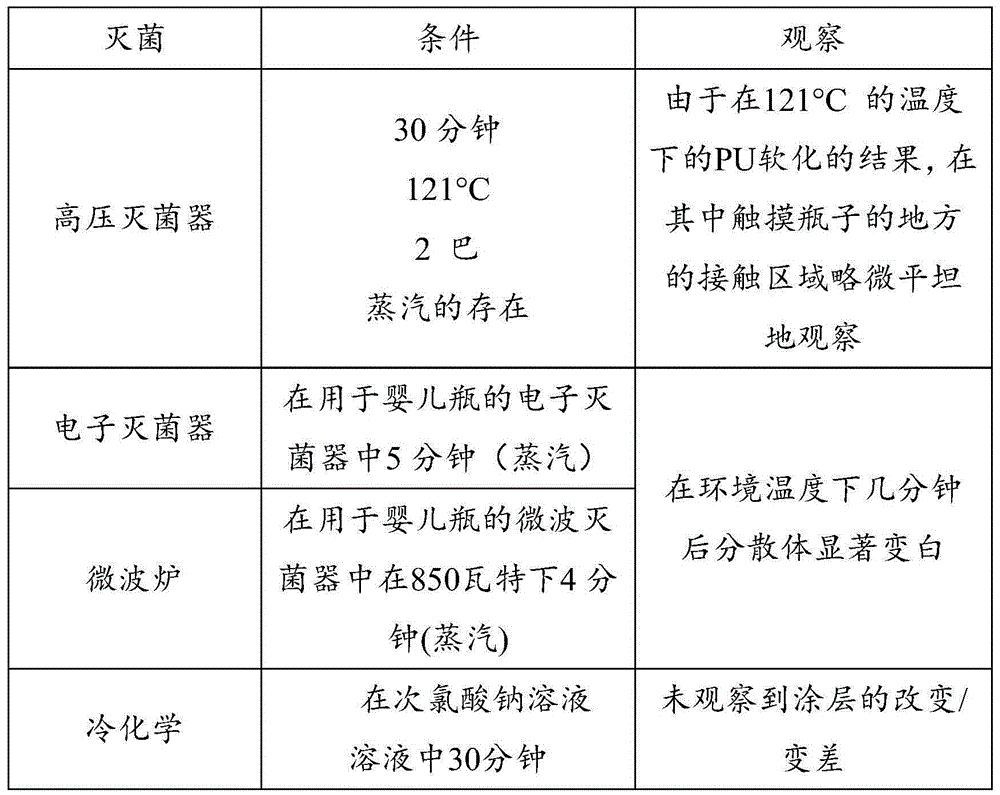

Container covered with a protection and retention coating, a kit for manufacturing protection and retention coating, and related manufacturing method

A container covered with a protection and retention coating, a kit for manufacturing a protection and retention coating, and a related manufacturing. The invention provides a container (1) comprising a glass wall (2) defining a reception cavity (3) for receiving a fluid substance, said container (1) further comprising a protection and retention coating (5) that covers the outside of said glass wall (2), said container (1) being characterized in that said protection and retention coating (5) is a multilayer coating that is transparent and that comprises a bottom layer (5A) that covers the glass wall (2), and a top layer (5B) that covers said bottom layer (5A), said bottom layer (5A) being made up of a polyurethane-based material, while said top layer (5B) is made up of a polyurethane-based material that is functionalized by a fluoropolymer-based compound.

Owner:S G D

Ceramic sealing cover and producing method thereof

InactiveCN1490223AAvoid controlGuaranteed standardizationCapsClosure capsInjection mouldingComposite material

A sealing cover for ceramic container is composed of cover body with spiral thread and sealing pad, and is prepared through preparing mould, injection moulding, carving for shaping, baking, supplementing water, glazing, and high-temp calcining. Its advantages are high sealing, performance and high quality.

Owner:倪建国 +1

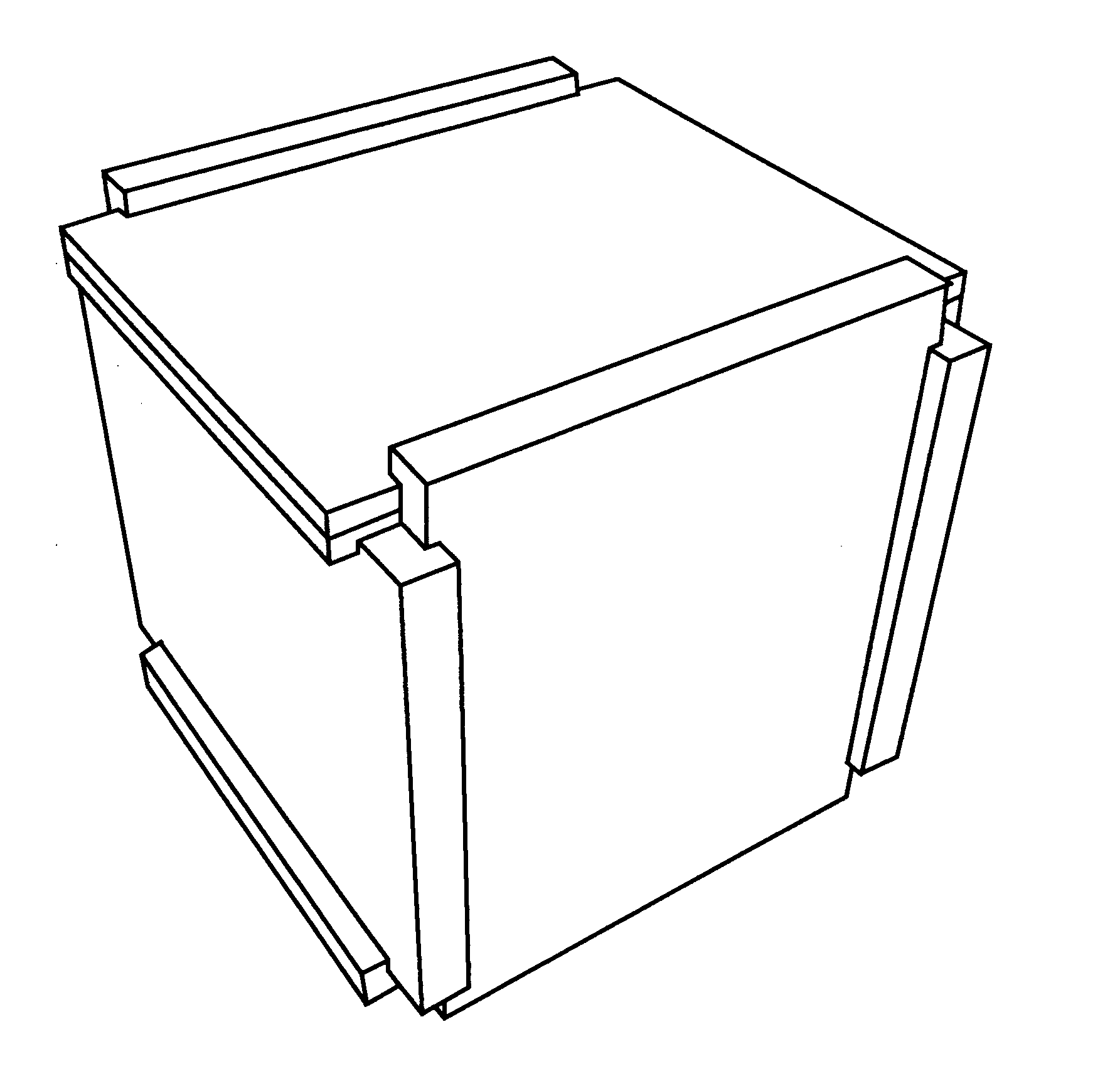

Joint building system for box structures

The present invention solves a problem of building geometry in a system to assemble and shut exclusively by jointing the six walls of a box parallelepiped built up with at least seven plates, so: the plates are divided in a first group of six, named primary, each one provided with a couple of grooves, and in a second group of the remaining plates, named secondary, not necessarily grooved; the walls of the structure are divided in two types: single walls, composed by only one primary plate: multiple walls, composed by one primary plate and at least one secondary plate; the structure, which must have at least one multiple wall, is assembled and shut jointing together first the six primary plates and then introducing at least one of the secondary plates. The system is suitable to build countless artefacts.

Owner:MASCI GIUSEPPE

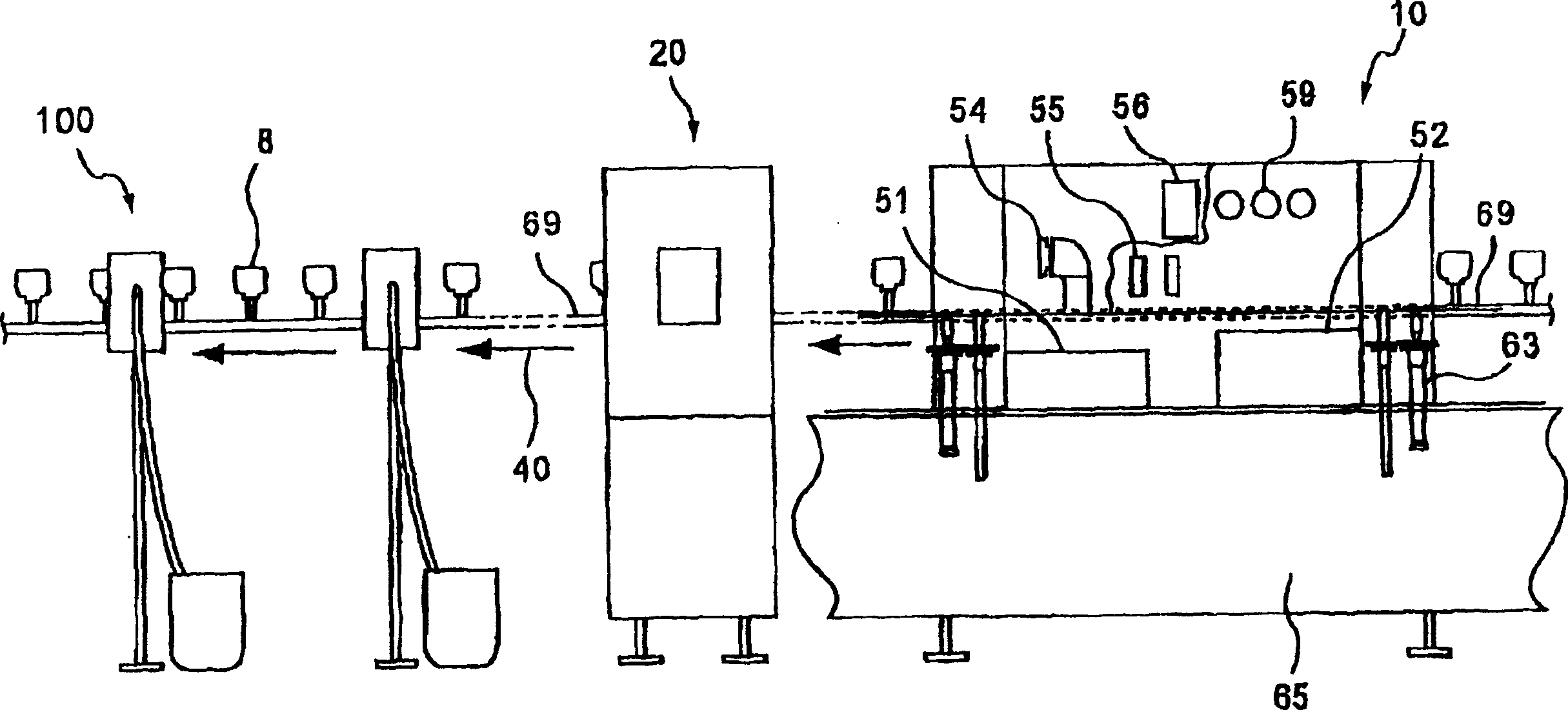

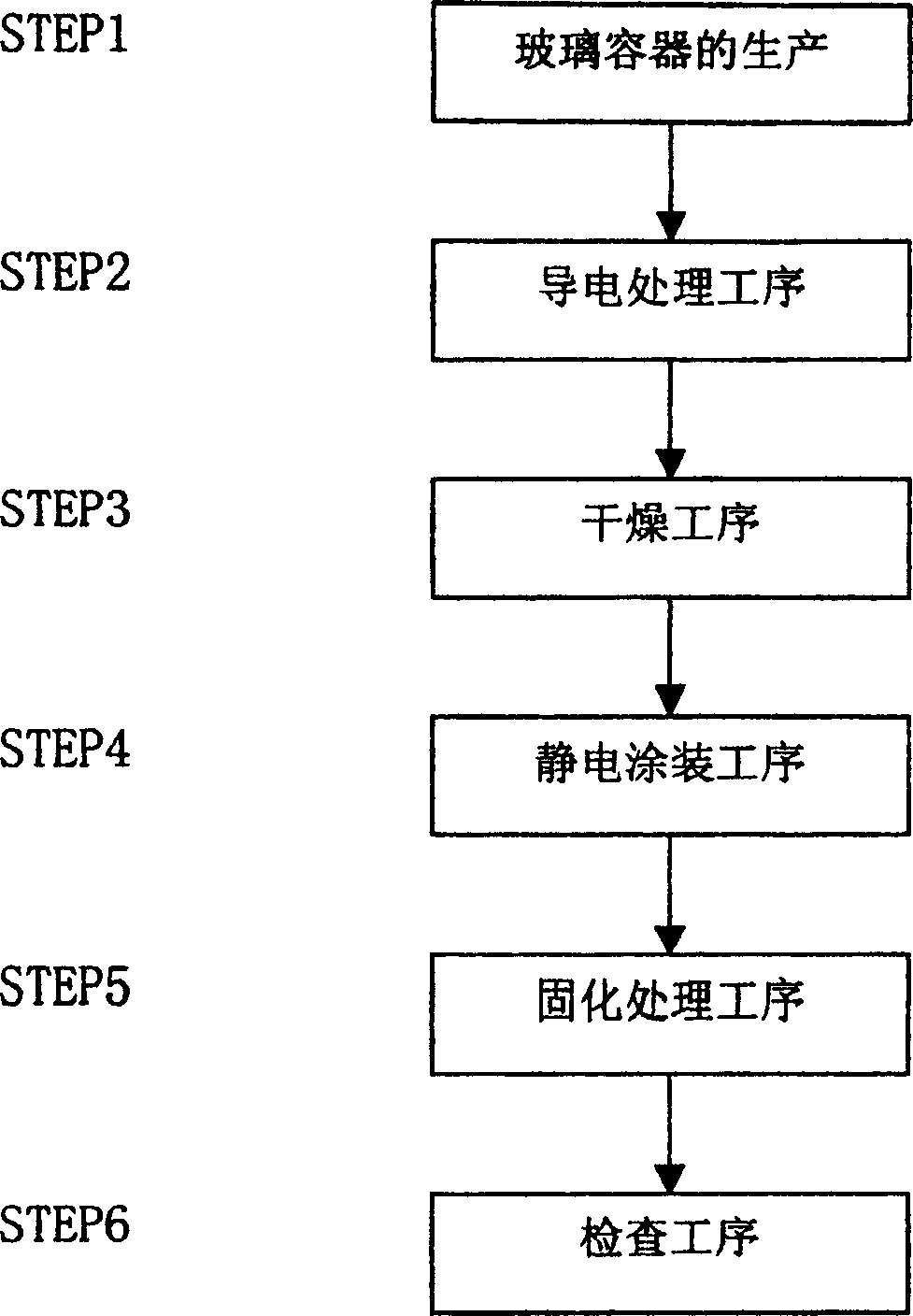

Painting device of glass container

InactiveCN1565756AEasy to operateReduce volumeLiquid spraying plantsCoverings/external coatingsActive agentEngineering

The invention relates to a coating preparation device for a glass container with high production efficiency, strong binding power, and uniform static coating layer on the surface of the glass container. The device comprises an electric-conducting treatment device and a static coating device, wherein the electric-conducting treatment device coats the conducting liquid with interfacial active agent on the glass container surface to form a conducting layer, and the static coating device coats the liquid paint on the conducting layer to form a uniform static coating layer.

Owner:上海高雅玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com