Painting device of glass container

A technology for glass containers and production devices, which is applied to the device for coating liquid on the surface, ceramic containers, coatings, etc. It can solve the problems of complex manufacturing process, high cost, and large difference in size and shape, and achieve uniform thickness of coating film Consistent, productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

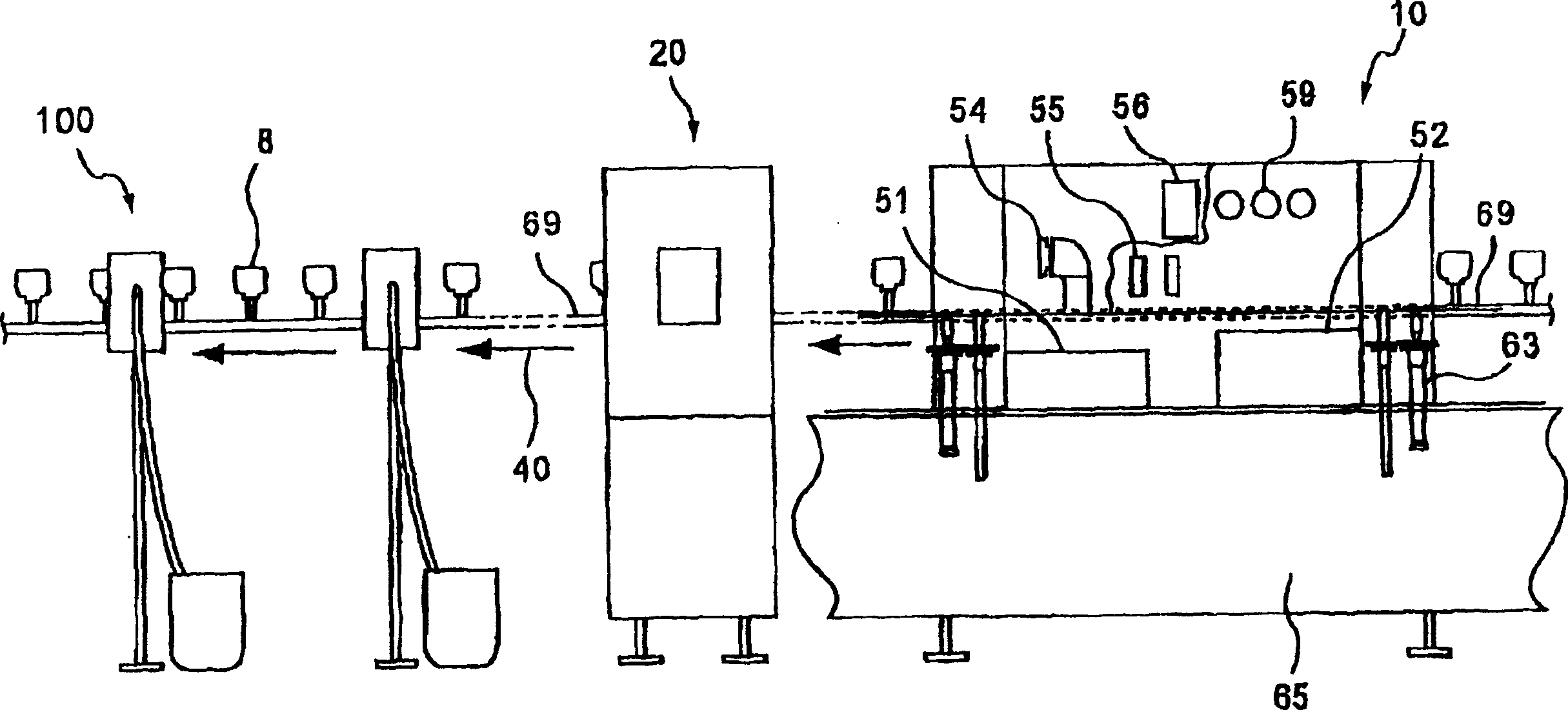

[0035] The first embodiment refers to figure 1 As shown, the conductive treatment device 10 and the electrostatic coating device 100 are arranged in sequence to form a glass container coating production device 30 .

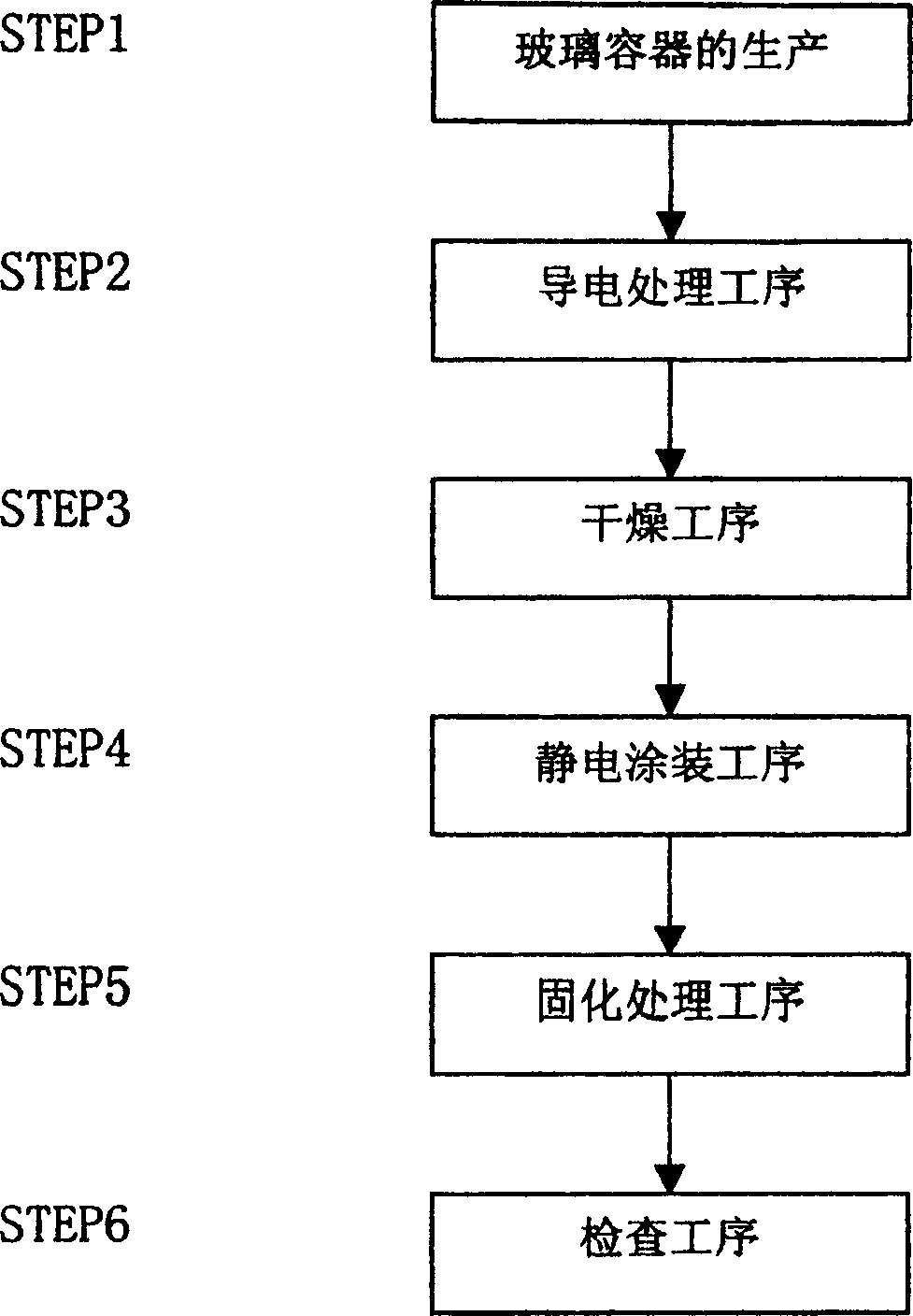

[0036] Using the glass container coating production device 30, the flow chart of coating production is as follows figure 2 shown. Among them, STEP2 represents the conductive treatment process, and STEP4 represents the electrostatic coating process. figure 2 Among them, there is a STEP3 between STEP2 and STEP4, that is, the drying process of the conductive layer. But in actual production, the conductive layer dries naturally quickly, so STEP3 can also be omitted, and STEP2 enters STEP4 directly.

[0037] 1. Glass container

[0038] ① shape

[0039] The shape of the glass container is not particularly limited, and cosmetic bottles, medicinal bottles, small-mouth bottles, wide-mouth bottles, square bottles, cylindrical bottles, special-shaped bottles, square c...

example 1

[0165] 1. Production of coated glass containers

[0166] ① Conductive treatment process

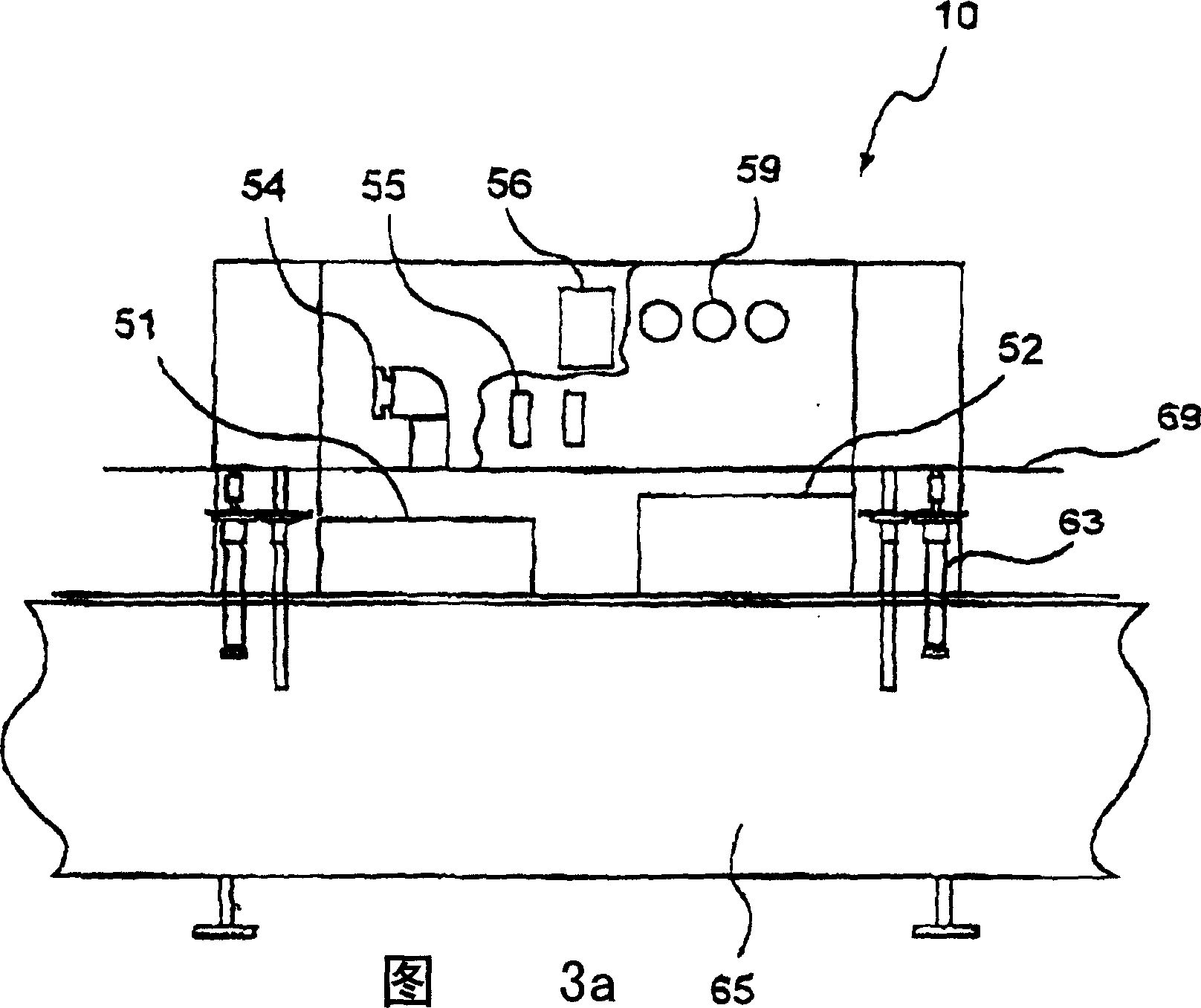

[0167] Put the glass container (small-mouth glass bottle with a height of 10cm) on the conductive treatment production line. The conductive treatment device is shown in Figure 3. The set conditions are as follows to conduct conductive treatment on the surface of the glass container.

[0168] Conductive liquid: 5% by weight aqueous solution of propylene ether

[0169] (polyoxyethylene lauryl ether)

[0170] Atomization pressure: 0.7mpa

[0171] Air supply pressure: 0.7mpa

[0172] Spray volume: 60cm 3 / Minute

[0173] ② Electrostatic coating process

[0174] Next, use the Figure 8 The electrostatic coating spray gun shown is set under the following conditions to electrostatically coat the surface of a glass container.

[0175] Liquid paint: colored varnish (acrylic melamine resin)

[0176] Viscosity: 100mpa.s

[0177] Spray volume: 60cm 3 / Minute

[0178] High voltage: 12kv

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com