Splicing structure, splicing method and splicing box body

A box body and reinforcement structure technology, which is applied in the field of water tank box body production in sewage treatment, can solve the problems of large space occupation, low production efficiency, and high cost, and achieve the effects of reduced space occupation, low production cost, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

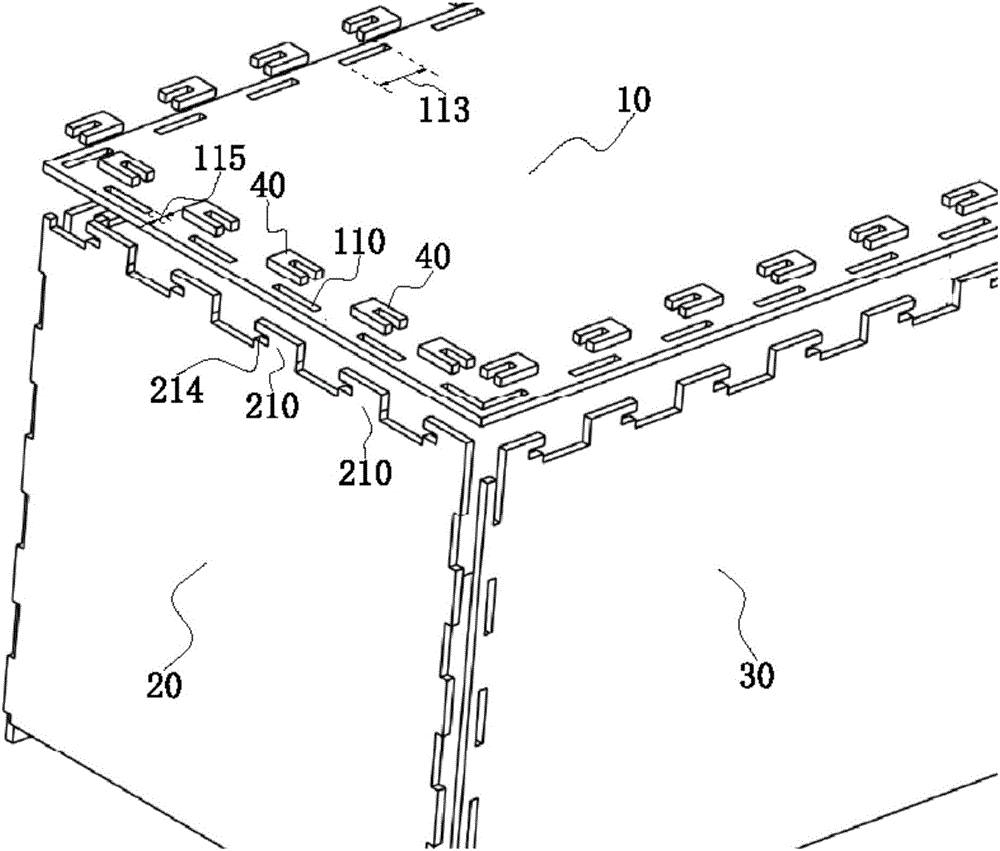

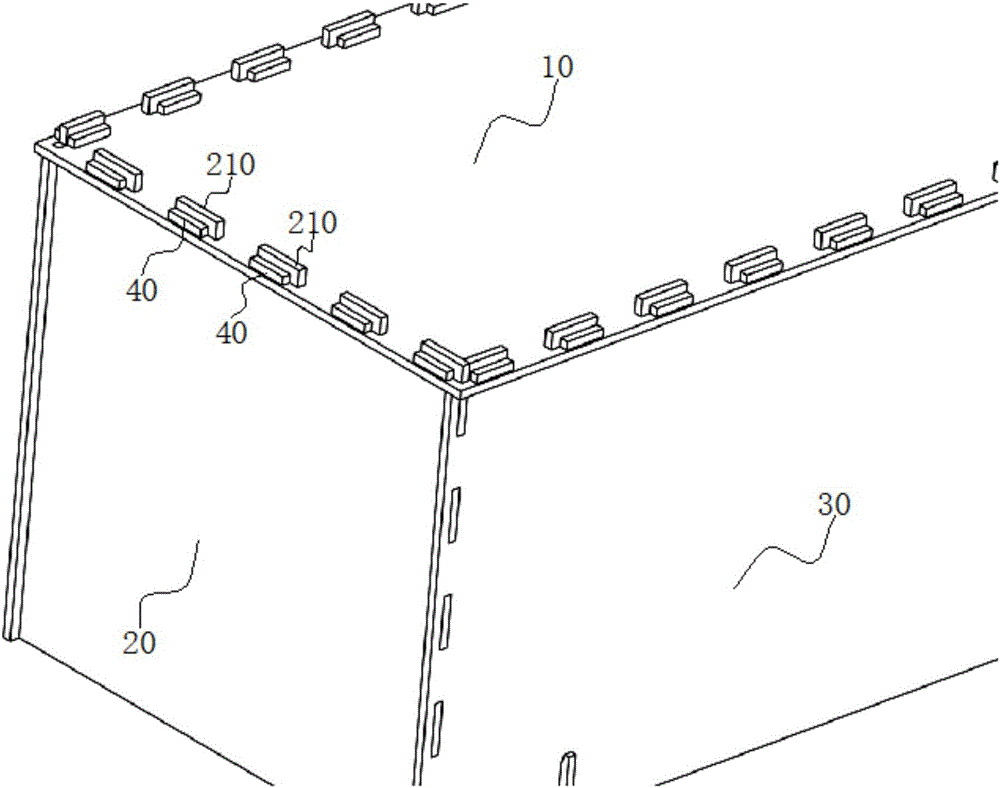

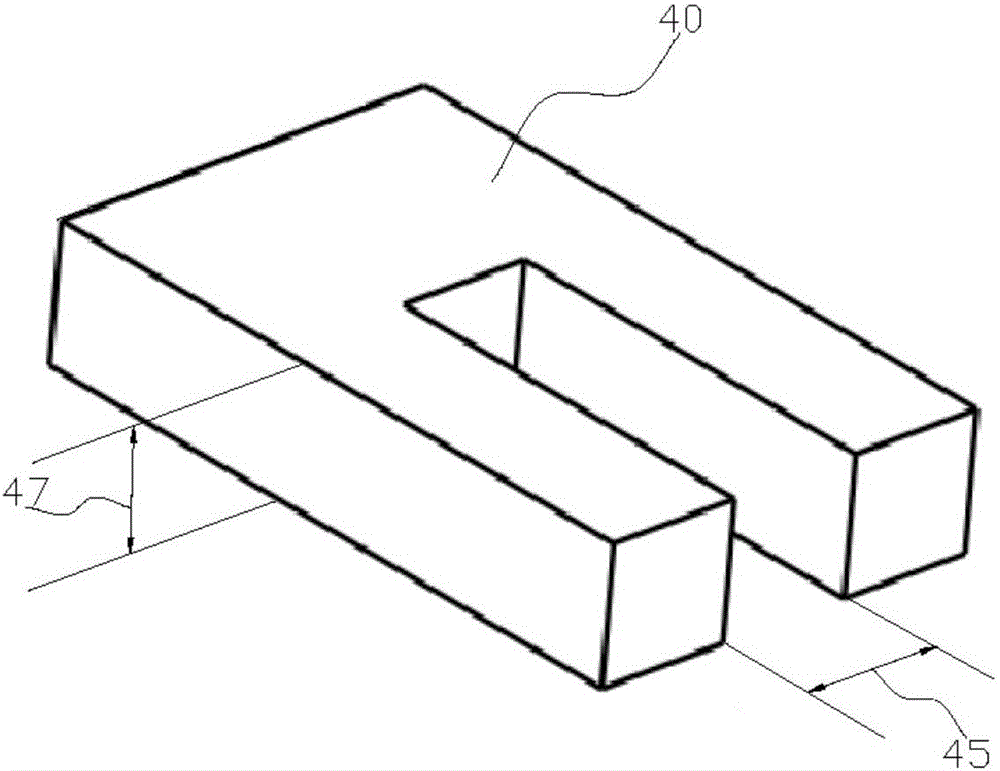

[0060] In order to describe in detail the technical content, structural features, achieved purpose and effect of the technical solution, the following in conjunction with specific embodiments and with the accompanying Figure 1a-Figure 6b Explain in detail.

[0061] see Figure 1a An exploded schematic view of a splicing structure provided by the inventor is shown, the splicing structure includes a first side plate 10, a second side plate 20, and a fastener 40; the splicing structure is a part of the box, and the first side plate and the second The two side panels are combined and fixed by the splicing structure as shown in the figure, so that the first side panel and the second side panel are L-shaped to each other.

[0062]The first side plate 10 is provided with at least one opening 110 close to at least one side thereof, and the opening 110 penetrates both sides of the first side plate; the size of the opening is not limited, and the first side plate 10 One side may have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com