Glass container with a hollow-out metal covering having a bottom and glass container with a ring-band shaped metal-covering ornament and their production methods

A technology of glass containers and manufacturing methods, which is applied in the direction of ceramic containers, coverings/external coatings, etc., can solve problems such as unsuitable process shapes, inability to express, and restrictions on the shape of metal decorative blocks, so as to achieve rich product types and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

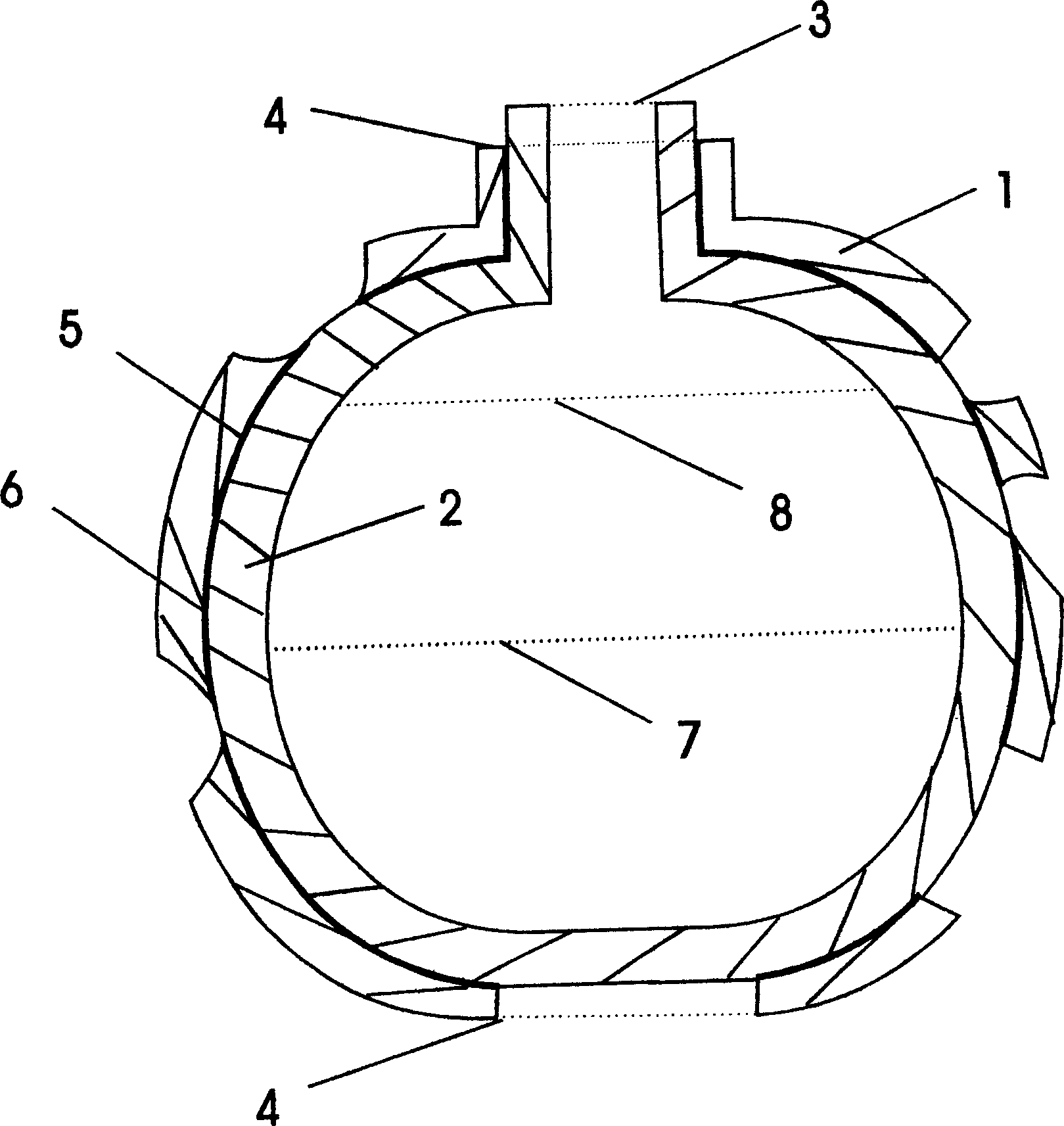

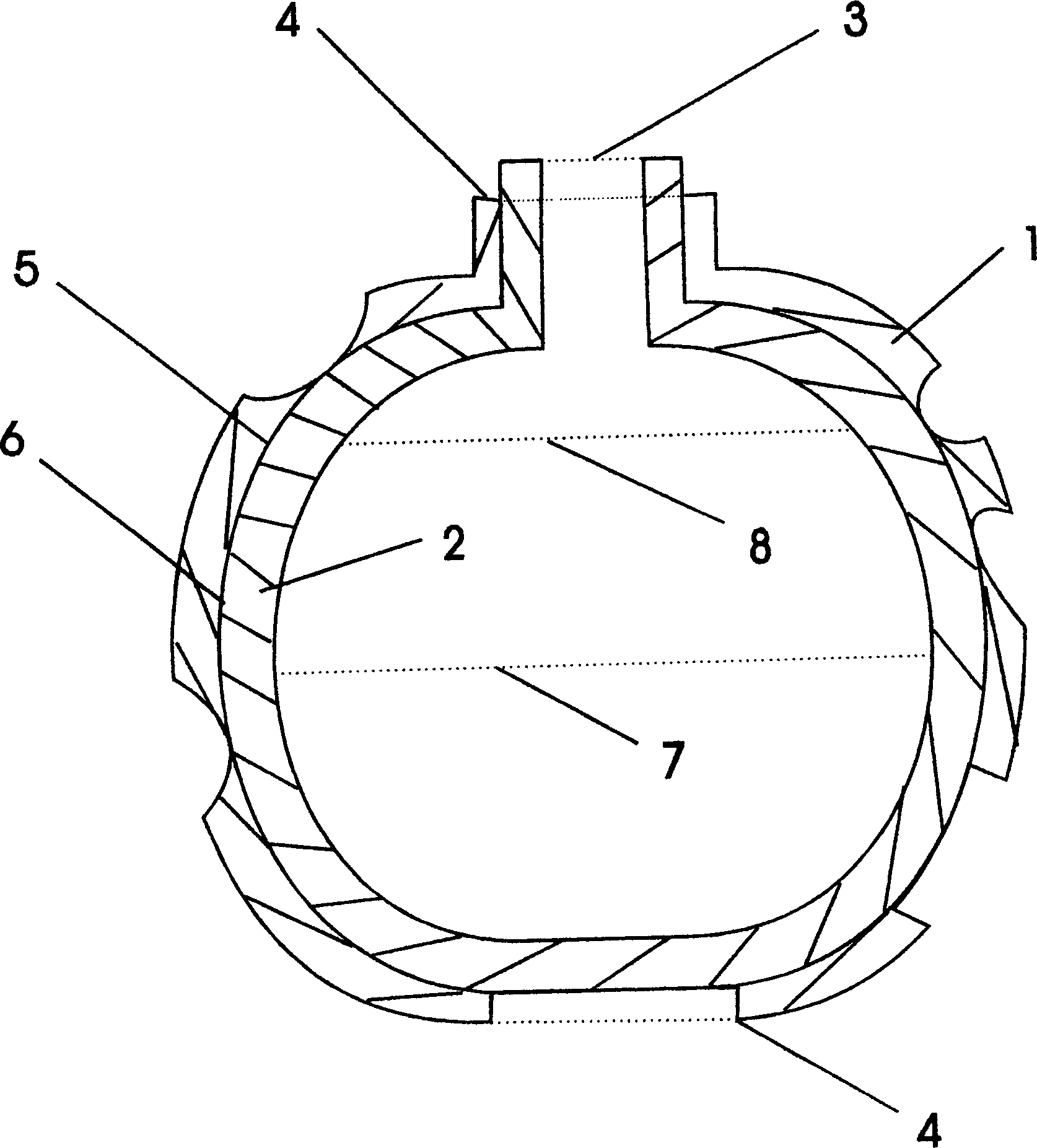

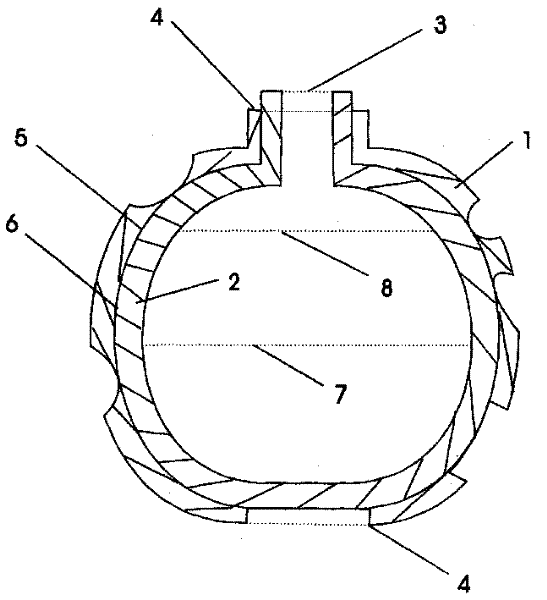

[0013] Such as figure 1 As shown, the metal jacket or the ring-shaped metal jacket with the bottom hollow band opening of the present invention is made of metal, and the surface of the metal jacket is decorated with decorative patterns or accessories of any shape, and the metal jacket has openings 4 (ring-shaped metal jacket) Decorated as two opposite openings), a glass container 2 with an opening 3 is built in the inner cavity of the above-mentioned metal jacket 1 (see figure 1 , figure 2 ).

[0014] When making the glass container of the present invention, embodiment one is: as figure 1 As shown, the metal jacket 1 is first made by casting or machining, and the inner wall 5 of the inner cavity of the metal jacket 1 is coated with a refractory heat-insulating material 6, such as expanded perlite, aluminum silicate fiber cotton, Any one or a combination of asbestos cloth, sodium silicate, monet asbestos, or other refractory materials with sufficient heat resistance. Then,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com