Heat insulation container and its producing method

A manufacturing method and container technology, which is applied in the direction of heat-insulating containers, chemical instruments and methods, containers, etc., and can solve the problems that the radiant heat prevention film cannot be configured and the performance cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

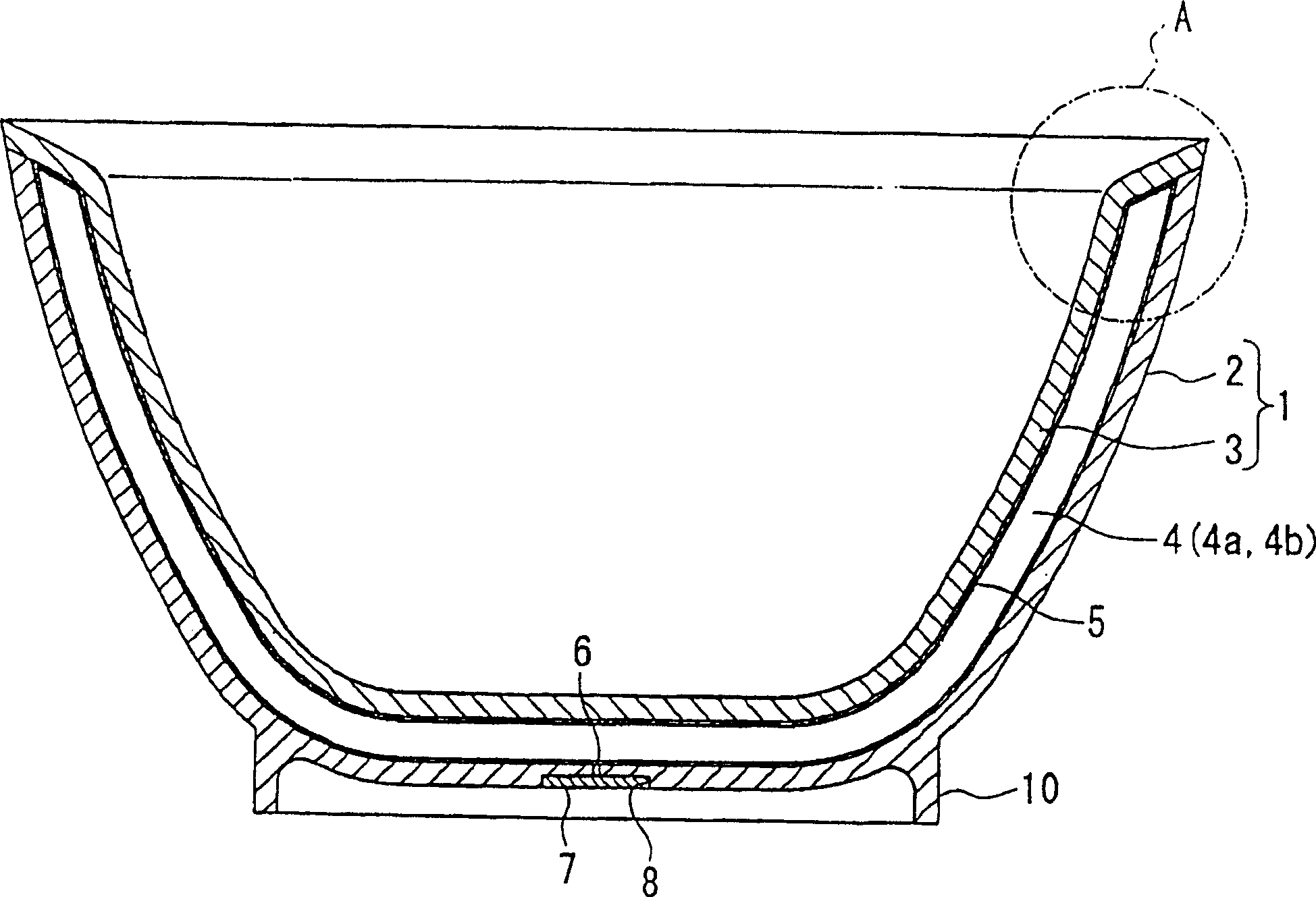

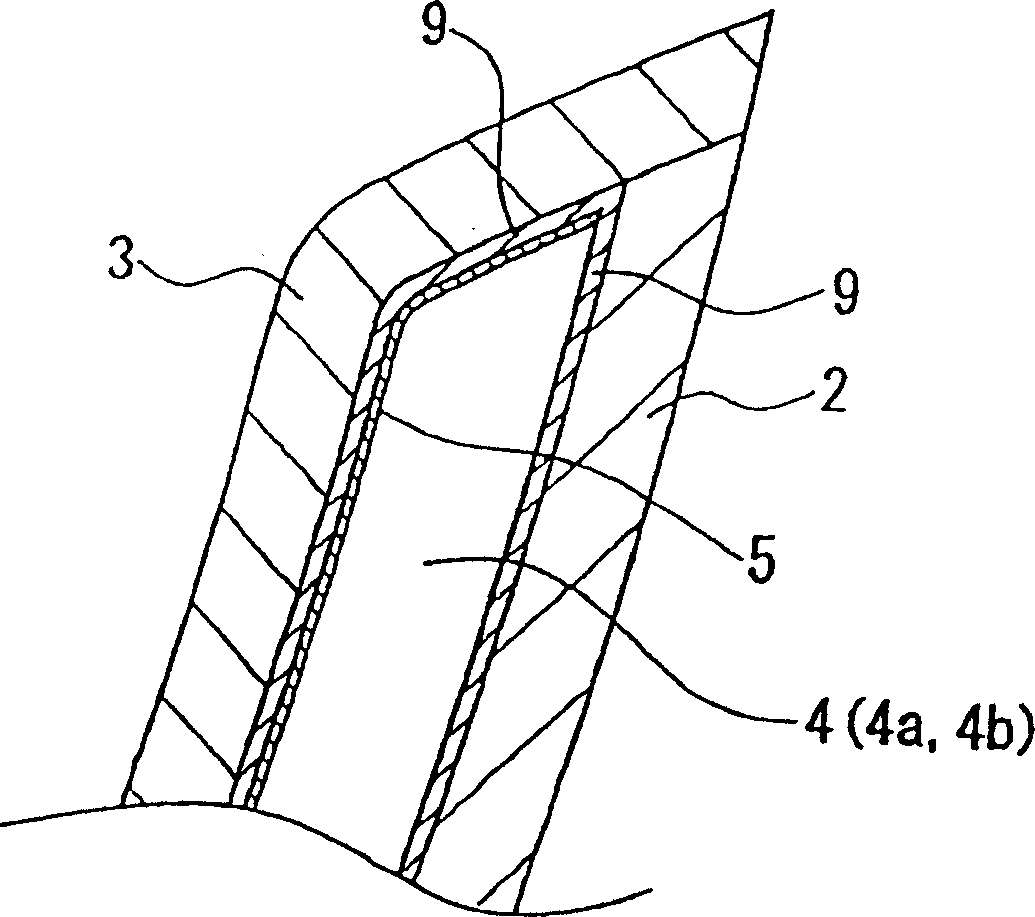

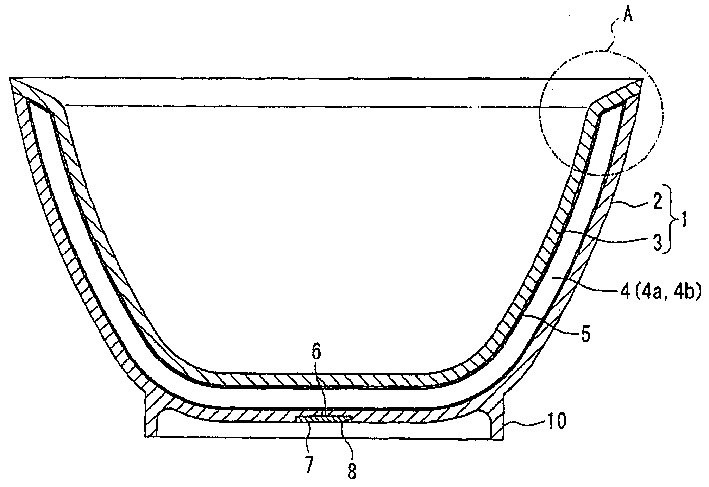

[0041] figure 1 It is a heat-insulating container made of ceramics according to an embodiment of the present invention. The heat-insulated container 1 has a structure in which an outer container 2 made of ceramics and an inner container 3 made of ceramics are integrated with a gap 4 interposed therebetween. On the outside of the inner container 3 and the inner surface of the outer container 2, such as figure 2 As shown, there is a vitreous layer 9 formed by melting and fixing the glaze. Further, on the vitreous layer 9 of the inner container 3, a radiant heat preventing film layer 5 formed of a metal film is provided. Also, at the bottom of the outer container 2, an annular foot 10 for stably placing the heat-insulating container 1 is provided, and a sealing portion is arranged in the annular center of the foot 10 to include a recess 8 and an opening 6 that runs through the center of the recess, and a closed Closing plate 7 of recess 8 .

[0042] The gap 4 between the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com