Ceramic sealing cover and producing method thereof

A technology of ceramic sealing and manufacturing method, which is applied in the field of sealing caps, can solve the problems of unhygienic sealing, poor sealing performance, and sealing failure, and achieve the effects of good sealing performance, convenient packaging and transportation, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

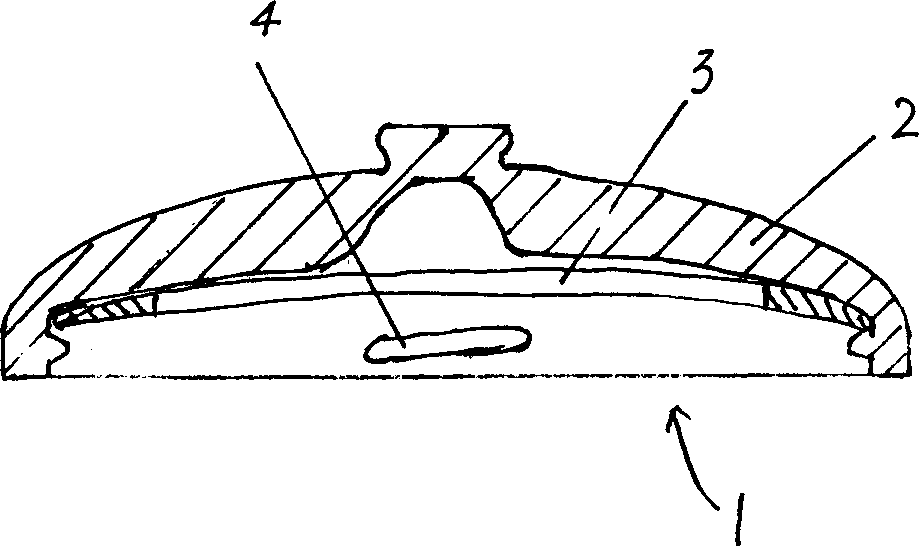

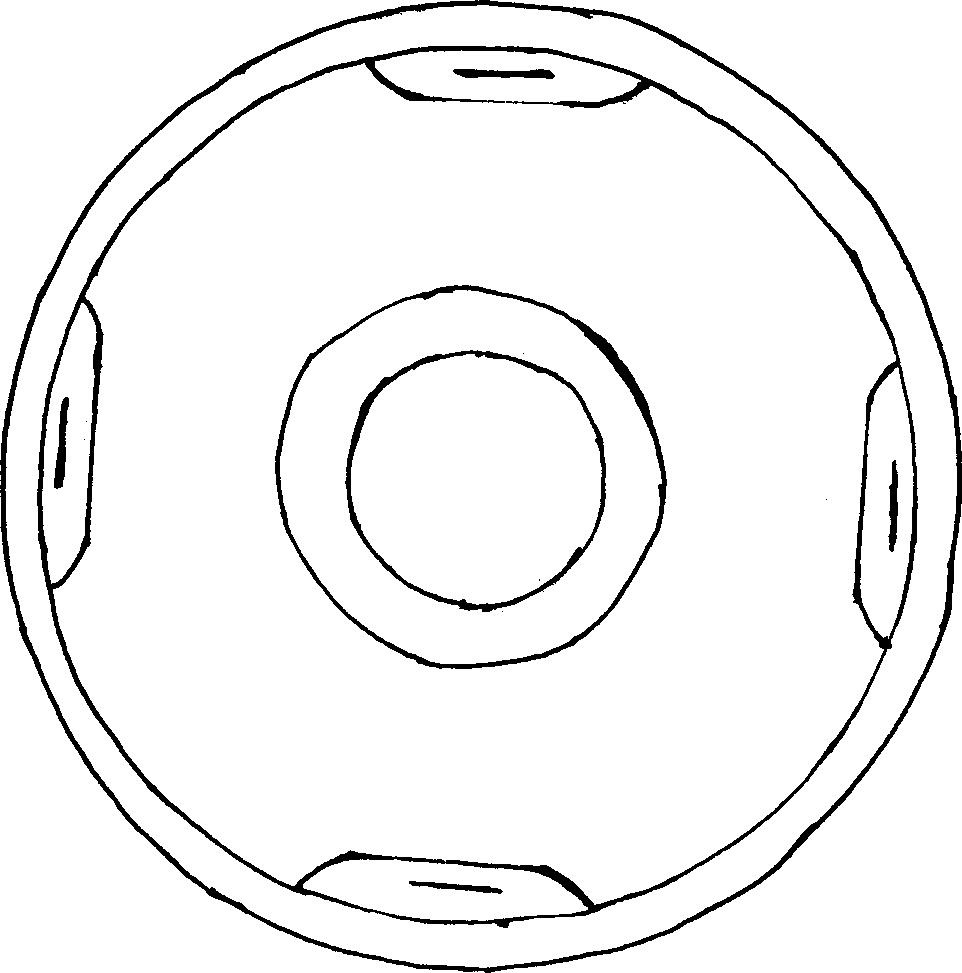

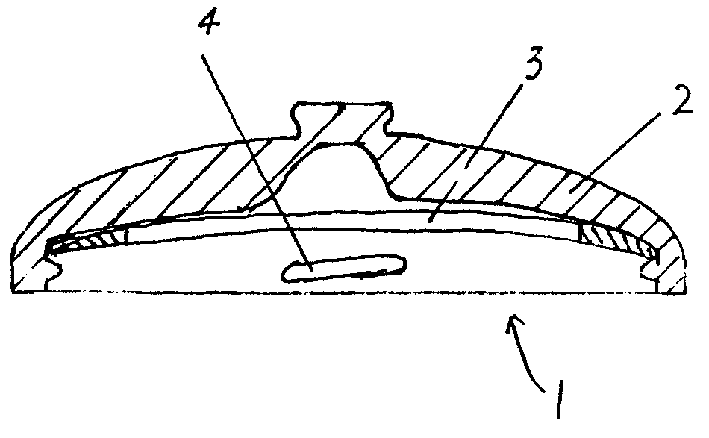

[0020] see figure 1 , figure 2 As shown, the ceramic sealing cap 1 of the present invention is composed of a cover body 2 and a sealing gasket 3, wherein the inner or outer surface of the mouth of the lid body 2 is provided with a screw thread on the outer or inner surface of the mouth of the ceramic tank. Thread 4, a sealing gasket 3 capable of closing the mouth of the ceramic jar is placed inside the lid body 2 .

[0021] When making the ceramic sealing cap 1, first use plaster molds to make the sealing cap mold; pressure grouting to complete the one-time molding of the sealing cap and the thread bayonet; use the sculpture process to complete the shaping of the cap and bayonet; The shape of the device is processed; the cover blank is dried at low temperature; the cover blank is watered and glazed in the traditional process; it is fired at a high temperature in a liquefied gas kiln at 1300-1500 degrees Celsius to make the ceramic sealing cover of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com