Low-gravity glass container and producing method thereof

A technology for glass containers and manufacturing methods, applied in glass manufacturing equipment, ceramic containers, glass blowing, etc., can solve problems such as difficult production of glass containers with thick bottom walls, and achieve the effect of easy removal and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

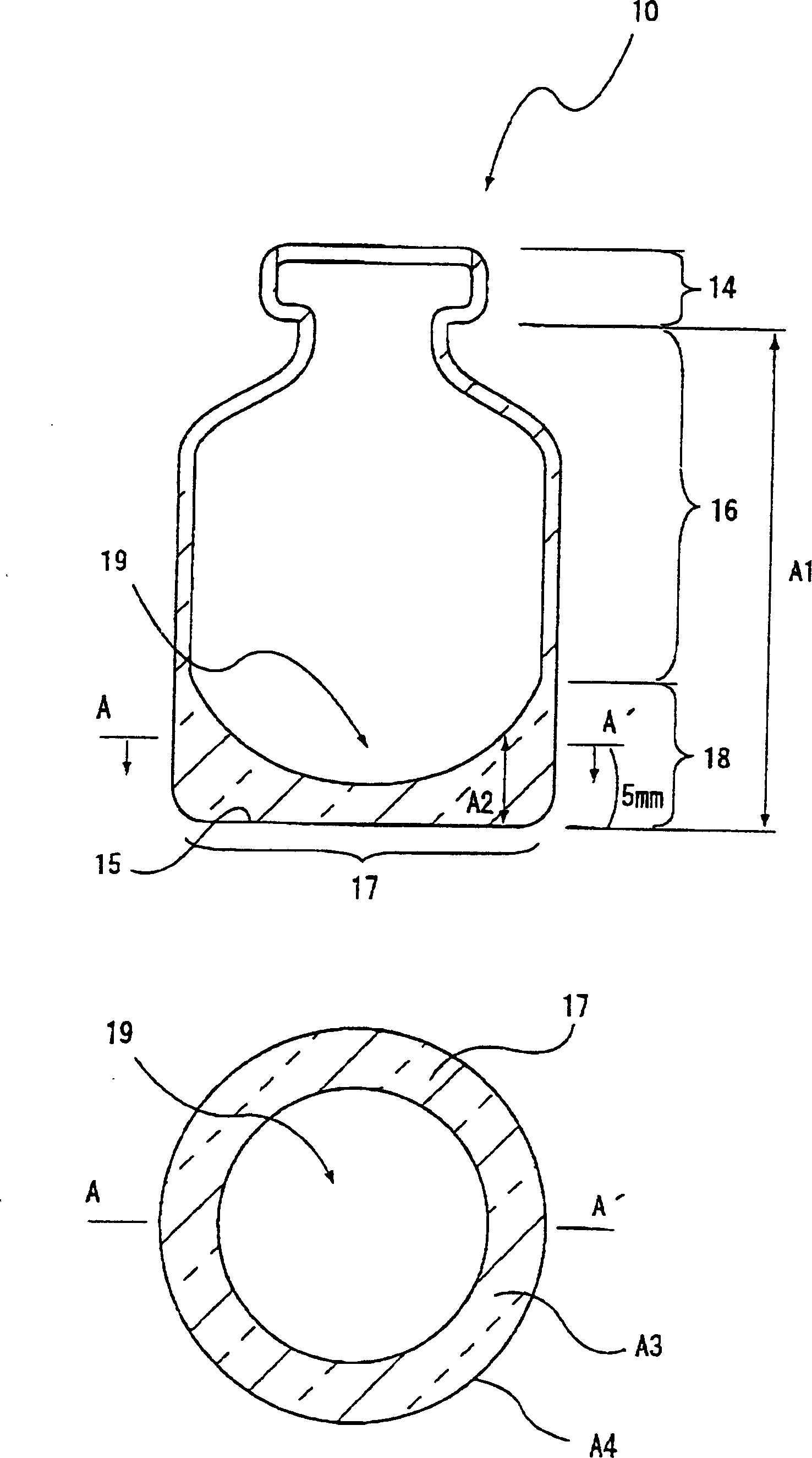

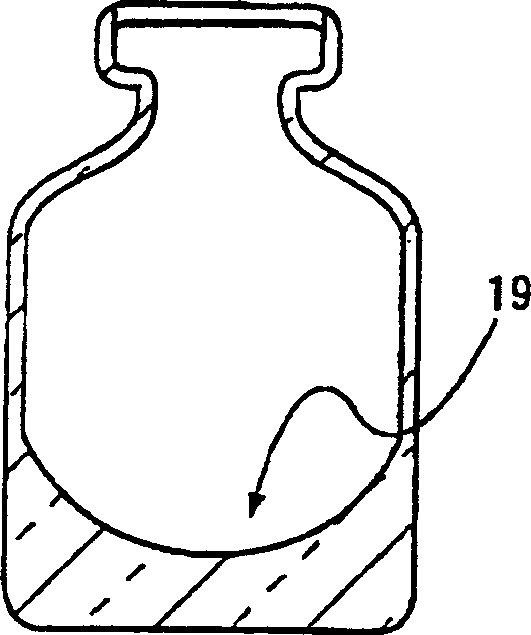

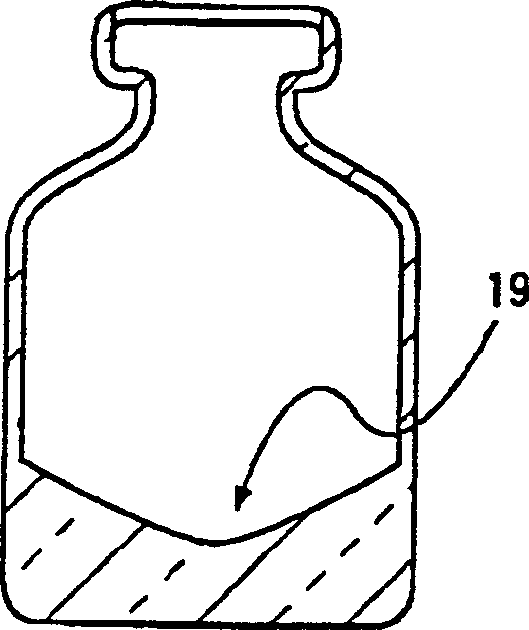

[0044] 1st embodiment, such as figure 1 As shown, the bottom 18 and the bottom wall 17 of the glass container 10 in this example are very thick, and the bottom of the cavity is concave 19 .

[0045] Hereinafter, each main point will be described in detail by taking the example glass container of the first embodiment as an example.

[0046] 1. Glass container

[0047] (1) shape

[0048] The shape of the glass container is not particularly limited, and it may be a narrow-mouth bottle, a rectangular bottle, a barrel-shaped bottle, an oval-shaped bottle, or a special-shaped bottle according to the application.

[0049] The ideal shape is as figure 1 The narrow mouth bottle shown.

[0050] The narrow-mouth bottle 10 has a bottleneck 14 above, a body 16 in the middle, and a bottom 18 below. The bottle base 18 is formed by the bottle wall 17 and the recess 19 .

[0051] The height of the glass container (called A1) should be controlled within the range of 20~150mm.

[0052] ...

no. 2 example

[0081] The second embodiment, as shown in FIG. 3, refers to a method of manufacturing a glass container with a low center of gravity and a concave bottom of the cavity. The blow molding die 43 is used together with the protruding bulkhead 20 to blow the molten glass 31 into a glass container.

[0082] Hereinafter, each main point of a manufacturing method is demonstrated in detail.

[0083] 1. Glass container

[0084] The detailed description has already been given in the first embodiment, so it will be omitted here.

[0085] 2. Blow molding mold

[0086] Containers produced by the blow molding method have high precision and high production efficiency. Mold As shown in Fig. 4 (a), (b), should use initial mold 43 and forming mold 103.

[0087] The blow molding mold is divided into the initial mold and the finished mold, which are introduced separately.

[0088] (1) initial model

[0089] The initial mold can be changed according to the specific shape of the glass containe...

example

[0128] The content of the present invention is described in more detail below by examples. Of course, the technical scope of the present invention is not limited to the examples, and can be appropriately adjusted within the purpose scope of the present invention according to actual conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com