Heat insulating container and manufacture method therefor

a technology of heat insulation container and manufacturing method, which is applied in the direction of manufacturing tools, domestic cooling equipment, lighting and heating equipment, etc., can solve the problems of difficult to produce heat insulation containers, low performance of radiation heat prevention film formed from metal oxide, etc., and achieve excellent thermal insulation capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

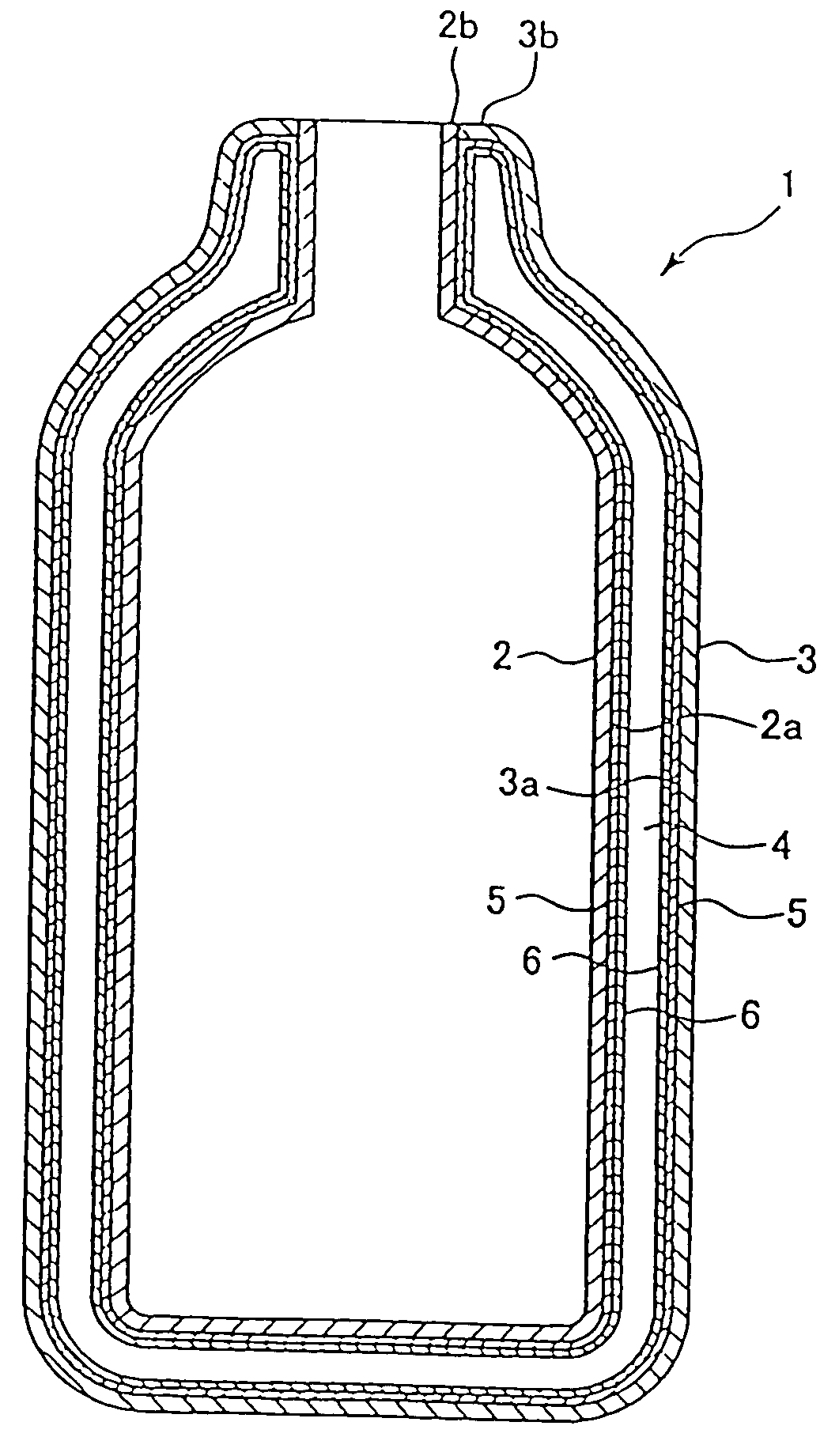

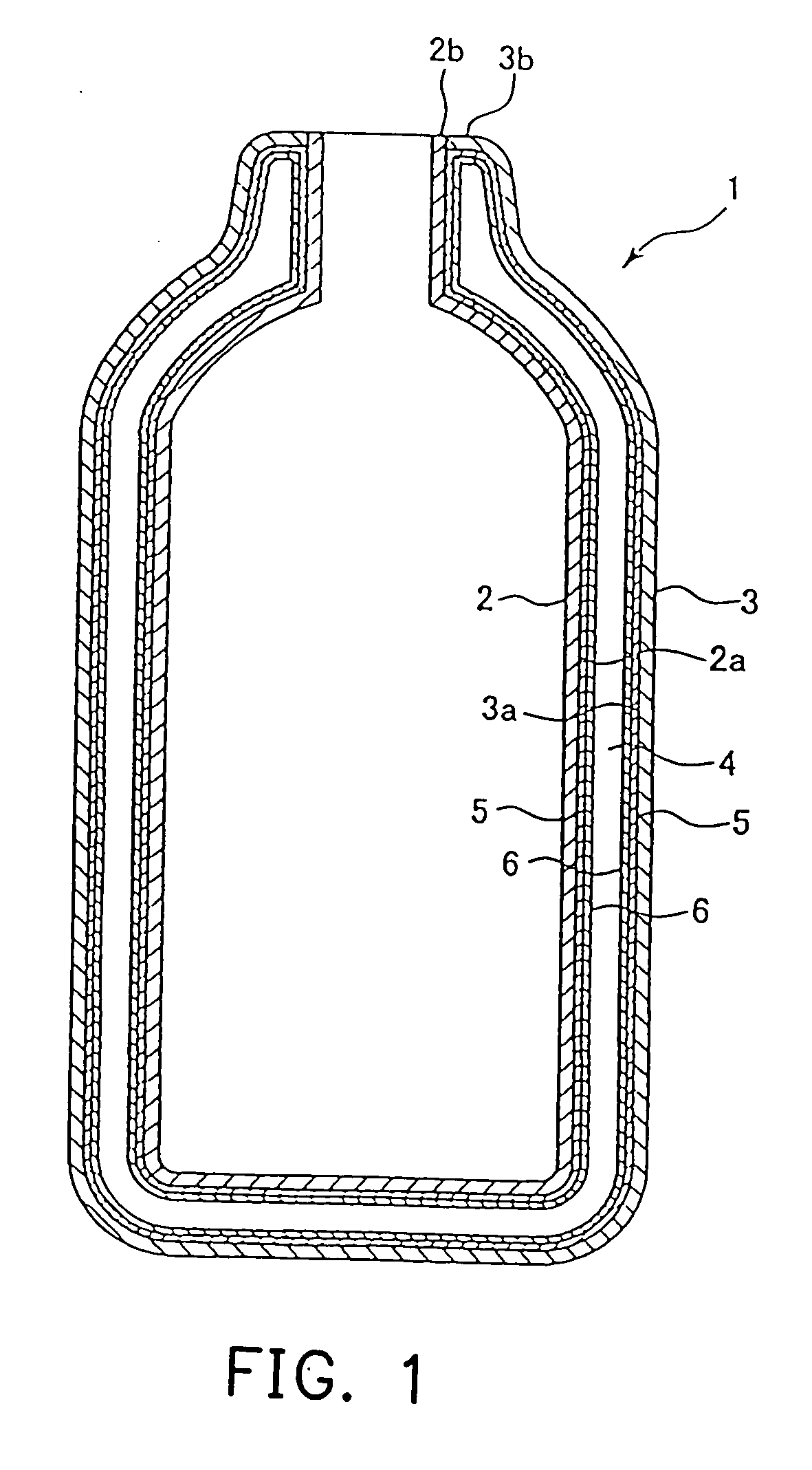

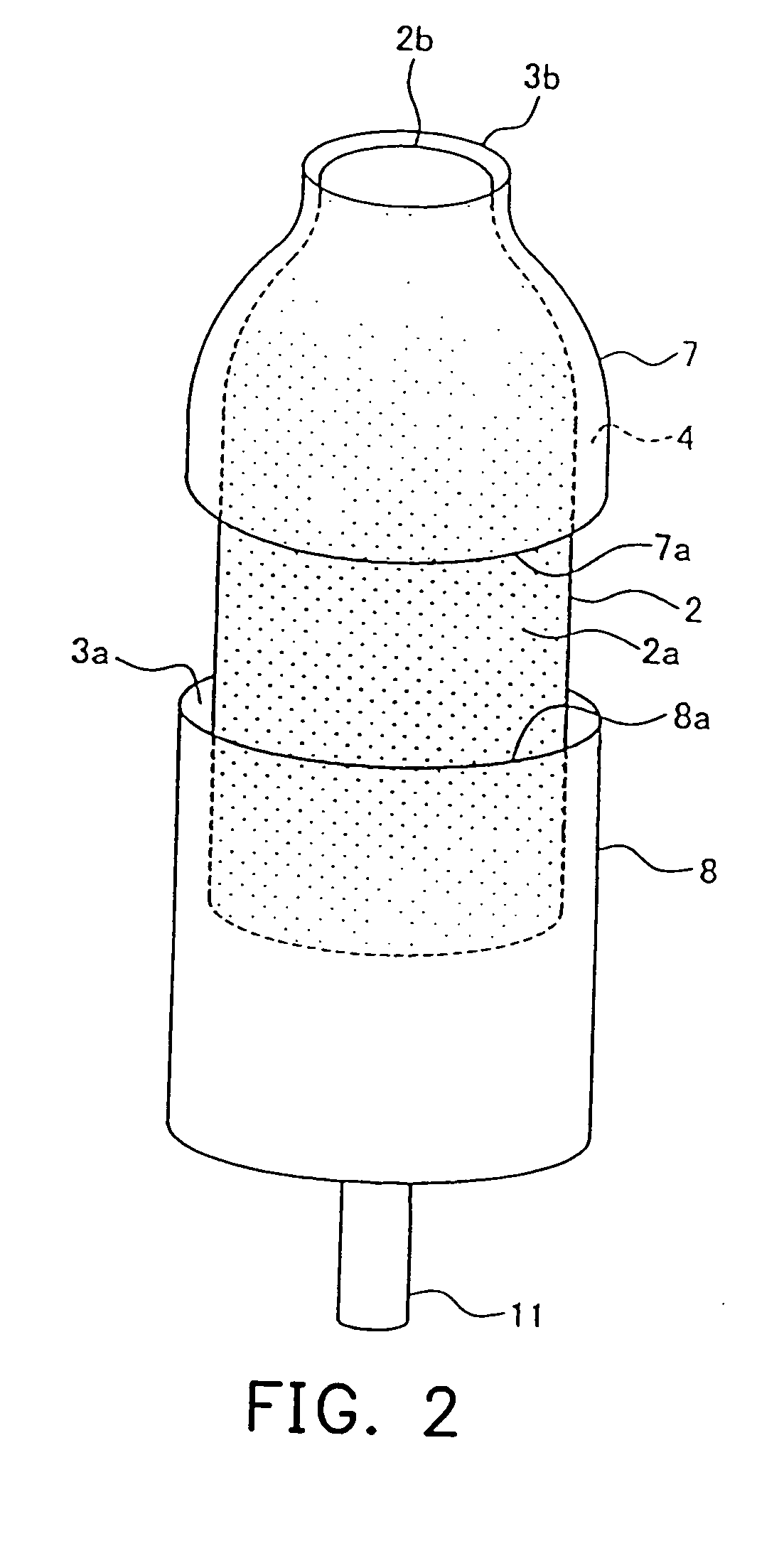

[0031] Refer to FIG. 1, which illustrates a sectional view of a heat insulating container according to a preferred embodiment of the present invention. In the heat insulating container 1 of the preferred embodiment, an inner glass container 2 is housed in an outer glass container 3 with a gap 4 formed in-between as a heat insulating layer.

[0032] The inner container 2 and the outer container 3 are joined together at respective opening ends 2b, 3b and integrated. In a preferred embodiment, both containers are joined together in an airtight manner by heating and softening the opening ends 2b and 3b, so as to make the gap 4 airtight.

[0033] The shape of the inner container 2 or the outer container 3 is not specifically restricted, and can be a cylinder shape, a ball shape or the like. However, in order to keep the width of the gap 4 between the inner container 2 and the outer container 3 approximately uniform, it is preferred that the inner container 2 and the outer container 3 have si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com