Anti-static anti-bacterial chitosan-casein composite leather finishing agent and preparation method thereof

A leather finishing agent, chitosan technology, applied in the direction of chitin polysaccharide coatings, conductive coatings, casein coatings, etc., to achieve the effect of improving quality and grade, increasing commercial value and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

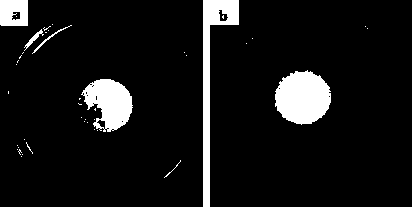

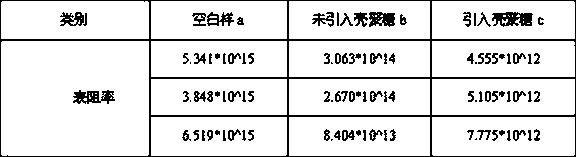

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of antistatic antibacterial chitosan-casein composite leather finishing agent, it is characterized in that, comprises the following steps:

[0030] Step 1: dissolving of chitosan;

[0031] Step 2: the dissolution of casein;

[0032] Step 3: Preparation of chitosan-casein composite leather finishing agent.

[0033] Described step is specifically: following is volume fraction,

[0034] Step 1: Dissolution of chitosan

[0035] Dissolve 1g~4g chitosan in 1%~8% acetic acid aqueous solution, set the temperature, stir, and the obtained solution is liquid A;

[0036] Step 2: Dissolution of casein

[0037] Dissolve 2~6g casein in 3%~5% acidic aqueous solution at a certain temperature, and stir, the obtained solution is B liquid;

[0038] Step 3: Preparation of chitosan-casein composite leather finishing agent

[0039] After ultrasonicating liquid A for 15 minutes, add liquid B dropwise into liquid A, heat up, stir, and tu...

Embodiment 1

[0047] Step 1: Dissolution of chitosan

[0048] Dissolve 1g of chitosan in 5% acetic acid aqueous solution prepared in advance, set the temperature at 55°C, adjust the speed at 400r / min, and stir overnight. The reaction time was 12 hours, and the resulting solution was marked as liquid A.

[0049] Step 2: Dissolution of casein

[0050] Dissolve casein in 5% acetic acid aqueous solution under the condition of temperature of 60°C, adjust the rotation speed to 300r / min, and stir for 2 hours. The resulting solution was labeled as solution B.

[0051] Step 3: Preparation of chitosan-casein composite leather finishing agent

[0052]After the liquid A dissolved according to step 1 is ultrasonicated for 15 minutes, then add the liquid B to the liquid A drop by drop, set the temperature at 60°C, adjust the speed at 300r / min, and stir for 4 hours. The obtained solution is marked as liquid C. Add 2% glycerin and 2% polydimethylsiloxane to liquid C, and the emulsification time is 10 m...

Embodiment 2

[0054] Step 1: Dissolution of Chitosan

[0055] Dissolve 2g of chitosan in 3% acetic acid aqueous solution prepared in advance, set the temperature at 60°C, adjust the speed at 400r / min, and stir overnight. The reaction time was 10h, and the resulting solution was marked as liquid A.

[0056] Step 2: Dissolution of casein

[0057] Dissolve the casein in 3% acetic acid aqueous solution under the condition of 65°C, adjust the rotation speed to 300r / min, and stir for 3 hours. The resulting solution was labeled as solution B.

[0058] Step 3: Preparation of chitosan-casein composite leather finishing agent

[0059] After the liquid A dissolved according to step 1 was ultrasonicated for 10 minutes, then the liquid B was added dropwise to the liquid A, the temperature was set at 70°C, and the speed was adjusted to 300r / min, and stirred for 3 hours. The obtained solution was marked as C liquid, and in the Add 1% glycerin and 1% polydimethylsiloxane to liquid C, emulsify for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com