Antibacterial casein-based nano ZNO composite leather finishing agent and preparation method thereof

A kind of leather finishing agent and nano technology, which is applied in the field of antibacterial casein-based nano-ZnO composite leather finishing agent and its preparation, which can solve the problem of unstable chemical properties, easy to be corroded by bacteria, etc., and limit the development of casein leather finishing agents, etc. problem, to achieve the effect of excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

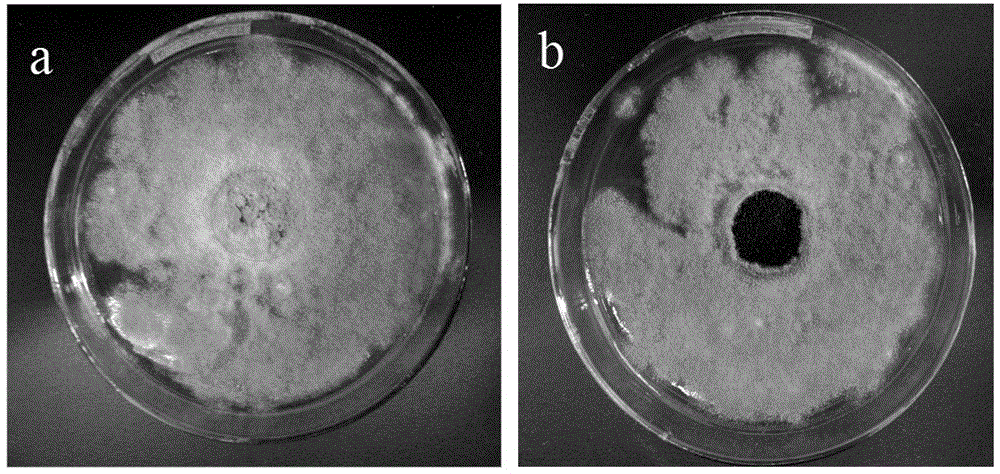

Image

Examples

preparation example Construction

[0029] The preparation method of the antibacterial type casein-based nanometer ZnO composite leather finishing agent that the present invention relates to, comprises the following steps:

[0030] Step 1: Preparation of casein solution:

[0031] Weigh 1.5~6.1 parts by weight of casein, 0.5~2.0 parts by weight of lye and 25.0~40.0 parts by weight of deionized water and add them into a three-necked flask. 0.5~2.5h to obtain casein solution;

[0032] Step 2: Preparation of Nano ZnO Dispersion Liquid:

[0033] Weigh 5.0-25.0 parts by weight of deionized water and 1.5-4.0 parts by weight of nano-ZnO in a beaker, and disperse nano-ZnO in water to obtain a nano-ZnO dispersion;

[0034] Step 3: Preparation of Casein-Based Nano-ZnO Composite Emulsion:

[0035] Composite the nano-ZnO dispersion obtained in step 2 with the casein solution obtained in step 1 according to the mass ratio of (1.68~1.90):1, and the composite time is 0.5~3h.

[0036] In step 1, the lye is selected from trie...

Embodiment 1

[0045] Step 1: Preparation of casein solution:

[0046] Weigh 1.5 parts by weight of casein, 2.0 parts by weight of lye and 25.0 parts by weight of deionized water and add them into a three-necked flask. The temperature of the water bath is 70° C., the stirring speed is 100 r / min, and the casein solution is obtained by heating for 2.5 hours;

[0047] Step 2: Preparation of Nano ZnO Dispersion Liquid:

[0048] Weigh 5.0 parts by weight of deionized water and 4.0 parts by weight of nano-ZnO in a beaker, and disperse nano-ZnO in water to obtain a nano-ZnO dispersion;

[0049] Step 3: Preparation of Casein-Based Nano-ZnO Composite Emulsion:

[0050] Composite the nano-ZnO dispersion liquid obtained in step 2 with the casein solution obtained in step 1 according to the mass ratio of 1.68:1, and the compounding time is 3 hours.

[0051] In step one, the lye selected mass fraction is 30% triethanolamine aqueous solution.

[0052] In step two:

[0053] Magnetic stirring is used fo...

Embodiment 2

[0060] Step 1: Preparation of casein solution:

[0061] Weigh 3.8 parts by weight of casein, 1.2 parts by weight of lye and 22.5 parts by weight of deionized water and add them into a three-necked flask. The temperature of the water bath is 60° C., the stirring speed is 250 r / min, and the casein solution is obtained by heating for 1.5 hours;

[0062] Step 2: Preparation of Nano ZnO Dispersion Liquid:

[0063] Weigh 15.0 parts by weight of deionized water and 2.7 parts by weight of nano-ZnO in a beaker, and disperse nano-ZnO in water to obtain a nano-ZnO dispersion;

[0064] Step 3: Preparation of Casein-Based Nano-ZnO Composite Emulsion:

[0065] Composite the nano-ZnO dispersion obtained in step 2 with the casein solution obtained in step 1 according to the mass ratio of 1.79:1, and the composite time is 1.7 h.

[0066] In step one, the lye is selected as a 30% aqueous solution of hydroxyethylethylenediamine in mass fraction.

[0067] In step two:

[0068] Magnetic stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com