Fireproof oil paint

A technology of fire-resistant paint and mica powder, which is applied in the field of paint, can solve the problems of high cost, difficult to make up for, and poor fire-proof effect, and achieve good flame-retardant effect, good corrosion resistance and crack resistance, and improved heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

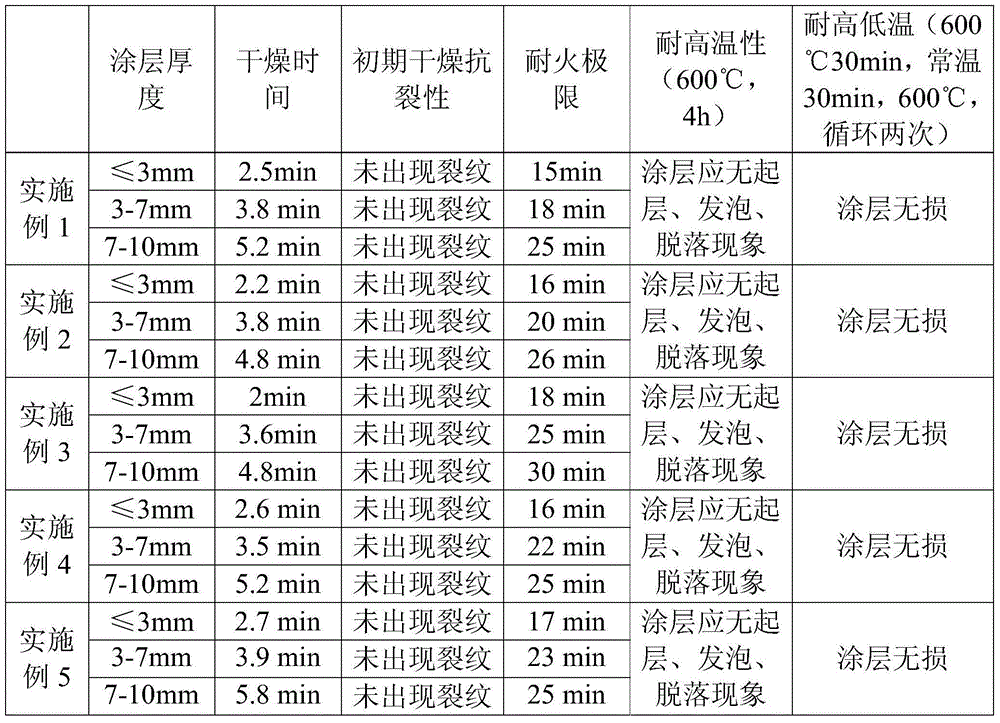

Examples

Embodiment 1

[0019] A kind of fireproof paint, the mass parts composition of described fireproof paint is as follows: 6 parts of stearic acid, 6 parts of sorbitan stearic acid, 3 parts of carbomer, 1.8 parts of mica powder, 5 parts of acrylic resin modified casein film-forming agent part, 0.2 part of flame retardant additive, and 8 parts of zeolite powder.

[0020] Wherein, the particle size of the mica powder is 10nm.

[0021] Wherein, the flame retardant additive is selected from water glass.

[0022] Wherein, the particle size of the zeolite powder is 500 mesh.

Embodiment 2

[0024] A fireproof paint, the composition of the mass parts of the fireproof paint is as follows: 8 parts of stearic acid, 7 parts of sorbitan stearic acid, 4 parts of carbomer, 2.1 parts of mica powder, 6 parts of acrylic resin modified casein film-forming agent parts, 0.3 parts of flame retardant additives, and 10 parts of zeolite powder.

[0025] Wherein, the particle size of the mica powder is 10nm, and the mica powder is modified mica powder, modified with silane coupling agent KH-570.

[0026] Wherein, the flame retardant additive is a mixture of modified amino resin and vinyl chloride copolymer resin, the mass ratio of which is 1:1.2.

[0027] Wherein, the particle size of the zeolite powder is 600 mesh.

Embodiment 3

[0029] A kind of fireproof paint, the mass parts composition of described fireproof paint is as follows: 9 parts of stearic acid, 8 parts of sorbitan stearic acid, 4.5 parts of carbomer, 3.2 parts of mica powder, 8 parts of acrylic resin modified casein film-forming agent part, 0.5 part of flame retardant additive, and 12 parts of zeolite powder.

[0030] Wherein, the particle size of the mica powder is 30nm; the mica powder is modified mica powder. Modified with silane coupling agent KH-570.

[0031] Wherein, the flame retardant additive is a mixture of modified amino resin and vinyl acetate copolymer resin, the mass ratio of which is 1:1.5.

[0032] Wherein, the particle size of the zeolite powder is 600 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com