ETFE film material processing equipment with negative pressure prevention function

A technology of ETFE film and processing equipment, applied in the field of film material processing, can solve the problems of negative impact of ETFE film material, lack of natural cooling guarantee mechanism, etc., and achieve the effect of avoiding high pressure and negative pressure environment and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

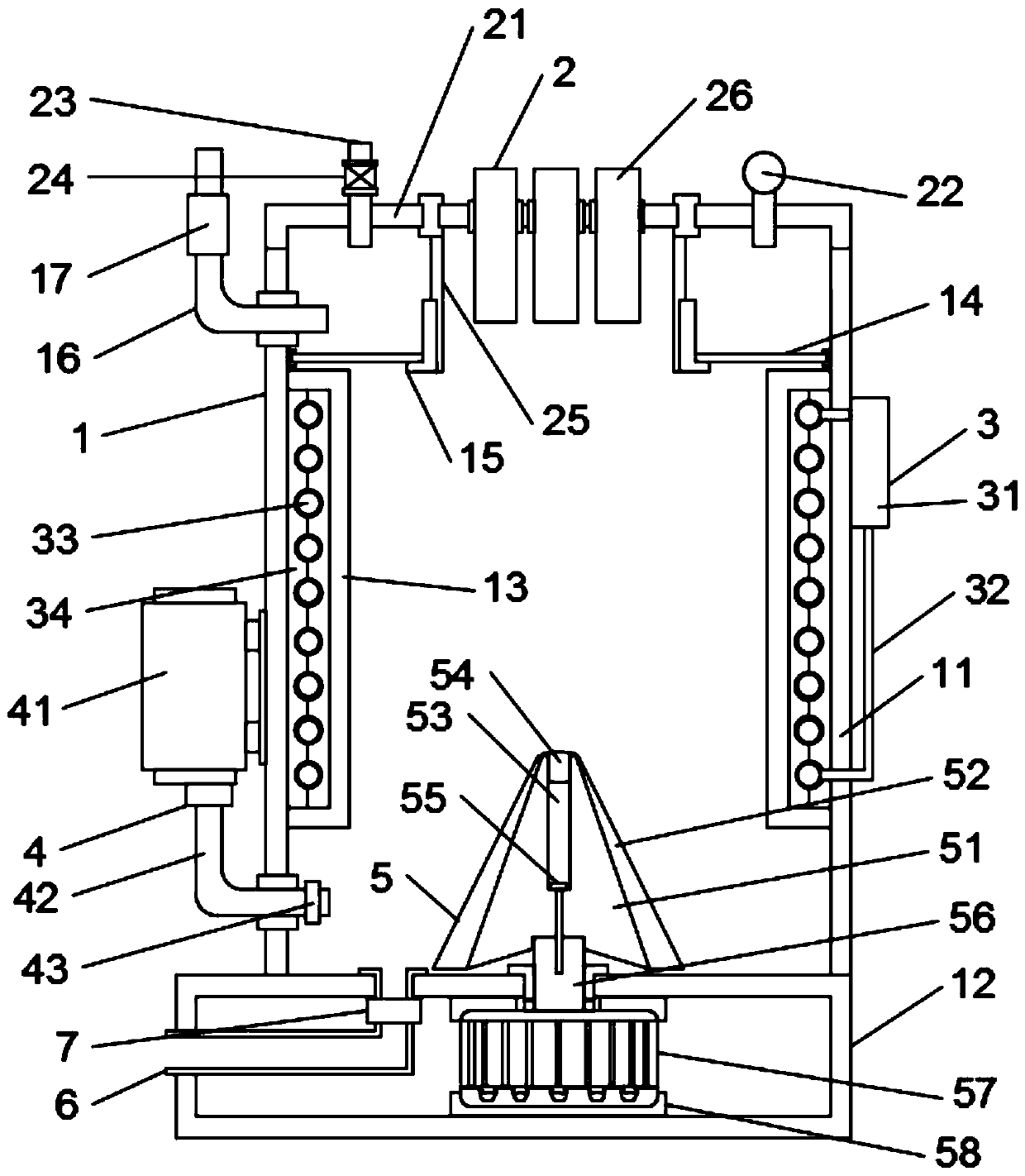

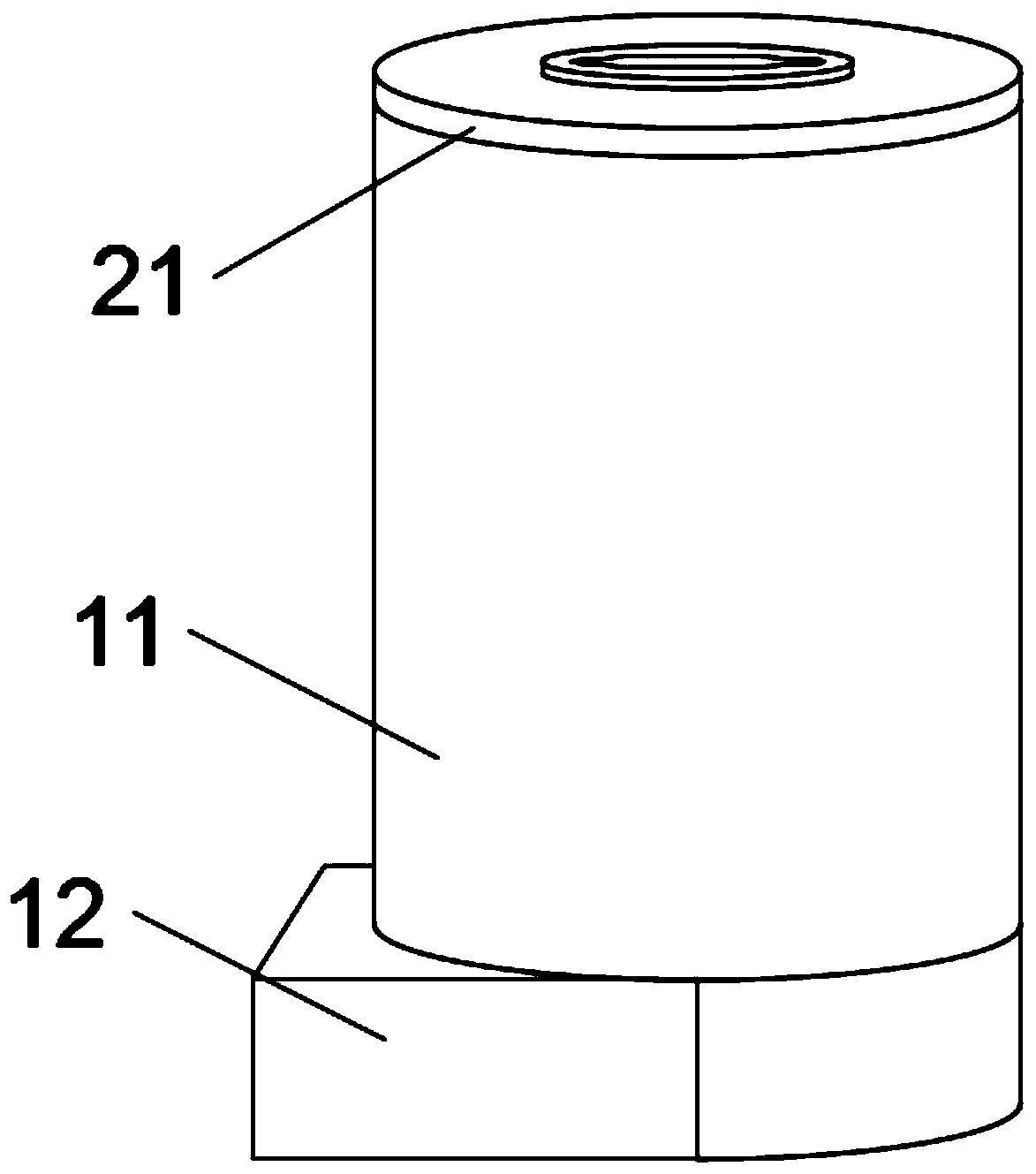

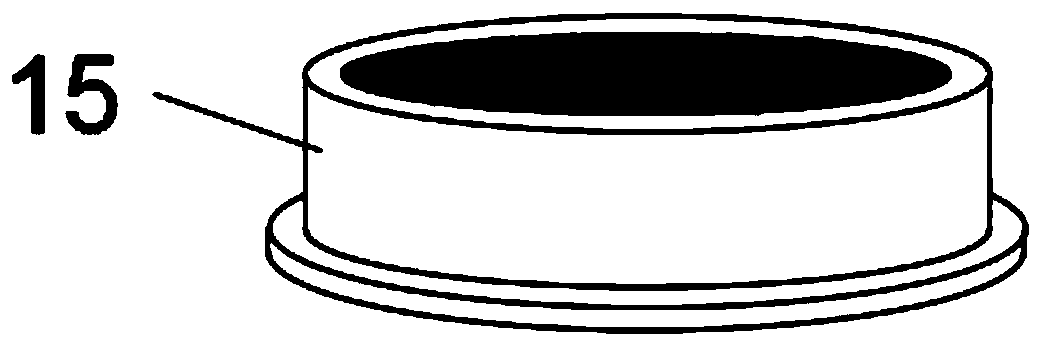

[0027] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a kind of ETFE film material processing equipment with anti-negative pressure function, including a housing mechanism 1, the upper end of the housing mechanism 1 is connected with a cover body mechanism 2, and the housing mechanism 1 The inside of the mechanism 1 is provided with a heating mechanism 3, and the bottom of the housing mechanism 1 is provided with a stirring mechanism 5, the lower part of the housing mechanism 1 is connected with a booster mechanism 4, and the housing mechanism 1 includes a main housing 11 , bottom shell 12, inner shell 13, upper filter screen 14, connecting pipe 15, intake pipe 16 and anti-negative pressure valve 17, the bottom of described main shell 11 is connected with bottom shell 12, and described main shell 11 is sealed and welded on the upper side of the bottom shell 12, the inside of the main shell 11 is sealed and welded with an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com