Roller mill with sealing gas impingement

A mill and drum technology, which is applied to coal mills, rotary grinding tables, and the field of operating such drum mills, can solve the problems of increased cost and increased cost, and achieve the effect of low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

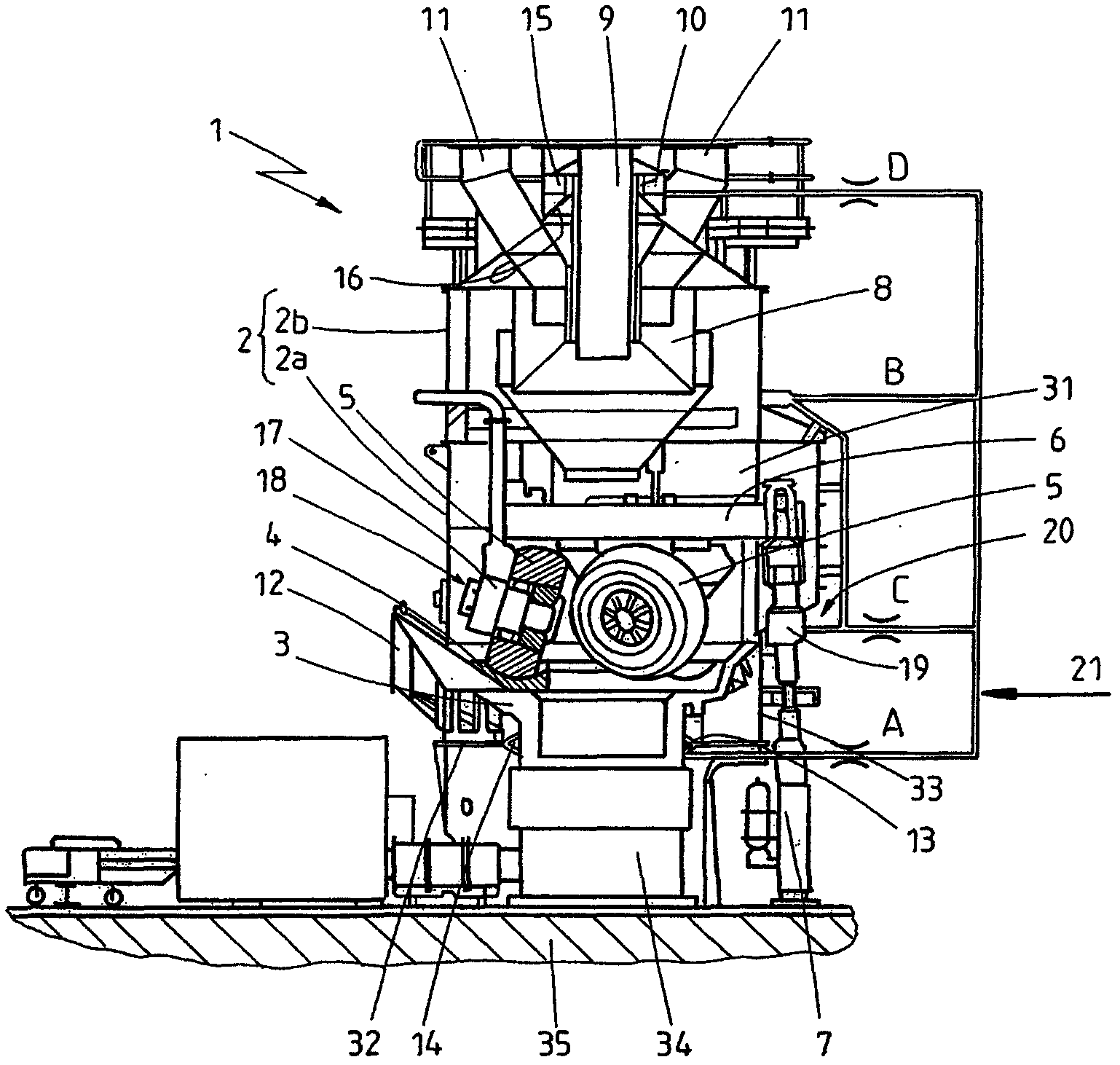

[0030] Drum mill as coal mill (in figure 1 1 ) has a mill housing (denoted as a whole by 2 ) comprising the actual mill housing 2 a and the screening housing 2 b. A rotating grinding table 4 is arranged on the bottom side of the grinding bowl carrier 3 in the mill housing 2a. A grinding roll 5 as a grinding tool is located on the rotary grinding table 4 . The grinding rollers are pressed against the grinding table 4 by means of a pressure frame 6 cooperating with connecting rods 7 . The grinding bowl carrier 3 is arranged on the transmission device 34 , and the transmission device 34 is placed on the base 35 . Centrally located in the upper region of the sifter housing 2b is a sieving machine 8 which is fastened by means of a suspension 10 to the outside of a central grind feed 9 in the form of a central grind feed tube and which surrounds the grind feed. Feeding device 9 rotates. Two grinding stock discharges 11 lead to the outside of the sifter housing 2b. Formed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com