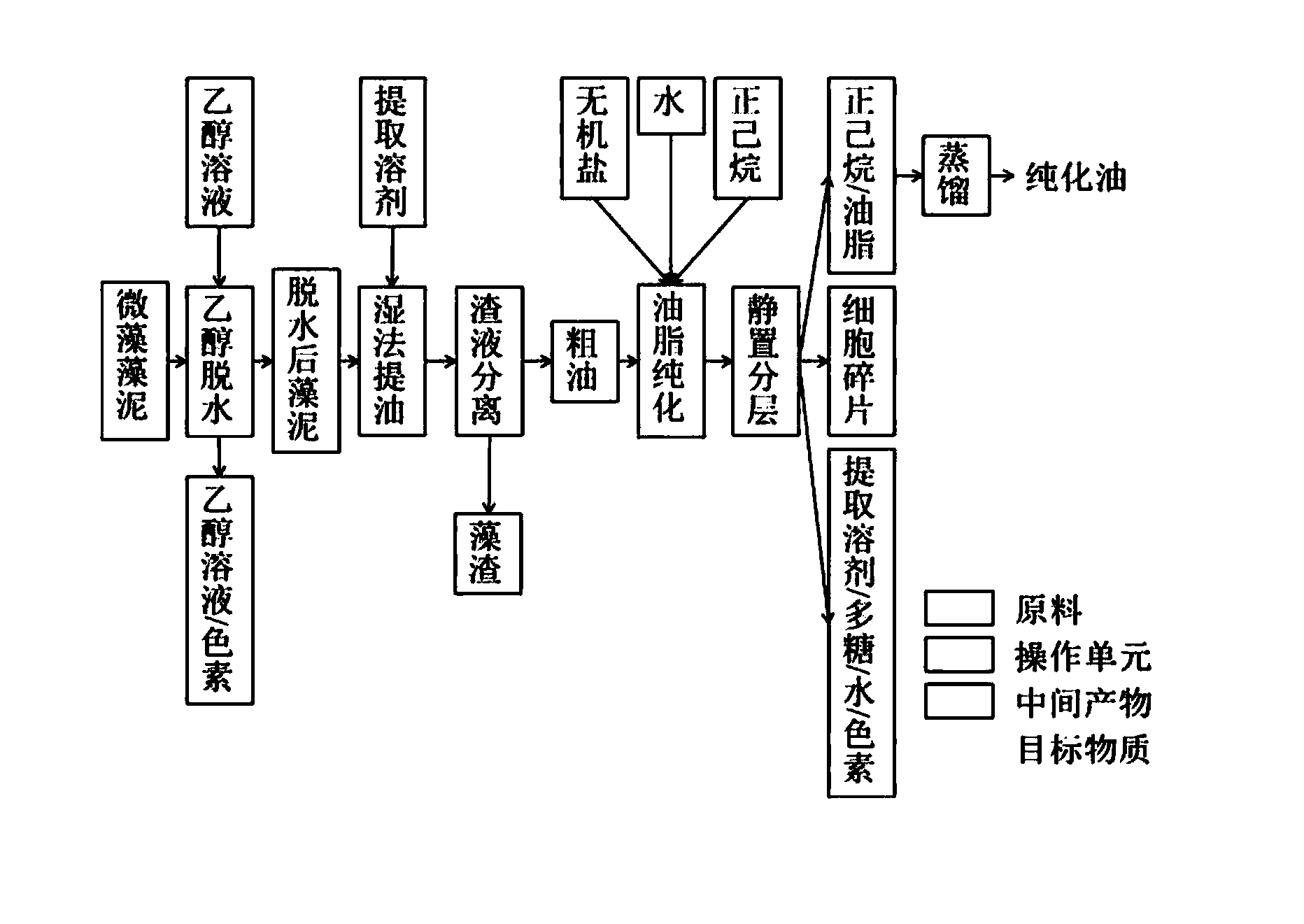

Method for wet extraction of purified microalgae oil

A microalgae algal oil and wet process technology, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, can solve the problems of high equipment and energy input, high price of ionic liquid, low oil extraction rate, etc. Low equipment and energy costs, easy industrial application, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for extracting and purifying microalgae oil by ethanol dehydration-wet oil extraction-n-hexane extraction, according to the following steps:

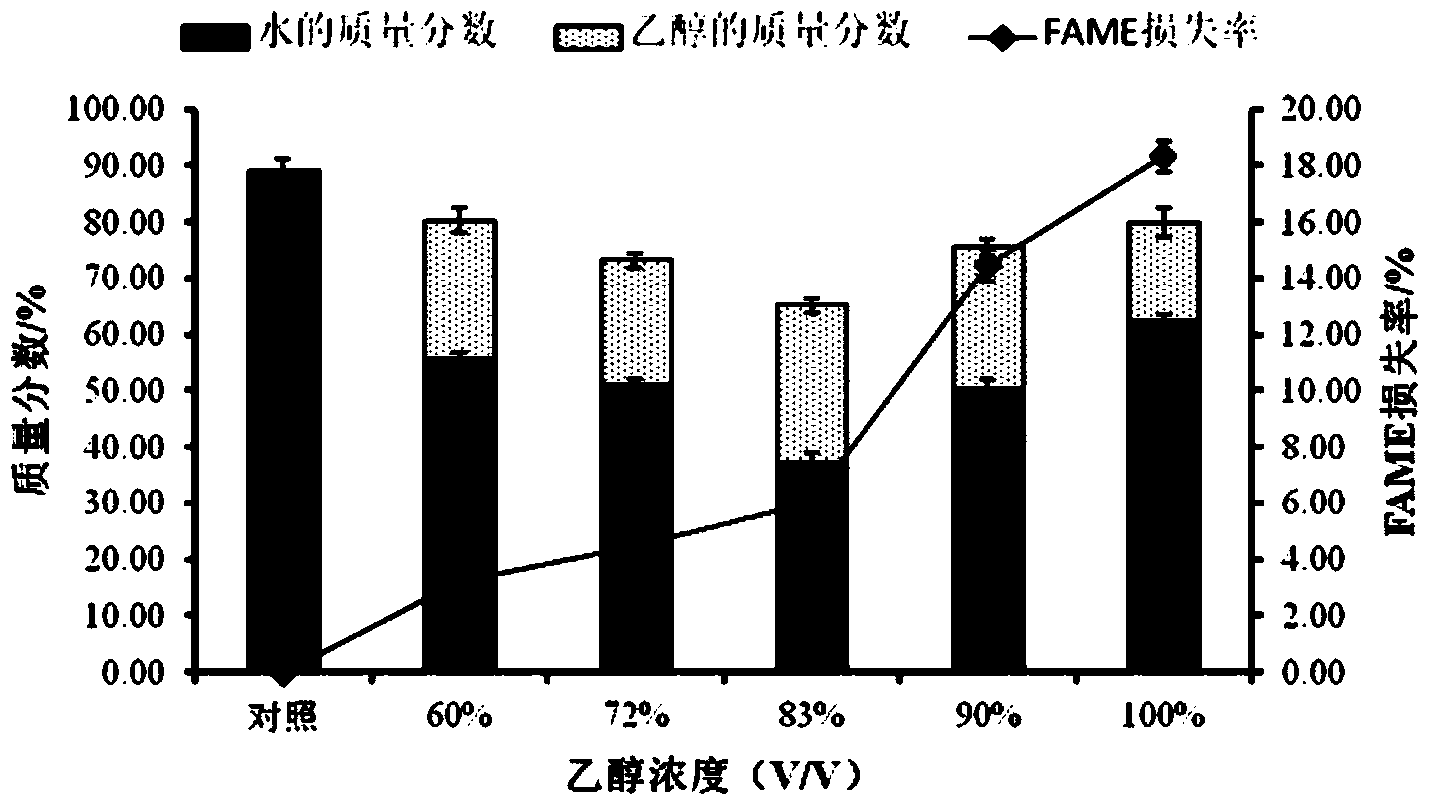

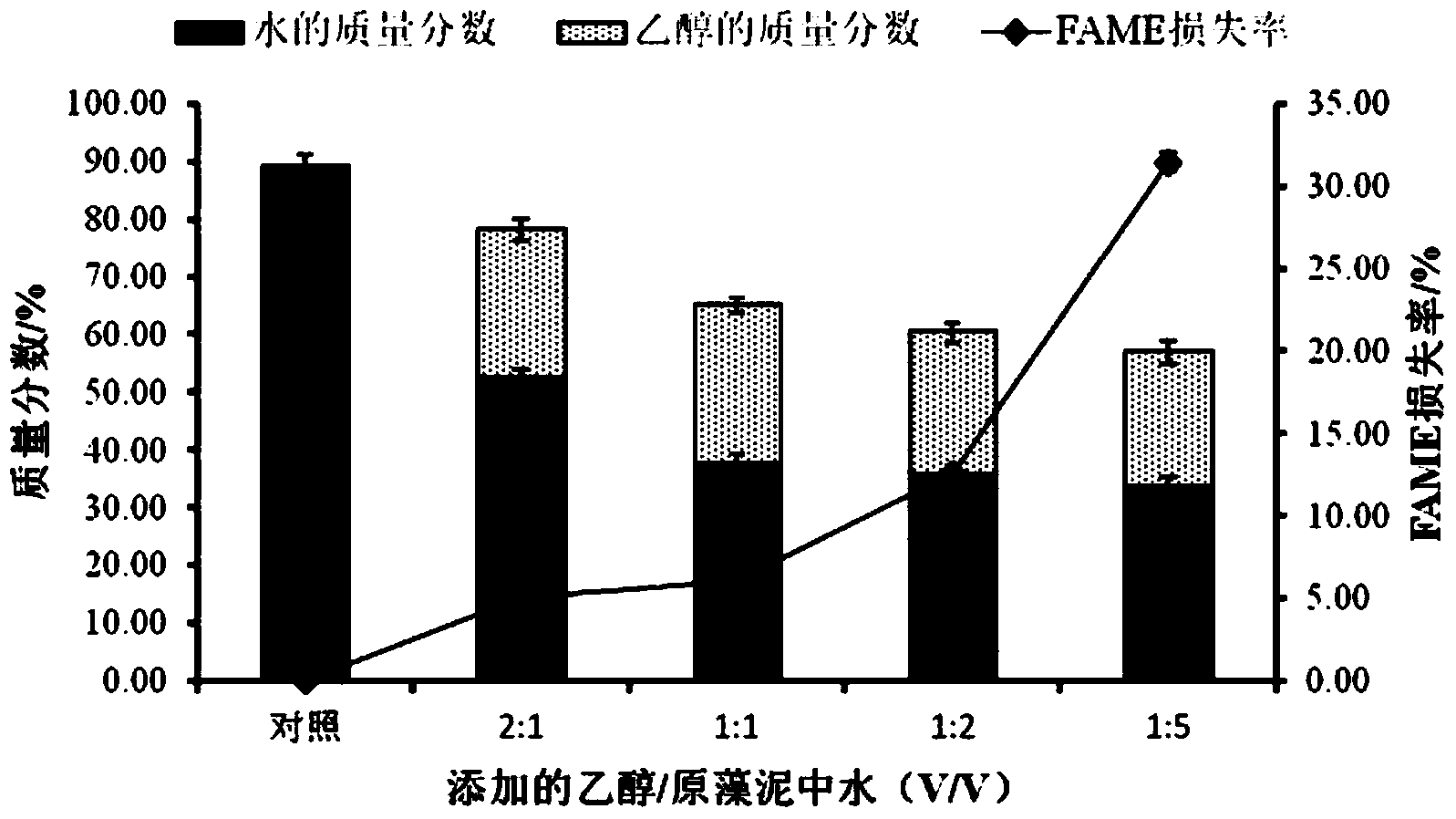

[0047] 1) Dehydration treatment: Weigh 5g of harvested microalgae mud into a 50mL sterile centrifuge tube, add ethanol solution to the microalgae mud, the addition of the ethanol solution is 1% of the water contained in the microalgae mud Double the volume, the ethanol solution is 83% (V / V) ethanol aqueous solution, after adding the ethanol solution, vortex for 0.5min, centrifuge at 10000r / min for 5min, collect the precipitate, and obtain the dehydrated algae mud;

[0048] After testing, the water content in the algae mud after dehydration drops from 90% of the freshly harvested algae mud to 37.41%. During the dehydration process, the loss rate of FAME was only 6.02%.

[0049] 2) Wet oil extraction: put the dehydrated algae mud in step 1 in a microwave reaction tank (Milestone ETHOS A), and add 20 mL of 95% (v / v) Ethan...

Embodiment 2

[0054] A method for extracting and purifying microalgae oil by ethanol dehydration-wet oil extraction-n-hexane extraction, according to the following steps:

[0055] 1) Dehydration treatment: Weigh 5g of harvested microalgae mud into a 50mL sterile centrifuge tube, add ethanol solution to the microalgae mud, the amount of the ethanol solution is 0.5% of the water contained in the microalgae mud Double the volume, the ethanol solution is 72% (V / V) ethanol aqueous solution, after adding the ethanol solution, vortex for 0.5min, centrifuge at 10000r / min for 5min, collect the precipitate, and obtain the dehydrated algae mud;

[0056] After testing, the water content in the algae mud after dehydration drops from 90% of the freshly harvested algae mud to 54.47%. During this dehydration process, the FAME loss rate was 4.21%.

[0057] 2) Wet oil extraction: put the dehydrated algae mud in step 1 in a microwave reaction tank (Milestone ETHOS A), and add 10 mL of 95% (v / v) Ethanol aque...

Embodiment 3

[0062] A method for extracting and purifying microalgae oil by ethanol dehydration-wet oil extraction-n-hexane extraction, according to the following steps:

[0063] 1) Dehydration treatment: take 5g of harvested microalgae sludge in a 50mL sterile centrifuge tube, add ethanol solution to the microalgae sludge, the amount of the ethanol solution is 2% of the water contained in the microalgae sludge Double the volume, the ethanol solution is 90% (V / V) ethanol aqueous solution, after adding the ethanol solution, vortex for 0.5min, centrifuge at 10000r / min for 5min, collect the precipitate, and obtain the dehydrated algae mud;

[0064] After testing, the water content in the algae mud after dehydration drops from 90% of the freshly harvested algae mud to 48.34%. During the dehydration process, the loss rate of FAME was only 16.12%.

[0065] 2) Wet oil extraction: put the dehydrated algae mud in step 1 in a microwave reaction tank (Milestone ETHOS A), and add 50 mL of 95% (v / v) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com