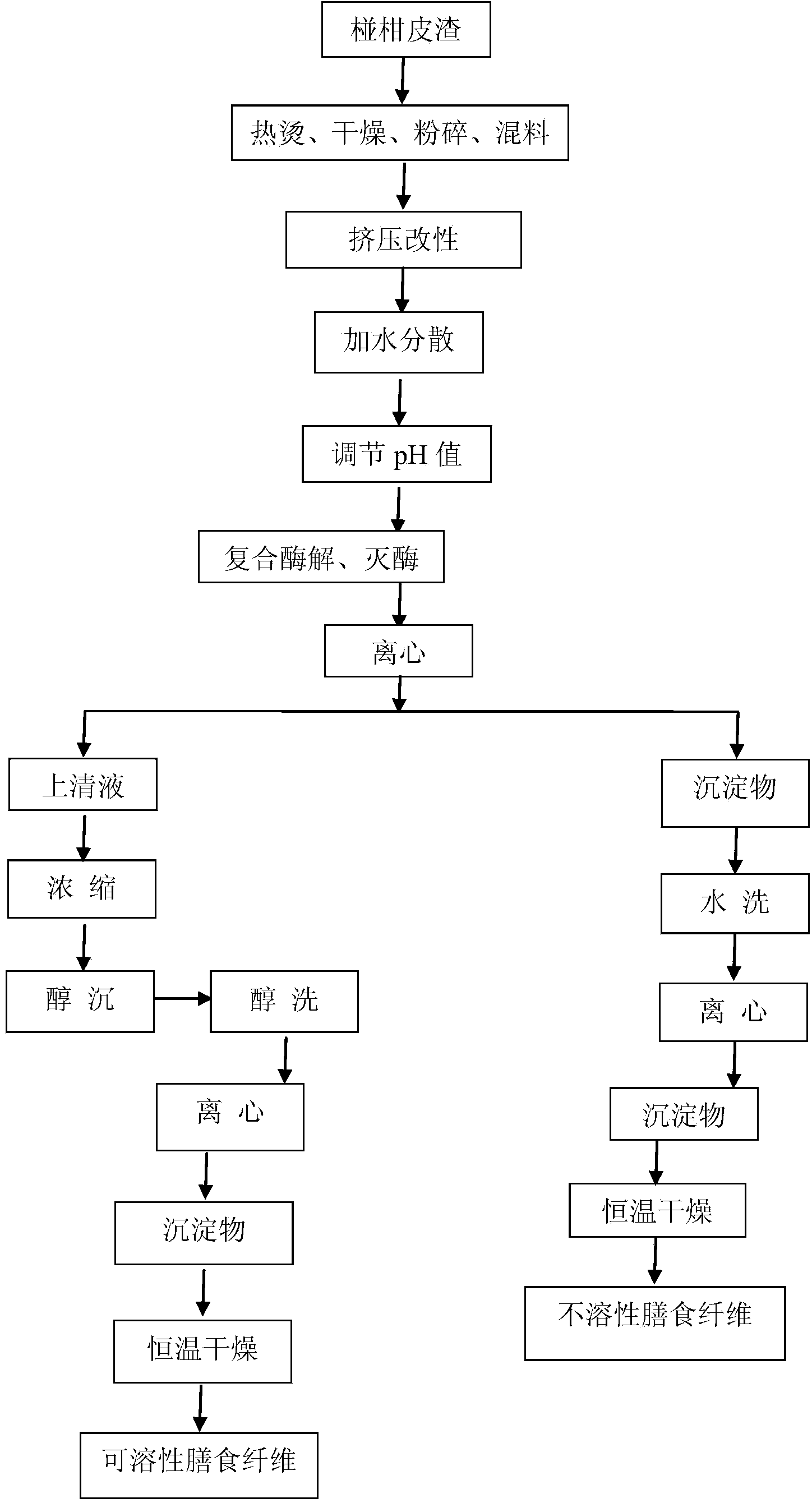

Method for extracting ponkan dietary fibers through extrusion modification and enzymolysis coupling

A technology of soluble dietary fiber and dietary fiber, which is applied in the directions of food extraction, function of food ingredients, food preparation, etc., can solve the problems that have not been reported, and achieve the effects of improving extraction rate, increasing oil holding capacity, and increasing swelling force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Pretreatment of raw materials: heat-treat the ponkan skin dregs obtained after the washed fresh ponkan fruit is squeezed for 1.5 minutes at a blanching temperature of 95°C. After blanching, the ponkan peel residue was drained, and dried in a 60°C electric constant-temperature blast drying oven for 48 hours. The water content was 8%, and it was crushed to 80 mesh to obtain the ponkan peel residue powder. The obtained powder was mixed with water, and the solid-to-liquid ratio was 100g: 25mL to obtain a mixture;

[0036] (2) Extrusion modification: the mixture obtained in step (1) is subjected to extrusion modification, the extrusion temperature is 130° C., the screw speed is 150 r / min, and the feed flow rate is 60 g / min;

[0037] (3) In addition to starch and protein: add water to the mixture after step (2) extrusion modification, the solid-to-liquid ratio is 1g: 3mL, stir evenly to make a dispersion liquid, and use NaOH solution with a concentration of 0.3mol / L Adju...

Embodiment 2

[0048] (1) Pretreatment of raw materials: the ponkan peel residue obtained after the washed fresh ponkan fruit was squeezed was subjected to heat treatment, and the blanching temperature was 90° C. for 2 minutes. After blanching, the ponkan peel residue was drained, and dried in a 60°C electric constant-temperature blast drying oven for 48 hours. The water content was 8%, and it was crushed to 80 mesh to obtain the ponkan peel residue powder. The obtained powder is mixed with water, and the solid-to-liquid ratio is 100g: 40mL to obtain a mixture;

[0049] (2) Extrusion modification: the mixture obtained in step (1) is subjected to extrusion modification, the extrusion temperature is 150° C., the screw speed is 140 r / min, and the feed flow rate is 70 g / min;

[0050] (3) Removal of starch and protein: Add water to the mixture modified by extrusion in step (2) and disperse it with a solid-to-liquid ratio of 1g: 4mL, stir evenly to make a dispersion, and use NaOH solution with a c...

Embodiment 3

[0061] (1) Pretreatment of raw materials: heat-treat the ponkan skin dregs obtained after the washed fresh ponkan fruit is squeezed for 3 minutes at a blanching temperature of 85°C. After blanching, the ponkan peel residue was drained, and dried in a 60°C electric constant-temperature blast drying oven for 48 hours. The water content was 8%, and it was crushed to 80 mesh to obtain the ponkan peel residue powder. The obtained powder is mixed with water, and the solid-to-liquid ratio is 100g: 50mL to obtain a mixture;

[0062] (2) Extrusion modification: the mixture obtained in step (1) is subjected to extrusion modification, the extrusion temperature is 160° C., the screw speed is 170 r / min, and the feed flow rate is 80 g / min;

[0063](3) Removing starch and protein: add water to the mixture after step (2) extrusion modification, the solid-to-liquid ratio is 1g: 5mL, stir evenly to make a dispersion liquid, and use NaOH solution with a concentration of 0.3mol / L Adjust the pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com