Method for extracting titanium from titanium-containing blast furnace slag by aluminothermy

A technology of blast furnace slag and process, which is applied in the field of titanium extraction from titanium-containing blast furnace slag, can solve the problems that acid leaching is difficult to complete and titanium minerals cannot be obtained, and achieves the effect of improving resource recovery and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

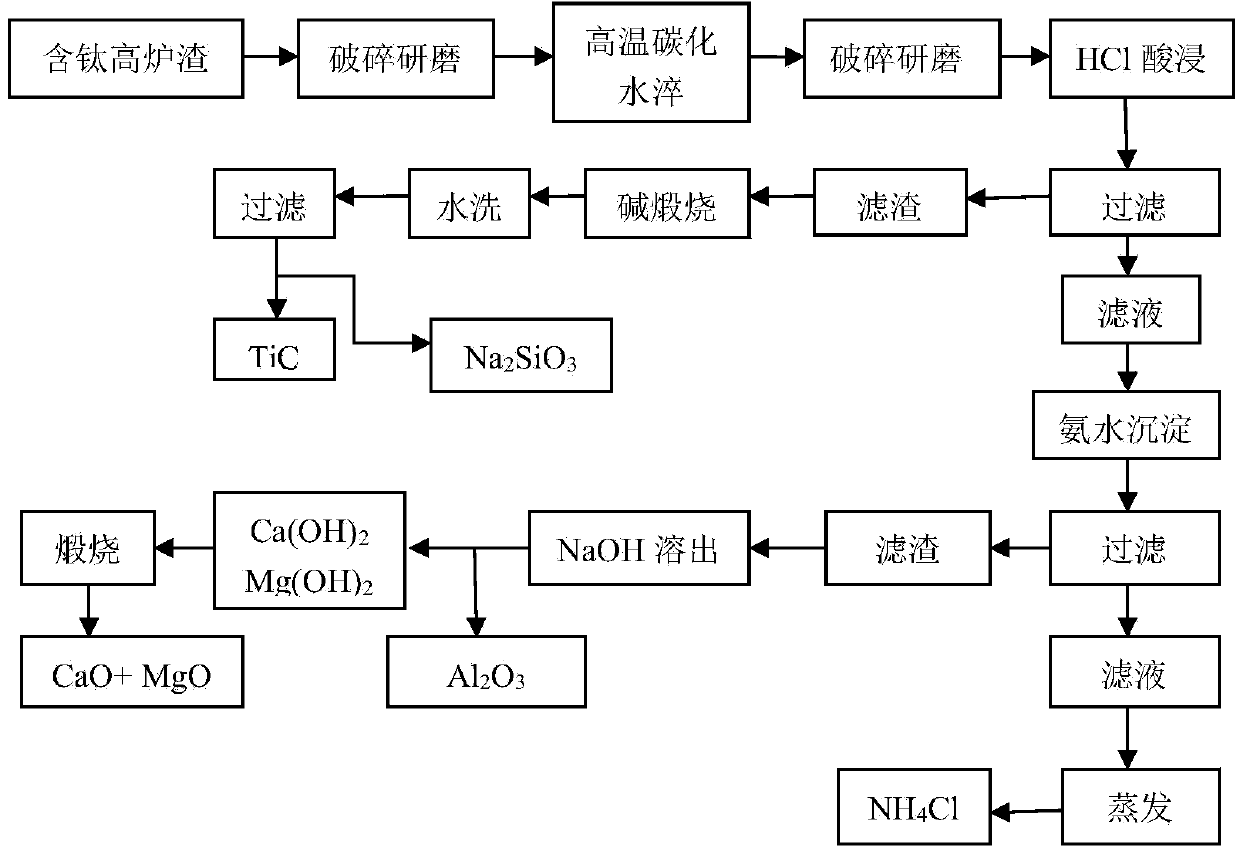

Image

Examples

Embodiment approach 1

[0028] 1) Crush and grind titanium-containing blast furnace slag to 180 mesh ± 10 mesh, and mix well.

[0029] 2) According to the mass ratio of slag: C=100:6.53, weigh 10 grams of titanium-containing blast furnace slag and 0.653 grams of carbon powder.

[0030] 3) Under an argon protective atmosphere, the temperature of the tube electric furnace was raised to 1600°C. Put the mixed ingredients into an alumina crucible, heat it into a tube electric furnace, and keep it warm for 2 hours.

[0031] 4) After the heat preservation is over, take it out at 1600°C, put it directly into water to cool it, and then put it into a drying oven for drying.

[0032] 5) Under the temperature condition of 95 DEG C, use HCl to carry out acid leaching treatment on the carbonized blast furnace slag, the HCl concentration is 36% ± 1%, and the addition amount of HCl is based on the liquid-solid ratio of HCl and carbonized blast furnace slag being 8: The ratio of 1 is added, and the time required fo...

Embodiment approach 2

[0036] 1) Crush and grind titanium-containing blast furnace slag to 180 mesh ± 10 mesh, and mix well.

[0037] 2) According to the mass ratio of slag: C=100:6.53, weigh 10 grams of titanium-containing blast furnace slag and 0.653 grams of carbon powder.

[0038] 3) Under an argon protective atmosphere, the temperature of the tube electric furnace was raised to 1600°C. Put the mixed ingredients into an alumina crucible, heat it into a tube electric furnace, and keep it warm for 2 hours.

[0039] 4) After the heat preservation is over, take it out at 1600°C, put it directly into water to cool it, and then put it into a drying oven for drying.

[0040] 5) Under the temperature condition of 85 DEG C, use HCl to carry out acid leaching treatment on the carbonized blast furnace slag, the HCl concentration is 36% ± 1%, and the addition amount of HCl is based on the liquid-solid ratio of HCl and carbonized blast furnace slag being 8: 1, the time required for acid leaching is 6h. Af...

Embodiment approach 3

[0044] 1) Crush and grind titanium-containing blast furnace slag to 180 mesh ± 10 mesh, and mix well.

[0045] 2) According to the mass ratio of slag: C=100:7.62, weigh 10 grams of titanium-containing blast furnace slag and 0.762 grams of carbon powder.

[0046] 3) Under an argon protective atmosphere, the temperature of the tube electric furnace was raised to 1600°C. Put the mixed ingredients into an alumina crucible, heat it into a tube electric furnace, and keep it warm for 2 hours.

[0047] 4) After the heat preservation is over, take it out at 1600°C, put it directly into water to cool it, and then put it into a drying oven for drying.

[0048] 5) Under the temperature condition of 95 ℃, utilize HCl to carry out acid leaching treatment to the blast furnace slag after carbonization, this HCl concentration is 36% ± 1%, the addition amount of HCl is based on HCl and carbonized blast furnace slag liquid-solid ratio is 6: 1, the time required for acid leaching is 8h. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com