Nano coating preparation method and device based on ultrafast ultrahigh pressure photodynamics effect

A nano-coating and preparation device technology, which is applied in coatings, metal material coating processes, etc., can solve problems such as inappropriate preparation of thicker coatings, difficult to handle parts, low efficiency, etc., to improve interface bonding strength and mechanical properties high performance, avoid thermal damage, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

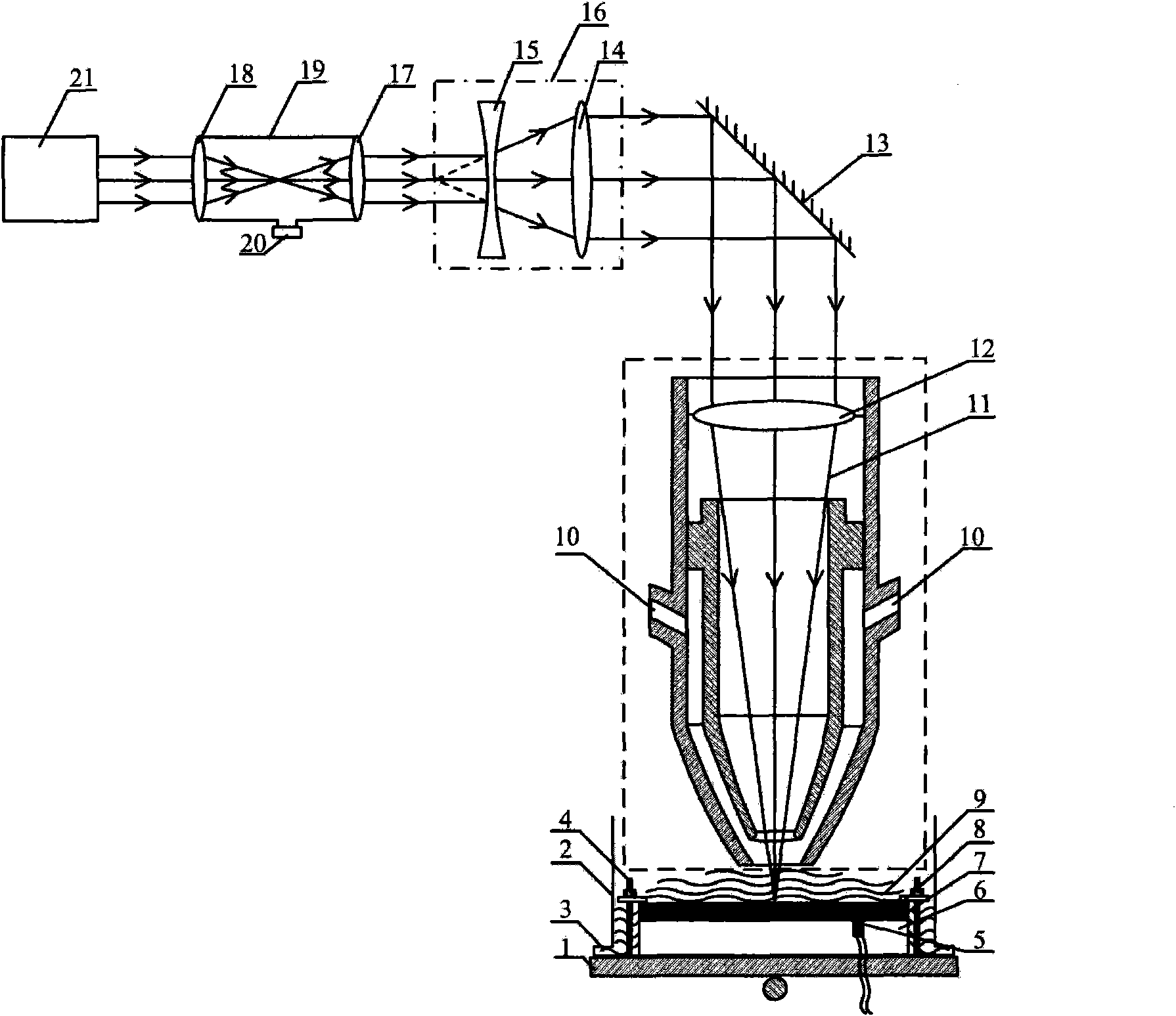

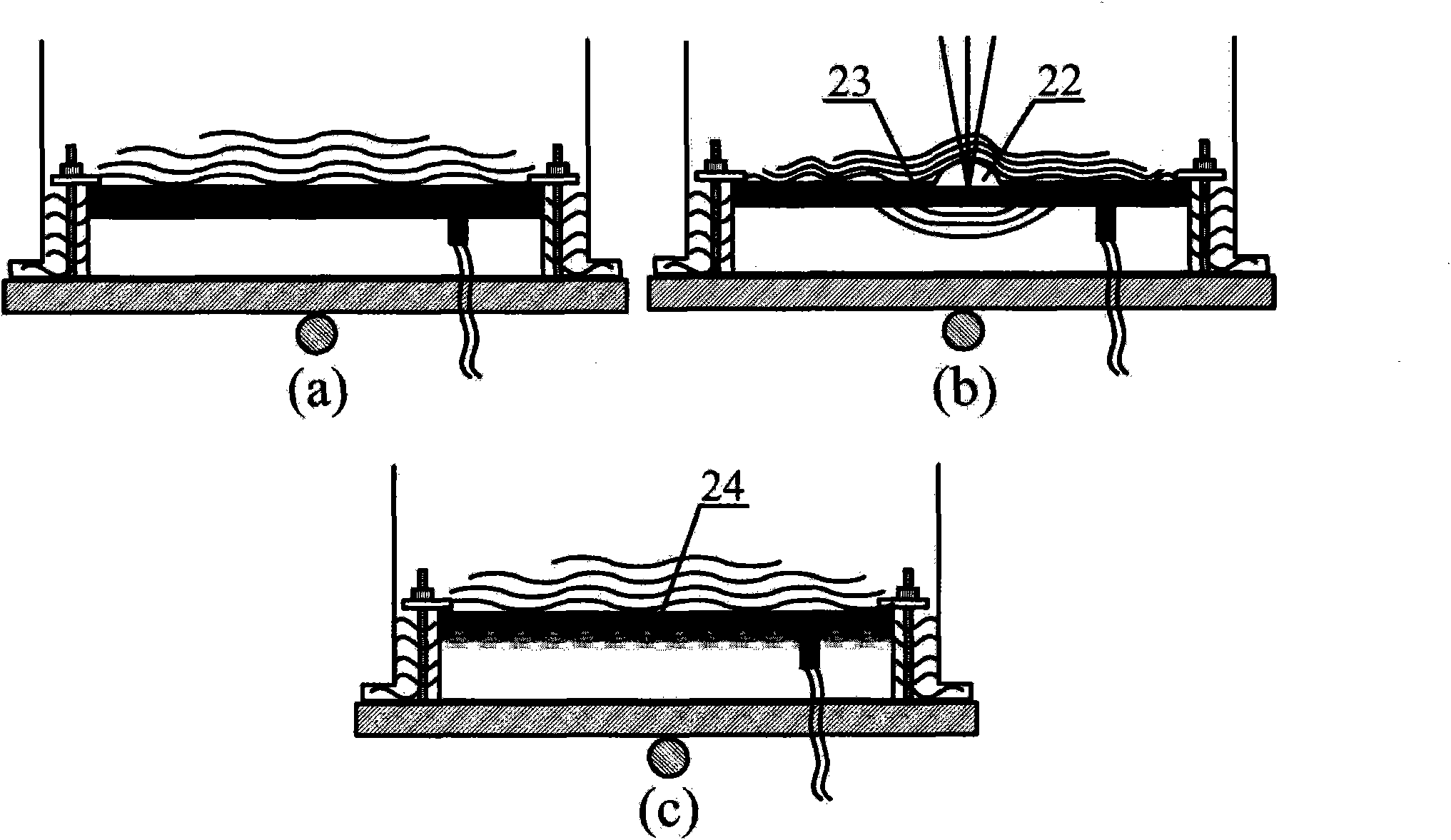

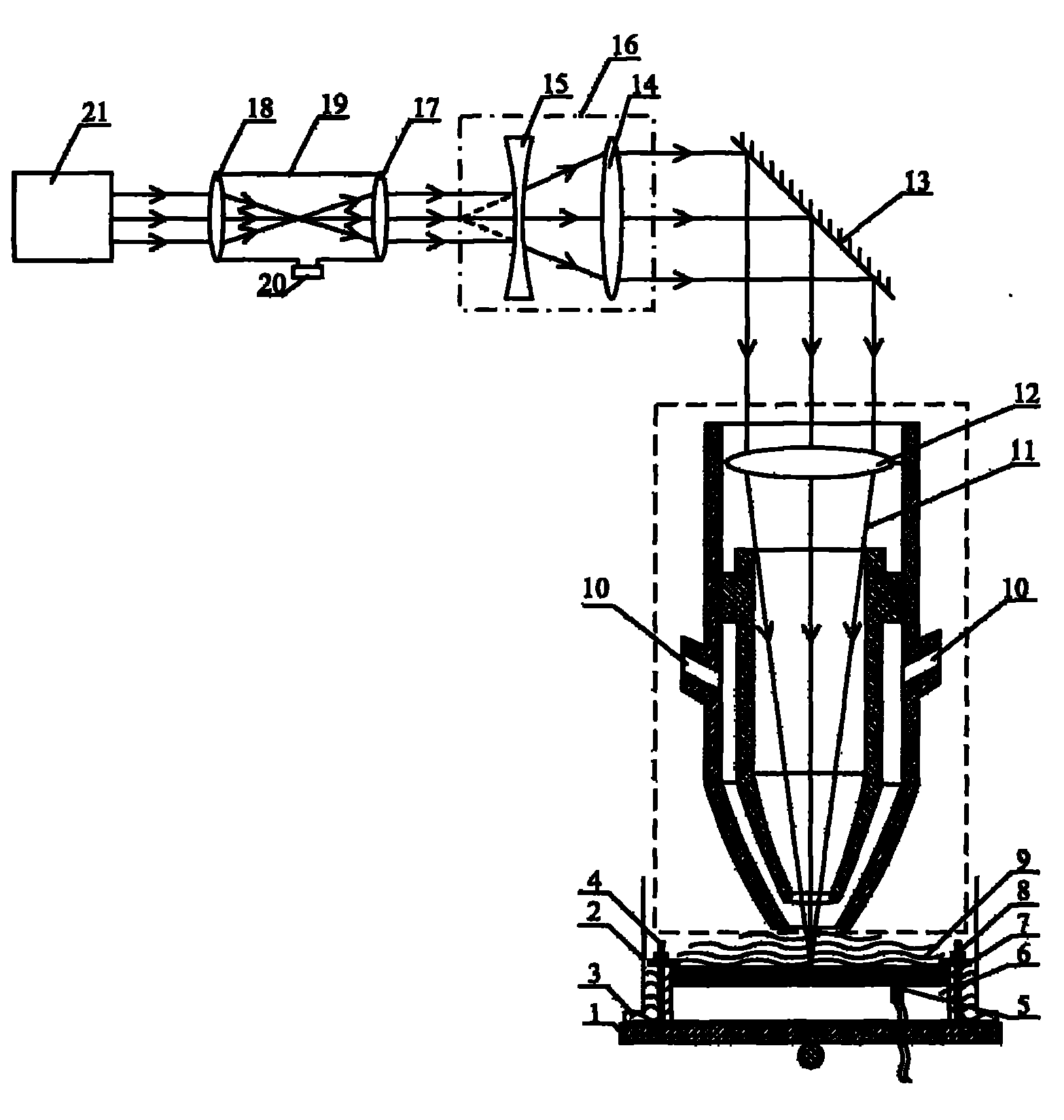

[0034] The device of the nano-coating preparation method based on the ultra-fast ultra-high pressure photomechanical effect, such as figure 1 shown, including:

[0035] Three-dimensional six-axis worktable (1), water tank (2), fixture (4), thermocouple (5), coaxial synchronous water feeder (10), laser focusing system (12), 45° full reflection mirror (13), Laser beam optimization system and nanosecond laser (21), wherein a water tank (2) with a water outlet pipe (3) at the bottom of the side is placed on a computer-controlled three-dimensional six-axis workbench (1), and the bottom of the water tank (2) is automatically A metal substrate (6) coated with nanoparticles (7) on the surface covered with black paint (8) is fixed with a clamp (4), and a laser shock confinement layer (9) and a laser focusing system are arranged directly above the metal substrate (6) (12) and a 45 ° total reflection mirror (13), on one side of the 45 ° total reflection mirror (13) is a laser beam optim...

Embodiment 1

[0040] 1) Select nano Fe-Ni powder for surface treatment, the average particle size is about 200nm;

[0041] 2) Select the AZ91D Mg alloy substrate to be treated, and carry out pretreatment on the Mg alloy substrate, including grinding, polishing, and then cleaning it with alcohol in ultrasonic waves;

[0042] 3) The nano-Fe-Ni powder selected in step 1) is made into an alcohol suspension and coated on the Mg alloy substrate treated in step 2), and left to dry, the thickness of the pre-coating layer is 500 μm;

[0043] 4) the whole surface of the Mg alloy coated with nanometer Fe-Ni powder prepared by step 3) is wrapped up with black paint, and the black paint is used as the absorbing layer simultaneously;

[0044] 5) The laser beam optimization system is used to optimize the selection of the laser beam, so that the output laser beam is evenly distributed in space, guided by a 45° full mirror, and then the laser beam is focused by the laser focusing system, with a spot diamete...

Embodiment 2

[0047] 1) Select nano-AlN powder for surface treatment, the average particle size is about 100nm;

[0048] 2) Select the pure Al metal substrate to be treated, and perform pretreatment on the pure Al metal substrate, including grinding, polishing, and then cleaning it with alcohol in ultrasonic waves;

[0049] 3) The nano-AlN powder selected in step 1) is made into an alcohol suspension and coated on the pure Al substrate treated in step 2), and left to dry, the thickness of the pre-coating layer is 100 μm;

[0050] 4) the whole surface of the pure Al substrate coated with nano-AlN powder prepared in step 3) is wrapped up with black paint, and the black paint is used as the absorbing layer simultaneously;

[0051] 5) The laser beam optimization system is used to optimize the selection of the laser beam, so that the output laser beam is evenly distributed in space, guided by a 45° full mirror, and then the laser beam is focused by the laser focusing system, with a spot diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| laser pulse width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com