Piezoelectric porcelain and method for preparation thereof and piezoelectric element

A technology of piezoelectric ceramics and manufacturing methods, which is applied in the direction of electrical components, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problems of low Curie temperature and large aging degradation of piezoelectric characteristics, and achieve the goal of burning Lower temperature, larger piezoelectric strain constant and mechanical strength, and less aging deterioration of properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

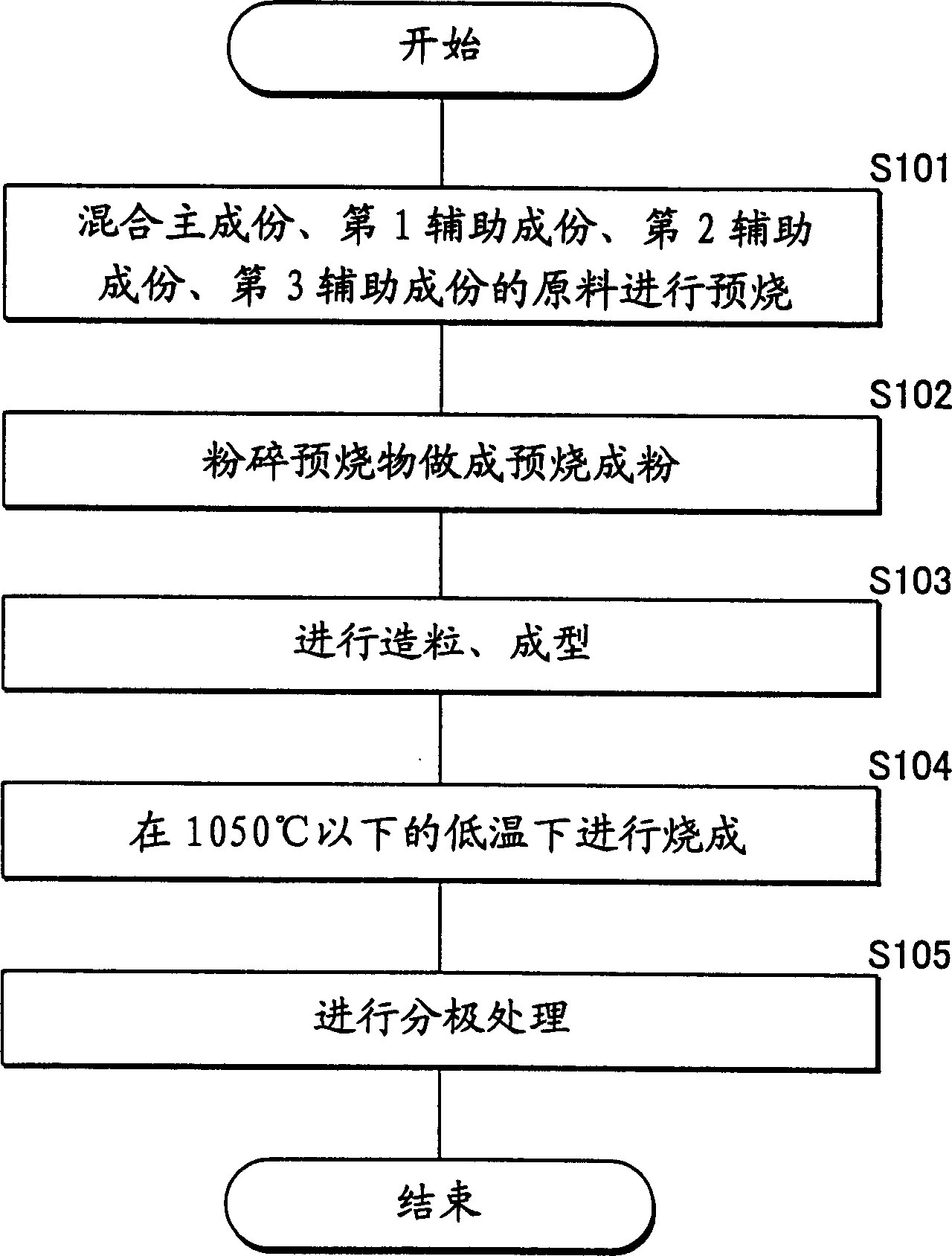

Method used

Image

Examples

no. 1 approach

[0036] The piezoelectric ceramic according to the first embodiment of the present invention contains the oxide represented by Chemical Formula 8 or 9 as a main component.

[0037] In Chemical Formula 8, A, a, b, c, and d are values that respectively satisfy the following ranges, that is, a+b+c+d=1, 0.99≤A≤1.01, 0.15≤a+b≤0.5, 0.05≤b≤ 0.25, 0.2≤c≤0.5, 0.15≤d≤0.6. (Mg 1 / 3 Nb 2 / 3 ) in the composition of manganese and niobium, (Zn 1 / 3 Nb 2 / 3 ) in the composition of zinc and niobium, and the composition of oxygen are obtained stoichiometrically, but compositions deviated from stoichiometric may be used.

[0038] In addition, in Chemical Formula 9, A, B, a, b, c, and d are values that respectively satisfy the following ranges, that is, a+b+c+d=1, 0.99≤A≤1.01, 0.005≤B≤0.1, 0.15≤ a+b≤0.5, 0.05≤b≤0.25, 0.2≤c≤0.5, 0.15≤d≤0.6. Me represents one of the group consisting of calcium, strontium and barium. (Mg 1 / 3 Nb 2 / 3 ) in the composition of manganese and niobium, (Zn 1 / 3 Nb ...

no. 2 approach

[0069] The piezoelectric ceramic according to the second embodiment of the present invention contains an oxide represented by Chemical Formula 10 as a main component.

[0070] In Chemical Formula 10, A, B, a, b, c, and d are values that respectively satisfy the following ranges, that is, a+b+c+d=1, 0.99≤A / B≤1.005, 0.005≤a≤0.03, 0.05≤ b≤0.2, 0.36≤c≤0.49, 0.39≤d≤0.48. (Co 1 / 3 Nb 2 / 3 ) in the composition of cobalt and niobium, (Zn 1 / 3 Nb 2 / 3 ) in the composition of zinc and niobium, and the composition of oxygen are obtained stoichiometrically, but compositions deviated from stoichiometric may be used.

[0071] The oxide shown in Chemical Formula 10 has a perovskite structure, the lead position is on the so-called A site, cobalt (Co), niobium (Nb), zinc (Zn), titanium (Ti) and zirconium (Zr) is located on the so-called B site.

[0072] A / B shown in Chemical Formula 10 is a factor affecting sinterability. The reason why A / B is set to 0.99 or more is that when it is lower ...

no. 3 approach

[0085] The piezoelectric ceramic according to the third embodiment of the present invention contains an oxide represented by Chemical Formula 11 or Chemical Formula 12 as a main component.

[0086] In Chemical Formula 11, A, a, b, and c are values that satisfy the following ranges respectively, that is, a+b+c=1, 0.99≤A≤1.005, 0.005≤a≤0.25, 0.35≤b≤0.50, 0.38≤c≤ 0.48. (Zn 1 / 3 Nb 2 / 3 ) in the composition of zinc and niobium, and the composition of oxygen are obtained stoichiometrically, but compositions deviated from stoichiometric may be used.

[0087] In addition, in Chemical Formula 12, A, B, a, b, and c are values that respectively satisfy the following ranges, that is, a+b+c=1, 0.99≤A≤1.005, 0.005≤B≤0.1, 0.05≤a≤0.25, 0.35≤b≤0.50, 0.38≤c≤0.48. Me represents at least one selected from calcium, strontium and barium. The composition of oxygen is always obtained stoichiometrically, but a composition deviating from stoichiometry is also possible.

[0088] The oxide shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com