A method for testing line defects of LCD (liquid crystal display) panel, array substrate and drive wires

A liquid crystal display panel and detection method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of a large number of probes, a large number of detection terminals, and high cost, and achieve the effect of reducing costs and saving the number of probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

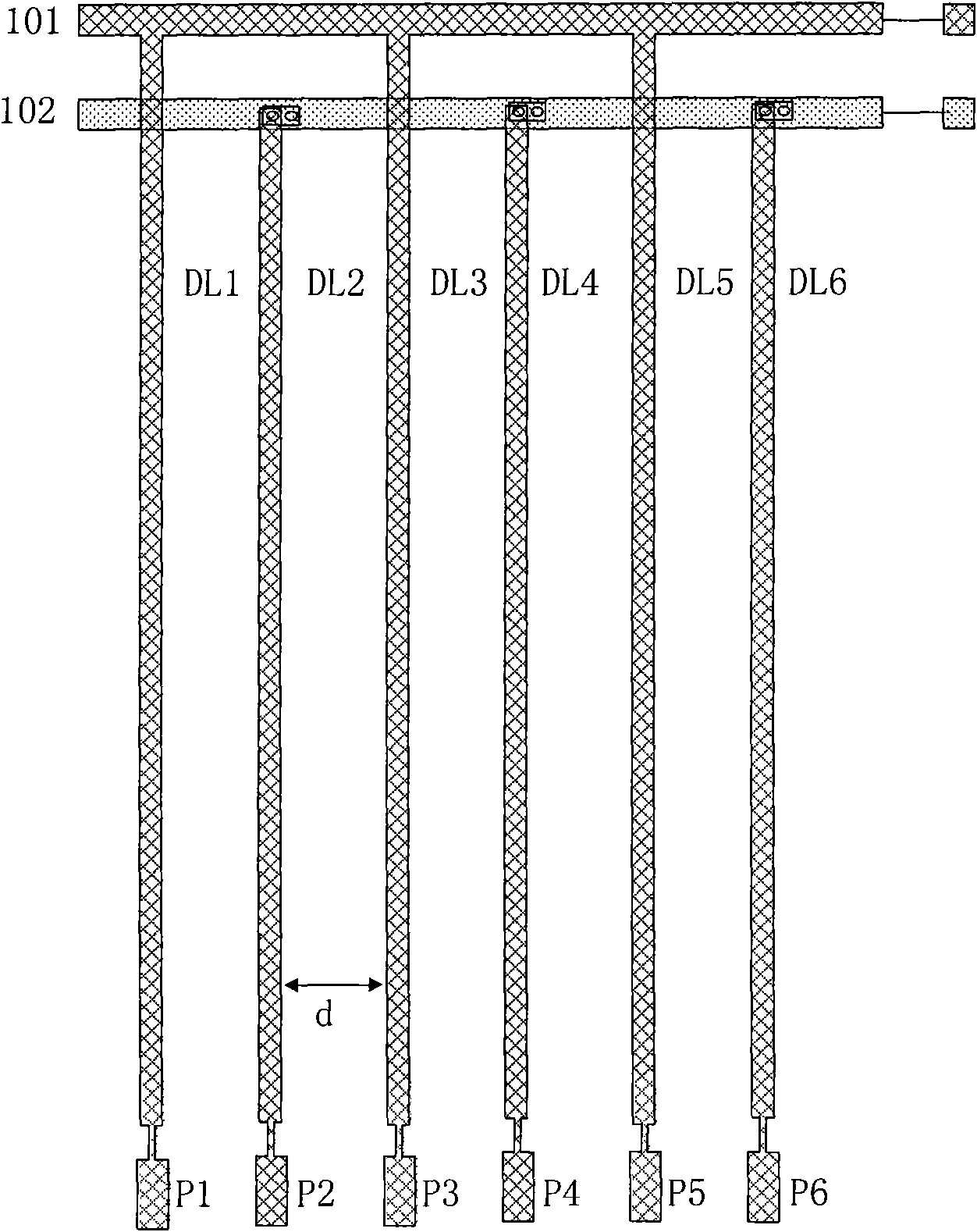

[0049] The specific embodiment of the present invention adds a first switch, a second switch, a first switch control line for controlling the first switch, and a second switch control line for controlling the second switch on the basis of the prior art, at least one One end of the two driving lines in a group of driving lines is respectively connected to a detection terminal through a first switch and a second switch, so at least two driving lines in each group of driving lines share a detection terminal, and the defect detection of the driving lines is performed At least one-third of the number of probes can be saved and the cost can be reduced.

[0050] The specific implementation manner of the present invention will be described in detail below in combination with specific embodiments and accompanying drawings.

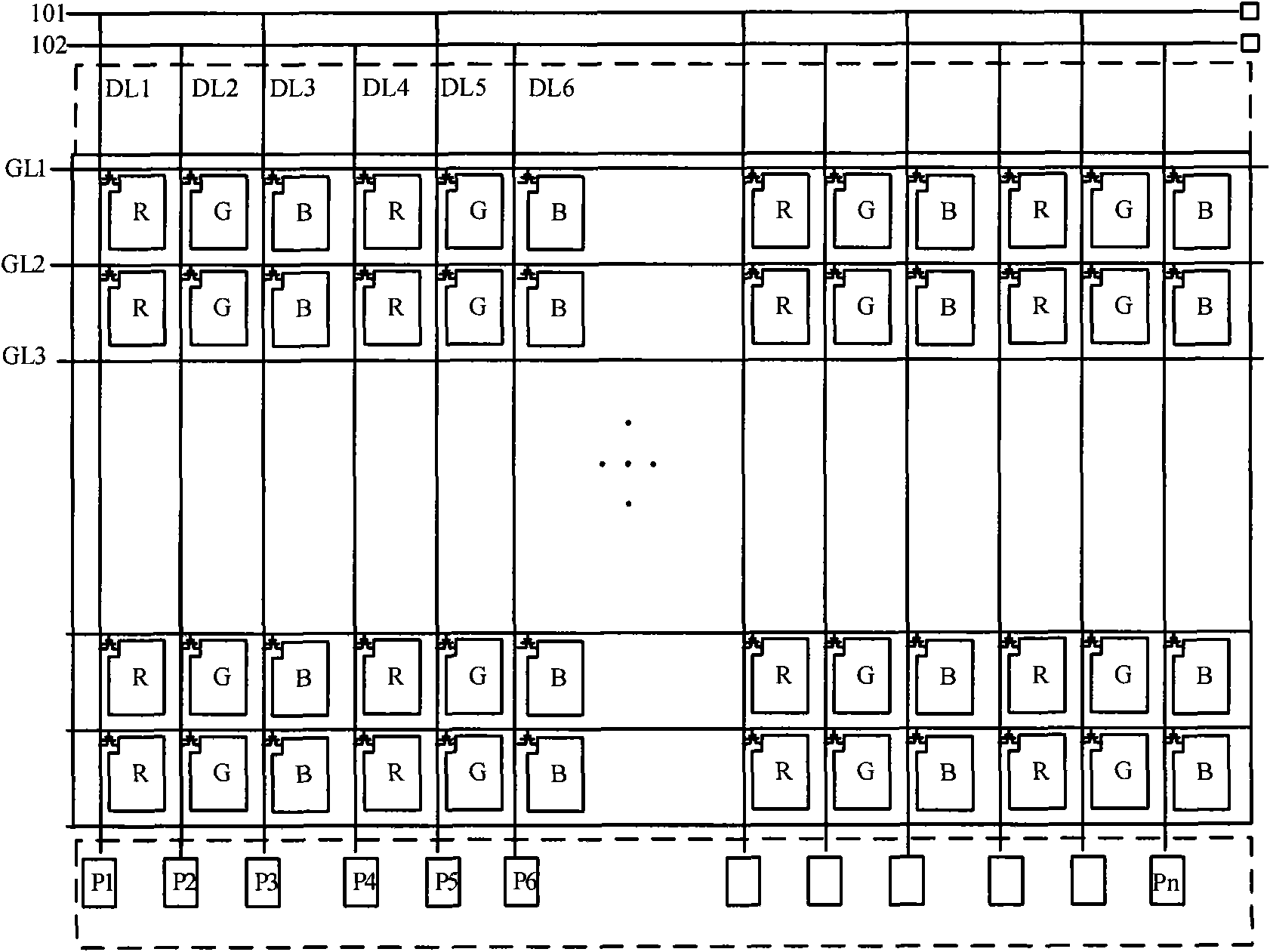

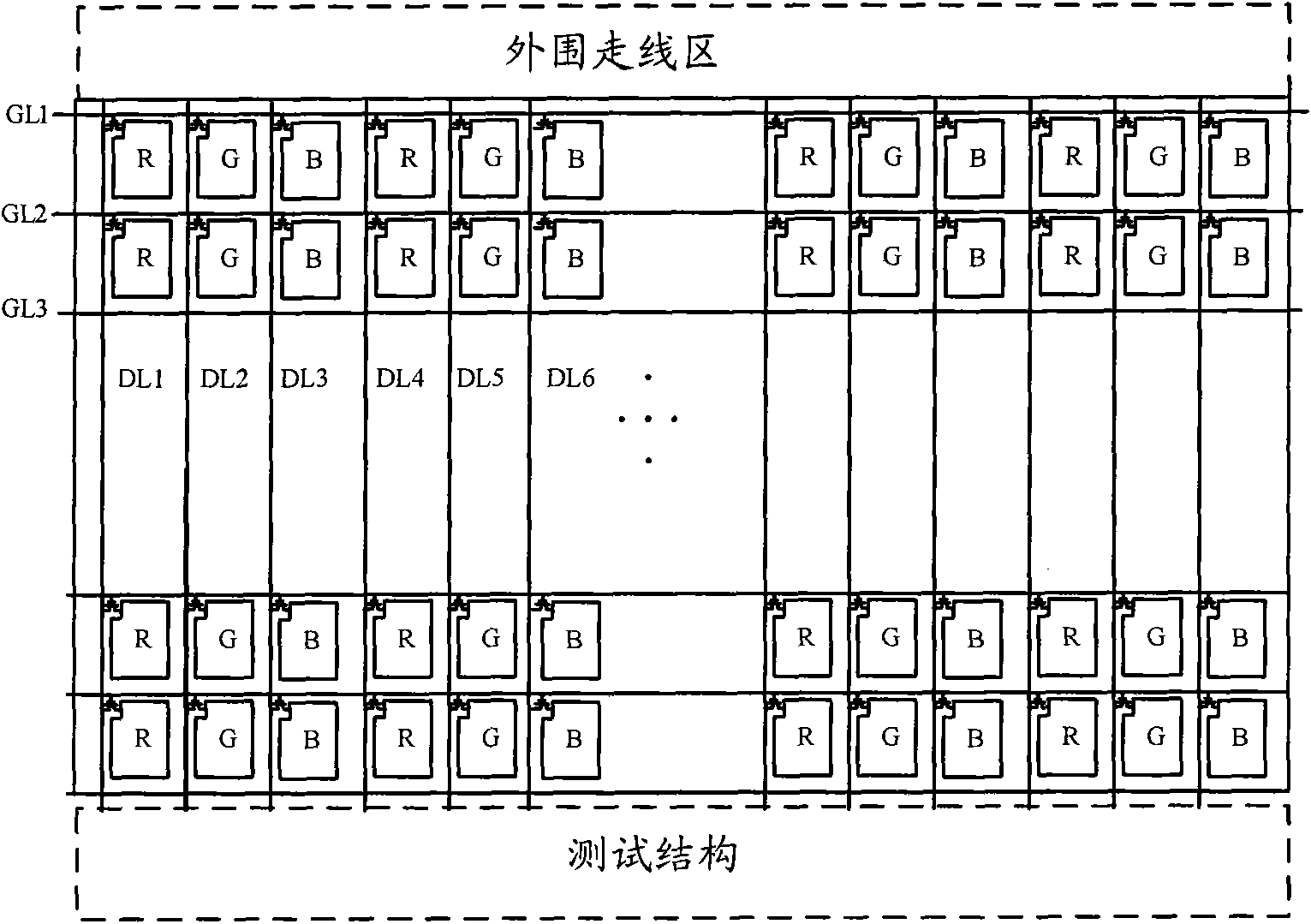

[0051] see image 3 , is a schematic diagram of the circuit structure of the display panel of the present invention. The liquid crystal display panel of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com