Simple electroless welding pen and preparation method of electroless welding pen

An electric welding pen, a simple technology, applied in the direction of welding equipment, welding equipment, thermite welding equipment, etc., can solve the problems of unstable welding process, pores, poor forming, incomplete separation of slag, etc., and achieve simple and fast welding operation Safety, good solderability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention mainly utilizes the aluminothermic reaction to release a large amount of heat as a heat source, and the molten metal drops to the welding place to form a weld for welding, and provides a simple welding device for field emergency.

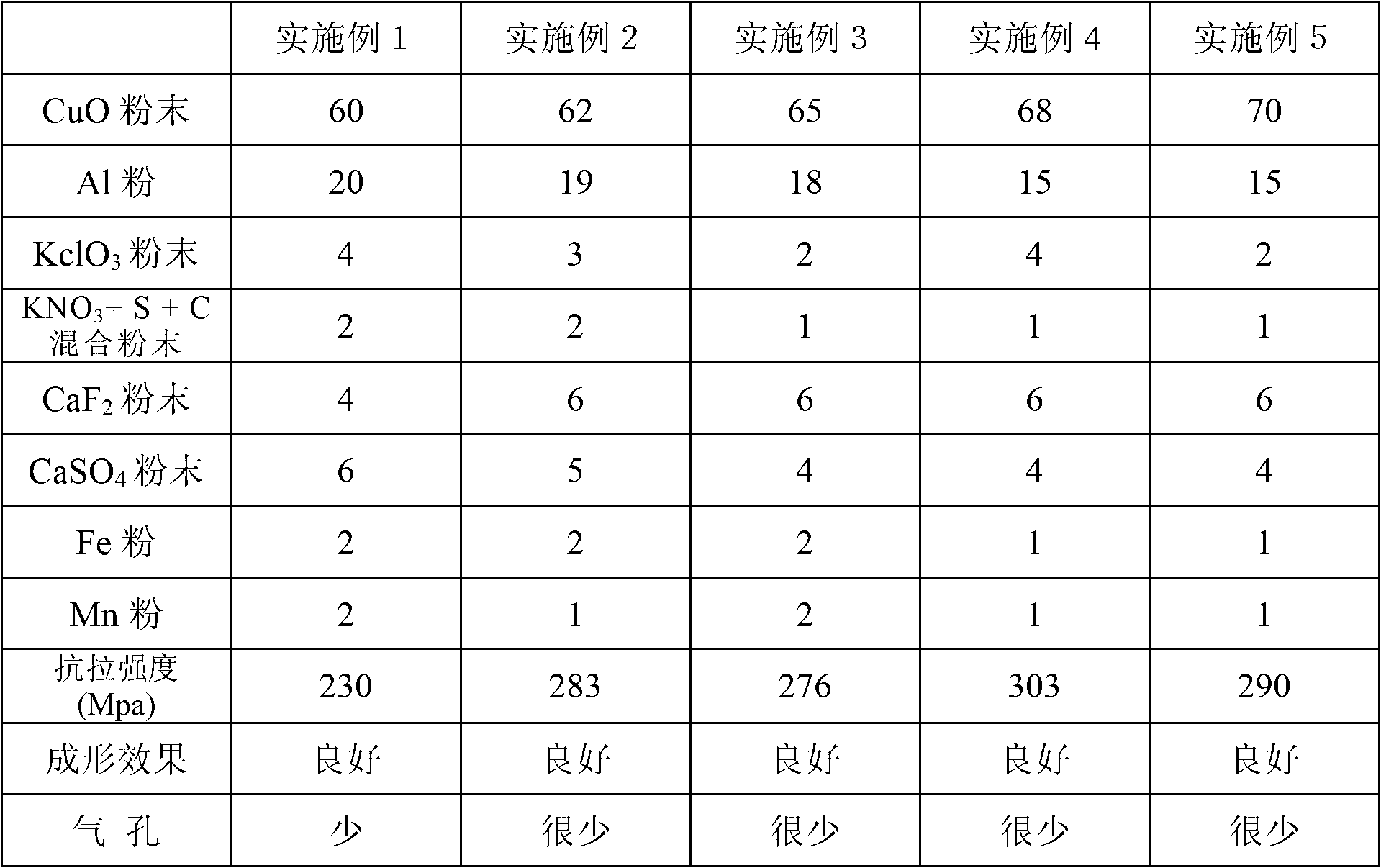

[0030] The composition and ratio of the heat source chemical powder of the welding pen can be designed according to the specific connection strength. The aluminothermic reaction is: 2Al+3CuO=3Cu+Al 2 o 3 +1519kJ. During welding, Al and CuO undergo a violent aluminothermic reaction. During the reaction, CuO is reduced, Al is oxidized, and a large amount of heat is released for welding.

[0031] The present invention will be described in further detail below in conjunction with examples.

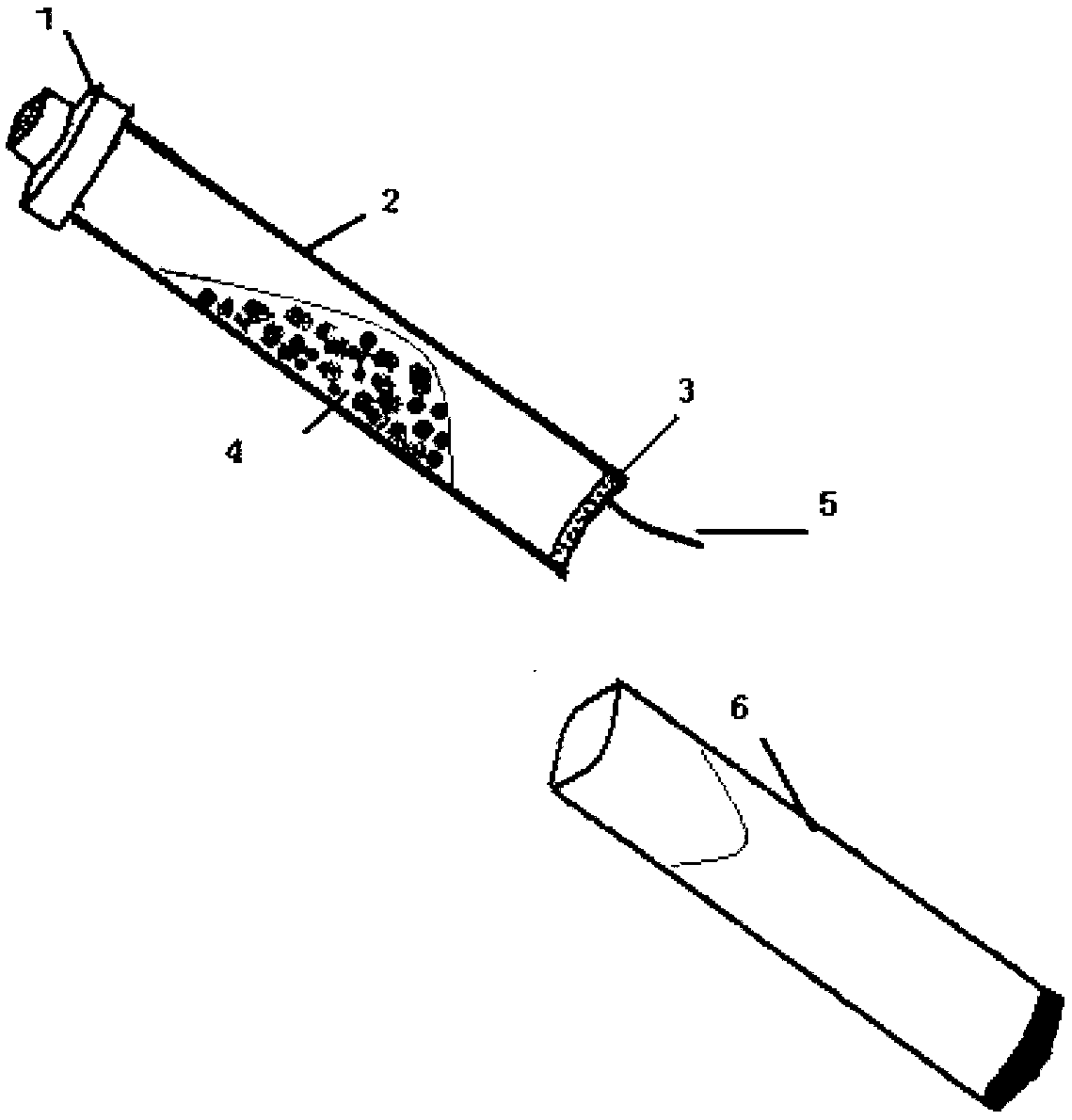

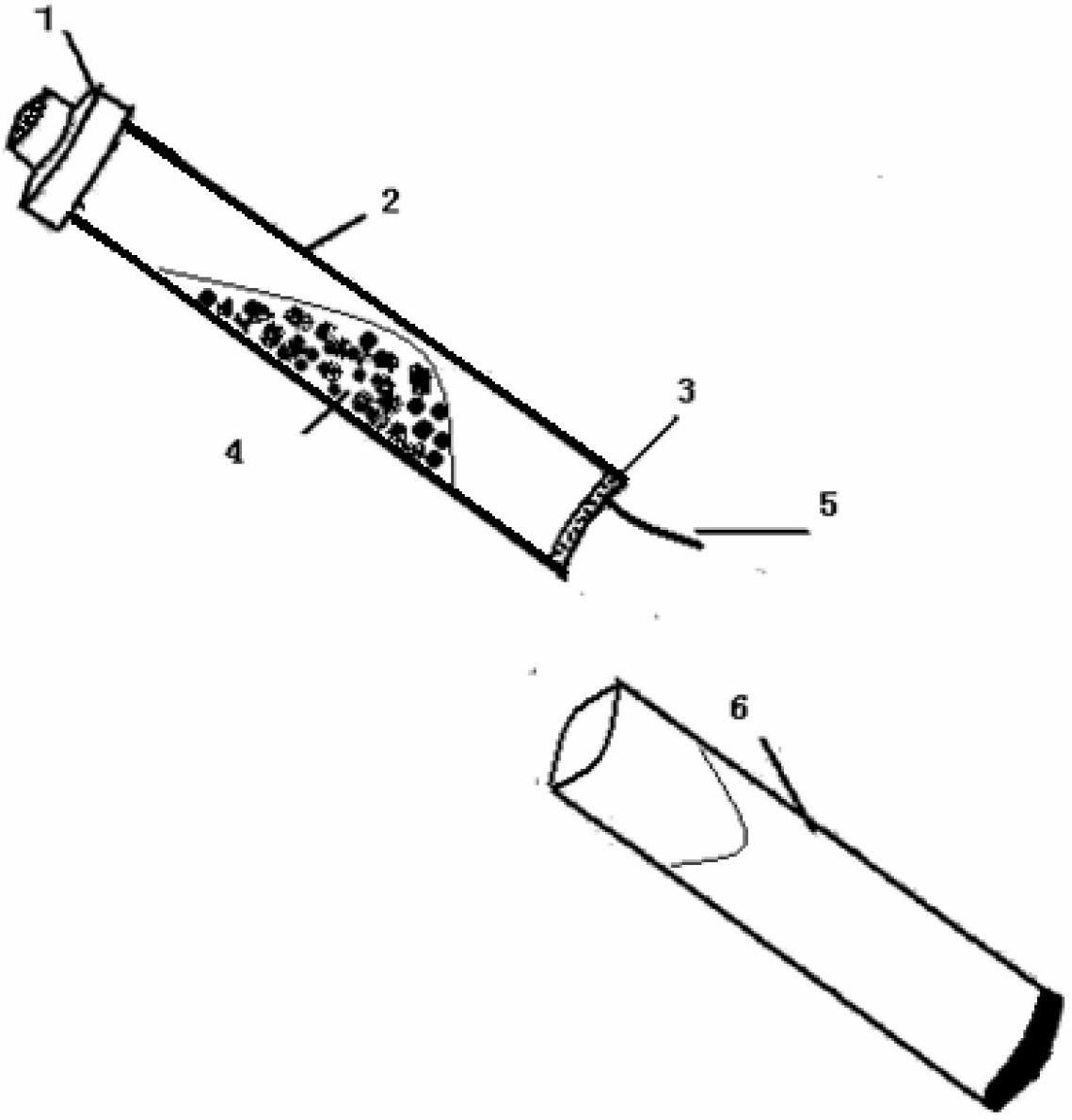

[0032] like figure 1 As shown, in the simple electric-free soldering pen of the present invention, the flux 4 provided in the drug tube 2 is thermite, also known as heat source powder, and the front end of the drug tube 2 is provided with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com