Surface roughness measurement method and device

A surface roughness and roughness technology, applied in the field of optical measurement, can solve the problems of low efficiency, strict measurement environment requirements and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

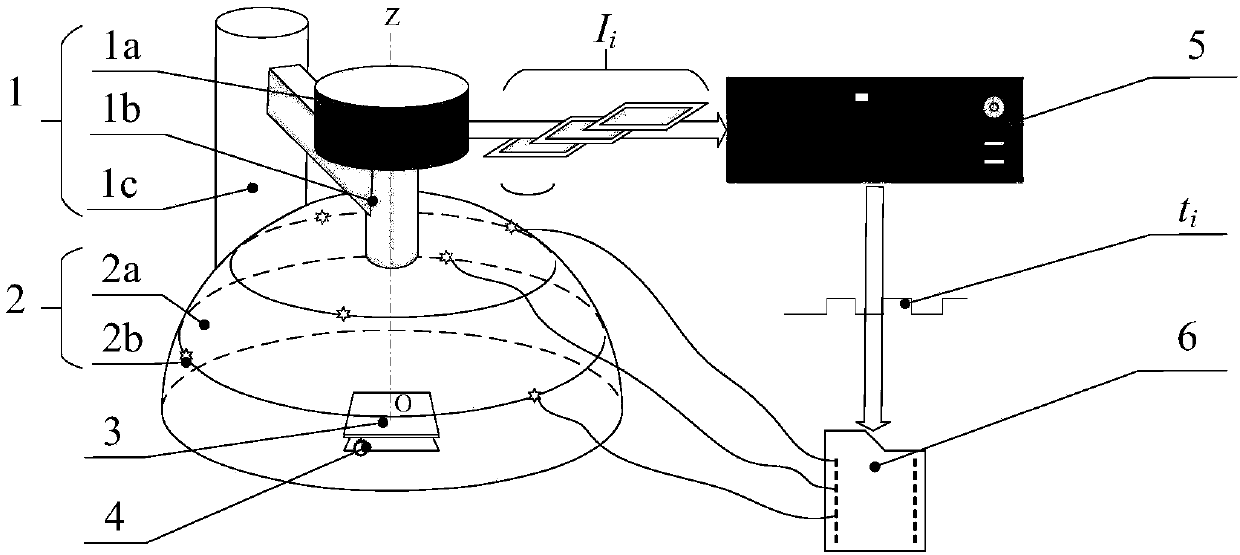

[0043] The measuring device such as figure 1 As shown, it consists of a microscopic imaging system 1 , a multi-light source spherical lampshade 2 , an object stage 3 and its fine-tuning device 4 , a computer 5 , and a control module 6 .

[0044] The multi-light source spherical lampshade 2 is hemispherical and fixed on the machine base. The inner spherical surface 2a is made of black non-reflective material, and n≥3 point light sources 2b are evenly distributed on the inner spherical surface, and are installed on the latitude ring of the multi-light source spherical lampshade.

[0045] The stage 3 is located at the spherical center of the multi-light source spherical lampshade, the plane of the stage is perpendicular to the axis of the multi-light source spherical lampshade, and is fixed on the machine base through the fine-tuning device 4 .

[0046] The microscopic imaging system 1 is composed of a high-resolution camera 1a and a long-object-distance microscope lens 1b. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com