A high-precision flexoelectric pressure sensor based on metal elastic elements

A pressure sensor and elastic element technology, applied in the field of pressure sensors, can solve the problems of increasing detection difficulty and small strain, and achieve the effect of high sensitivity and increased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

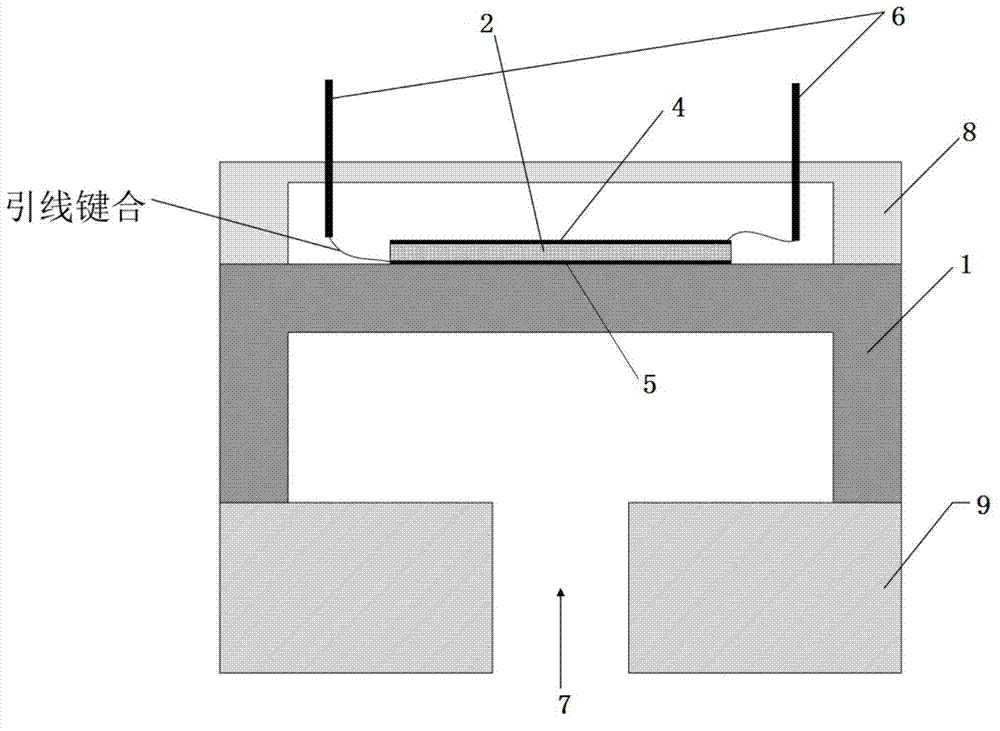

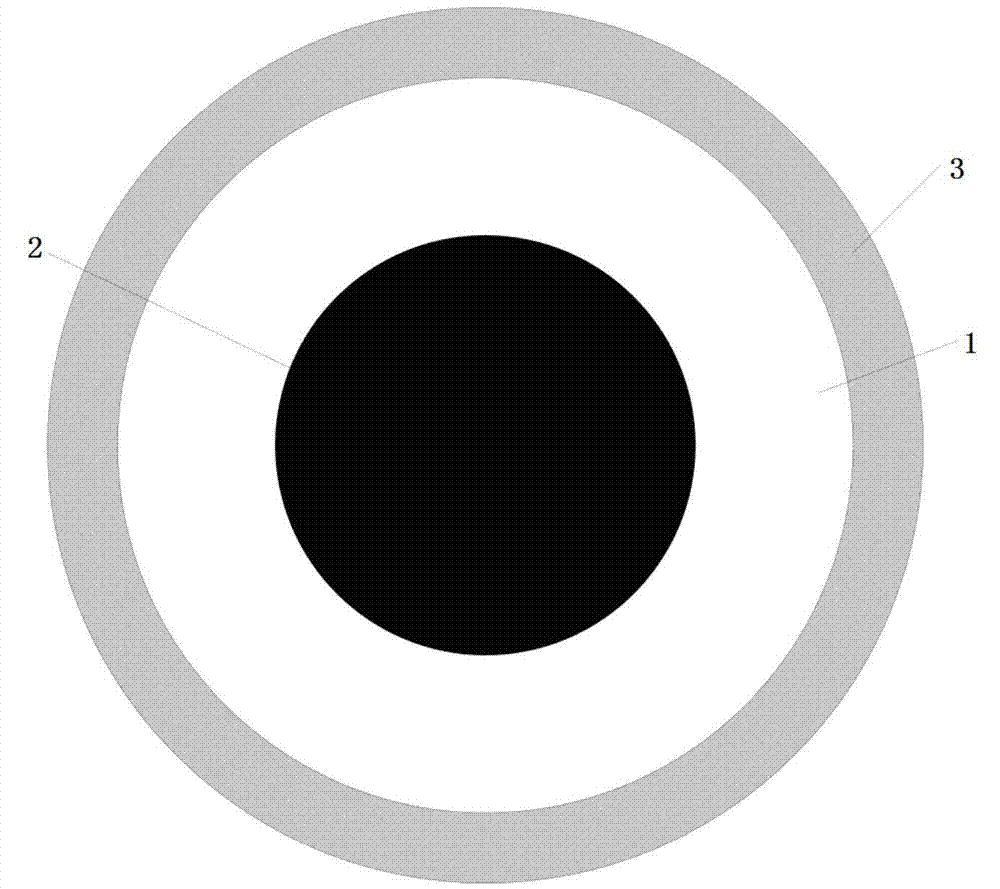

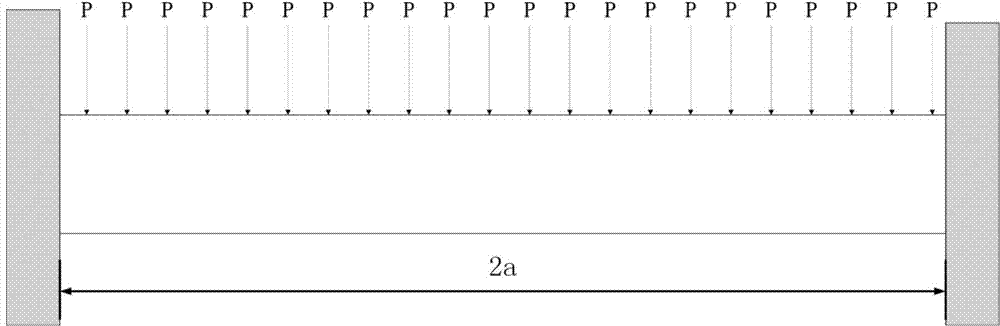

[0032] Such as figure 1 with figure 2 As shown, the present invention is a high-precision flexoelectric pressure sensor based on a metal elastic element, including a metal elastic element 1 for measuring mechanical vibration caused by micro pressure, and a flexure dielectric is pasted on the top of the metal elastic element 1 The film 2 is provided with an insulating layer 3 around it, and the upper and lower surfaces of the flexible dielectric film 2 are respectively provided with an upper metal electrode 4 and a lower metal electrode 5, and the upper metal electrode 4 and the lower metal electrode 5 of the flexible dielectric film 2 The metal electrodes 5 are respectively connected with two lead wires 6 that output the measurement charge signal, and there is a pressure channel 7 for applying pressure under the metal elastic elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com