Forging method of large-sized die forging part of fine-grain AF1410 steel

A die forging and fine-grain technology, which is used in the field of forging large-scale die forgings of AF1410 ultra-high strength steel with fine-grained structure, can solve the problems of insufficient impact forming characteristics and forming ability, large projected area of large forgings, and many times of die forging. problems, to achieve the effect of improving comprehensive performance, improving the quality of forgings, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

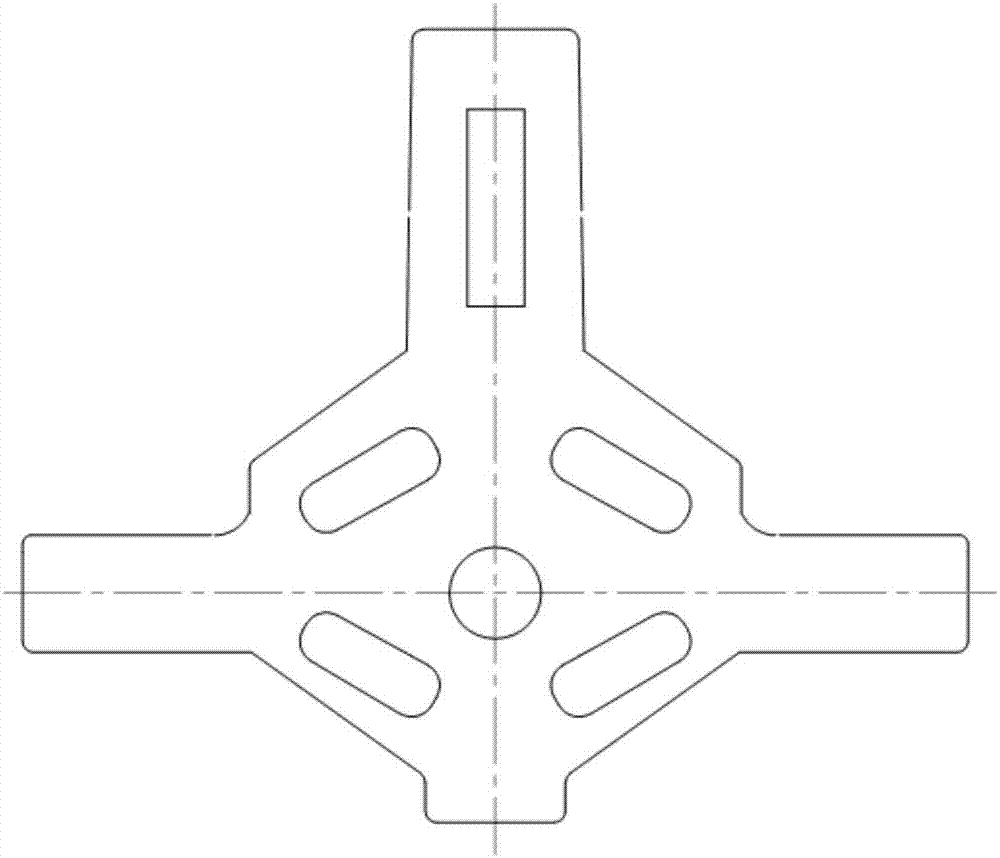

[0042] Forging cross forgings, the structure of the cross forgings is as follows figure 2 shown.

[0043] (1) Raw material: AF1410 alloy bar stock with a diameter of φ250mm, see Table 1 for the chemical composition.

[0044] element

[0045] Table 1 Chemical composition of AF1410 alloy bars

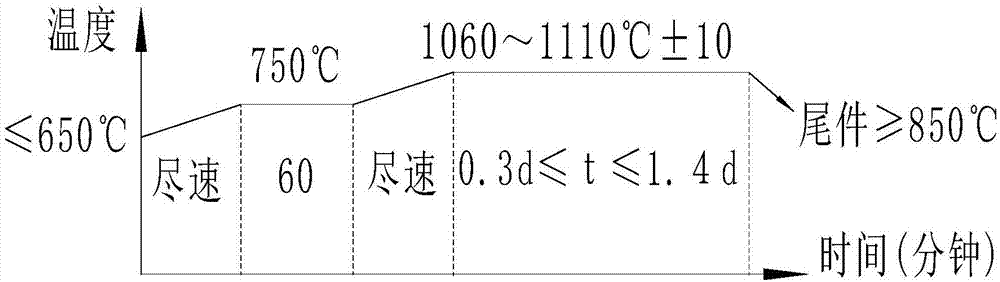

[0046] (2) Heating equipment and heating system: large-scale industrial resistance furnace, the precision of resistance furnace is ±10°C. See the specific heating system figure 1 , The heating temperature control is based on the display of the resistance furnace instrument. The maximum heating temperature of the billet is 1110°C, and the holding time is 300min. The maximum heating temperature of forging is 1090°C, and the holding time is 130min.

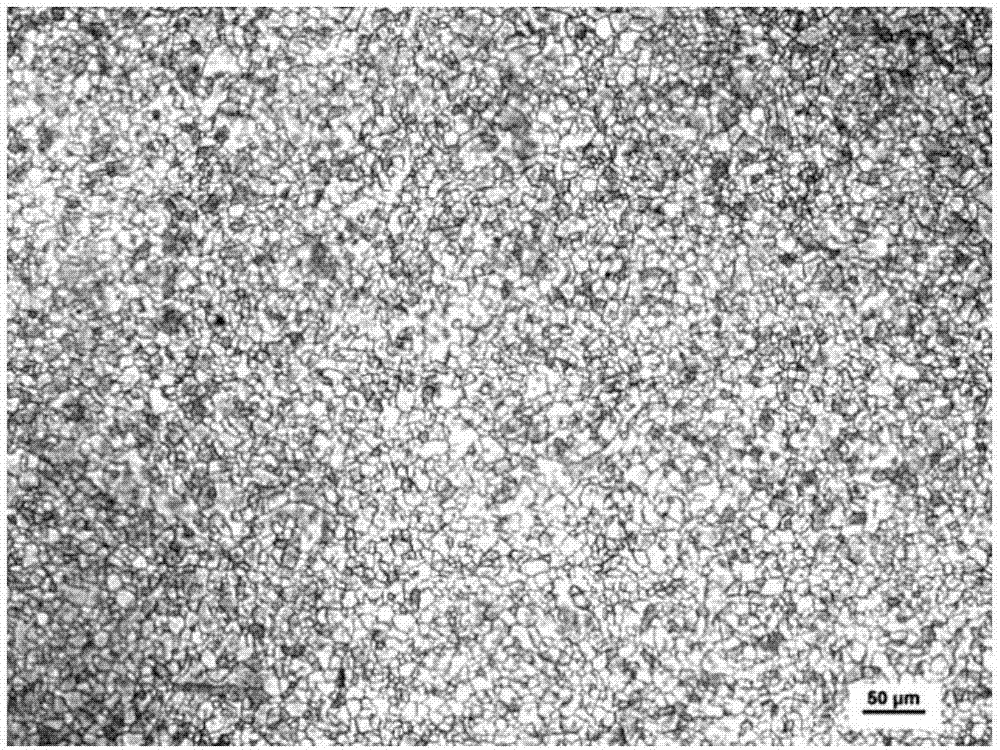

[0047] (3) Billet making: the billet making equipment is a 5-ton forging hammer and a 50MN hydraulic press, and the billet is made for 4 fires. The cumulative deformation of each area of the billet during the billet making proces...

Embodiment 2

[0054] It is also a cross forging, and the structure of the forging is the same as that of Embodiment 1.

[0055] (1) Raw materials: adopt the same raw materials as in the examples.

[0056] (2) Heating equipment and heating system: large-scale industrial resistance furnace, the precision of resistance furnace is ±10°C. See the specific heating system figure 1 , The heating temperature control is based on the display of the resistance furnace instrument. The maximum heating temperature of the billet is 1110°C, and the holding time is 350min. The maximum heating temperature of the forging is 1090°C, and the holding time is 170min.

[0057] (3) Billet making: the billet making equipment is a 5-ton forging hammer and a 50MN hydraulic press, and the billet is made for 4 fires. The cumulative deformation of each area of the billet during the billet making process is ≥50%, the forging stop temperature is ≥850°C, and the forging is pit-cooled.

[0058] (4) Die forging: Die forgin...

Embodiment 3

[0064] Forging long arm forgings, forging structure such as Figure 5 shown.

[0065] (1) Raw material: AF1410 alloy bar stock with a diameter of φ250mm, the chemical composition is shown in Table 4.

[0066] element

[0067] Table 4 Chemical composition of AF1410 alloy bars

[0068] (2) Heating equipment and heating system: large-scale industrial resistance furnace, the precision of resistance furnace is ±10°C. See the specific heating system figure 1 , The heating temperature control is based on the display of the resistance furnace instrument. The maximum heating temperature of the billet is 1110°C, and the holding time is 280min. The maximum heating temperature of the forging is 1090°C, and the holding time is 120min.

[0069] (3) Billet making: The billet making equipment is a 5-ton forging hammer, and the billet is made for 2 fires. The cumulative deformation of each area of the billet during the billet making process is ≥ 45%, the forging stop temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com