An optical fiber sensing system temperature compensating method

An optical fiber sensing system and temperature compensation technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of deformation and uniform thermal expansion of the measured object, and cross-sensitivity of strain and temperature, and can solve the problems of deformation, uniform thermal expansion and thermal expansion. Strain and temperature cross-sensitive, lightweight, easy-to-apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

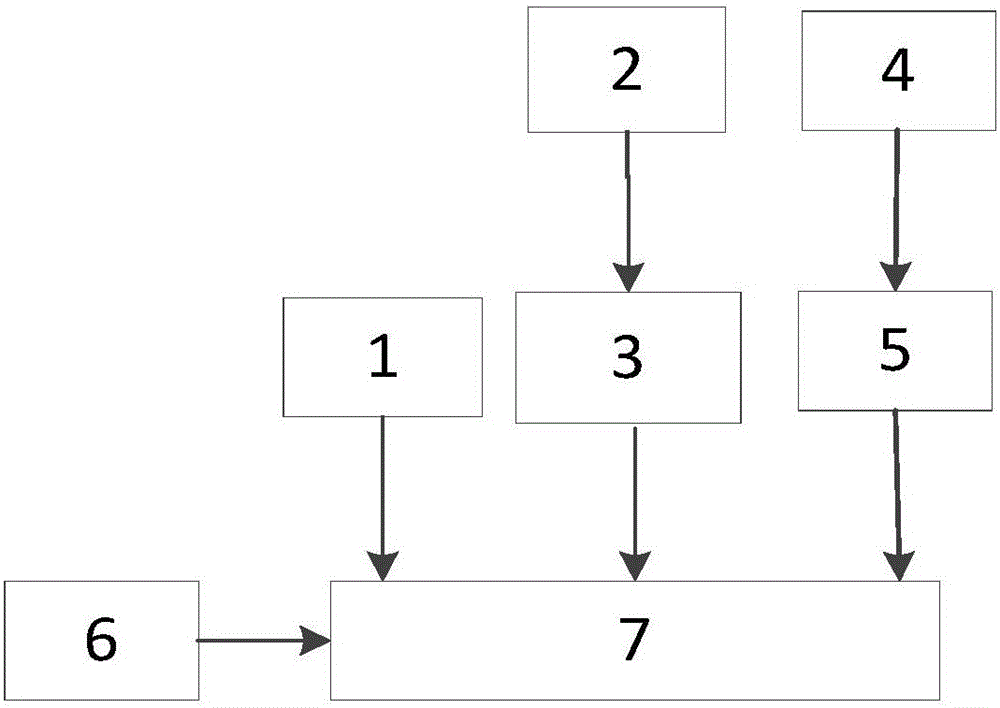

[0022] Such as figure 1 Shown, the present invention comprises following 7 steps: 1, carry out temperature calibration to bare fiber grating sensor, obtain the temperature sensitivity coefficient K of fiber grating T1 2. Paste the bare fiber grating on the surface of the same material test piece of the test piece with glue. 3. Carry out temperature calibration on the fiber grating sensor pasted on the surface of the test piece of the same material as the test piece, and obtain the uniform thermal expansion coefficient K of the test piece T2 ; 4. Paste the bare fiber grating on the surface of the equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com