Method for measuring anisotropic material heat conductivity based on small-plane heat source

A technology of anisotropy and normal thermal conductivity, which is applied in the field of thermal physical property measurement of materials, can solve problems such as cumbersome procedures, high difficulty, and reduced system practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

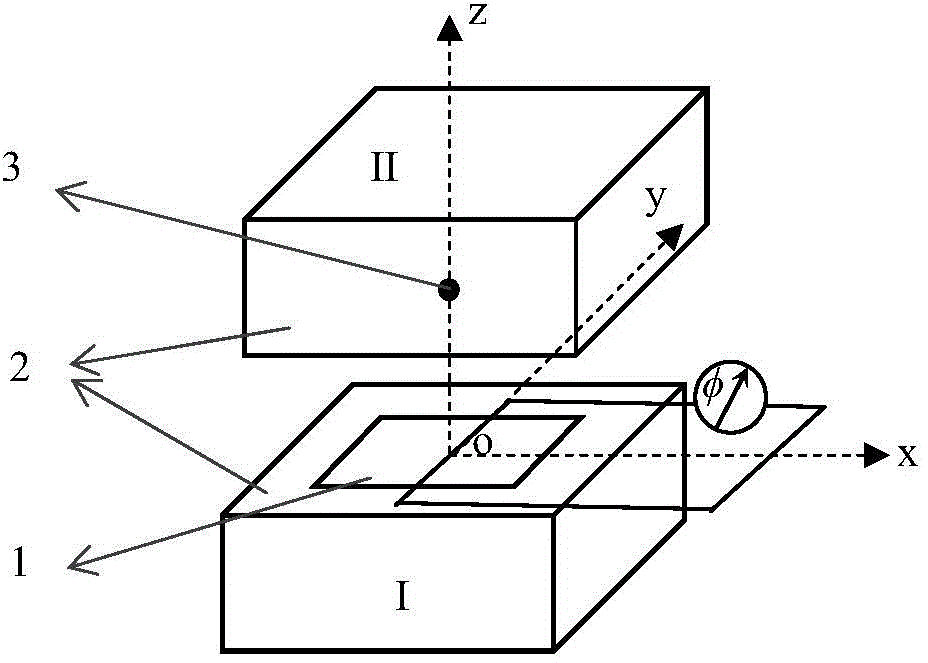

[0035] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings. In the following description, well-known functions or constructions are not described in detail to avoid obscuring the invention in unnecessary detail.

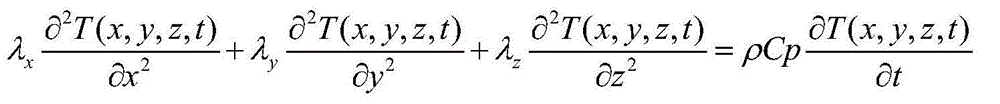

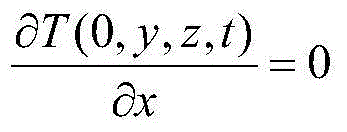

[0036] In the specific implementation, it is assumed that in the measured temperature range, the rectangular anisotropic material has orthotropic characteristics, its normal thermal conductivity and tangential thermal conductivity are unknown parameters to be estimated, other size parameters and All physical parameters are constant. In the established three-dimensional heat transfer model of a rectangular anisotropic material with height H=0.05m and side length b=0.10m in the Cartesian coordinate system, the governing equations and boundary conditions are shown in Equation 4 and Equation 5, respectively:

[0037] λ x ∂ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com