Projection lens polarization aberration in-situ detection method of photoetching machine

A projection objective lens, in-situ detection technology, applied in the field of lithography machine, can solve the problems of complex structure of detection system, phase error, limited polarization aberration measurement range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the examples and drawings, but the examples should not limit the protection scope of the present invention.

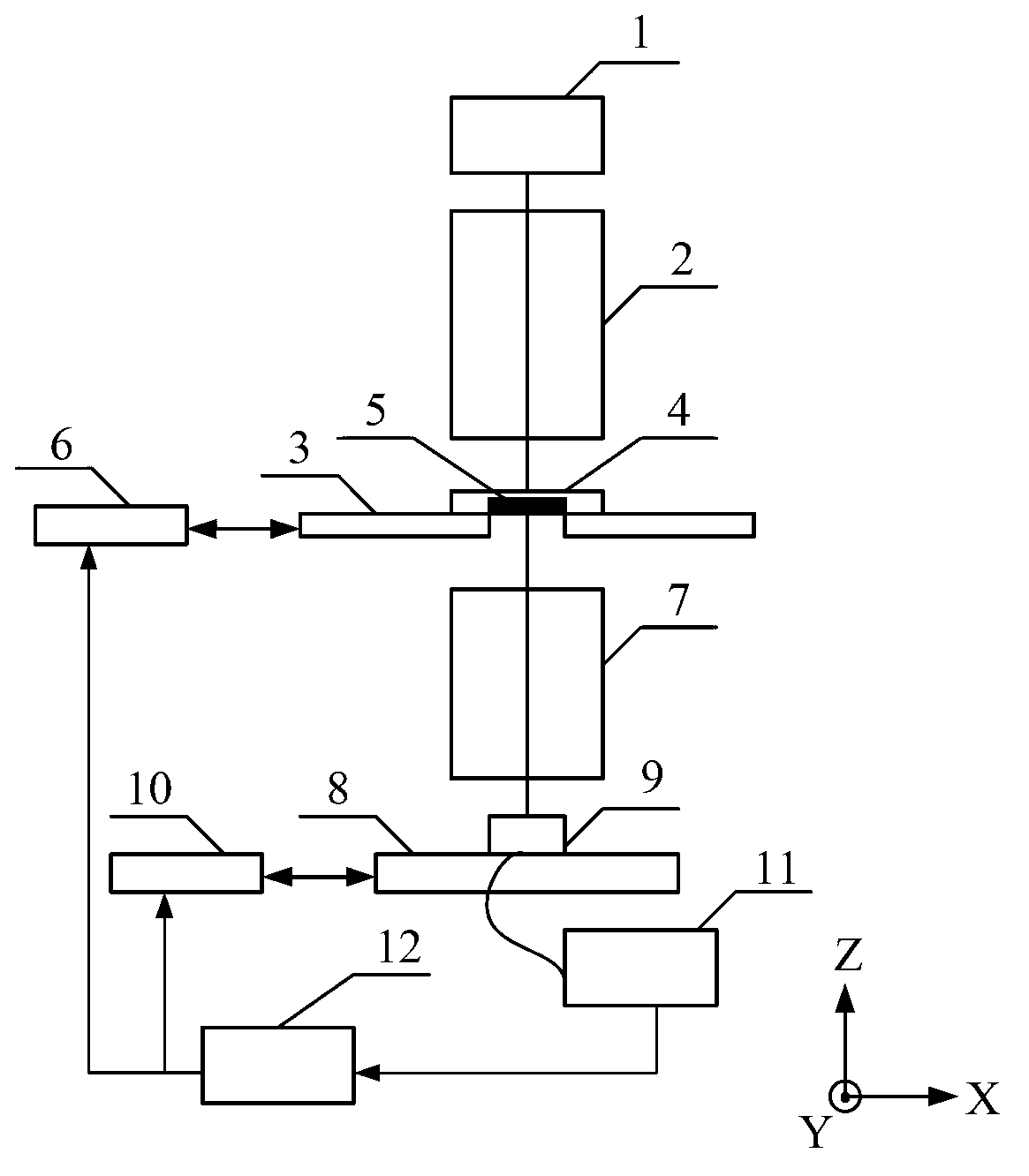

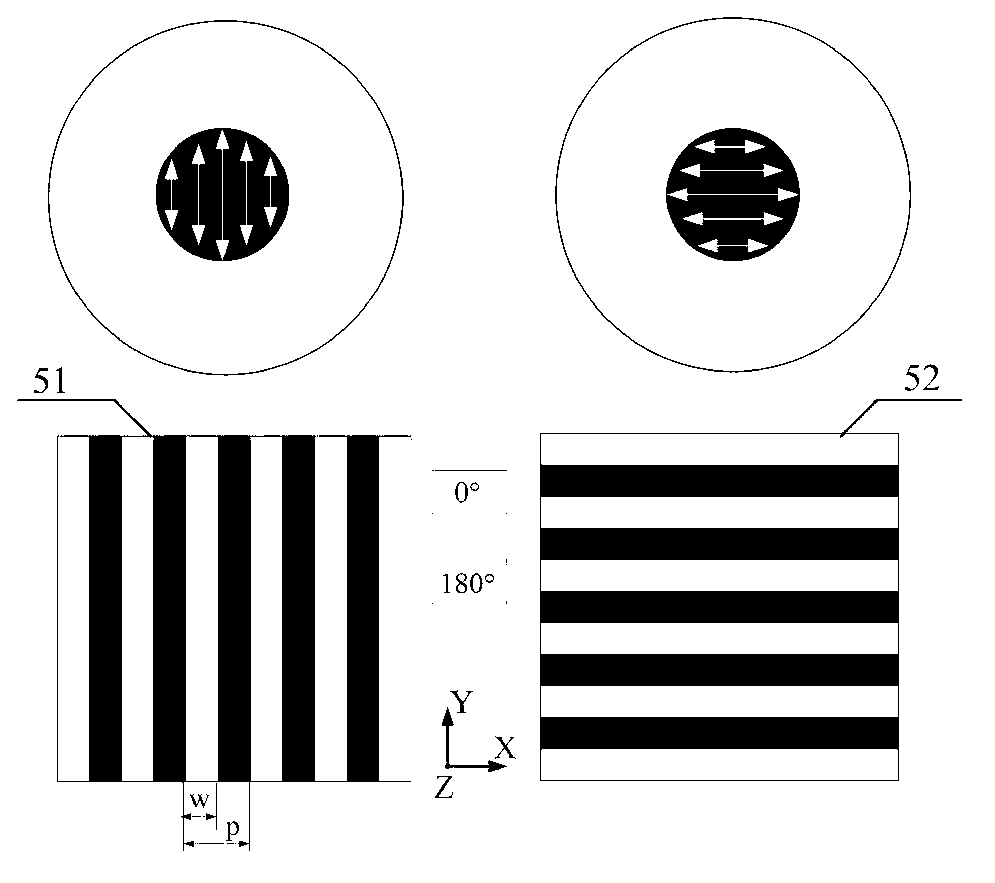

[0058] figure 1 Schematic diagram of the structure of the projection objective polarization aberration detection system used in the present invention, including a light source 1 that generates an illumination beam, an illumination system that adjusts the illumination mode (including polarization illumination mode) and partial coherence factor of the beam emitted by the light source 1 and makes the beam uniformly illuminated 2. A mask table equipped with a mask and using a positioning system 6 to achieve precise positioning 3. A mask 4 including a polarization aberration detection mark 5. A projection objective lens with large numerical aperture capable of imaging the mask pattern and having an adjustable numerical aperture 7. A workpiece table 8 capable of carrying silicon wafers and using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com