An online calibration device and method for fiber grating strain sensor

A strain sensor, fiber grating technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of large differences, different, ineffective online calibration, dynamic calibration in-situ calibration, etc., and achieve convenient calibration methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

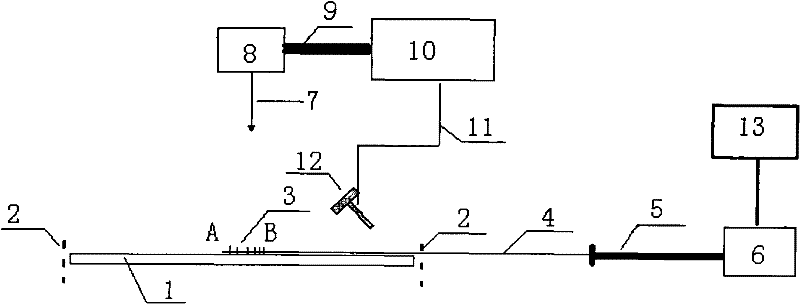

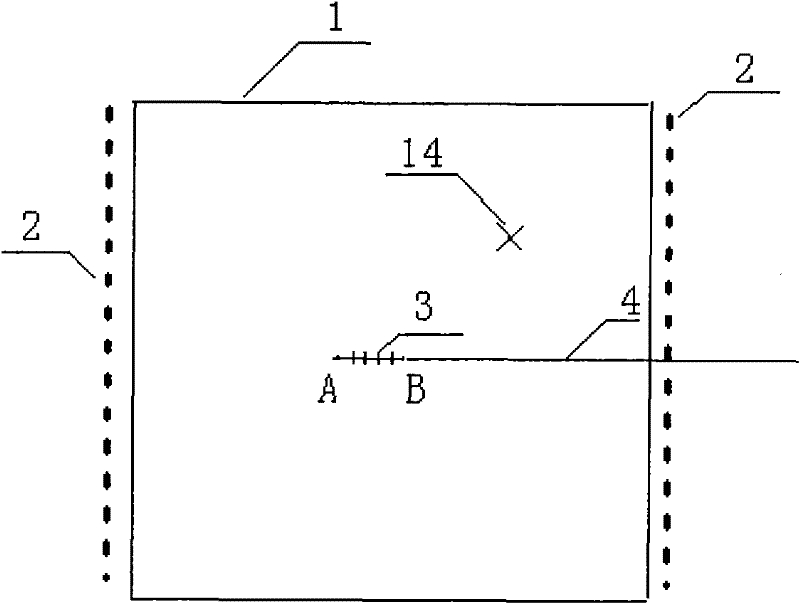

[0039] An online calibration device for fiber grating strain sensors, such as figure 1 and figure 2 As shown, it includes the simulated board to be tested, the boundary support member, the fiber grating strain sensor, the first transmission cable, the fiber grating demodulation instrument, the host computer, the laser lens, the second transmission cable, the laser scanner vibration test and analysis system, and the excitation device and excitation device connection line;

[0040] The above-mentioned excitation device adopts a force hammer;

[0041] The above fiber grating strain sensor is a linear structure with a diameter of 125um and a length of 15mm;

[0042] The above laser lens is Polytec's PSV-400 scanning head;

[0043] The above-mentioned laser scanner vibration test and analysis system is OFV-5000 vibrometer controller of Polytec Company;

[0044] The model of the fiber grating demodulation instrument mentioned above is SM130;

[0045] The length of the above si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com