Manufacturing method for manmade rock sample for simulating real form of hydraulic fracturing crack

A technology of hydraulic fracturing and production methods, which is applied in the fields of earthwork drilling, data processing application, measurement, etc. It can solve the problem that the strength of slabs cannot reach the interaction between fracturing construction and formation pressure, the inability to obtain artificial rock samples, and the deviation of mechanical properties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with accompanying drawing and example.

[0063] A method for making artificial rock samples for simulating the real shape of hydraulic fracturing fractures, the main steps are as follows:

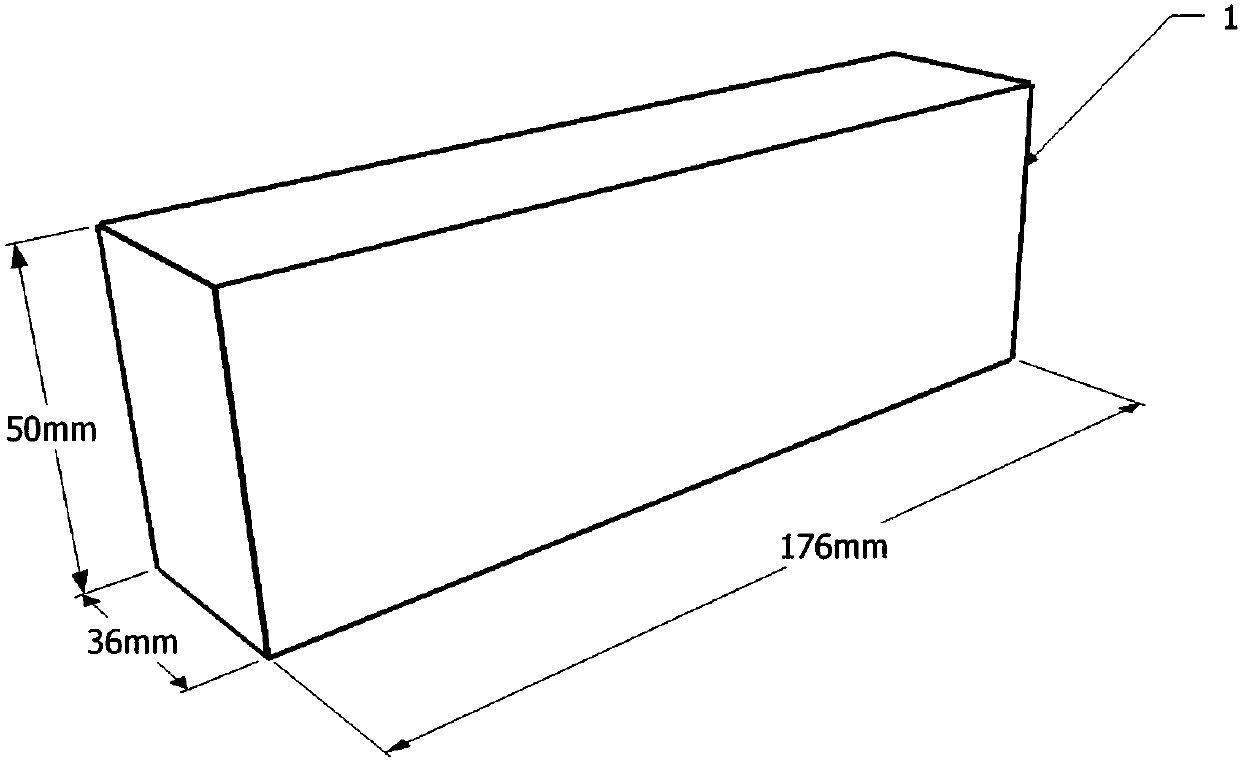

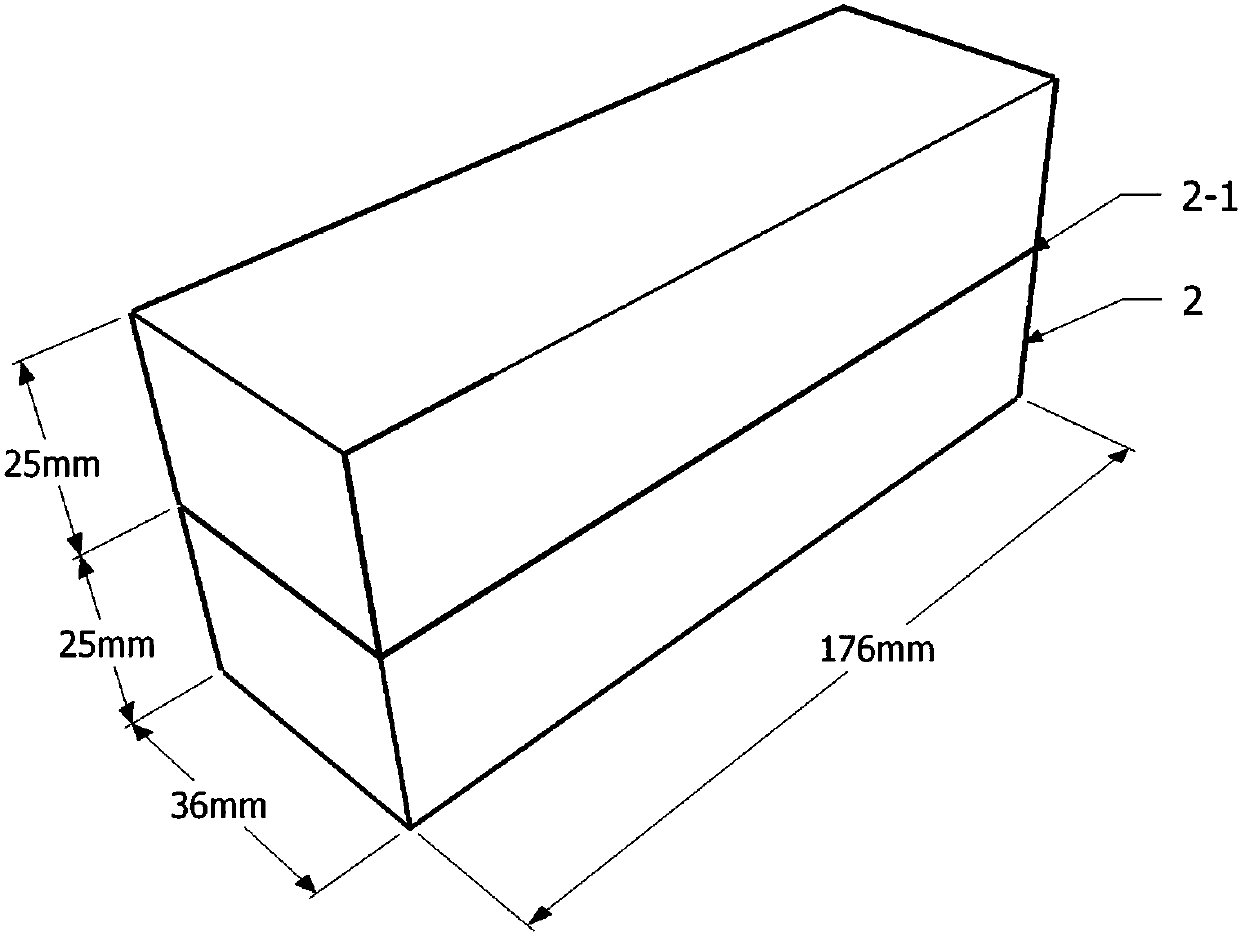

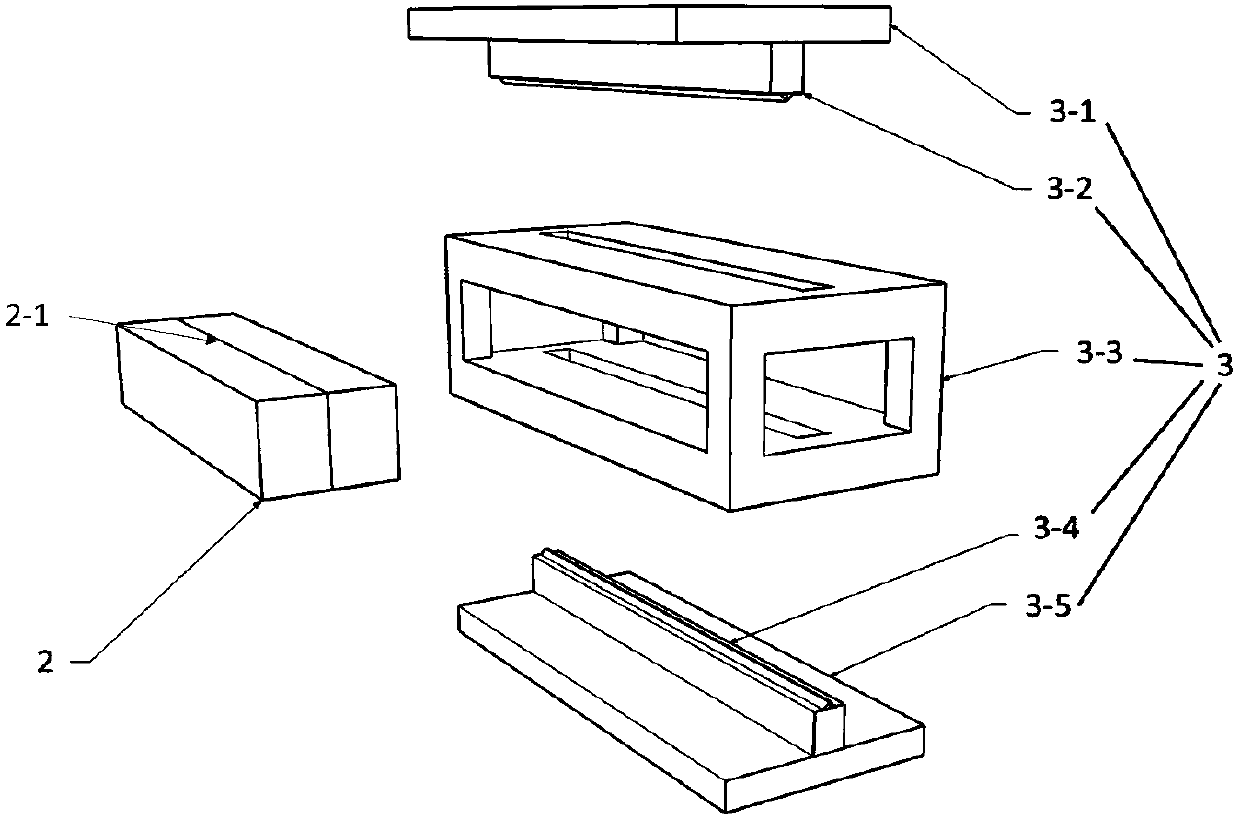

[0064] Make the original square rock slab 1 using the downhole core of the oil and gas reservoir section or outcrop rock in the same layer; prefabricate the scratch 2-1 in the middle of the original square rock slab 1; use the rock slab splitting device 3 to split the square rock with the prefabricated scratch Plate 2, and use a three-dimensional laser scanner to obtain the surface roughness morphology data of rock sample 4 after splitting; calculate the surface roughness coefficient JRC of rock sample 4 after splitting, and select a pair that best represents the reservoir according to the roughness coefficient JRC The split rock sample 4 of the hydraulic fracturing fracture surface morphology; the selected split ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com