Quantitative evaluation method of structural surface roughness coefficient anisotropy

A technology of roughness coefficient and quantitative evaluation, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems such as the inability to quantitatively determine the anisotropy of the roughness coefficient of the structural surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0042] Example: A quantitative evaluation method for the anisotropy of the roughness coefficient of the structural surface, the process is as follows:

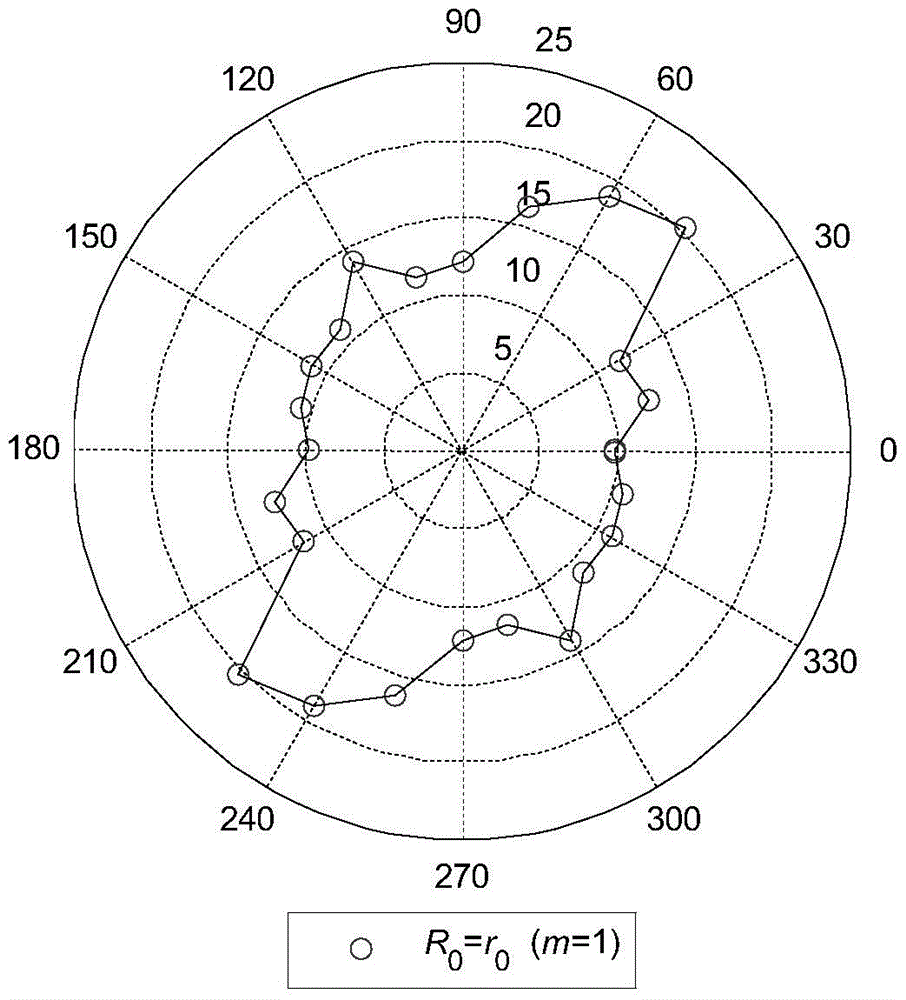

[0043] First, representative granite structural planes were measured in the field. The roughness coefficients of the structural planes measured along different directions are shown in Table 1, and the anisotropy diagram is shown in figure 1 As shown, the value of m is equal to 0 at this time;

[0044]

[0045] Table 1

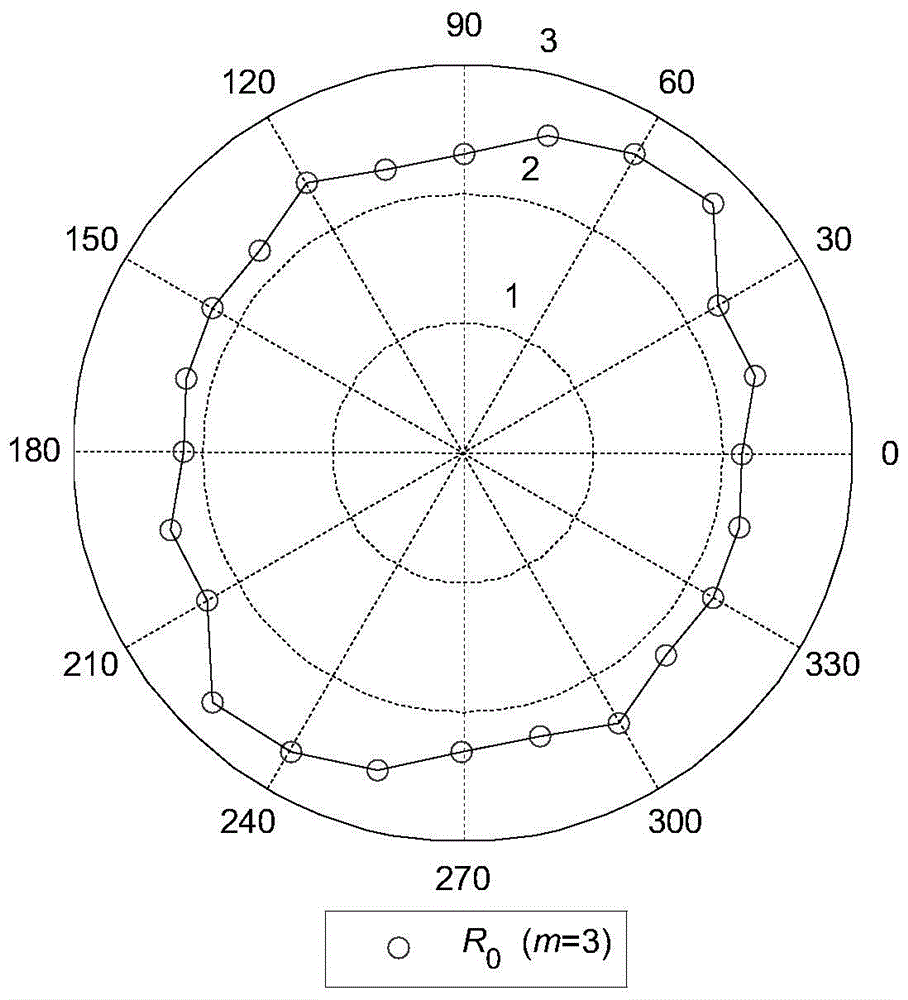

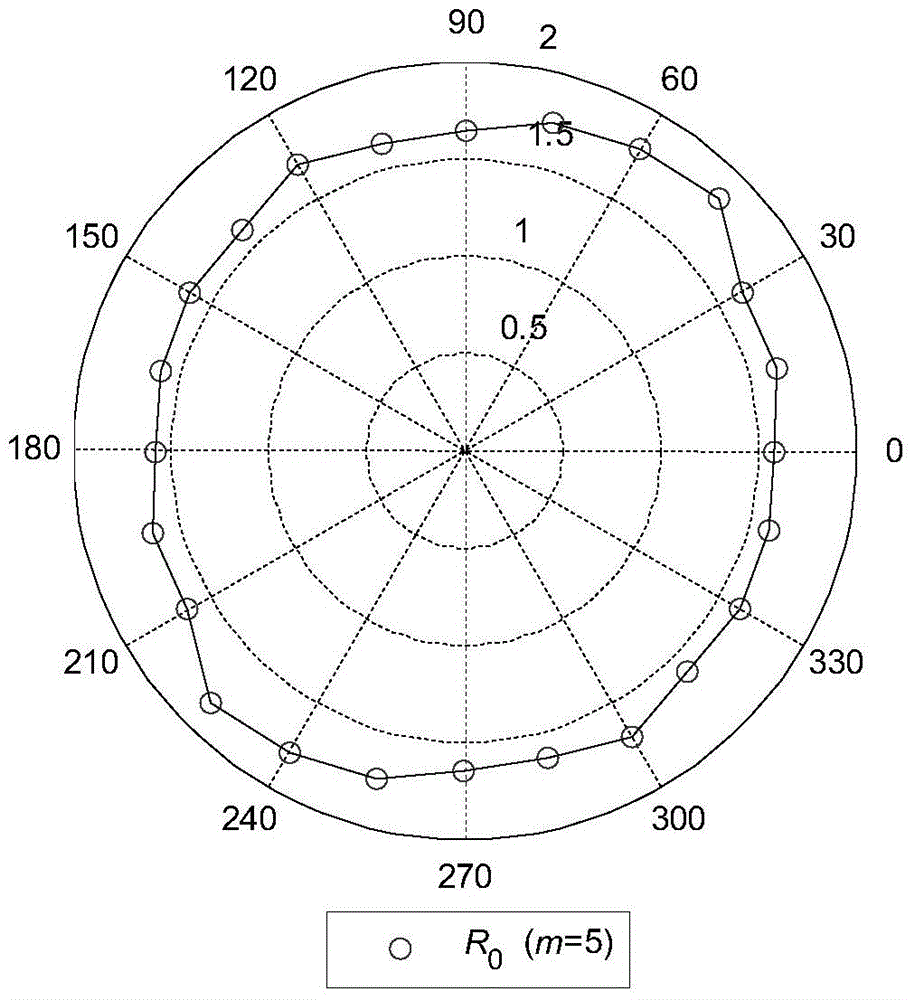

[0046] Secondly, since the roughness coefficient varies greatly in each direction, the elliptic equation cannot be used to directly fit the experimental data. When the value of m is 3 and 5 respectively, the roughness coefficient after processing is in The difference in each direction is significantly reduced, and the irregular shape gradually tends to the elliptical shape. But it does not meet the condition of grade ratio analysis, so it is necessary to continue to increase the value of m;

[0047] Then, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com