Evaluation method for representitiveness of rock structural fece sample

An evaluation method, representative technology, applied in the direction of testing material strength by applying stable shear force, mechanical roughness/irregularity measurement, special data processing application, etc., can solve the problem that the shear strength value of direct shear test cannot be determined Problems such as the relationship between shear strength values, to achieve maximum implementation value and social and economic benefits, good use effect, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

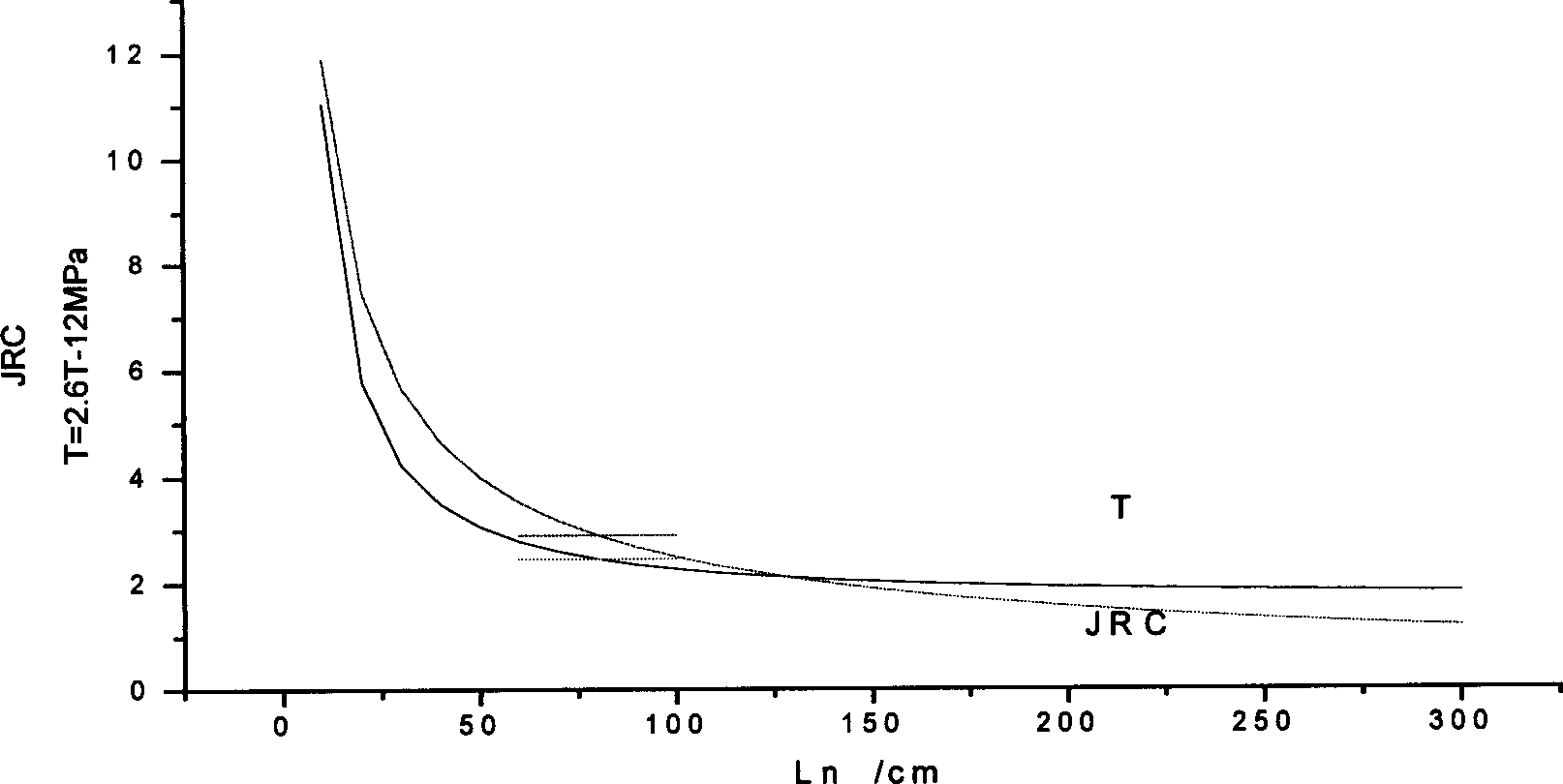

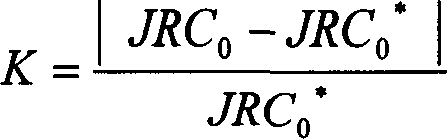

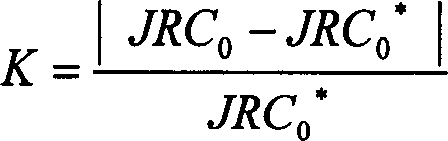

[0013] The test directions were calibrated on the selected rock mass structural surface samples (the granite NEE joint of Tianhuangping Pumped Storage Power Station 20cm×20cm) and the in-situ rock mass structural surface (the field granite NEE joint), so that the rock mass structural surface The measurement direction of the roughness coefficient of the sample and the in-situ rock mass structural surface is consistent; according to the calibrated direction, the rock mass structural surface sample (the granite NEE group joint of Tianhuangping Pumped Storage Power Station 20cm×20cm) is in the test direction , The 16 contour curves of the bottom wall are used for the directional statistical measurement of the roughness coefficient, and the roughness coefficient characteristic value JRC of the rock mass structural surface sample is obtained 0 =6.97; On the in-situ rock mass structure (NEE joints of field granite), along the calibration direction, according to the length of the rock mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com