All-lining debris flow draining and guiding groove with roughened groove bottom and application thereof

A technology for drainage channel and debris flow, which is applied in dikes, coastline protection, dams, etc., can solve the problems such as roughening of debris flow drainage channels that are not suitable for full lining, so as to save project operation and maintenance costs, reduce project maintenance costs, and improve The effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

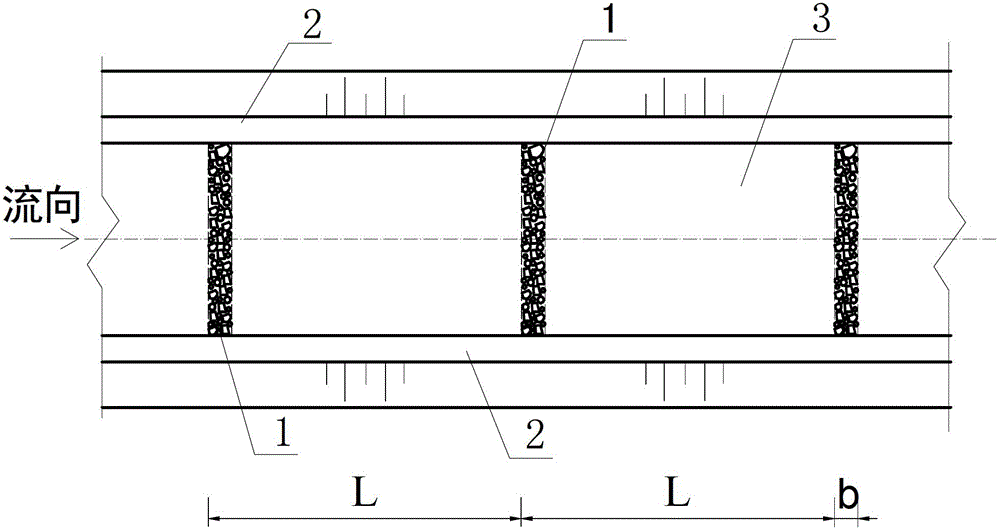

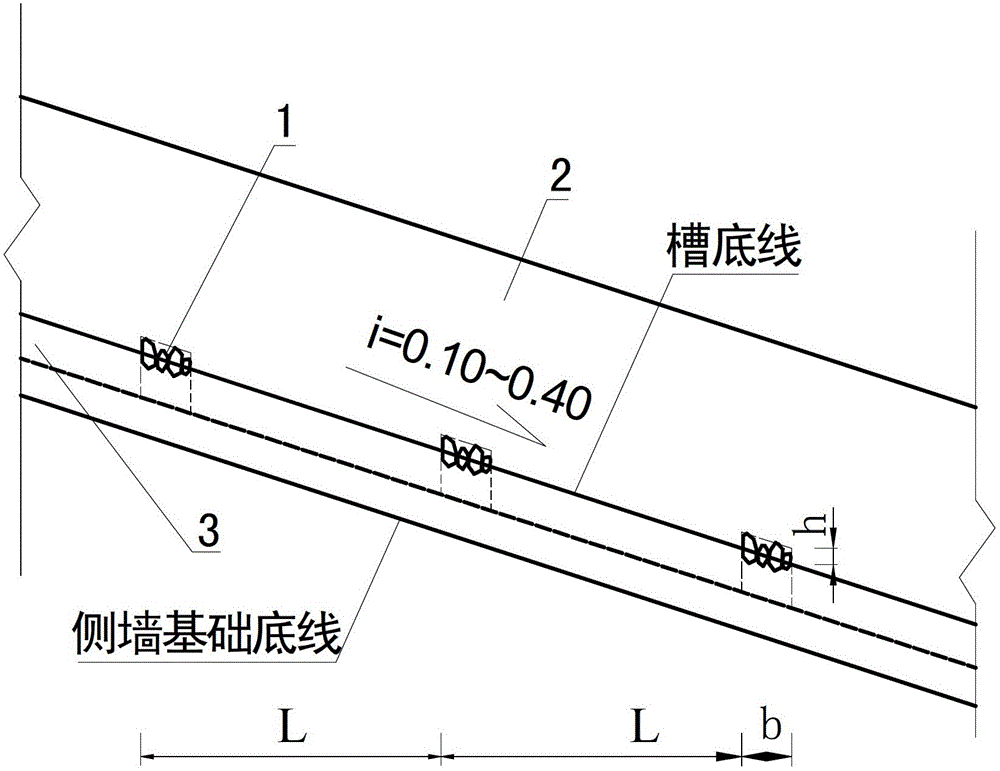

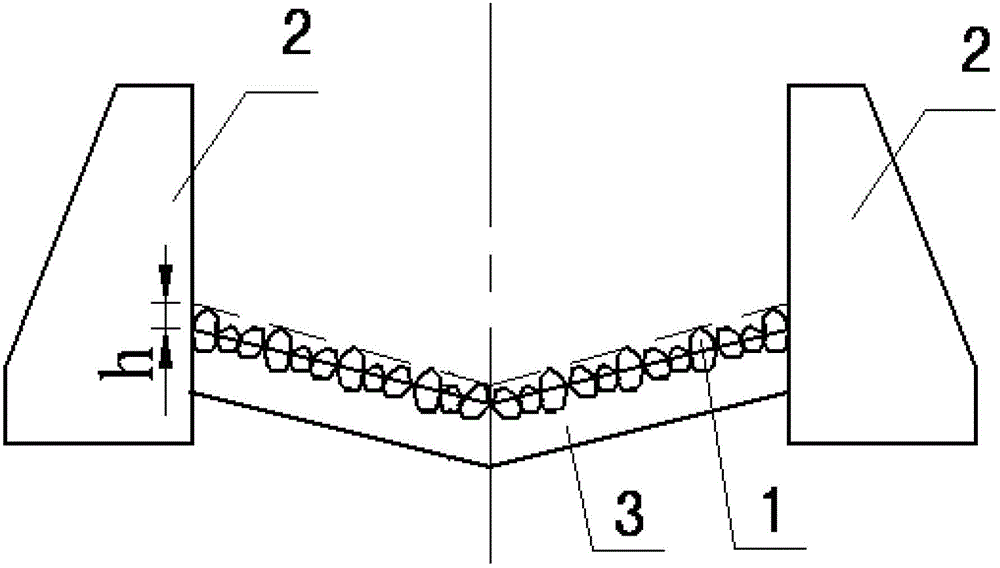

[0025] Such as figure 1 , figure 2 , image 3 shown. For a watershed area of 1.3km 2 , the slope of the accumulation fan is 40%, and the design flow rate of the once-in-20-year debris flow is 52m 3 / s, the density of debris flow is 20kN / m 3 , on the debris flow accumulation fan, build a fully lined debris flow drainage channel with a rough bottom, including a fully lined drainage channel bottom plate 3 and drainage channel side walls 2 on both sides. Above the bottom plate 3 of the guide groove, there are several roughened belts 1 that penetrate horizontally along the guide groove, are connected with the bottom plate 3 of the guide groove, are distributed at a certain distance, have a certain width and a convex height, and several roughened belts 1 with different convex heights. The roughened bodies are randomly arranged to form the roughened belt 1, and the top surface of the roughened belt 1 is uneven.

[0026] According to the slope of the accumulation fan, the ver...

Embodiment 2

[0029] Such as figure 1 , figure 2 , image 3 shown. For a basin area of 18.4km 2 , the slope of the accumulation fan is 10%, and the designed flow rate of debris flow once in 20 years is 126m 3 / s, the density of debris flow is 15kN / m 3 , on the debris flow accumulation fan, build a fully lined debris flow drainage channel with a rough bottom, including a fully lined drainage channel bottom plate 3 and drainage channel side walls 2 on both sides. Above the bottom plate 3 of the guide groove, there are several roughened belts 1 that penetrate horizontally along the guide groove, are connected with the bottom plate 3 of the guide groove, are distributed at a certain distance, have a certain width and a convex height, and several roughened belts 1 with different convex heights. The roughened bodies are randomly arranged to form the roughened belt 1, and the top surface of the roughened belt 1 is uneven.

[0030]According to the slope of the accumulation fan, the vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com