Surface structure of silicon crystal cell and manufacturing method thereof

A technology of battery surface and manufacturing method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuit, etc., can solve the problems of low photoelectric conversion efficiency, fragmentation, thin thickness of crystalline battery, etc., to improve photoelectric conversion efficiency, An effect that reduces the chance of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

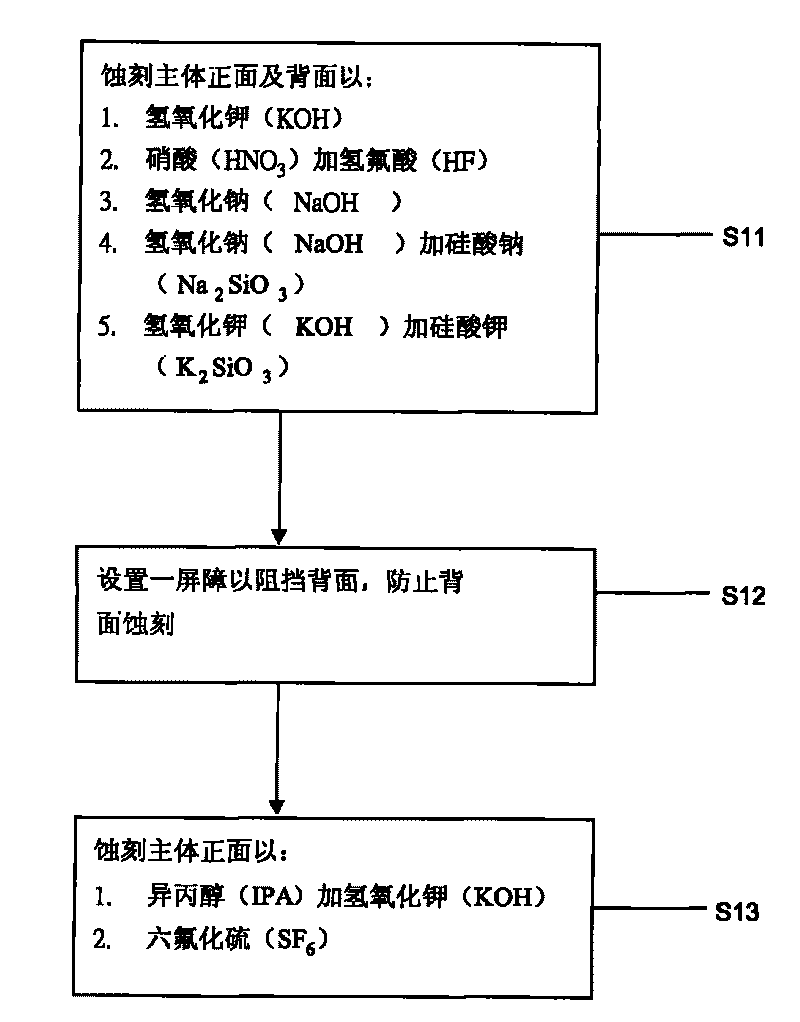

Method used

Image

Examples

Embodiment Construction

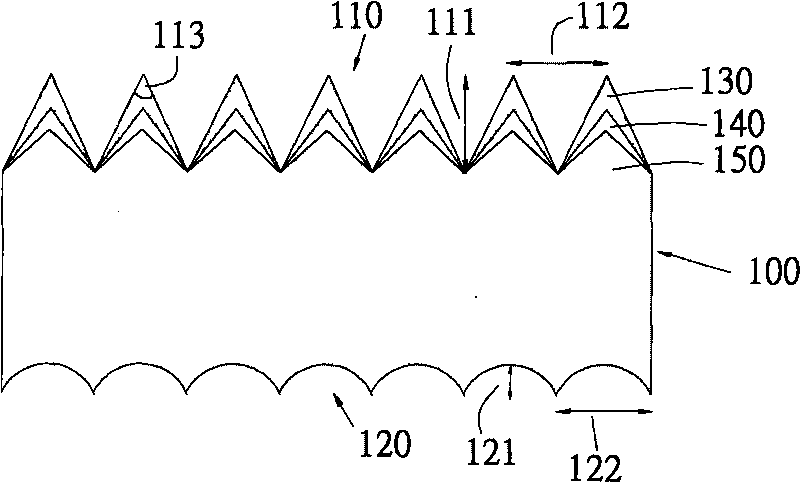

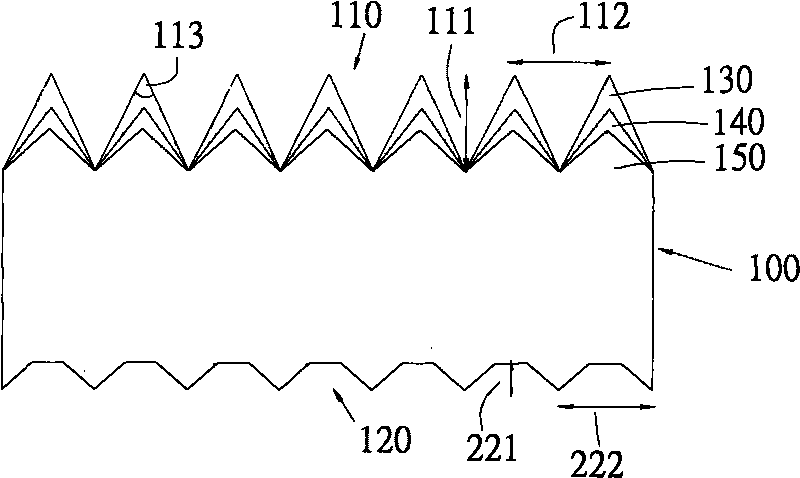

[0021] figure 1 with figure 2 It is a schematic diagram of two embodiments of the surface structure of the silicon crystal battery proposed by the present invention. Such as figure 1 As shown, the surface structure of the silicon crystal battery includes: a main body 100 , the main body 100 has a front surface 110 and a back surface 120 , and the roughness coefficient of the structure of the front surface 110 is greater than that of the structure of the back surface 120 . The surface morphology of the microstructure of the front surface 110 includes a plurality of cones, and the direction of the apex of the cones is away from the main body 100 . In addition, the surface morphology of the microstructure of the back surface 120 includes a plurality of arcs. figure 2 Showing another implementation structure, the surface morphology of the microstructure on the back surface 120 includes a plurality of polygonal structures.

[0022] figure 1 wherein, the height 111 of the fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Vertex angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com