Design method of nuclear main pump impeller

A design method and nuclear main pump technology, applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve problems such as nuclear accidents, nuclear main pump head performance degradation, and reactor failure. , to achieve high efficiency, lift and excellent hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

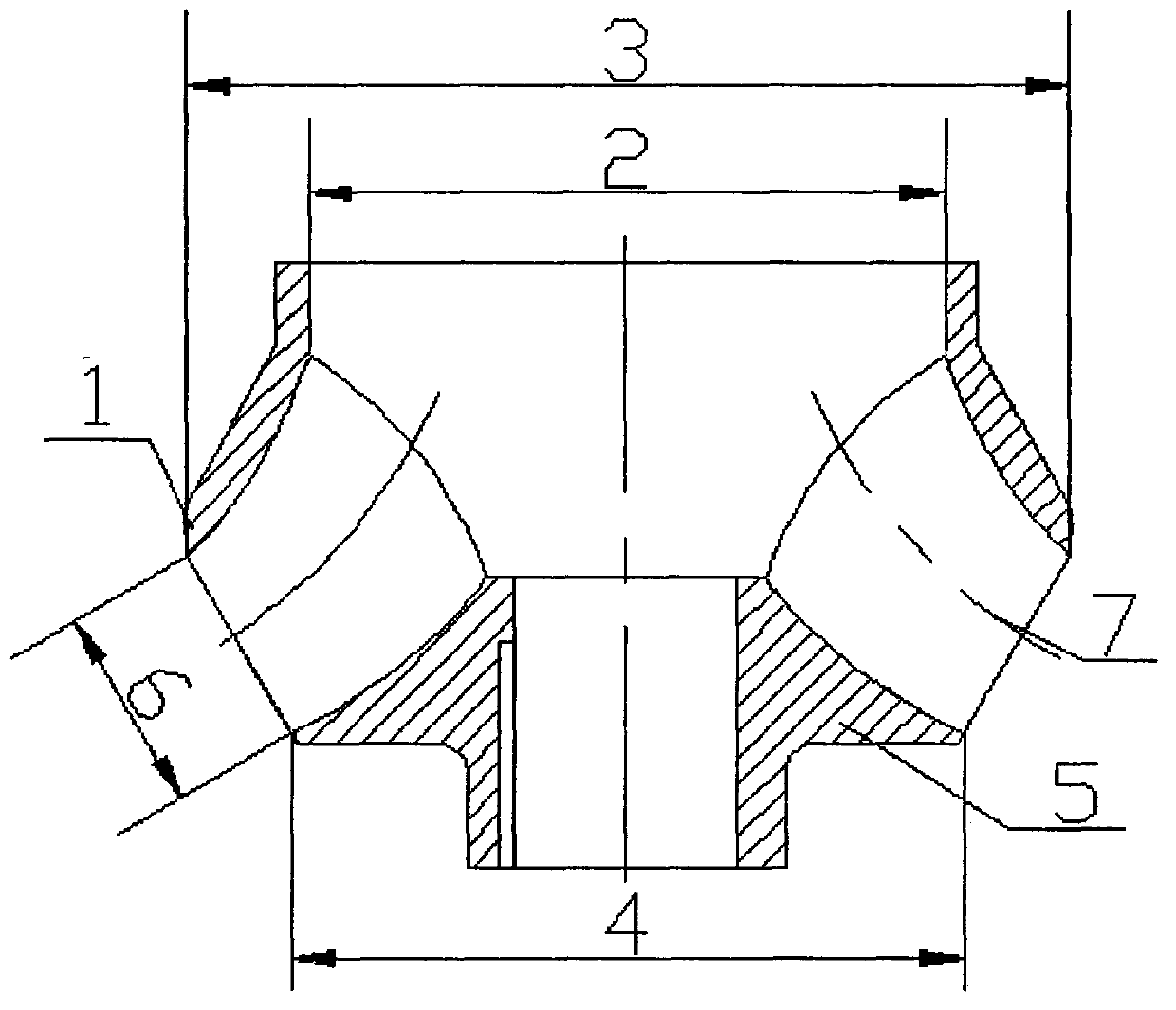

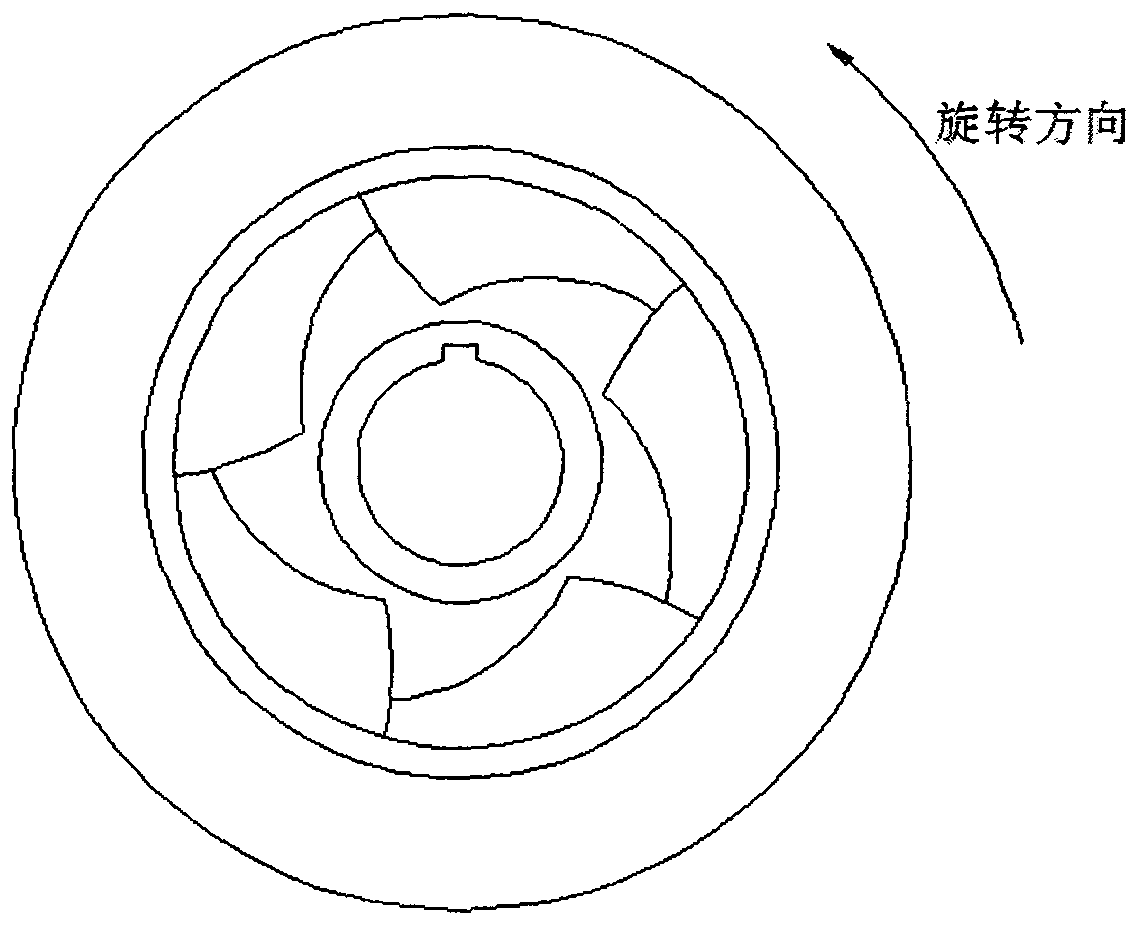

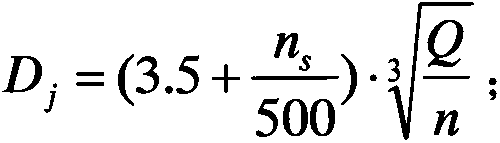

[0036] figure 1 is the axial projection of the example. Like most impellers, it has an impeller front cover (1) and an impeller rear cover (5). It is a closed impeller with 5 blades, which can improve the flow conditions, improve the hydraulic performance and gas resistance of the mixed pump effect on its delivery capacity. The present invention determines the shape of the impeller by the following relations: impeller inlet diameter D j (2), impeller outlet diameter D 2 , impeller blade outlet width b 2 (6).

[0037] D j = ( 3.65 + n s 300 ) · Q n 3 ;

[0038] D 2 = D 20 + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com