Hydraulic design method of high-cavitation-resistance nuclear main pump impeller and high-cavitation-resistance nuclear main pump impeller

A technology of hydraulic design and nuclear main pump, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems such as pipeline rupture, pipeline pressure changes, and water loss accidents, and improve safety Performance and stability, high cavitation resistance, excellent hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

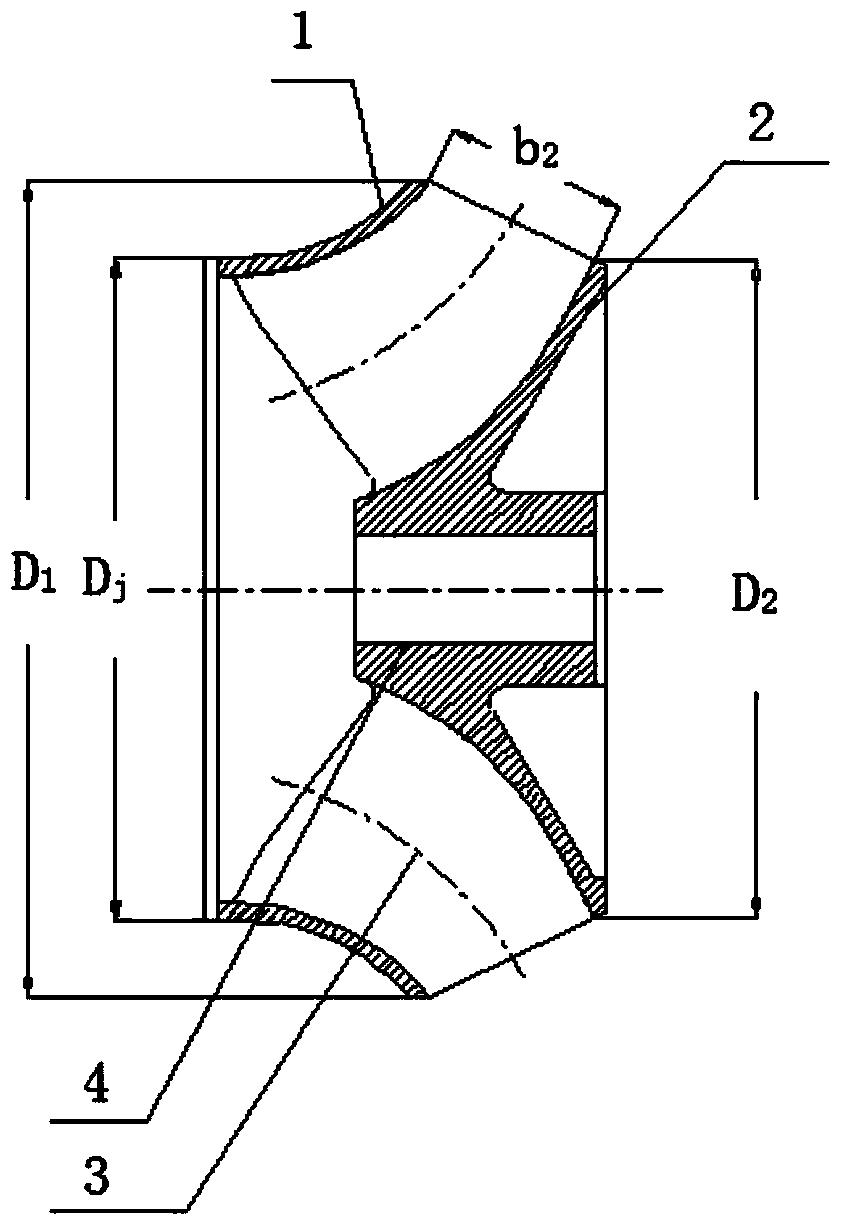

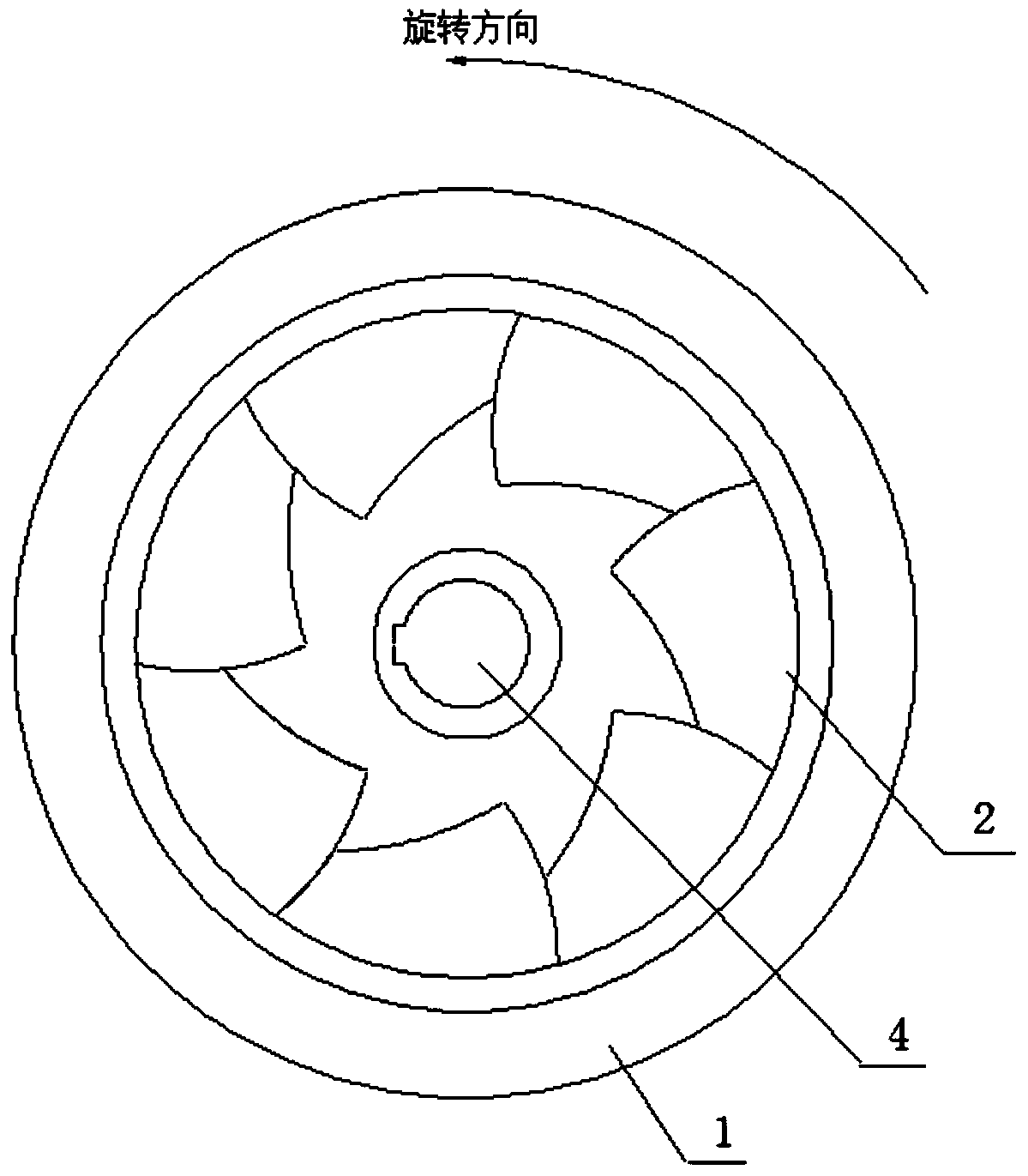

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0026] The hydraulic design method of the high-cavitation-resistant nuclear main pump impeller of the present invention adopts the method of increasing the rotating speed of the nuclear main pump to improve the head of the nuclear main pump that drops sharply under the loss of water accident; the selected nuclear main pump rotating speed is 1800r / min , to increase the pressure at the inlet of the nuclear main pump in case of a loss of water accident. The specific speed is selected according to the following theory: when the specific speed is too low, the flow rate decreases and the head is too high. However, in a loss of water accident, the nuclear main pump needs to provide a large flow in a short time to take away the heat of the core, thereby reducing the possibility o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com