Design method for non-clogging vortex-pump impeller with long and short edgefold blades

A design method and swirl pump technology, applied to parts, pumps, pump elements, etc. of pumping devices for elastic fluids, can solve energy waste, cannot effectively limit radial to axial circulation flow, and swirl flow Problems such as poor hydraulic performance of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

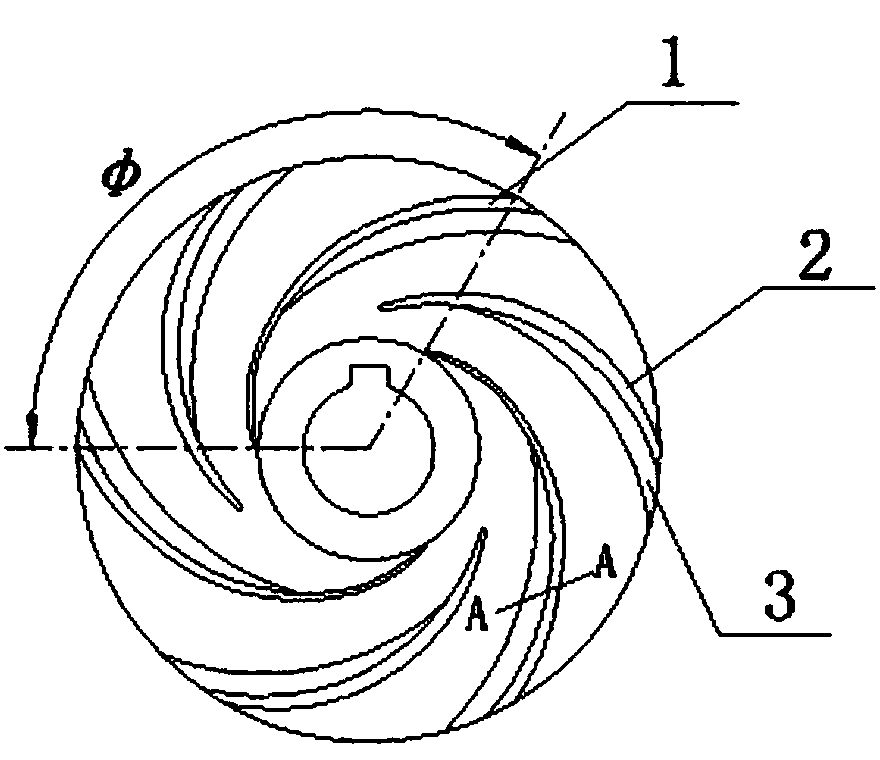

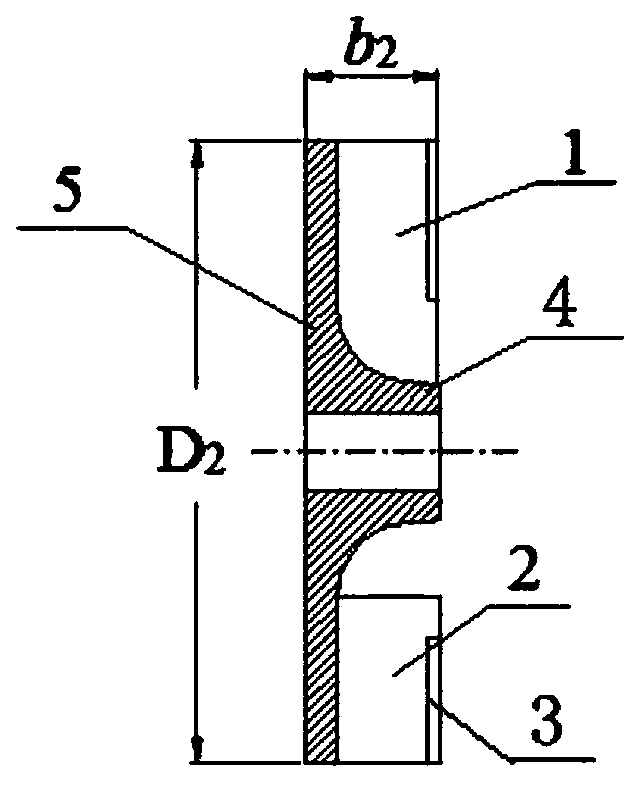

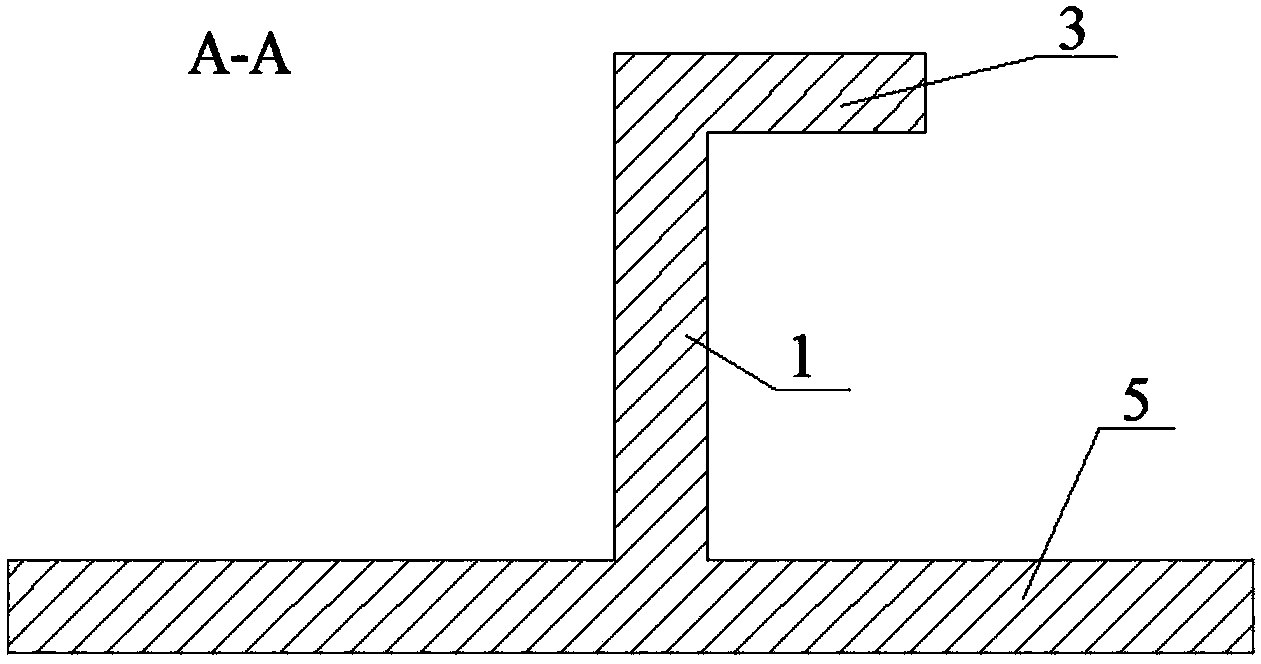

[0038] According to the design method of the non-clogging swirl pump impeller with long and short folded blades in the present invention, the impeller adopts a semi-open impeller with a rear cover plate 7, a hub 4 and blades, and the blades of the impeller include lengths of different lengths. The blade 1 and the short blade 2, the long blade 1 and the short blade 2 each have a folded edge 3 extending in a direction opposite to the rotation direction of the impeller. The impeller outer diameter D of the swirl pump impeller 2 , impeller outlet width b 2 , impeller inlet diameter D 1 , the total number of blades Z, the width of the volute without blade cavity L, the width of the folded edge 3 b 0 , blade wrap angle φ is obtained by the following formula:

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com