Combined type method for designing variable-camber low-specific-speed centrifugal pump impeller

A centrifugal pump impeller, low specific speed technology, applied in the direction of non-variable-capacity pumps, pumps, pump components, etc., can solve the problem of head reduction, impeller turbulence and vortex, pump unit vibration intensity and operation instability increase and other problems, to achieve the effect of increasing head, improving hydraulic performance and conveying capacity, and increasing head and operable flow range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

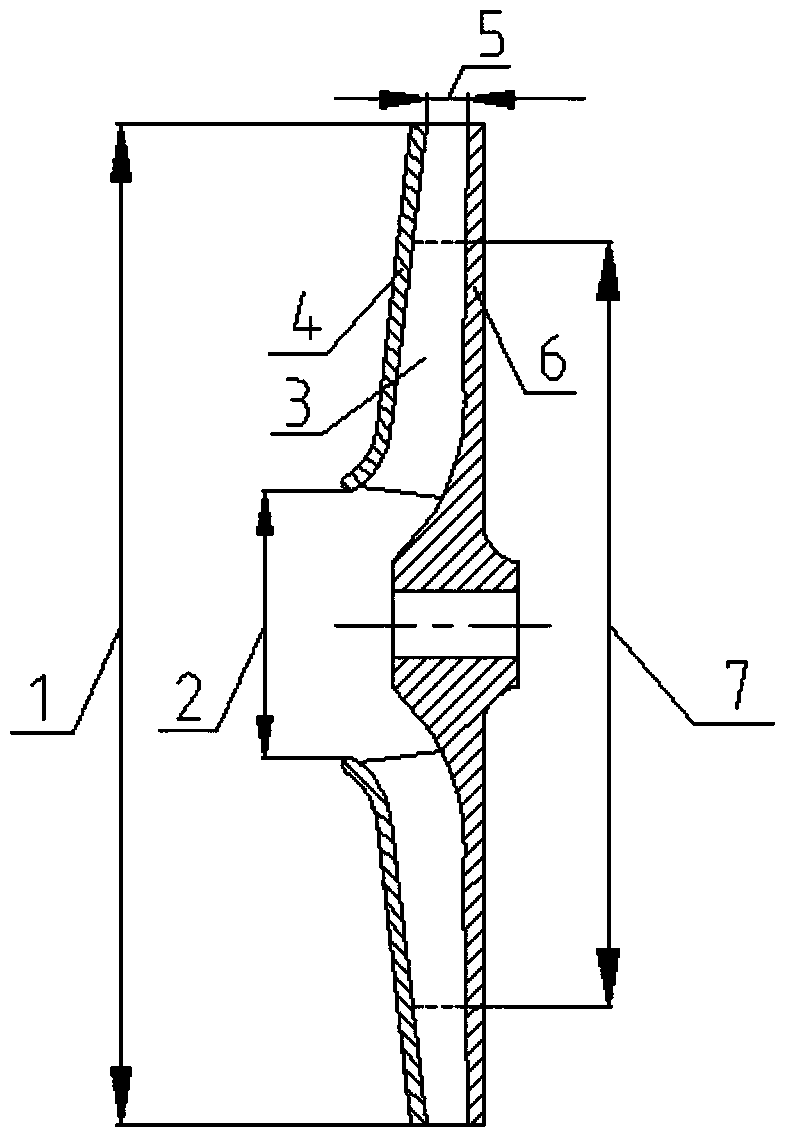

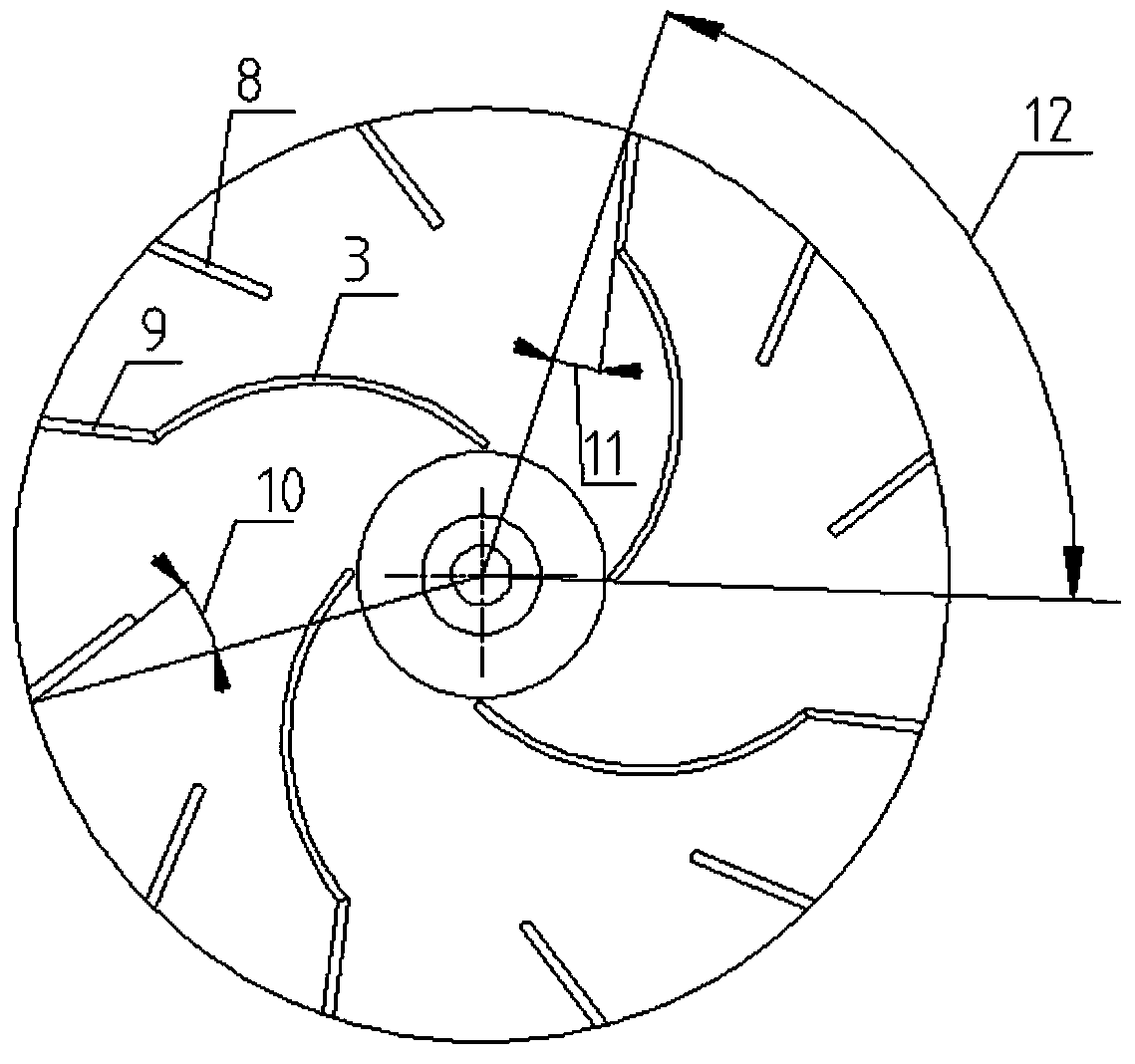

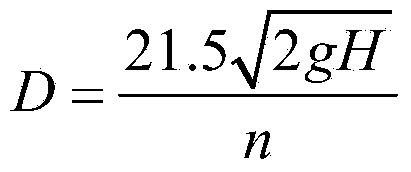

[0039] figure 1 and figure 2 Together determine the impeller shape and geometry for this embodiment. This is a compound variable curvature low specific speed centrifugal pump impeller with a closed structure. The radial size and structure of the impeller front cover (4) and impeller rear cover (6) are straight, and the axial section through the flow channel is relatively small. Wide enough to allow solid particles of a certain size to pass through. The splitter blades (8) and the forward curved blades (9) are distributed on the outer edge of the impeller, both adopt the straight blade type, and the splitter blades (8) are evenly distributed between the backward curved blades (3), and the blade inclination angles are α 1 and alpha 2 . The present invention determines impeller outer diameter (1) D and impeller inlet diameter (2) D through the following relations j , the width of the impeller outlet (5)b, the inner diameter of the forward curved blade (7)D f , splitter bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com