Axial flow pump device guide vane body hydraulic optimization method based on tests

A technology of hydraulic optimization and guide vanes, which is applied to components, pumps, and pump control of pumping devices for elastic fluids, and can solve problems such as mismatching hydraulic performance and increasing head loss in outlet channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

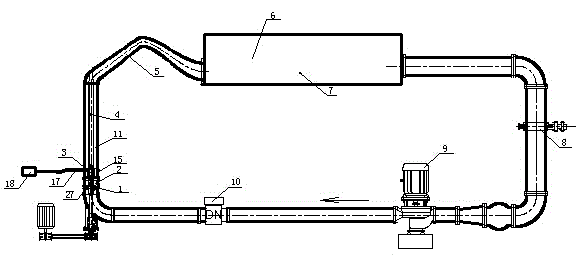

[0062] A large-scale vertical axial-flow pump device using a siphon outlet flow channel, the test-based hydraulic optimization method for the guide vane body of the device includes the following steps:

[0063] (1) Design and build a model test device in which the average velocity circulation of the guide vane outlet of the axial flow pump device affects the hydraulic performance of the outlet channel, such as figure 1 As shown, it is composed of model pump 1, guide vane body 2, average velocity circulation meter 3, water outlet channel 5, water outlet pool 6, gate valve 8, auxiliary pump 9, and flow meter 10 connected in sequence through pipelines, and the inlet of water outlet channel 5 The wall of the pipeline 11 is provided with a pressure measuring hole 4 at the inlet of the outlet channel, and a pressure measuring tube connected with the inlet of the outlet channel is installed on the pressure measuring hole 4 of the inlet of the outlet channel. The outlet pressure measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com