Hydraulic design method of no-jam cyclone pump

A technology of hydraulic design and swirl pump, which is applied to components, pumps, and pump components of elastic fluid pumping devices, can solve problems such as energy waste and large hydraulic loss, and achieve reduced energy loss, improved efficiency, The effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

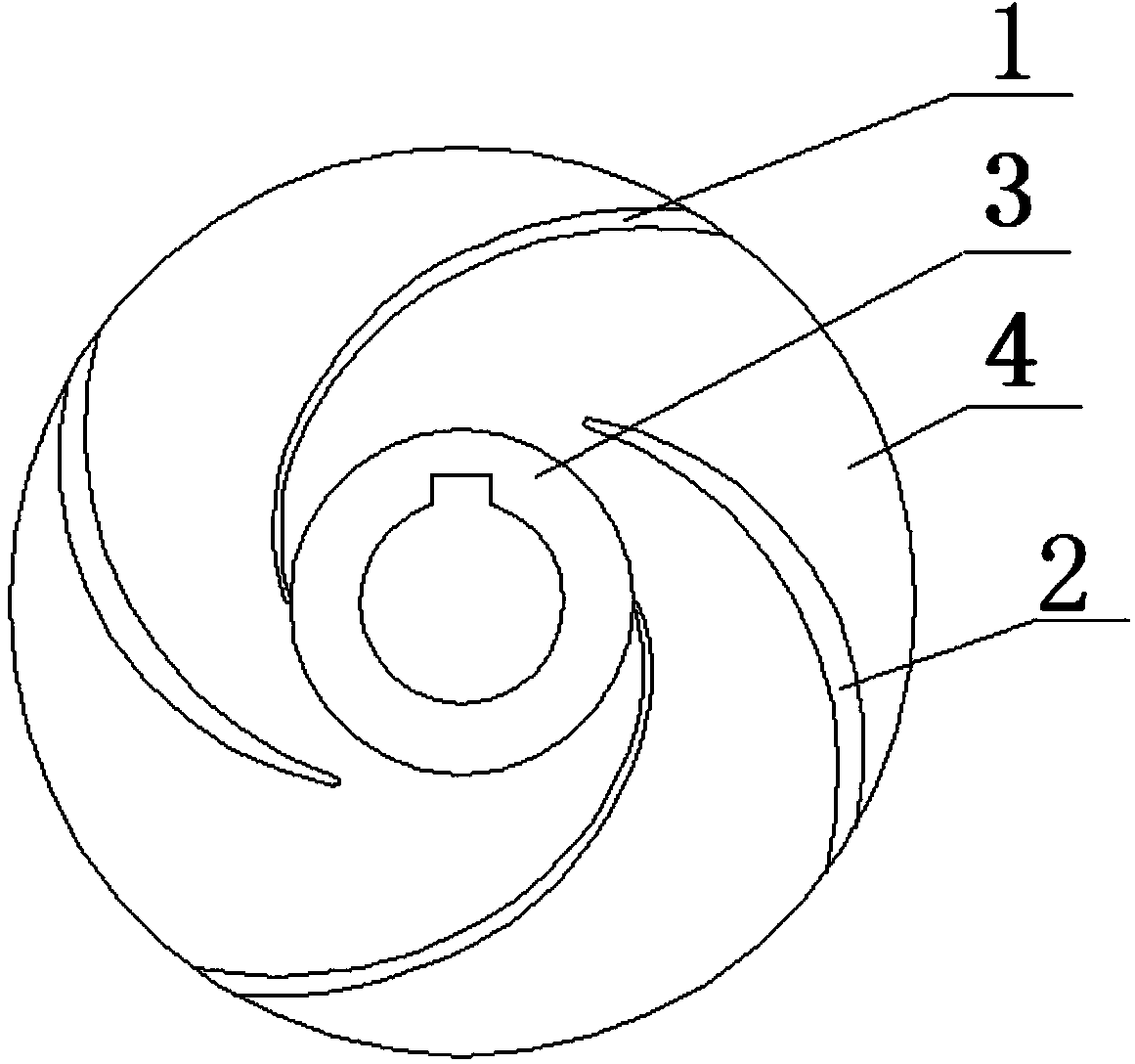

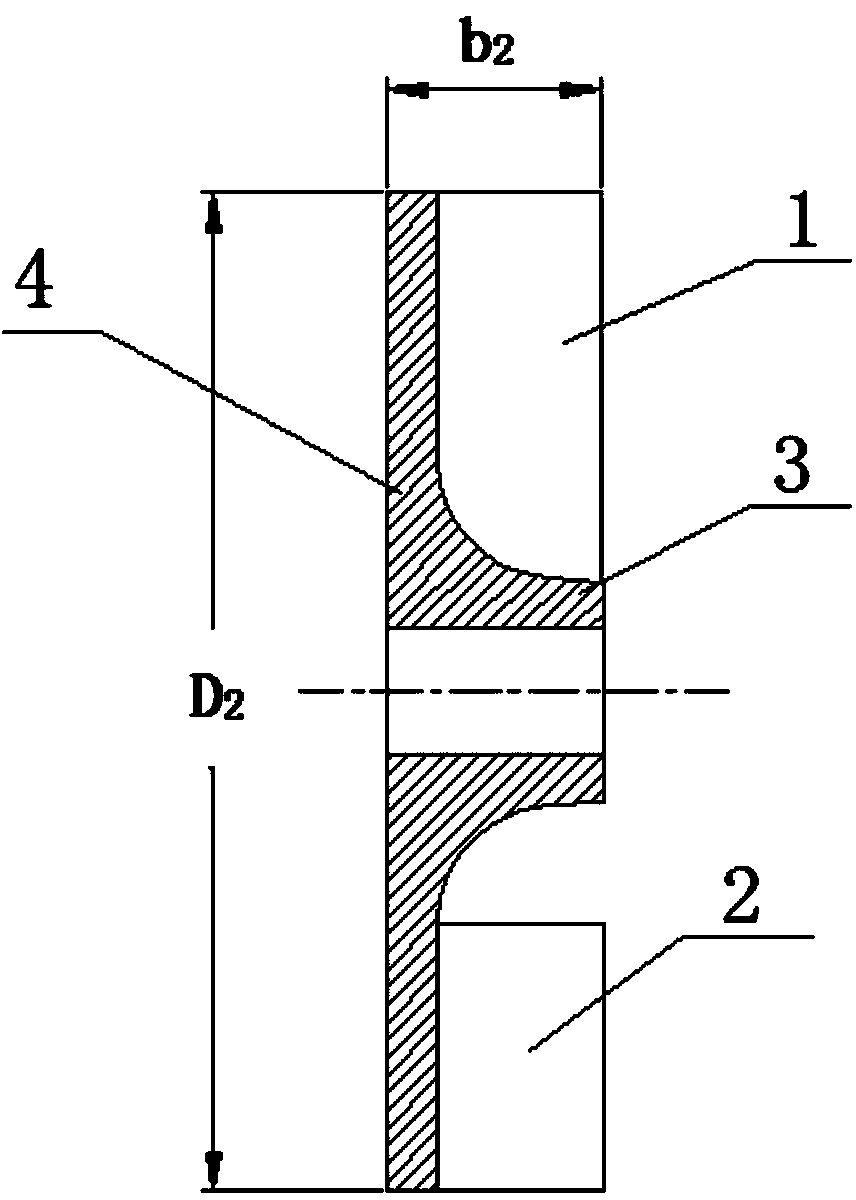

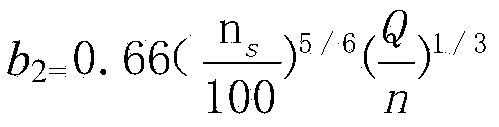

[0040] The hydraulic design method of the non-clogging swirl pump of the present invention, the impeller of the swirl pump is as figure 1 , figure 2 As shown, a semi-open impeller is selected, including a blade, a hub 3, and an impeller rear cover 4. The blade is arranged on one side of the impeller rear cover 4, and the hub 3 is located at the center of the impeller rear cover 4. The blades adopt several long blades and short blades with different lengths to improve the internal flow of the pump and improve the hydraulic performance and reliability of the swirl pump. Specifically, the length L of the long blade 1 with short blade length L 2 The ratio of The number of the long blades and the short blades is 2, and in order to keep the balance of the impeller, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com