Modified anion resin material and preparation method and application thereof

An anion resin and modification technology, applied in the direction of anion exchange, organic anion exchanger, ion exchange, etc., can solve the problems that the preparation method has not been reported, and achieve good application prospects, good mechanical strength, and excellent adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

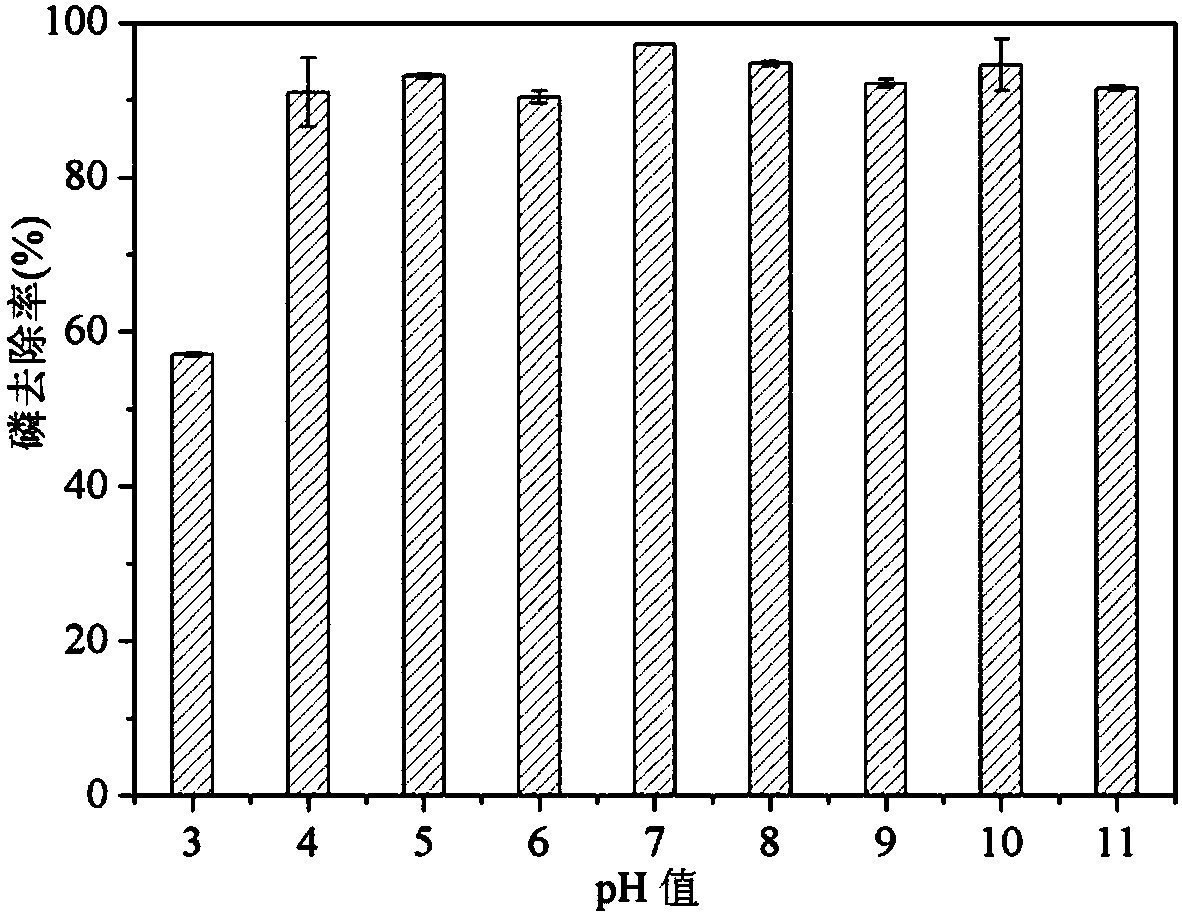

Image

Examples

preparation example Construction

[0035]

[0036] A kind of preparation method of modified anion resin material, it comprises the steps:

[0037] (1), strong base type anion resin material is carried out 5-6 rinse with deionized water, and dry strong base type anion resin material that obtains drying;

[0038] (2), the hydrochloric acid solution of ferric chloride (FeCl 3 +HCl) and hydrochloric acid solution of zirconium oxychloride (ZrOCl 2 ·8H 2 O+HCl) are mixed to obtain the first mixed solution, then the dry strong base anion resin material of step (1) is added into the first mixed solution, and stirred at 25±5°C for impregnation;

[0039] (3), add sodium hydroxide (NaOH) solution in the reaction system of step (2) with the speed of 5 drops per second and adjust the pH value of this reaction system to 7‐8, stir at 25 ± 5 ° C to obtain the first Two mixed solution;

[0040] (4) Centrifuge the second mixed solution in step (3), and dry it to a constant weight to obtain a modified anion resin material. ...

Embodiment 1

[0056] The preparation method of the modified anion resin material of the present embodiment comprises the steps:

[0057] (1), strong base anion resin material (containing quaternary ammonium salt functional group) is rinsed 6 times with deionized water, and dry to obtain dry strong base anion resin material, the temperature of drying is 50 ℃, the drying The time is 12h;

[0058] (2), 0.1mol / L ferric chloride hydrochloric acid solution (FeCl 3 +HCl) and 0.1mol / L zirconium oxychloride hydrochloric acid solution (ZrOCl 2 ·8H 2 O+HCl) are mixed to obtain the first mixed solution, then the dry strong base anion resin material in step (1) is added into the first mixed solution, and stirred at 25°C for impregnation, wherein the stirred The rotating speed is 300rpm, and the soaking time is 2h;

[0059] (3), add 0.5mol / L sodium hydroxide (NaOH) solution in the reaction system of step (2) with the speed of 5 drops per second and adjust the pH value of this reaction system to be 7,...

Embodiment 2

[0068] The preparation method of the modified anion resin material of the present embodiment comprises the steps:

[0069] (1), strong base anion resin material (containing quaternary ammonium salt functional group) is rinsed 6 times with deionized water, and dry to obtain dry strong base anion resin material, the temperature of drying is 70 ℃, the drying The time is 24h;

[0070] (2), 0.5mol / L ferric chloride hydrochloric acid solution (FeCl 3 +HCl) and 0.5mol / L zirconium oxychloride hydrochloric acid solution (ZrOCl 2 ·8H 2 O+HCl) are mixed to obtain the first mixed solution, then the dry strong base anion resin material in step (1) is added into the first mixed solution, and stirred at 25°C for impregnation, wherein the stirred The rotating speed is 400rpm, and the soaking time is 3h;

[0071] (3), add 1.0mol / L sodium hydroxide (NaOH) solution in the reaction system of step (2) with the speed of 5 drops per second and adjust the pH value of this reaction system to be 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com