Baffle fixed at a separation from the internal wall of an enamelled container by means of a local connection

A technology of baffles and fixed distances, applied in the field of baffles, can solve problems such as damage and damage to protective enamel coatings, and achieve the effect of reducing industrial costs and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

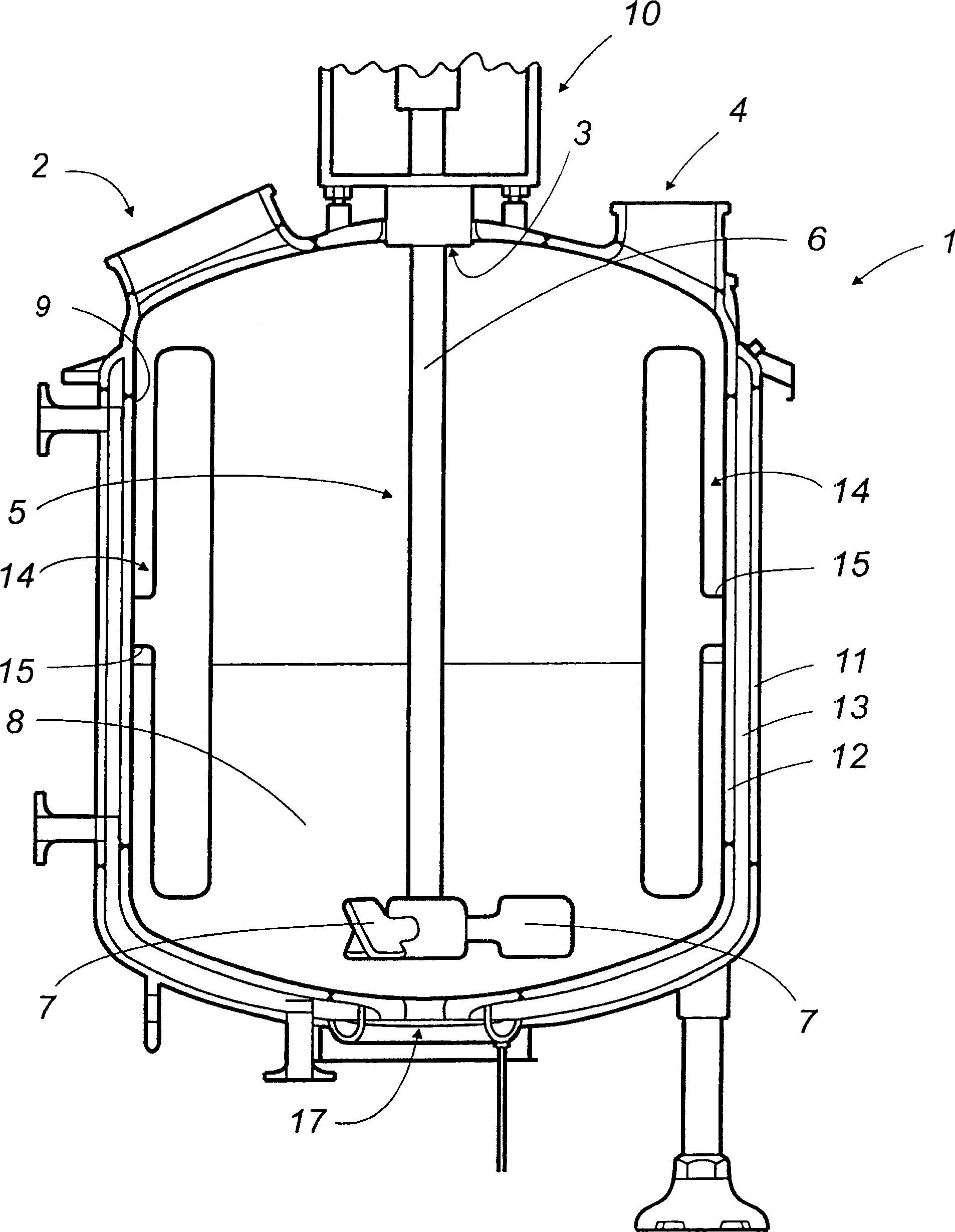

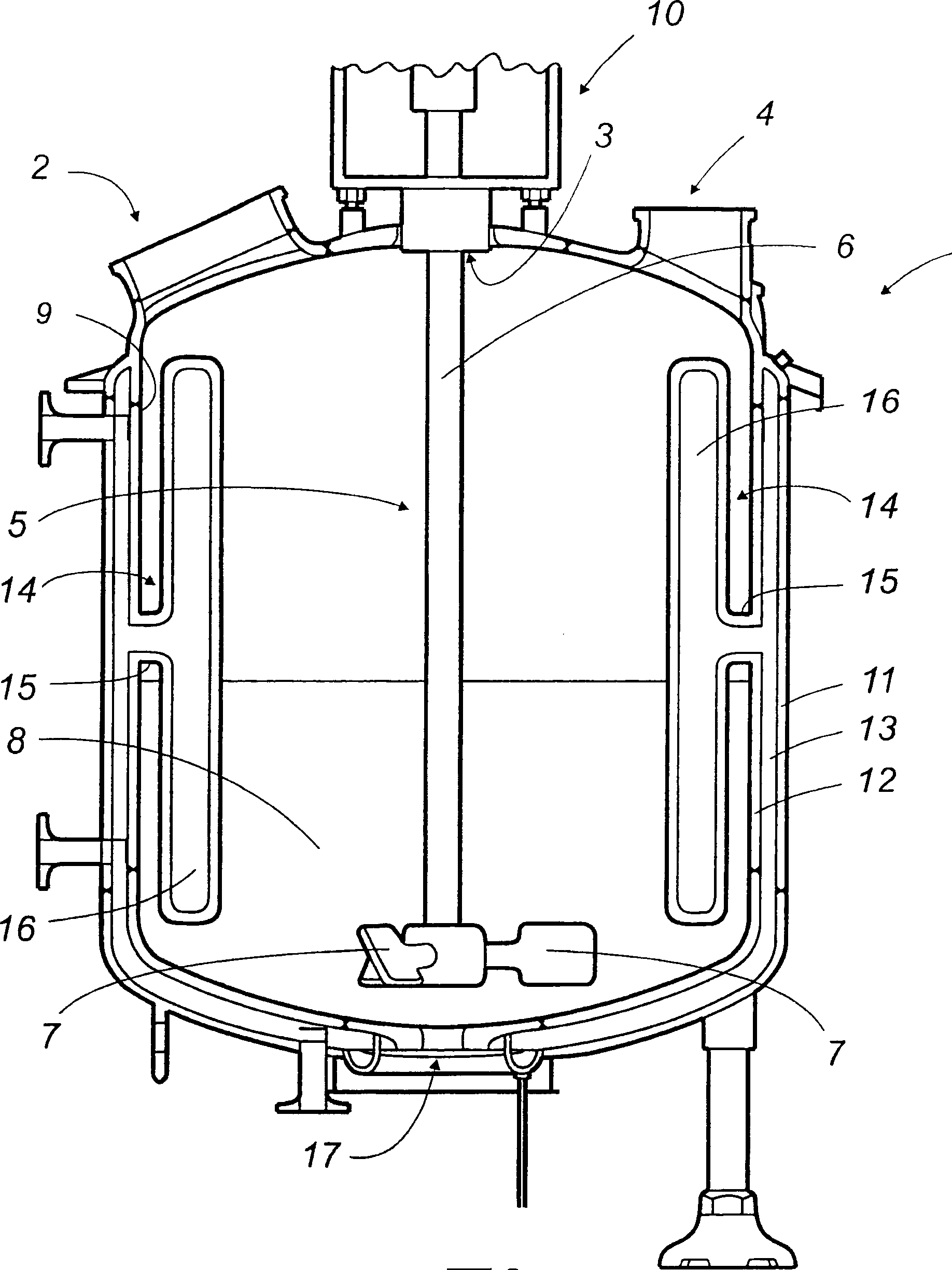

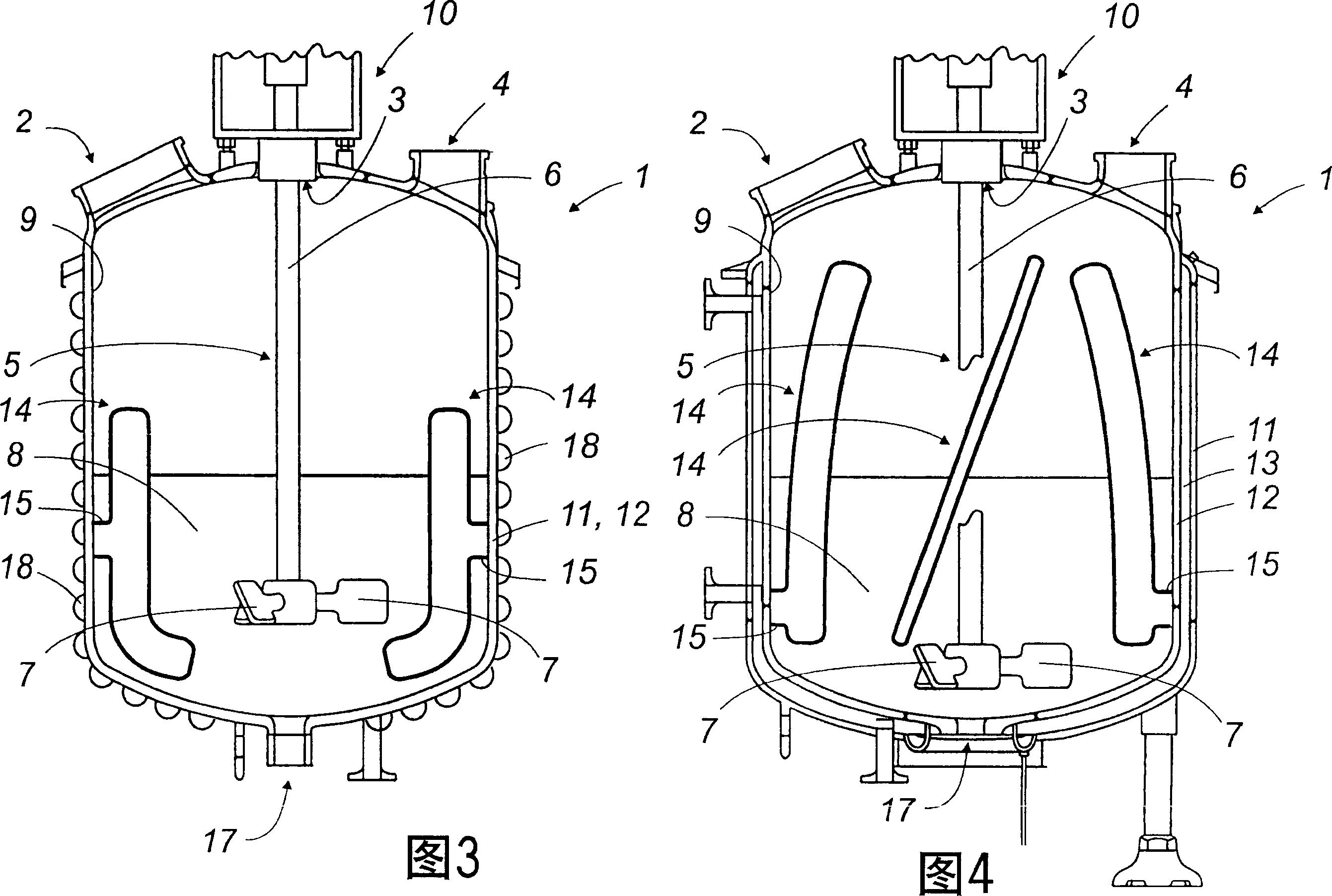

[0049] figure 1Shown is a chemical reaction tank or vessel 1 fitted with three integral top openings 2, 3 and 4 which can be used to introduce various reactants, solvents and catalysts, or as various instruments or accessories (impellers, detectors , emptying pipe and / or device, etc.) through and into the tank or container 1 passage.

[0050] The tank or container 1 is equipped with a mechanical impeller 5 whose pivot 6 intersects the central opening 3 and extends towards the lower part of the tank or container 1 . The pivot 6 terminates, for example, in a wheel body equipped with three inclined blades 7 to agitate the substance 8 inside the tank or container 1 when the pivot 6 is rotated by a drive mechanism 10 located outside the tank or container.

[0051] In order to facilitate the ability to resist the attack of any corrosive or acidic reactants introduced or produced in the tank or container 1 and used to form the substance 8 of the tank or container 1, the inner surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com