Leakage-free hydraulic buffering vacuum breaker valve

A technology of hydraulic buffering and vacuum destruction, which is applied in the directions of safety valves, balance valves, valve devices, etc., can solve the problems of the failure of the buffering function of the air supply device, the hidden danger of the operation of the turbine, the metal collision between the valve plate and the valve seat, etc., and achieves a simple structure. , Axial force balance, the effect of avoiding seal wear and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

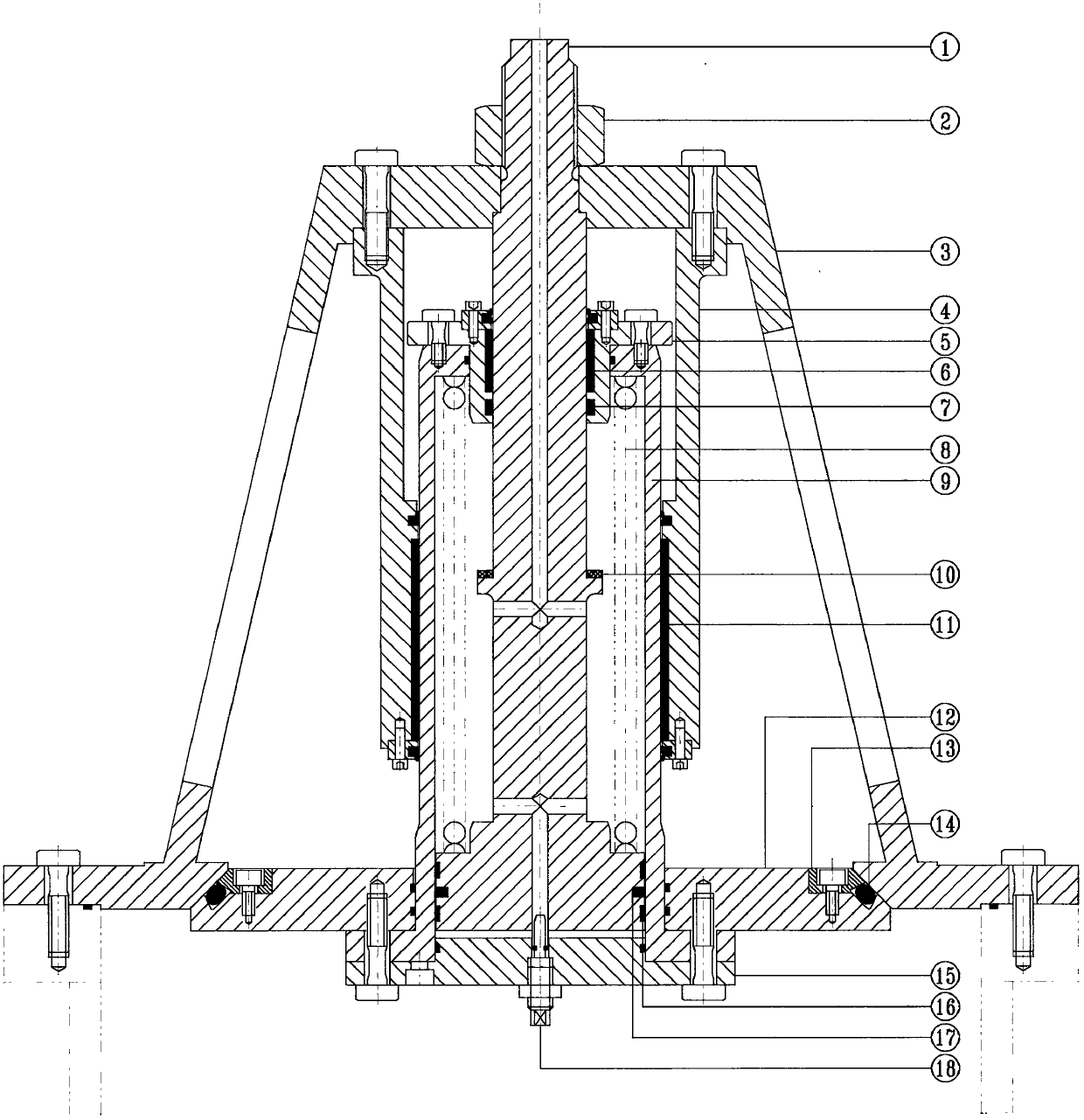

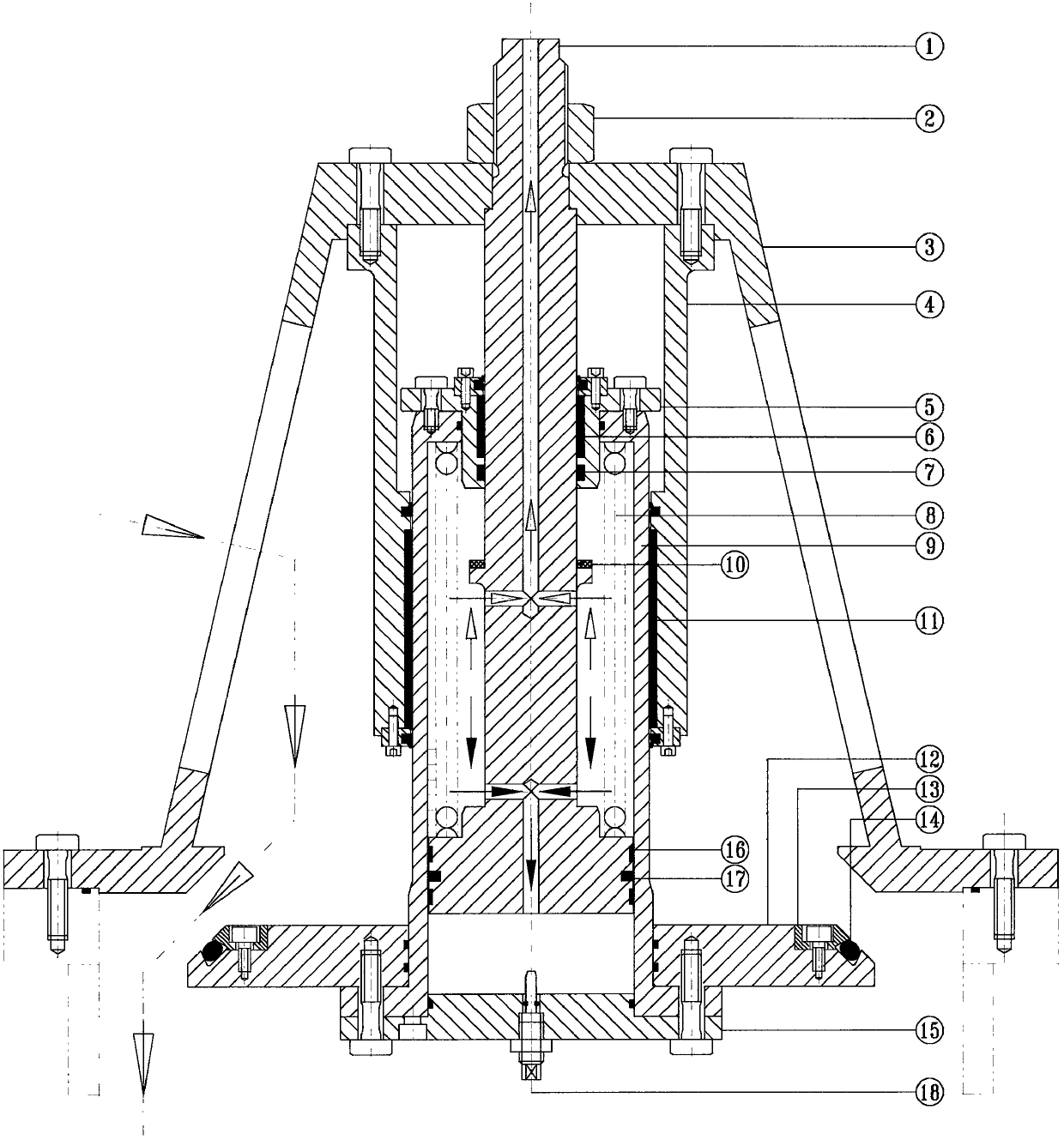

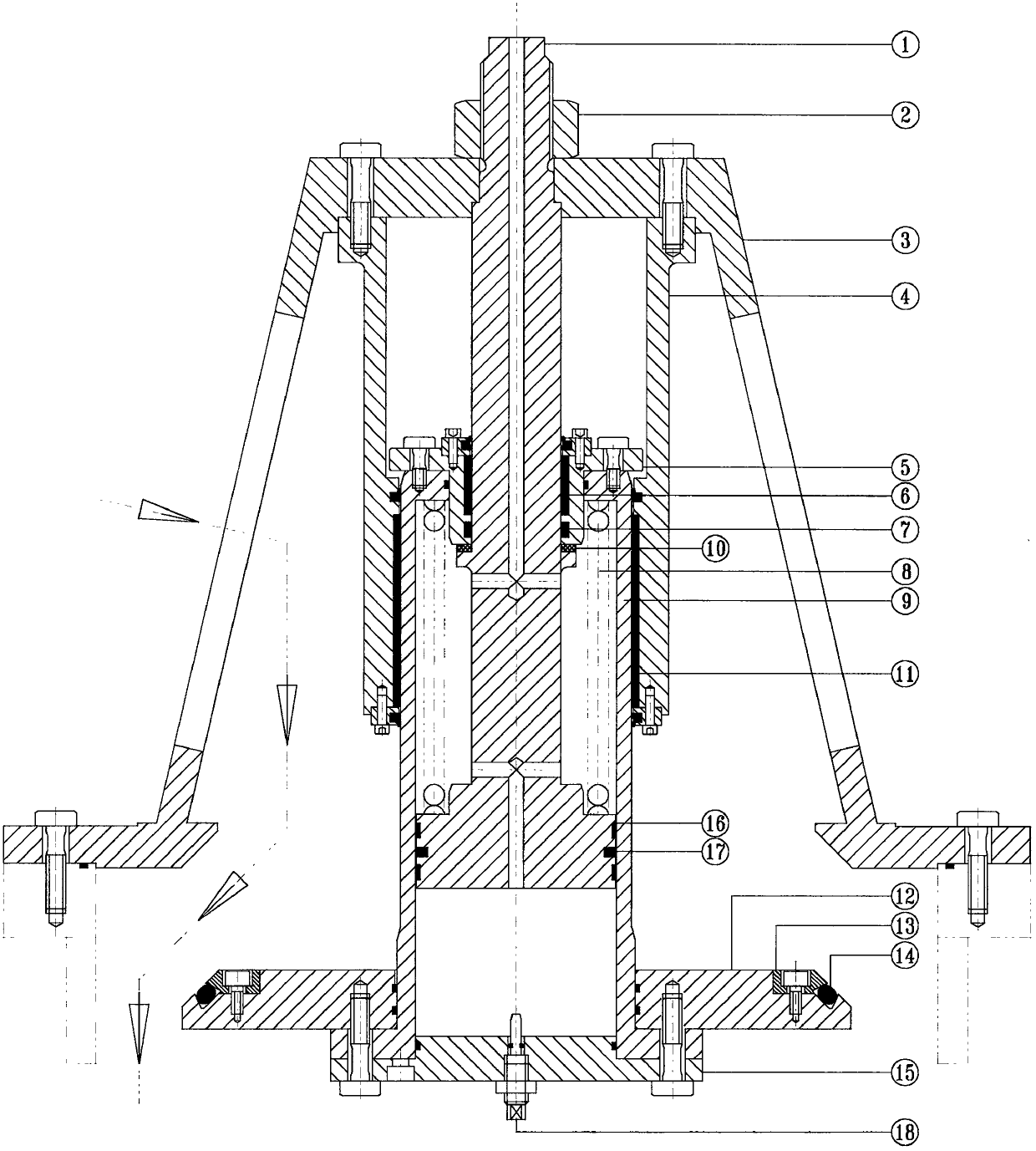

[0024] Such as Figure 1-Figure 4 As shown, a non-leakage hydraulic buffer vacuum breaks the gas supply valve, which consists of a valve stem 1, a nut 2, a valve body 3, a support sleeve 4, an upper cylinder head 5, a valve stem bearing bush 6, a valve stem seal 7, a spring (8 ), hydraulic cylinder 9, buffer plate 10, valve plate 12, pressure plate 13, main seal 14, lower cylinder cover 15, guide belt 16, piston seal 17, and throttle valve 18.

[0025] Such as Figure 1-Figure 4 As shown, the upper end of the valve stem 1 is provided with intake and exhaust holes, the bottom end of the valve stem 1 is provided with an oil hole, the middle part of the valve stem 1 is provided with a boss, the boss is provided with a buffer plate 10, and the valve stem 1 is provided with a ventilation passage, oil passage, the valve stem 1 is fixedly connected with the valve body 3 through the nut 2, the lower end of the valve stem 1 and the spring 8 are put into the hydraulic cylinder 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com