Easily controlling hydraulic corner self-servo valve

A technology of self-servo and angle of rotation, applied in the field of servo valves, can solve problems such as unsatisfactory dynamic characteristics of the spool, unbalanced radial force of the spool, unsatisfactory servo dead zone, etc., and achieve small deformation of the valve port, resistance and hydraulic card Small tightening force and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

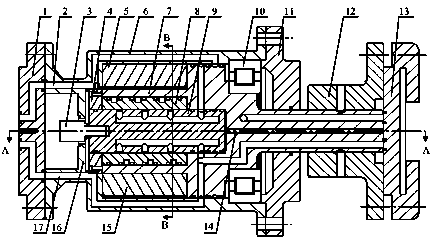

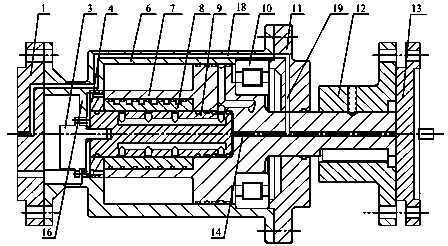

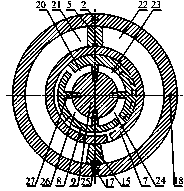

[0039] An easy -to -control hydraulic corner from the servo valve, such as figure 1 and figure 2 Show, the resignation rotor comes from the servo valve including fixed gear 5, cylinder body 6, valve body 7, valve cover 8, valve core 9, and leaves 15.

[0040] The left end of the cylinder 6 is equipped with a left end cover 1, a partition 16 in the cylinder 6 near the left end, and the inner wall of the tank 6 on the right side of the partition 16 is equipped with a fixed shield 5, a fixed shield 5 and a valve valveThe body 7 is a motion coordination. The fixed gear 5 and the valve body 7 are equipped with a block seal; the hollow cylindrical body 35 of the valve body 7 is fixed with leaves 15, leaf 15 and cylinder 6 are motion.Leaves 15 and the cylinder body 6 are equipped with a dense seal of the blades; the initial assembly position of the blade 15 and the fixed gear 5 is axisymmetric layout, and the leaf 15 and the fixed gear 5 are located on the lead vertical surface of the ax...

Embodiment 2

[0054] An easy -to -control hydraulic corner from the servo valve.Except for the following technical parameters, the remaining embodiments 1.

[0055] There are 2 valve ports evenly on the 4 -line lines of the valve core 9 cylindrical surface. Each valve port on each element line is connected through the oil channel, and the 4 plain lines are evenly distributed.The valve port corresponding to the other plain line is located at the same cross section;

[0056] The cylindrical surface of the valve cover 8 is evenly provided with 2 upper semi -cycloped oil rings 36 and 2 lower circular oil rings 37 along the axis.

Embodiment 3

[0058] An easy -to -control hydraulic corner from the servo valve.Except for the following technical parameters, the remaining embodiments 1.

[0059] There are 4 to 5 valve ports on the 4 -line lines of the valve core 9 cylindrical surface. Each valve port on each element line is connected through the oil channel, 4 plain lines are evenly distributed, and 4 on each prime line 4~ 5 valve ports as the valve port corresponding to the remaining vegetarian lines are located at the same cross section;

[0060] The cylindrical surface of the valve cover 8 is evenly provided with 4 to 5 upper semi -circular oil rings 36 and 4 ~ 5 lower semi -circular oil rings 37 along the axis.

[0061] The high -pressure oil imports of this specific embodiment entered the high -pressure oil channel 2 of the cylinder body 6 through its oil duct, and the exit of the high -voltage oil channel 2 in the cylinder body 6 into the high -pressure outer oil ring slot 31 of the valve body 7, and then through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com