Novel double-suction pump with flow channel type guide blade

A channel-type, double-suction pump technology, applied to non-variable pumps, parts of pumping devices for elastic fluids, pumps, etc., can solve the problem of unstable pump operation, easy damage to mechanical seals, long shaft 25 And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

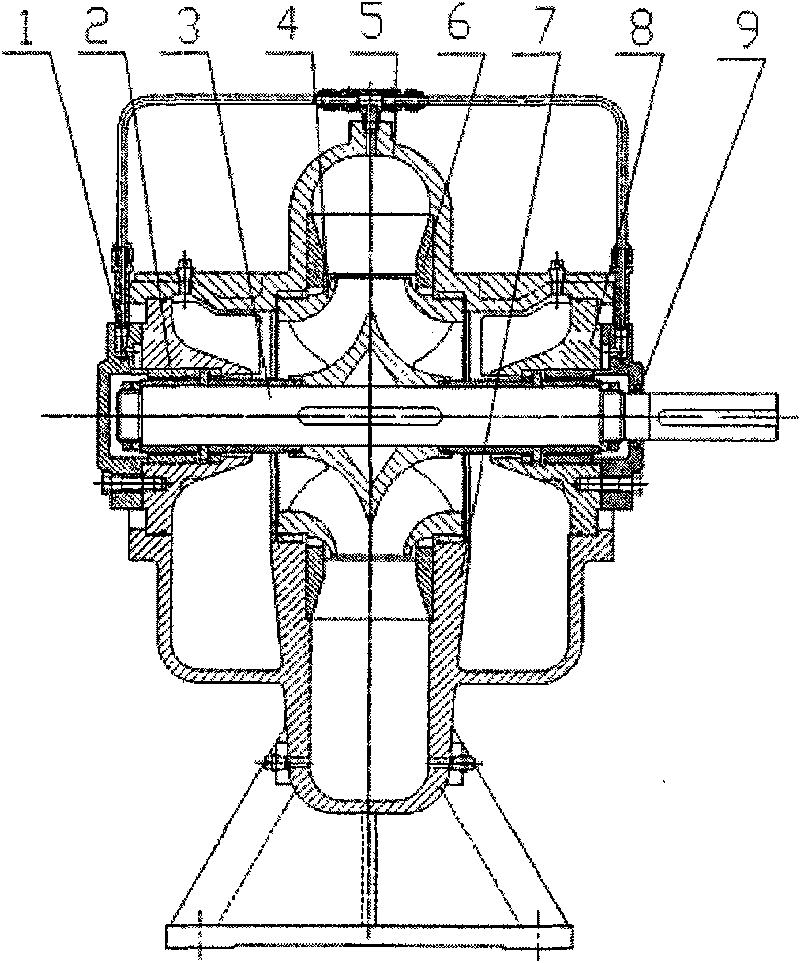

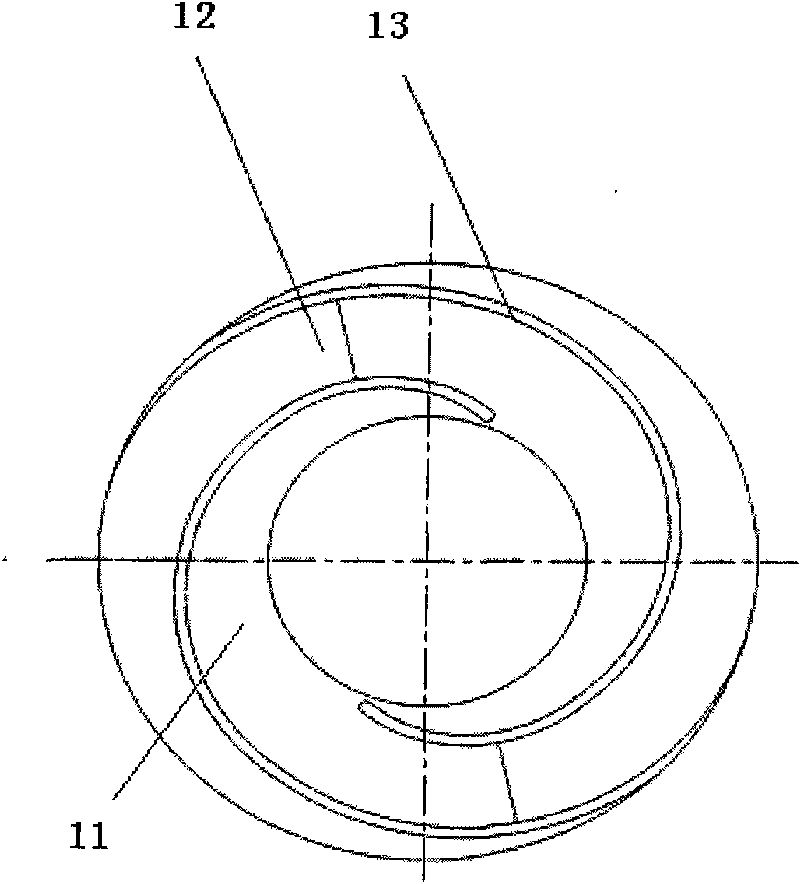

[0008] The figure includes: sliding bearing gland 1, sliding bearing 2, shaft 3, impeller 4, pump cover 5, pump body 7, sliding bearing body 8, auxiliary seal 9, and it is characterized in that: the pressure chamber of the pump is increased by a Runner guide vane 6. The channel-type guide vane 6 is composed of a guide vane cover plate 11, two flow channels 12, and guide vane blades 13. The guide vane blades 13 are of two helical shapes, and the two helical guide vane blades 13 are distributed in symmetrical positions 180° apart. position.

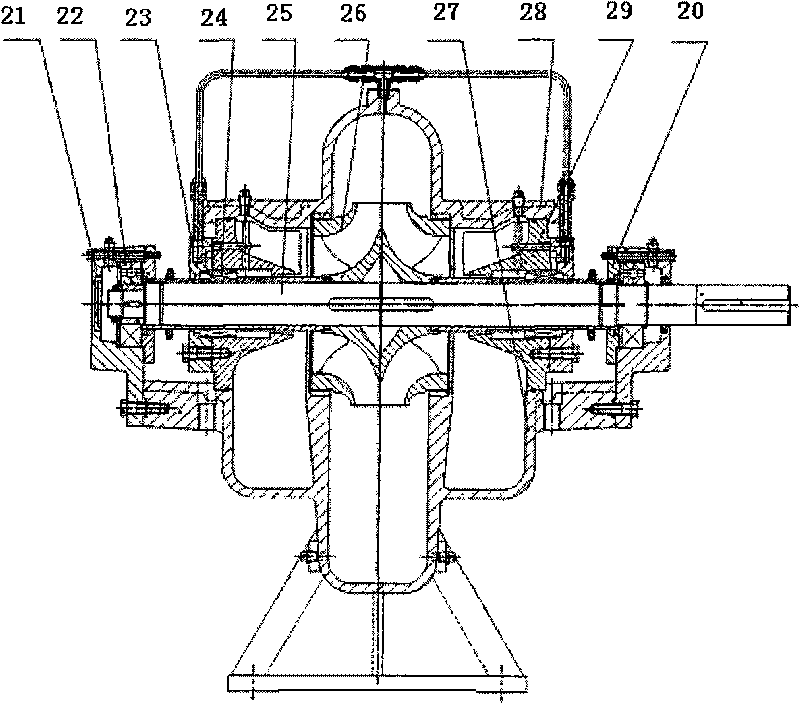

[0009] This invention patent is realized in this way: on the basis of the existing double suction pump, the bearing body 21, the rolling bearing 22, the mechanical seal gland 23, the mechanical seal 24, and the bearing gland 20 are removed, (see attached Figure 1 ) Change the rolling bearing to sliding bearing 2, and use the liquid delivered by the pump itself to lubricate the sliding bearing (see attached Figure II ). Since the shaft l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com