Easily controlling hydraulic corner self-servo valve

A technology of self-servo and rotation angle, applied in the field of servo valve, can solve the problems of unsatisfactory dynamic characteristics of the valve core, unbalanced radial force of the valve core, easy formation of dead space of the valve core, etc., and achieve small deformation of the valve port, resistance and Small hydraulic clamping force and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

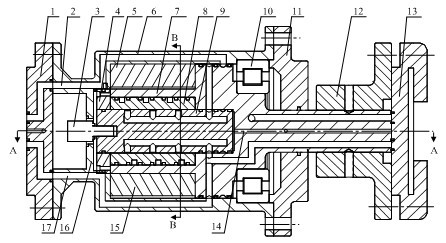

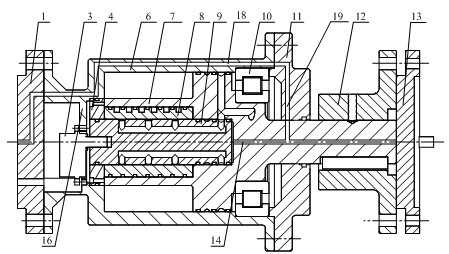

[0039] An easy-to-control hydraulic angle self-servo valve, such as figure 1 and figure 2 As shown, the hydraulic rotary self-servo valve includes a fixed block 5 , a cylinder body 6 , a valve body 7 , a valve sleeve 8 , a valve core 9 and vanes 15 .

[0040] The left end cover 1 is installed on the left end of the cylinder body 6, and the cylinder body 6 close to the left end is provided with a dividing plate 16, and the inner wall of the upper part of the cylinder body 6 on the right side of the dividing plate 16 is equipped with a fixed stopper 5, and the fixed stopper 5 is connected with the valve. The body 7 is a dynamic fit, and a stopper sealing strip is installed between the fixed stopper 5 and the valve body 7; the outer wall of the hollow cylinder 35 of the valve body 7 is fixedly equipped with a blade 15, and the blade 15 is a dynamic fit with the cylinder body 6. A blade sealing strip 25 is installed between the blade 15 and the cylinder body 6; the initial assem...

Embodiment 2

[0054] An easy-to-control hydraulic angle self-servo valve. Except following technical parameter, all the other are with embodiment 1.

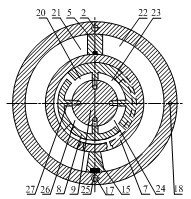

[0055] There are 2 valve ports evenly opened on the 4 prime lines of the cylindrical surface of the valve core 9, and the valve ports on each prime line communicate through oil passages, the 4 prime lines are evenly distributed, and the 2 valve ports on each prime line The port is located in the same cross-section as the valve ports corresponding to the other prime lines;

[0056] The cylindrical surface of the valve sleeve 8 is evenly provided with two upper semicircular oil ring grooves 36 and two lower semicircular oil ring grooves 37 along the axis.

Embodiment 3

[0058] An easy-to-control hydraulic angle self-servo valve. Except following technical parameter, all the other are with embodiment 1.

[0059] There are 4 to 5 valve ports evenly opened on the 4 plain lines of the cylindrical surface of the valve core 9, and the valve ports on each plain line are communicated through oil passages, and the 4 plain lines are evenly distributed, and 4 valve ports on each plain line ~5 valve ports are located in the same cross-section as the valve ports corresponding to the rest of the prime lines;

[0060] The cylindrical surface of the valve sleeve 8 is evenly provided with 4 to 5 upper semicircular oil ring grooves 36 and 4 to 5 lower semicircular oil ring grooves 37 along the axis.

[0061]

[0062] The high-pressure oil inlet P of this specific embodiment enters the high-pressure oil passage 2 of the cylinder 6 through its oil passage, enters the high-pressure outer oil ring groove 31 of the valve body 7 through the outlet of the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com