Rotary atomizer system

A rotary atomizer and rotary atomization technology, applied in the field of atomizers, can solve the problem of uneven distribution of material and liquid, and achieve the effects of increasing the thickness of one side, improving the service life, and facilitating collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

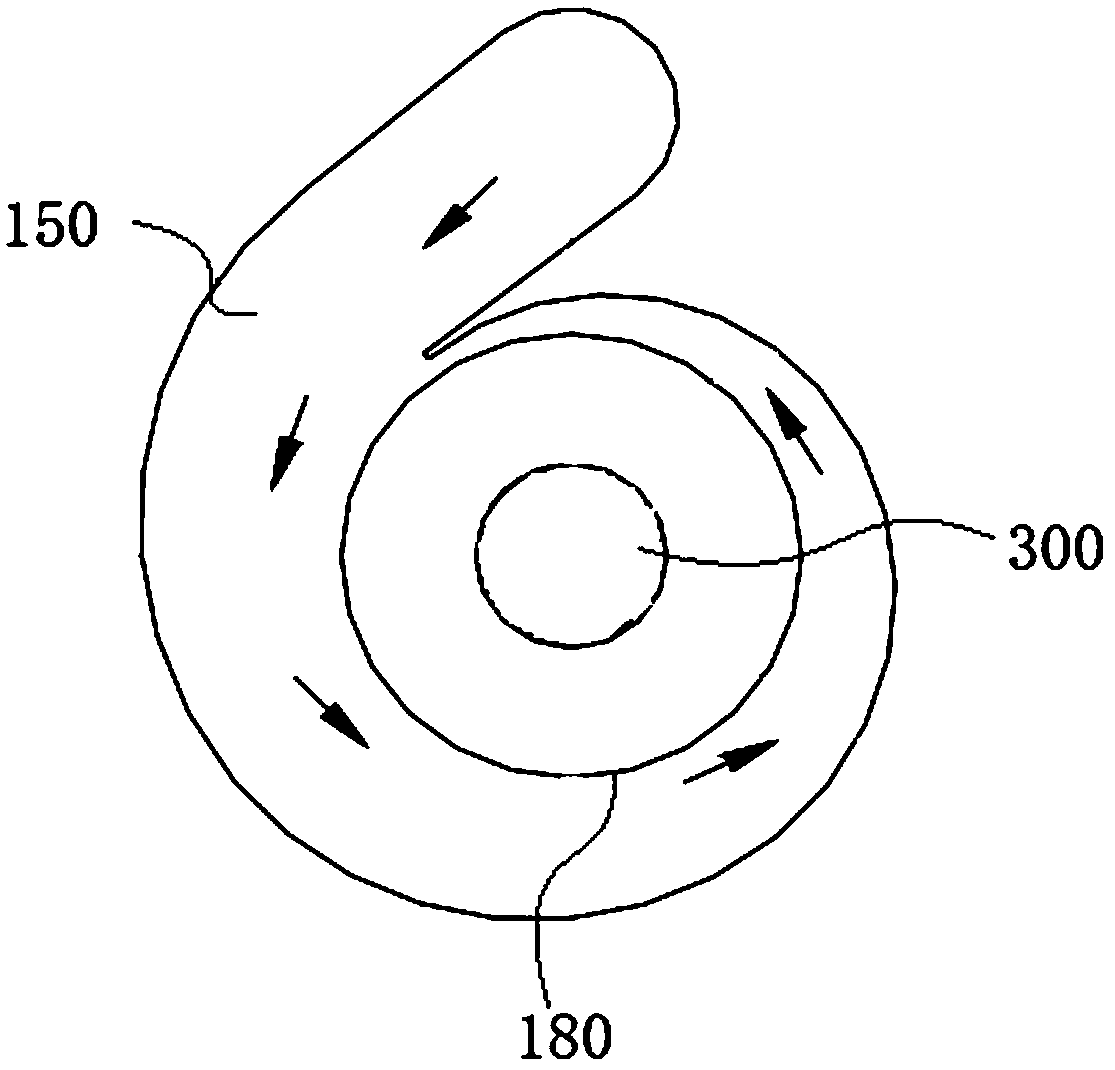

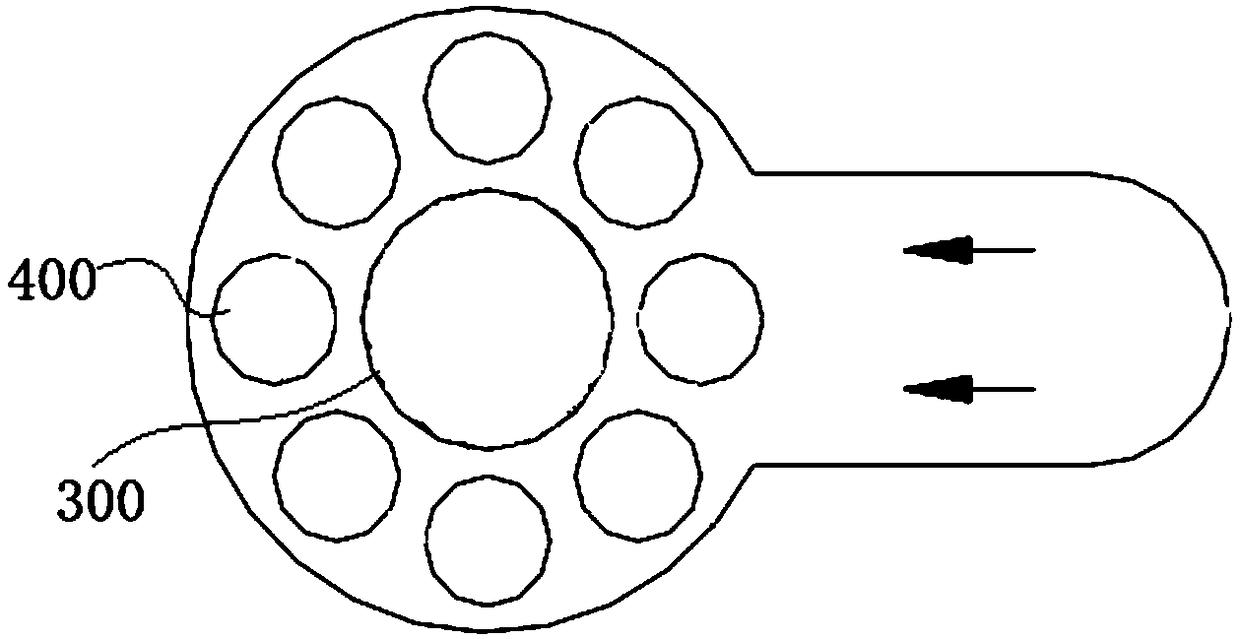

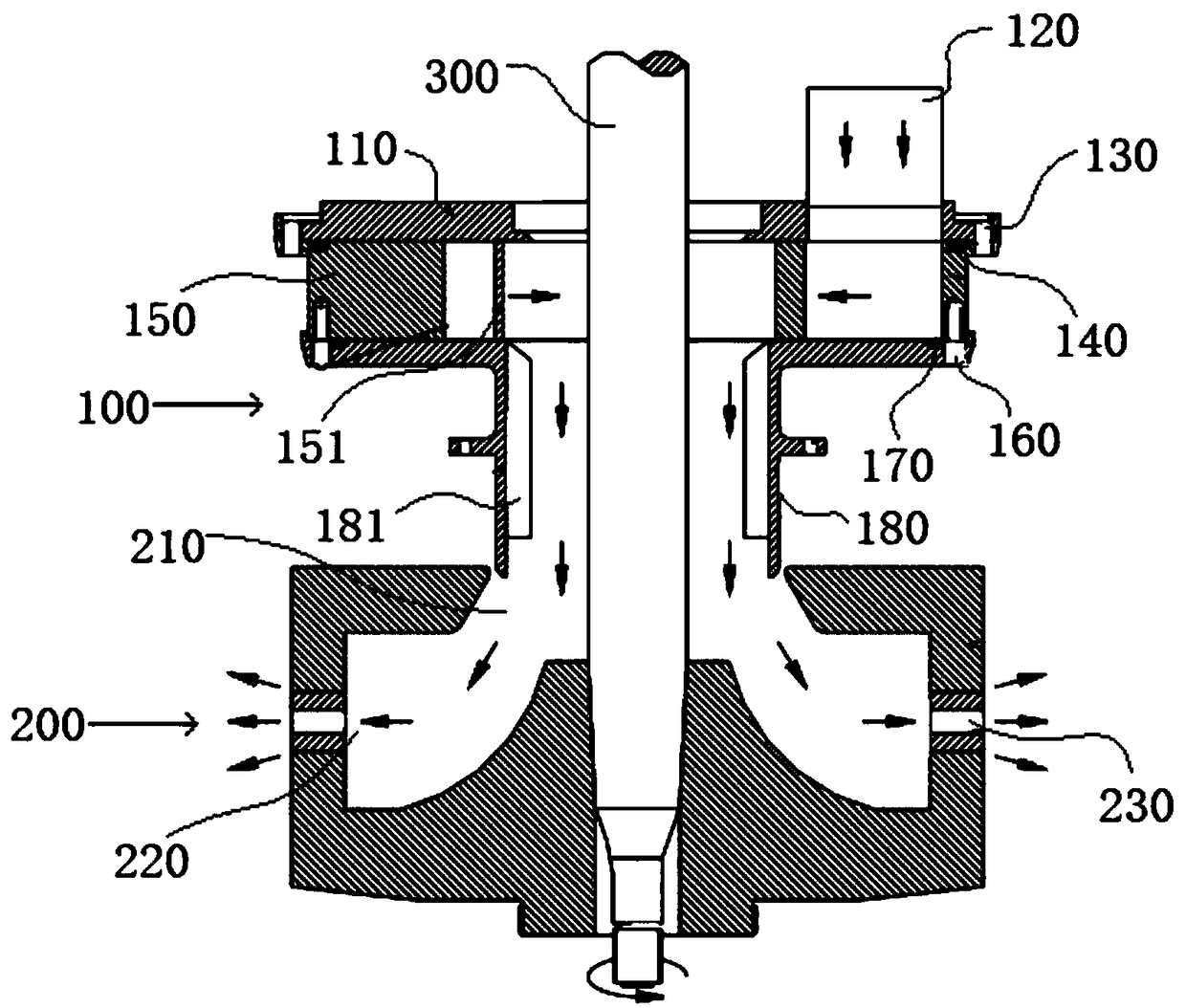

[0050] Such as image 3 As shown, a rotary atomizer system in this embodiment includes a feed liquid distributor 100, a rotary atomizer wheel 200 and a rotary spindle 300, wherein the discharge pipe 180 of the feed liquid distributor 100 corresponds to the rotary atomizer wheel 200 The atomizing wheel inlet 210, the material-liquid distributor 100 and the top plate 110 are connected to the base of the rotating main shaft 300 on the top of the top plate 110 by bolts. Such as figure 1 and figure 2 Shown is the conventional design structure of the feed-liquid distributor 100 in the high-speed rotary dry atomizer in the prior art, and the design adopts the volute type respectively (see figure 1 ) and orifice plate (see figure 2 )structure. The size of the involute of the volute material-liquid distributor is determined according to the design flow. When the design flow is running, the flow rate of the material and liquid in each section of the involute is uniform, and it is ...

Embodiment 2

[0059] A kind of rotary atomizer system of this embodiment, the basic structure is the same as that of Embodiment 1, the difference is that in this embodiment, α=30°, the oblique setting of multiple guide vanes 181 makes it in the discharge pipe 180 The inner wall is helically distributed as a whole, which can evenly divide the incoming material liquid and produce a pre-swirl effect on the flow of the material liquid, so that the material liquid enters the rotating atomizing wheel 200 at a tangential angle, and the inclination angle of the guide vane 2 181 is set to conform to the rotation The rotation direction of the atomizing wheel 200 makes it easier for the feed liquid to enter the nozzle 230 , which can further improve the service life of the rotating atomizing wheel 200 , and ultimately ensure the smooth operation of the rotating atomizing wheel 200 and the rotating spindle 300 .

Embodiment 3

[0061] A rotary atomizer system in this embodiment has the same basic structure as that in Embodiment 2, except that α=45° in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com