Vertical disintegratable self-suction dredge pump

A sewage pump and vertical technology, which is applied in the field of vertical pulverized self-priming sewage pumps, can solve the problems of normal operation and blockage, and achieve the effects of reasonable structure, improved energy efficiency and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

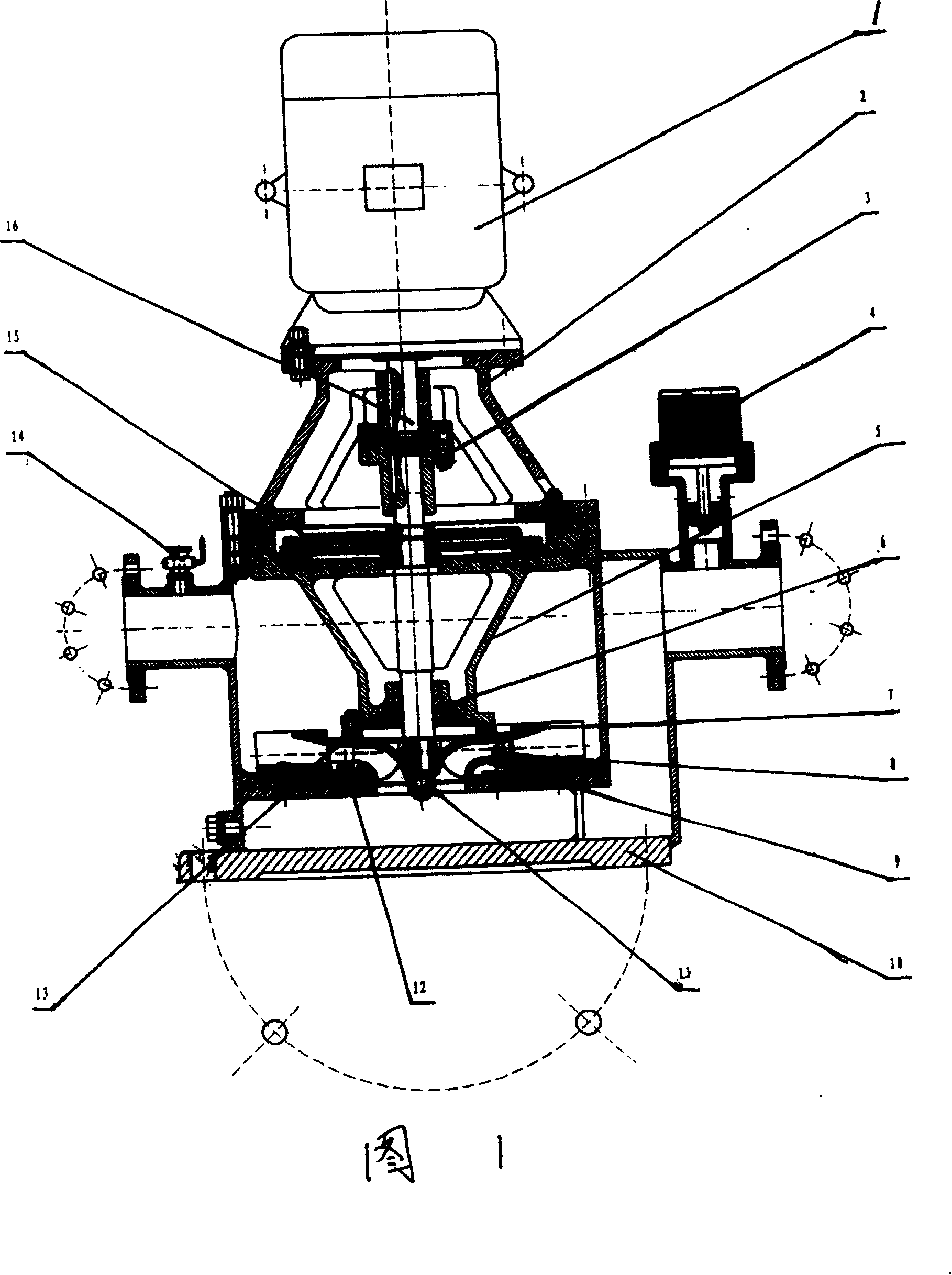

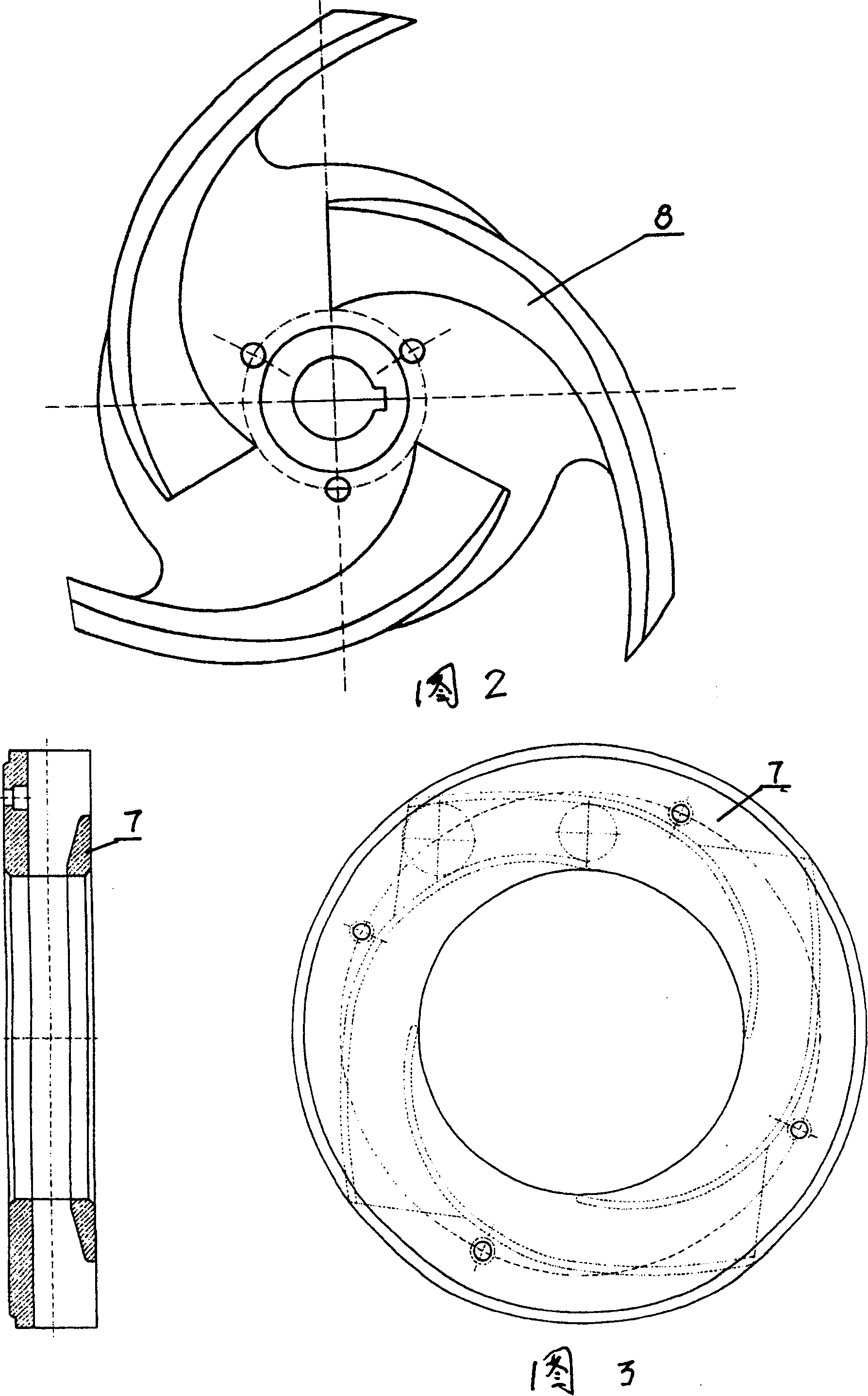

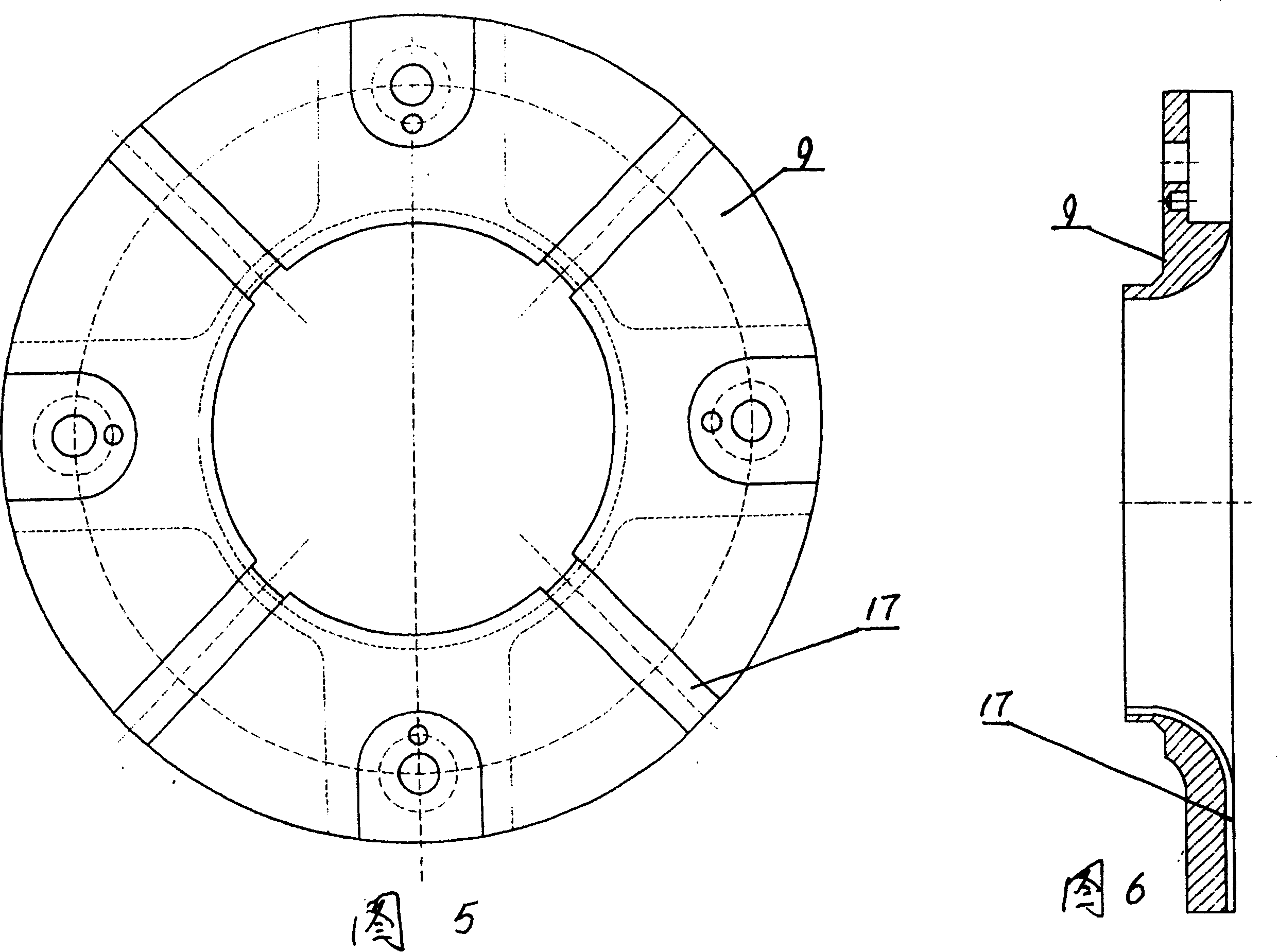

[0017] The present invention consists of a motor 1, a motor coupling frame 2, a normally closed solenoid valve 4, a bracket 5, a guide vane 7, a fully open impeller 8, a front wear-resistant lining plate 9, a pump body 10, a rear guard plate 13, and a steam release valve 14 , shaft 16, block 18, electric coupling 21 and shaft coupling 22, the upper end of the pump body 10 is connected to the motor coupling frame 2, the motor coupling frame 2 fixes the motor 1, the pump body 10 inner bracket 5 passes through the shaft 16, and the shaft The lower end of 16 is connected to the fully open impeller 8, the inner wall of the pump body 10 at the front end of the fully open impeller 8 is connected to the front wear-resistant liner 9, and the connection is fixed using hole connection and anti-loosening device 12, and the support behind the fully open impeller 8 The front end of 5 is connected with solid back guard plate 13, and cutting groove 17 is all set on front wear-resistant liner p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com