Negative-type milling blade

A blade and milling technology, which is applied in the field of indexable negative milling blades, can solve problems such as friction and scratches on the support surface, affecting positioning accuracy, and accumulation of small chips, so as to achieve high economy and avoid the effect of not brisk cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

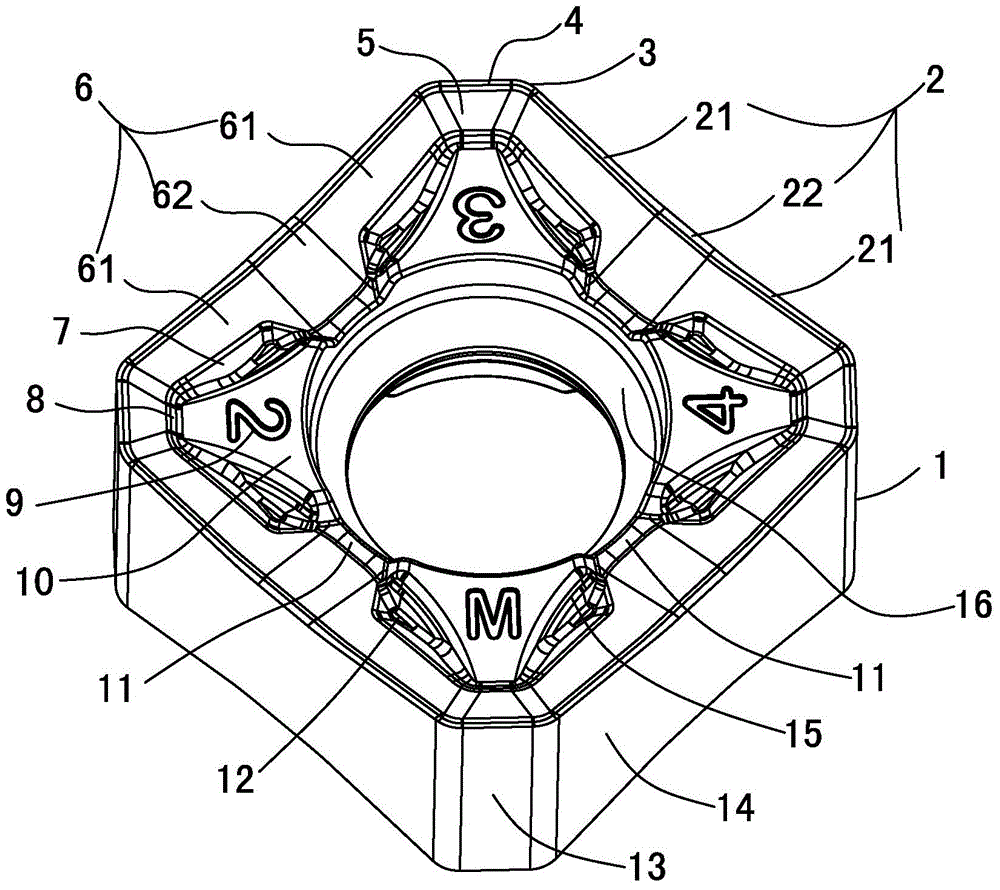

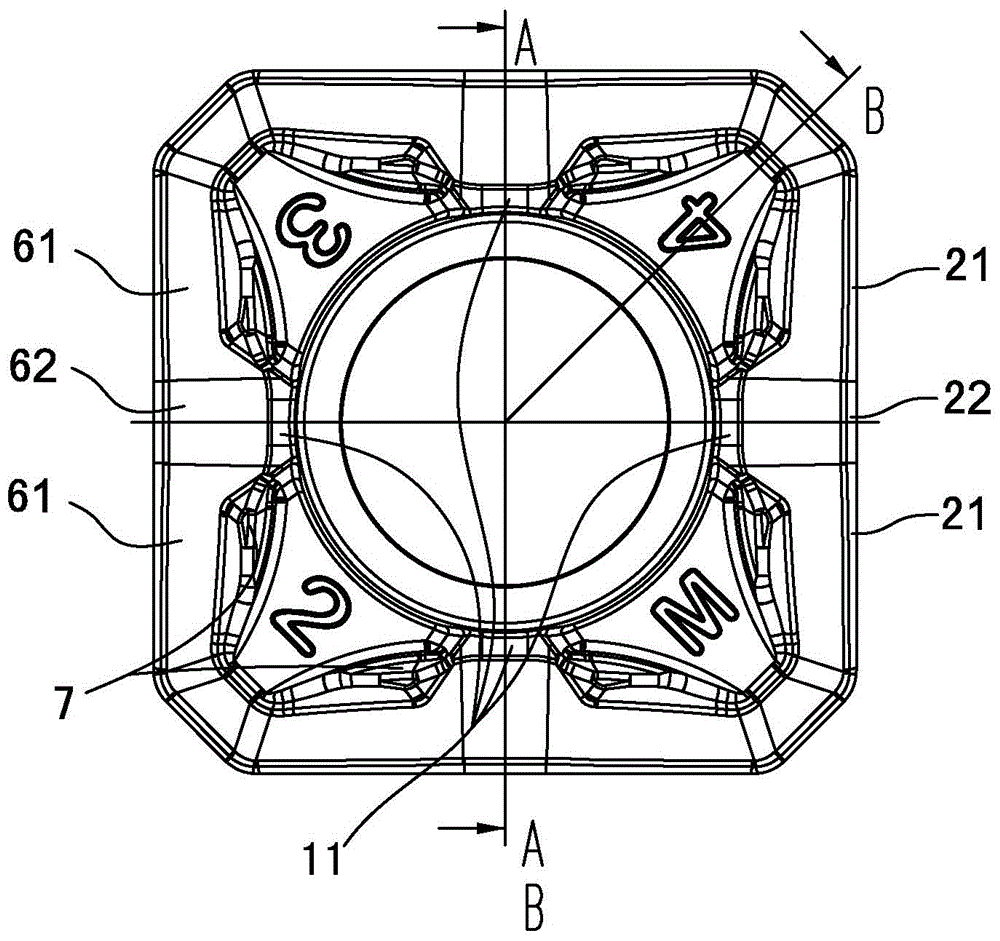

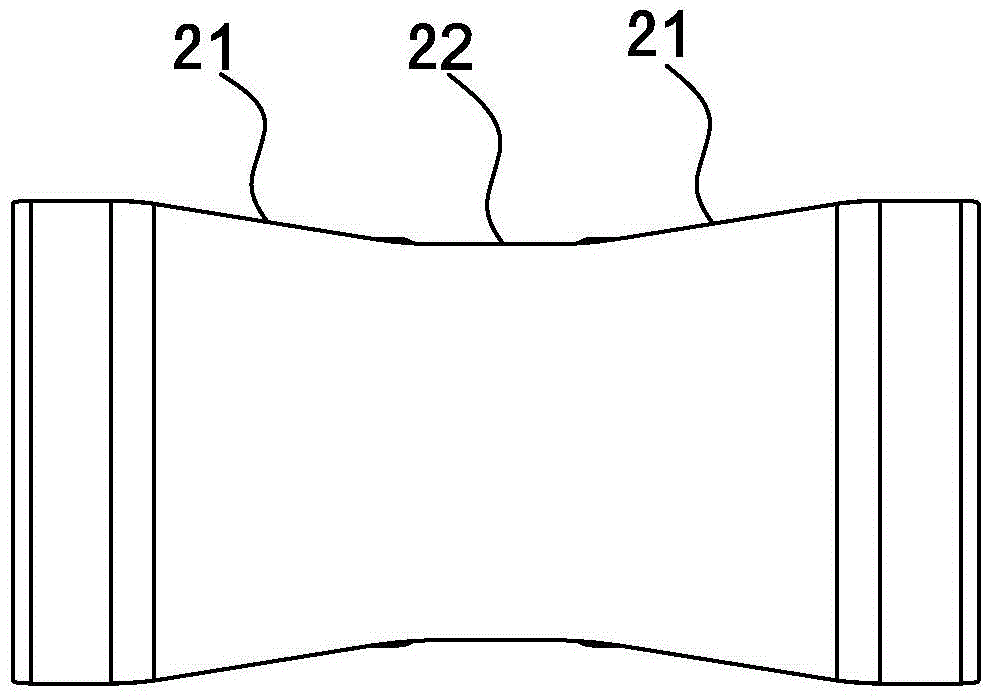

[0036] see Figure 1 to Figure 9As shown, a negative milling insert of the present invention includes a insert body 1; the insert body 1 has upper and lower surfaces parallel to each other, and a quadrilateral formed by an outer peripheral surface (i.e. a side surface), and the angle formed by the intersection of the upper and lower surfaces with the outer peripheral surface It is a right angle (i.e. the blade body of the 0° rear angle); the blade body 1 is provided with a through hole 16 vertically passing through the upper and lower surfaces, and the bosses for clamping and positioning are evenly distributed around the through hole 16; the blade body The upper and lower surfaces of 1 respectively form the rake face, and the side faces form the flank face, and the intersecting ridges of the rake face and the flank face form a cutting edge, and the cutting edge includes a main cutting edge on a side of a quadrilateral 2 and the wiper edge 4 at the corner of the quadrilateral, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com