IPM motor and vacuum inhaling apparatus using the same

A technology for suction devices and motors, applied in electromechanical devices, parts of pumping devices for elastic fluids, liquid fuel engines, etc., can solve cogging torque and reluctance torque fluctuations, gap magnetic flux density changes and Current distortion and other problems, to achieve the effect of uniform distribution of magnetic flux density, reduced power consumption, and increased suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, the present invention will be described in detail through examples. The same reference numerals in the respective drawings denote the same components.

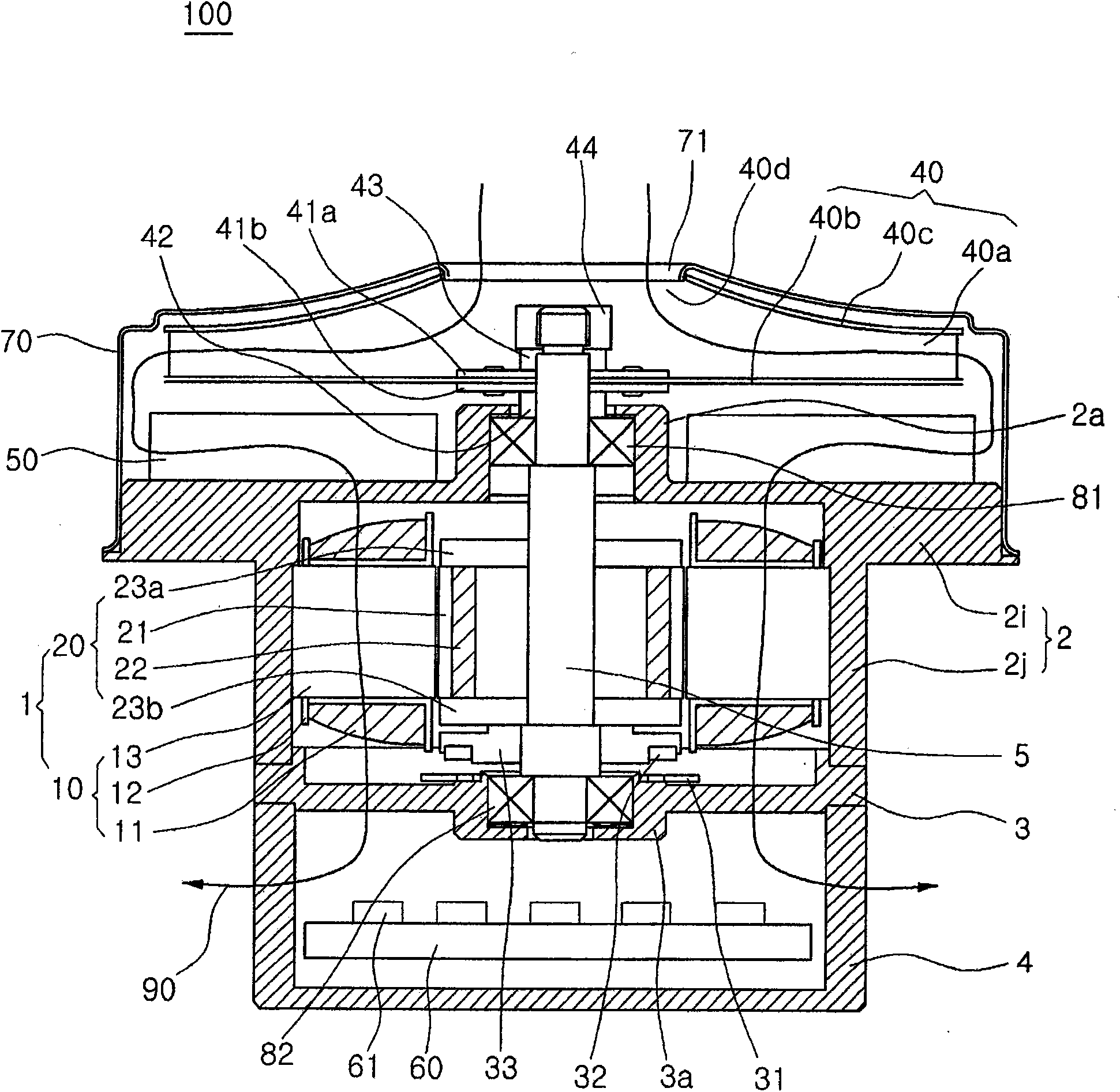

[0062] figure 1 It is a cross-sectional view showing a vacuum suction device of a vacuum cleaner using an IPM motor according to an embodiment of the present invention.

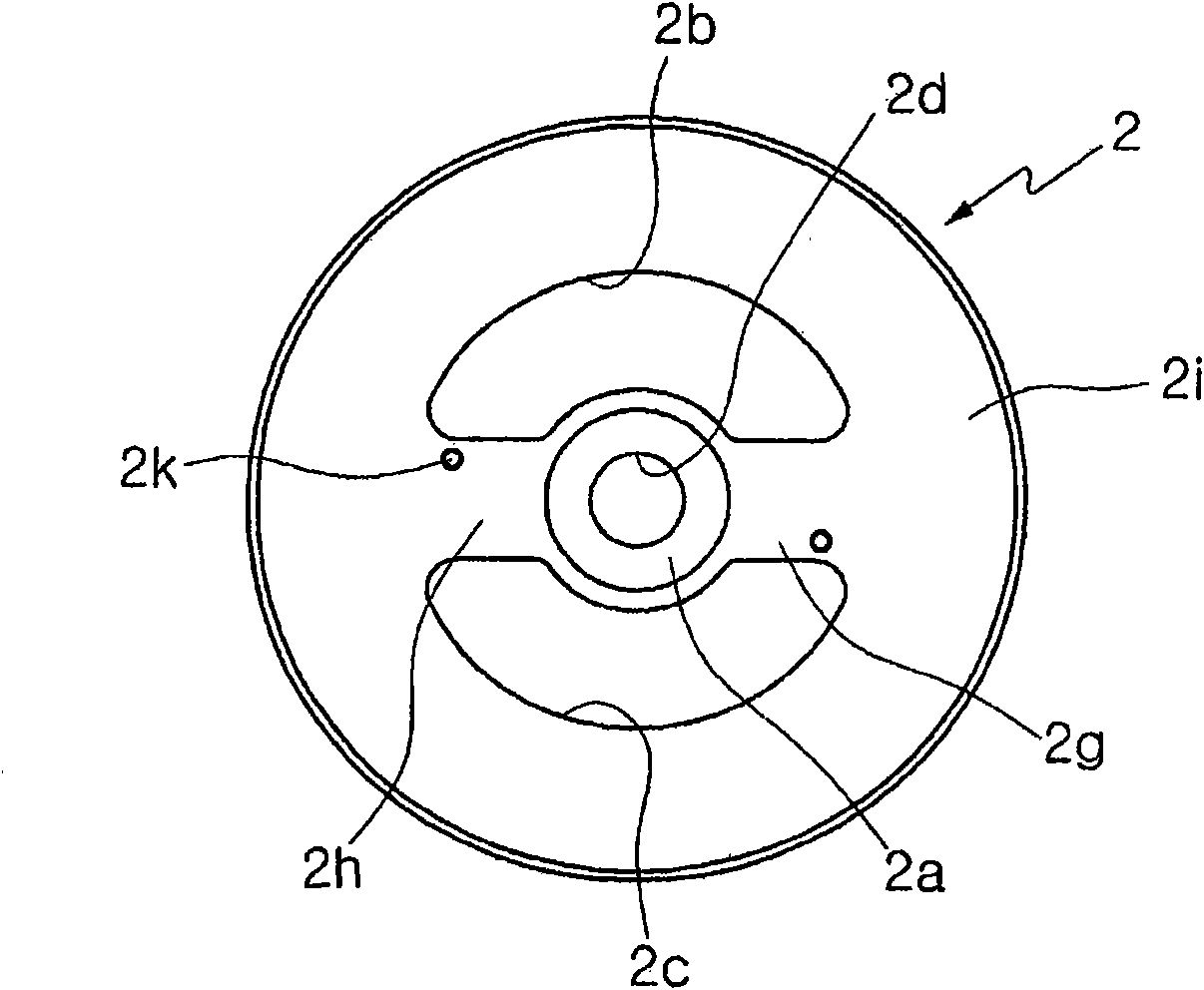

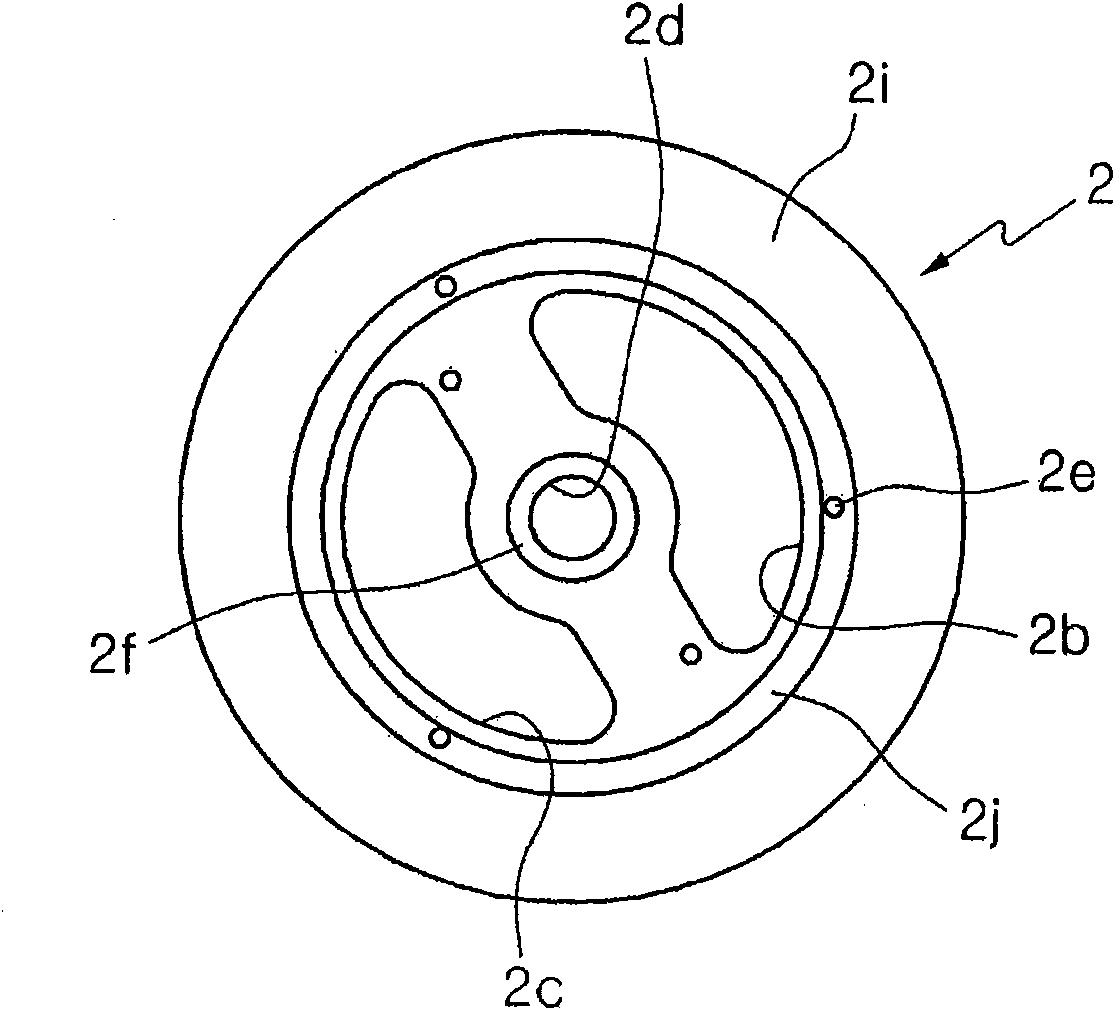

[0063] refer to figure 1 , the vacuum suction device 100 of the present invention includes: an IPM motor 1, which is composed of a stator 10 and a rotor 20, and generates rotational force; an upper housing 2, which protects the upper part and the outer peripheral surface of the IPM motor 1; an intermediate housing 3, which The peripheral part is fixedly combined with the lower end of the upper casing 2, and supports the IPM motor 1; the rotating shaft 5 is fixedly combined with the center of the rotor 20 and can rotate; the impeller 40 is located on the upper part of the rotor 20, Fixedly combined with the upper end of the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com