High-frequency-link driver for brushless motor of electric automobile

A technology for brushless motors and electric vehicles, applied in electrical components, torque ripple control, output power conversion devices, etc., can solve the problems of switching device damage, high noise, low efficiency, etc., and improve power density and reliability , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

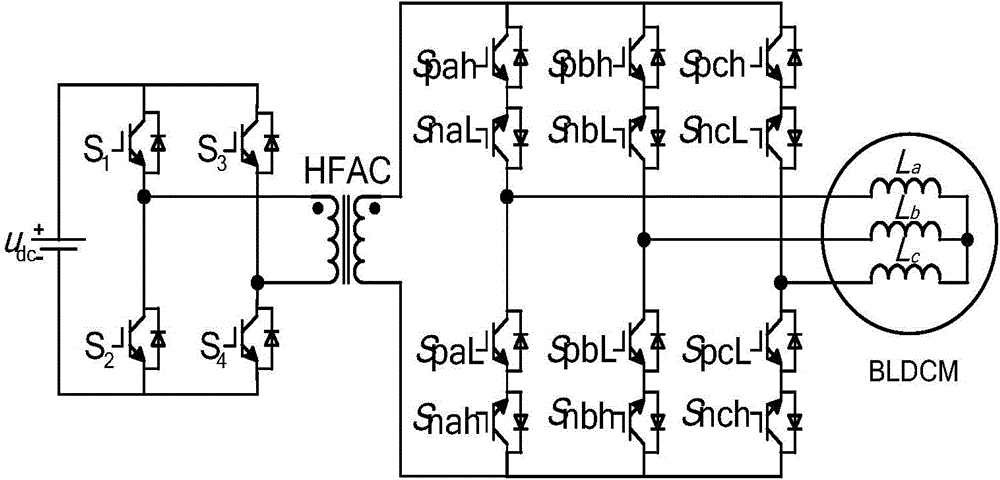

[0021] figure 1 It is an example of the main circuit of the high-frequency chain matrix converter with a brushless DC motor mentioned in the present invention. The front and back stages of the high-frequency chain matrix converter are defined by the primary and secondary stages of the high-frequency transformer, and the front stage is a high-frequency inverter circuit composed of four IGBT switch tubes, which generate high-frequency positive and negative conversion square waves with dead zones; The latter stage is a matrix converter, which converts the high-frequency AC square wave into a three-phase AC of power frequency. The matrix converter is composed of two IGBT switch tubes reversely connected in series to form a bidirectional switch. The bidirectional power switch is used in the circuit and there is no intermediate energy storage link, which is the distinctive feature of this power supply structure.

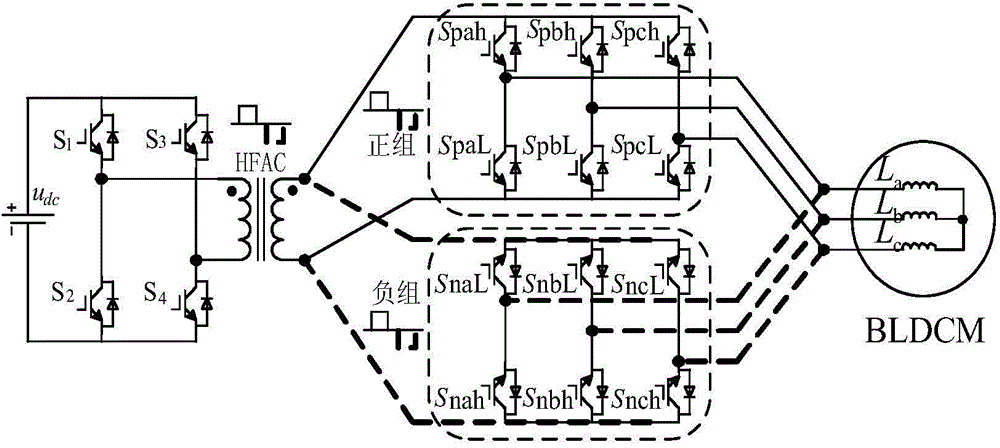

[0022] figure 2 It is an example of a decoupling structure diagram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com