High power wide velocity modulation built-in permanent magnet brushless wheel motor for electric automobile

An electric vehicle, permanent magnet brushless technology, applied in electric vehicles, motors, vehicle components, etc., can solve the problems affecting the smooth and low-noise operation of the motor, difficult to achieve industrialization, and high comprehensive performance requirements, and achieve convenient constant power speed regulation. , The effect of good starting characteristics and smooth rotor surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

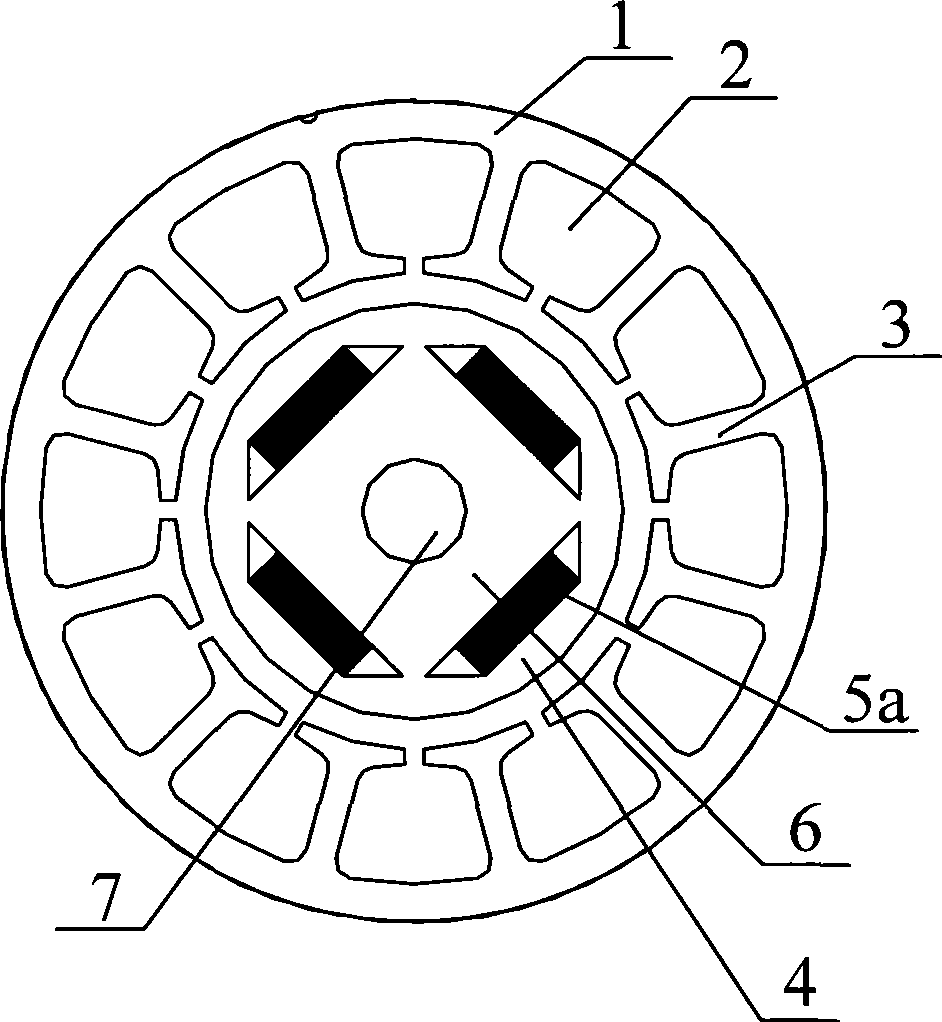

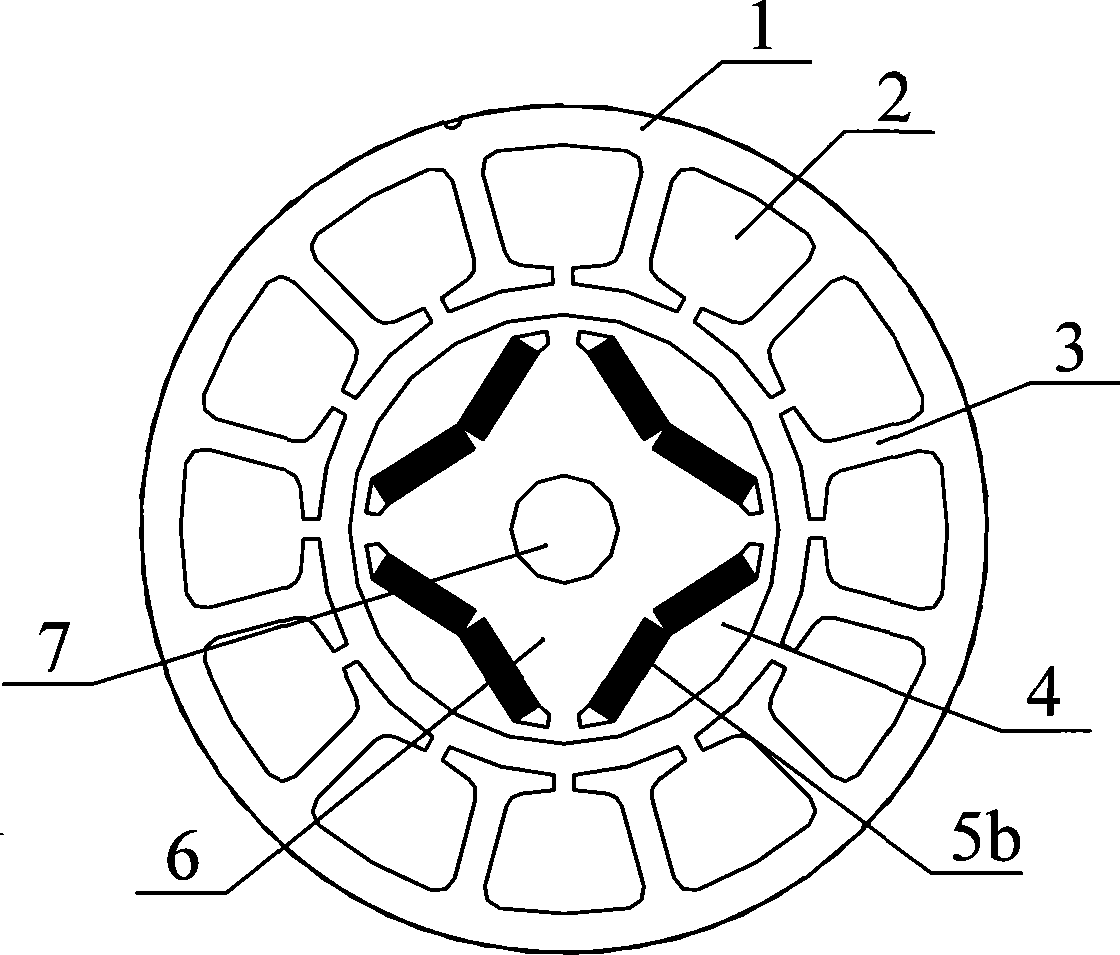

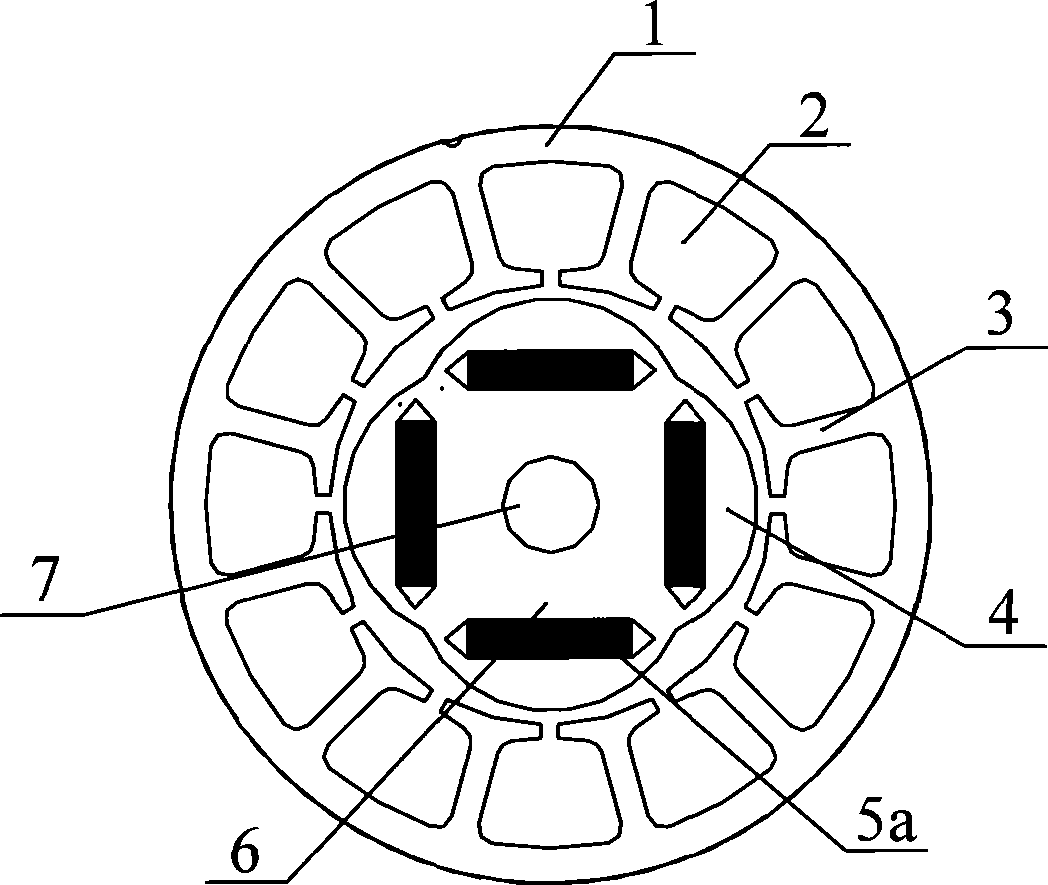

[0032] High-power and wide-speed adjustable built-in permanent magnet brushless wheel motor for electric vehicles, including the casing and the stator and rotor inside the casing. The stator includes the stator core and stator winding fixed on the inner wall of the casing. The casing also serves as the stator magnetic conduction yoke, Figure 1a , 1b As shown, the stator core includes a stator yoke 1, stator slots 2 and stator teeth 3, the rotor includes a rotating shaft 7 and a rotor core 6, and the inner circumference of the rotor core 6 is uniformly inlaid with radially magnetized rectangular strip magnets 5a, Such as Figure 1a , or the inner circumference of the rotor core 6 is evenly inlaid with a split-type radially magnetized rectangular strip magnet 5b, such as Figure 1b , the radially magnetized rectangular strip magnet 5a or the split type radially magnetized rectangular strip magnet 5b and the pole shoe 4 form a permanent magnetic pole, and the pole shoe 4 can pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com